You’ve probably been in this awkward situation: the jewelry itself is exquisite, but the packaging ruins the first impression when customers open it.

For luxury brands, packaging is critical: a leather jewelry box shapes customers’ initial judgment of value and impacts repeat purchases, brand reputation, and recommendations.

After speaking with numerous brand owners and buyers, I’ve found that the real challenges aren’t about whether to use leather. Instead, they boil down to three more practical questions:

This guide answers these questions in a buyer-friendly way. It breaks down “luxury” into verifiable dimensions, not just empty adjectives.

Many brands treat packaging as the final step, but consumers see it as the first proof of quality.

In fact, before customers even touch the jewelry, the leather box already answers one crucial question: Is this piece worth the price?

If your products target the luxury market, packaging isn’t a bonus—it’s a requirement.

I’ve seen three common types of hidden losses. You might save money on boxes upfront, but end up paying more for returns, negative reviews, exchanges, and lost repeat customers.

This is especially true when launching new product lines, expanding sales channels, or using products as corporate gifts. Consistent, reliable delivery of jewelry boxes directly determines if you can replicate a uniform brand experience every time.

The deadliest flaw of cheap packaging isn’t that it looks bad—it’s that it’s mismatched.

If a jewelry box feels flimsy, has an odd smell, features shoddy hardware, or doesn’t close smoothly, consumers will subconsciously link this carelessness to the product inside.

Luxury customers rarely complain directly about bad packaging. Instead, they use sharper feedback: it doesn’t feel luxurious, it’s not worth the price, or I can’t give this as a gift.

If you’re considering upgrading your packaging, start with a simple test:

Luxury packaging does more than close a sale. It sends crucial retention signals.

For independent designer brands and boutique buyers, repeat customers form fixed expectations after their first experience.

A well-crafted box turns this sense of stability into lasting memories.

You can break down these retention signals into three actionable steps:

The more these signals show up, the easier your repeat sales, customer referrals, and membership management become.

Shareability isn’t about how good the product looks in a video. It’s about three key questions during unboxing: Is the process smooth? Does it feel special? Can people explain in one sentence why it’s expensive?

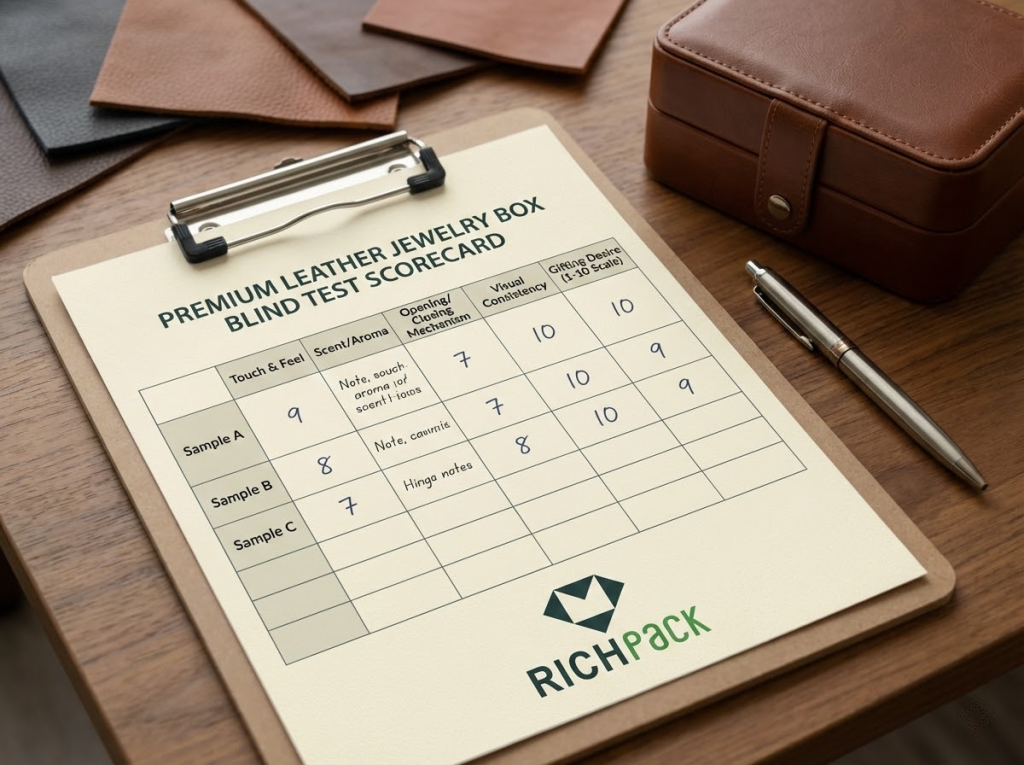

After working with over 100 jewelry brands, I’ve found buyers always nod in approval at small details: consistent resistance when opening and closing, lint-free lining, scratch-free metal parts, non-sticky, odorless edge paint, and a logo that doesn’t look cheap.

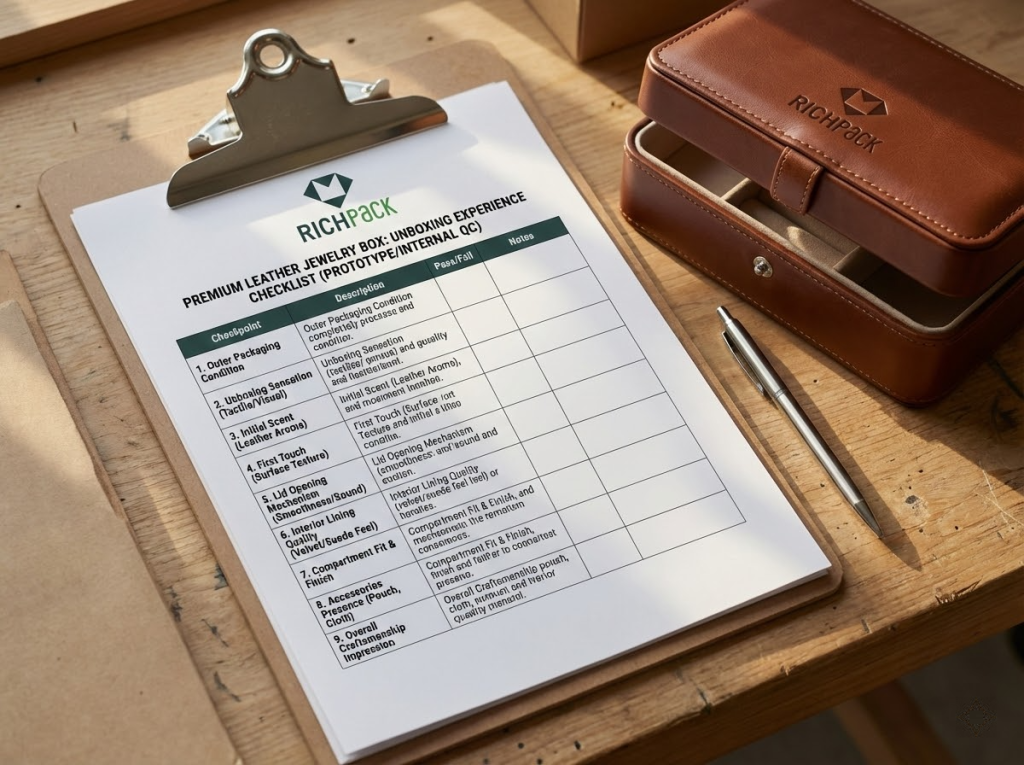

To better control the unboxing experience, add these experience checkpoints to your sample approval list:

Packaging is usually seen as a cost because it’s rarely treated as an asset. Once you standardize and scale your packaging, it drives long-term profits.

With an asset-based mindset, you can do two key things:

This way, your operations stay stable whether you’re making custom leather jewelry boxes now or scaling up bulk purchases in the future.

One easy-to-overlook fact: you’re not just buying a box. You’re maintaining a brand system.

If you have different product types like rings, necklaces, and earrings, but your boxes lack visual and tactile consistency, buyers will think you’re not ready to scale.

Worse, this inconsistency turns into a trust crisis when entering the corporate gift market or displaying products in multiple stores.

Here’s a practical solution: define fixed and flexible elements early in the design phase.

This lets you meet different needs without making your brand look different every time.

A final reminder: if you’re moving from brand testing to wholesale leather jewelry boxes, the core of strategic value isn’t how luxurious you make the boxes—it’s how controllable you make the process. Many teams bring in more strategic packaging partners at this stage. These partners handle sample production, confirmation, quality inspection, restocking systems, and logistics management all in one. This reduces rework and communication costs.

Many teams make mistakes when choosing leather jewelry boxes.

It’s not because they lack aesthetic taste, but because they don’t have a practical evaluation framework.

This leads to problems: samples look great, but hidden issues emerge in mass production—like color inconsistency, uneven texture, loose hardware, and peeling lining.

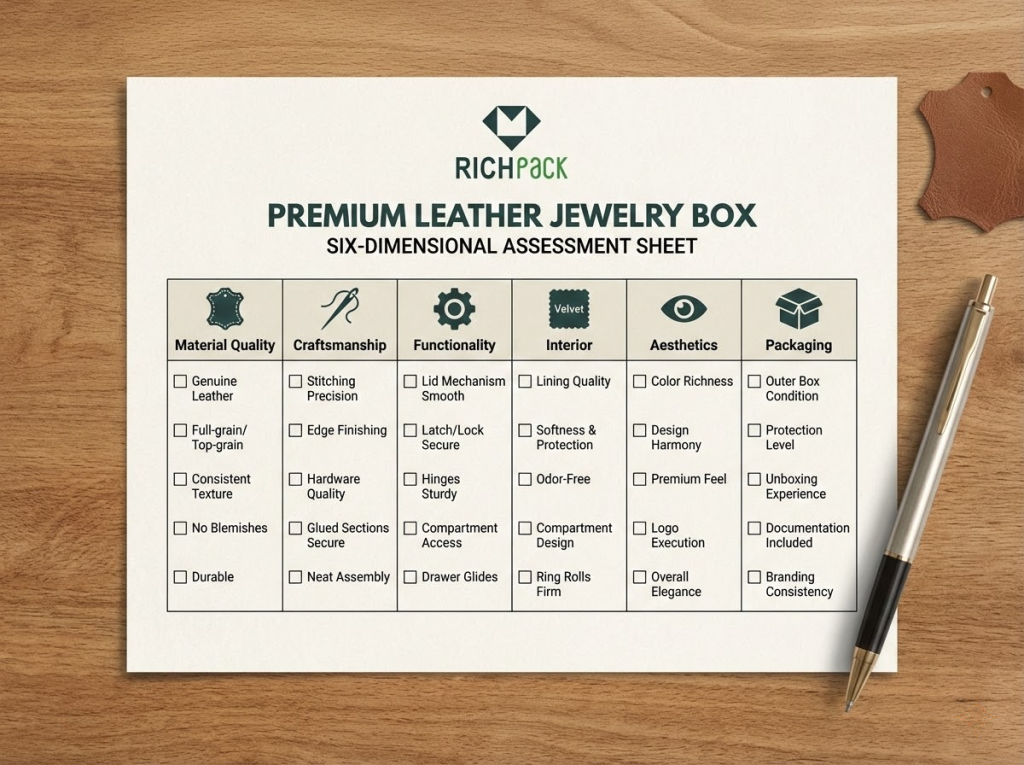

I always recommend starting with a six-dimensional framework. Align team expectations first, then communicate with suppliers.

This way, you won’t be misled by superficial luxury when evaluating samples, discussing custom leather jewelry boxes, or scaling up purchases later.

You can use these six dimensions directly as the main part of your evaluation checklist.

Leather is the first touchpoint. The moment customers pick up the box, they judge its perceived value by its feel, texture, smell, and luster.

You don’t need to explain all leather grades here, but one point is non-negotiable: three factors determine if the luxury feel lasts more than six months—stable leather material, durable surface finish, and neat edges.

Actionable inspection tips:

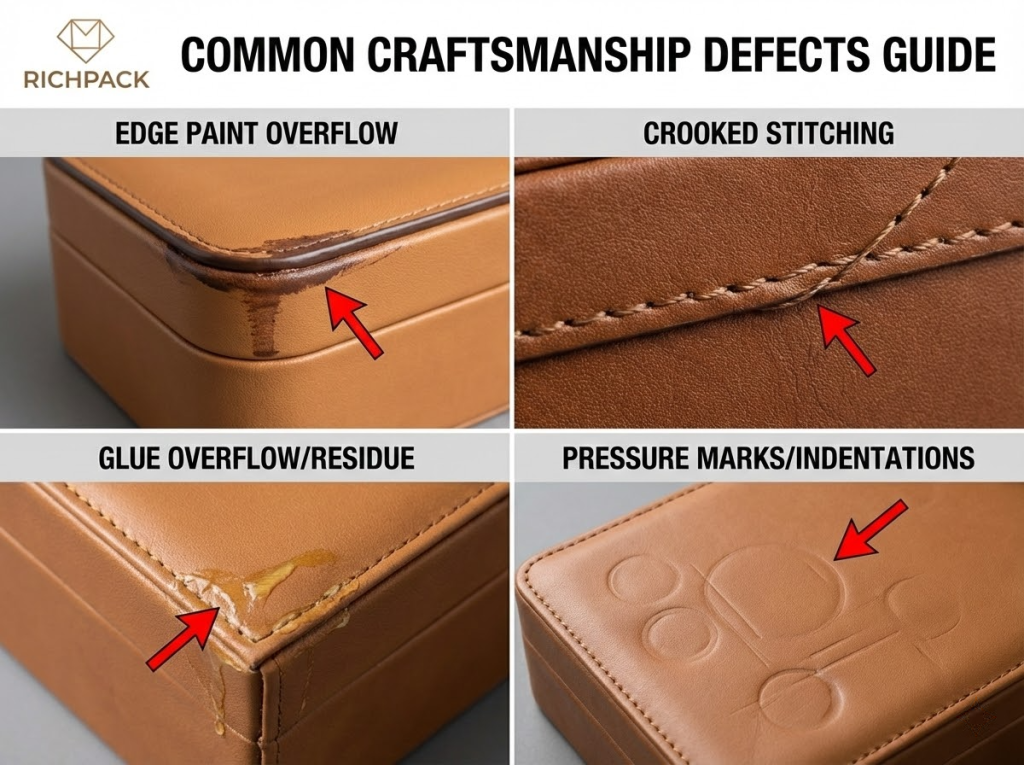

There’s a big difference between looking luxurious and feeling luxurious to use. The key is structural craftsmanship. Think of this as a mass production risk indicator, covering stitching, splicing, tolerances, gluing, and opening/closing resistance.

If any of these are inconsistent, mass production will lead to rework and customer complaints.

In the prototyping stage, one practical test I always do is: open and close the box 30 times in a row, then twist the lid gently to check its structural rebound.

This quick action uncovers problems like loose hinges, warped casings, and mismatched assembly tolerances.

Actionable inspection tips:

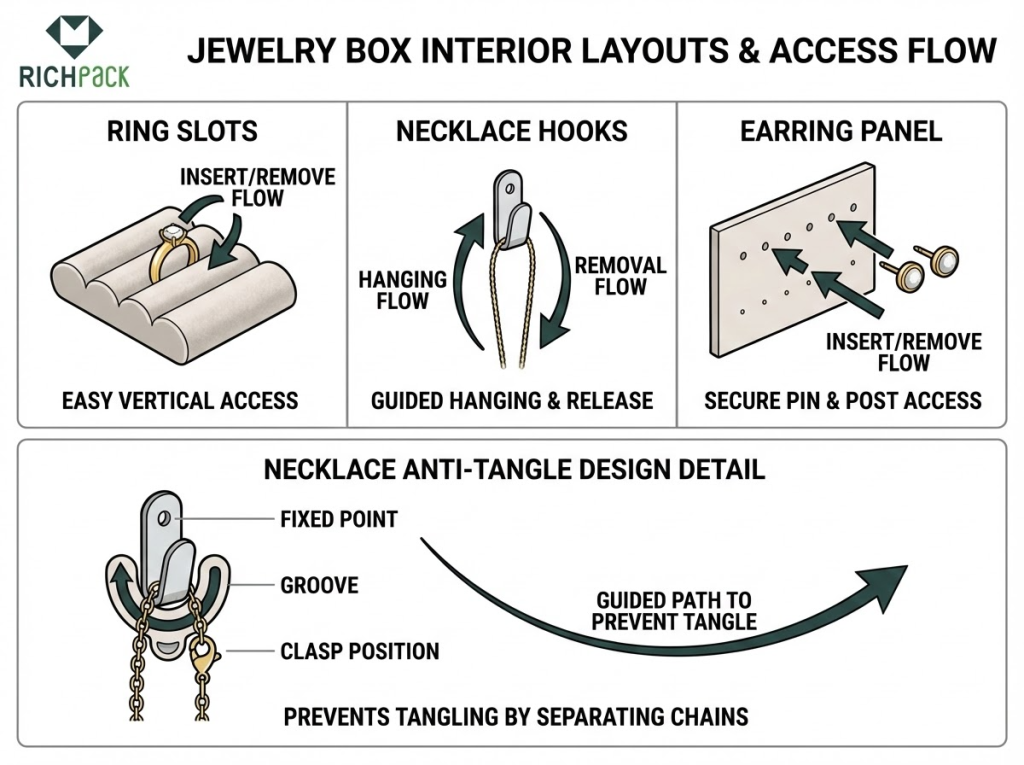

Space design isn’t about how much it can hold—it’s about matching the brand’s style.

Buyers and brands share one big worry: the same jewelry feels cramped inside the box, getting creased or tangled. In the end, customers stop using the box, making it disposable packaging (this affects storage longevity).

Practical design tips (suitable for most product types):

You don’t need to list all structural solutions here, but three points must be clear: zoning logic, internal support materials, and item access paths. These three determine if customers will use the box long-term—they’re signals of retention rate.

When it comes to innovation, most brand buyers care less about fancy features. They focus more on whether the product solves real problems in retail display, shipping protection, gift unboxing, and travel storage.

Great functional design cuts after-sales explanation costs and reduces the risk of damage during shipping.

Actionable evaluation questions:

Luxury doesn’t equal complexity. Luxury means a consistent brand language. What truly makes you stand out is your ability to turn your logo, color scheme, hardware style, and lining texture into a reusable system.

You never need to start from scratch or test every step for each custom product. The core point: custom craftsmanship must be scalable. Otherwise, it will only increase communication and rework costs.

Practical coordination tips:

Sustainability isn’t just a slogan. It means you can clearly explain to buyers and corporate gift clients: Are the materials more durable? Easier to maintain? Do they generate less waste?

This factor is often mentioned in procurement negotiations, especially when targeting overseas markets. But you don’t need to “promise environmental protection”—you need verifiable information.

You can take these actions:

By now, you should have a verifiable evaluation framework. Next, judging materials will be much easier when you move to that stage, like what the real differences are between genuine, faux, and vegan leather, and which differences become more obvious during mass production and use.

Everyone talks about genuine leather, but they’re actually referring to two things: feel and durability.

When buying, however, you need a third, more important thing—verifiability.

All products may be labeled genuine leather, but pieces from different factories or batches vary greatly in feel, color, smell, and wear resistance. That’s why some brands’ samples look amazing, but mass-produced products fall short.

When inspecting actual samples, we first separate material grades from marketing terms. Then we focus on two easier-to-judge aspects: whether the leather surface is intact and how many processing steps (coating/embossing) it’s been through.

You don’t need to be a leather expert. But you need to ask a few key questions to judge quickly: Does the luxury feel of this genuine leather jewelry box come from the leather itself, or heavy post-processing (corrected grain)?

In luxury scenarios, full-grain leather prioritizes natural texture and long-term durability. Top-grain leather is more commonly used for products that need a neater appearance and better batch consistency.

You’ll find the real logic for choosing leather when buying isn’t which is more luxurious. The key is: does your brand need natural texture or consistency (batch consistency)?

Ask suppliers for multiple samples of the same color and check for differences in texture and luster consistency.

If your products are for boutique display or corporate gifts and need a highly uniform visual style, top-grain leather is often easier to achieve consistent results with. If you value handcrafted texture and natural grain, full-grain leather is a better fit. But you need to accept its natural variations in advance.

Corrected-grain leather often creates an illusion of luxury. This is because coating and embossing processes usually make the surface more uniform.

But this type of leather has drawbacks: the more processing it undergoes, the more likely two problems are to arise. First, it may feel plastic. Second, its surface is more prone to wear and fine cracks over time.

If you plan to customize leather jewelry boxes and buy them in bulk later, you should add a processing grade to your specifications. List specific details like acceptable luster range, embossing depth, and methods to test surface durability.

Thicker isn’t always better—thickness needs to match structure and craftsmanship. Too thin, and the material sags and feels loose; too thick, and it can ruin edge binding and corner treatment, leading to uneven edges.

The same principle applies to texture consistency. Natural leather always has variations, but the key question is: are these variations within the acceptable range?

When inspecting samples, we use calipers to measure the thickness of key parts (edges, surface, sides), then press the leather gently from different directions with our fingers to check if its rebound is uniform.

You don’t need to record specific values, but you can add check key measurement points to your inspection checklist. This way, you can quickly compare samples when you receive them next time.

Luxury feel is easily ruined by smell. A strong, unpleasant odor usually means poor-quality coating or adhesive, or inadequate production control. This is especially true for gift-giving scenarios, where consumers are more sensitive to smells.

Colorfastness is also crucial. Fading or color transfer can directly stain linings or jewelry pouches, ultimately leading to after-sales issues.

You can ask suppliers to do two simple but effective self-inspections and provide the results:

For more formal, compliant statements, refer to industry standard documents or material testing guidelines. These documents clearly state testing methods and acceptable standard ranges. Avoid absolute statements like completely colorfast.

The real way to cut communication costs is to break down genuine leather into specific, clearly definable items. You don’t need suppliers to provide the full formula, but you must obtain key information for repeat purchases. Otherwise, it will be difficult to ensure consistency across future batches.

We recommend including the following in your Request for Quotation (RFQ) or sample confirmation form (spec sheet):

Clarifying this information stabilizes subsequent processes—whether you’re adding more SKUs or moving from sample production to wholesale leather jewelry boxes.

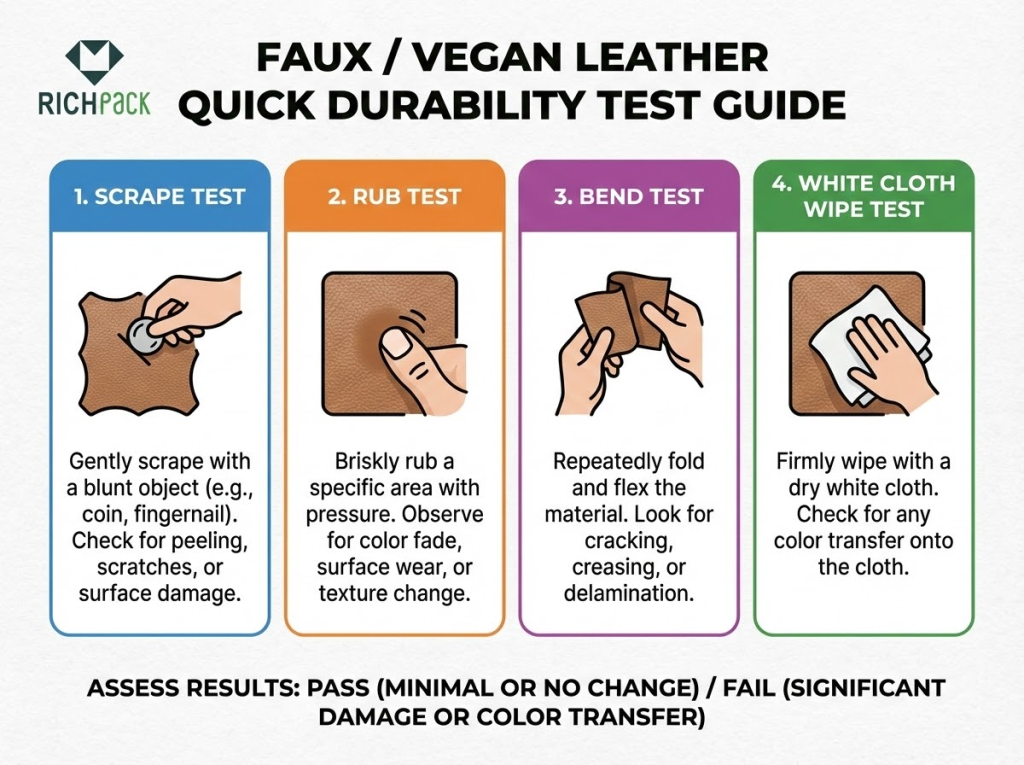

When you start choosing faux or vegan leather jewelry boxes, the real question isn’t if it’s luxurious enough—it’s if it’s durable enough.

In the faux leather market, many products look just like genuine leather at first glance. But once mass production and shipping start, common problems quickly surface: peeling, cracking, curling edges, glue smell, sticky surface, or fading. All these issues directly impact the gifting experience and weaken buyers’ trust in the brand’s reliability.

When inspecting samples, I start with a simple test. I gently scratch the edges with a fingernail, then rub the same spot repeatedly with my palm for 20 seconds. After that, I check if the surface turns white, peels, or leaves hard-to-clean fingerprints.

This isn’t a professional experiment, but it quickly reveals basic differences in material quality and craftsmanship—what we call surface durability. You don’t have to label faux leather as a low-end product; what you really need is a set of standards to spot and avoid risks early.

In the jewelry packaging industry, polyurethane (PU) is more of a material system, while vegan leather is more of a product label.

Many vegan leather products end up being made of polyurethane or polyurethane composite systems. The only differences lie in the supply chain, formula, and how compliance information is disclosed.

For buyers, you should focus on three things: composite structure, coating feel, and batch consistency—not the label itself.

Actionable communication tips:

The most common problems with faux leather occur at the edges and bending points. You won’t see these issues on samples, but they often appear after repeated opening/closing, shipping pressure, or temperature and humidity changes.

These problems include edge peeling, corner cracking, and surface coating delamination. Once they happen, customers blame the brand—not the supplier.

You should add two simple early detection tests to the sample inspection stage:

Professional tip: For more formal descriptions, refer to material testing standards or industry reports. These documents clearly specify testing methods and evaluation criteria for flex resistance, wear resistance, and weather resistance. Never make absolute promises like never cracks.

Many people think peeling is a material issue. In fact, it’s often related to bonding and lamination processes. This is especially true for high-gloss or soft-touch coatings. If the bonding system is unstable, problems like stickiness, blistering, curling edges, and even deformation after high-temperature shipping (thermal sensitivity) can occur.

These problems create high hidden costs during mass shipping. Replacing defective products, reworking, and remaking samples can eat up the budget you originally wanted to save.

Actionable verification methods:

If you’re screening PU leather jewelry box suppliers, the key isn’t who offers the lowest price—it’s who can clearly explain and resolve various uncertainties.

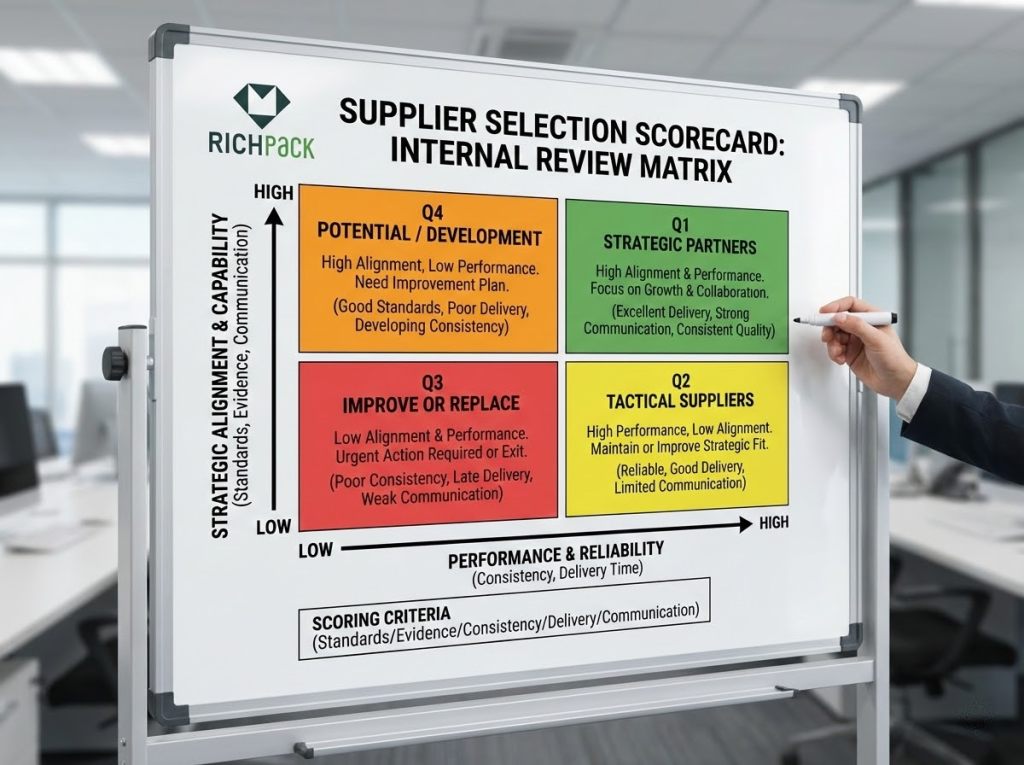

The biggest worry in procurement isn’t high costs—it’s inconsistency between samples and mass-produced products. Therefore, when evaluating suppliers, focus on three aspects: standards, evidence, and repeat purchase capability.

You can use the following questions for initial screening:

Faux leather itself isn’t more or less luxurious. It’s better suited for gift projects that prioritize the following: uniform appearance, stable texture, easy cleanability, and clear material sourcing.

This is especially true when targeting multi-country markets, making corporate gifts, or customizing event items—where consistency is often more important than natural texture variations.

If you want to create a luxury feel with faux leather, focus on three key aspects:

This way, the brand experience is more replicable when you customize leather jewelry boxes or scale up orders later.

Many teams focus all their attention on the appearance and leather surface when evaluating leather jewelry boxes. But what truly determines customer satisfaction is often the internal experience when the lid is opened.

Lining isn’t just for decoration—it’s a protection system. It prevents jewelry from scratching, tangling, oxidizing, moisture damage, and color transfer. Finally, it must feel luxurious to the touch (premium feel).

Problems with the lining lead to more than just negative reviews. They result in reshipments, returns, and higher costs for customer service explanations. This is especially sensitive for boutique buyers and corporate gift purchasers.

When inspecting samples, I always do two things first: gently scratch the lining with a ring face or metal edge; then wrap a necklace around the divided areas quickly twice and take it out to check if the necklace slides smoothly and if the fabric snags.

These two simple steps let me quickly judge if the jewelry box’s protection logic actually works. The key isn’t listing fancy material terms—but practical functional protection.

Velvet has an immediate gift-like feel at first sight, but it also has more obvious problems: it sheds lint easily, attracts dust, and pills after long-term friction.

Microfiber is usually more durable, stable, and easy to clean. However, if the fiber density and surface treatment don’t meet standards, it can feel dry, thin, and often lack a luxury feel.

You can use a simple standard to choose:

Lining material is just the foundation. What truly prevents scratching is contact surface design, and what truly prevents tangling is path design. Many seemingly luxurious inserts fail because of poor zoning: ring slots are too tight, leaving creases; necklaces have no fixed points; earring areas are hard to access. In the end, customers stop using the box for storage, turning your packaging asset into a disposable item (this impacts the reuse rate).

Actionable layout inspection tips:

If your customers often ask, Will my silver jewelry tarnish? Then the jewelry box lining is about more than just feel—it’s about material and environmental control.

Strictly speaking, lining can’t stop all oxidation reactions, but it can reduce oxidation risks: less friction, less moisture buildup, and protection from sulfur-containing substances (anti-tarnish effect).

Practical communication and design tips:

Professional tip: For more accurate statements, refer to industry material guidelines or standard documents. These explain oxidation mechanisms and packaging limitations—they can only reduce risk. Avoid absolute promises.

Overseas shipping and storage come with higher uncertainties. Changes in temperature and humidity, long-distance pressure, and outer box friction can turn small problems into customer complaints.

The most common hidden costs in the lining system come from two aspects. First, moisture absorption leads to odors or stickiness. Second, dark linings transfer color to jewelry pouches or metal surfaces during friction (this is called color bleeding).

We recommend two quick checks at the sample stage:

These two simple checks can significantly reduce the risk of problems when you ship in large quantities later.

Luxury feel usually comes from consistency. Even with different box styles and SKUs, products from the same batch should feel like they’re from the same brand—not random parts from different suppliers.

This is especially important when customizing leather jewelry boxes or expanding product lines.

The feel of the lining and its rebound after pressing directly impact the sense of trust customers feel when opening the box.

Here are actionable tips for lining standards (you can add these to your product specifications):

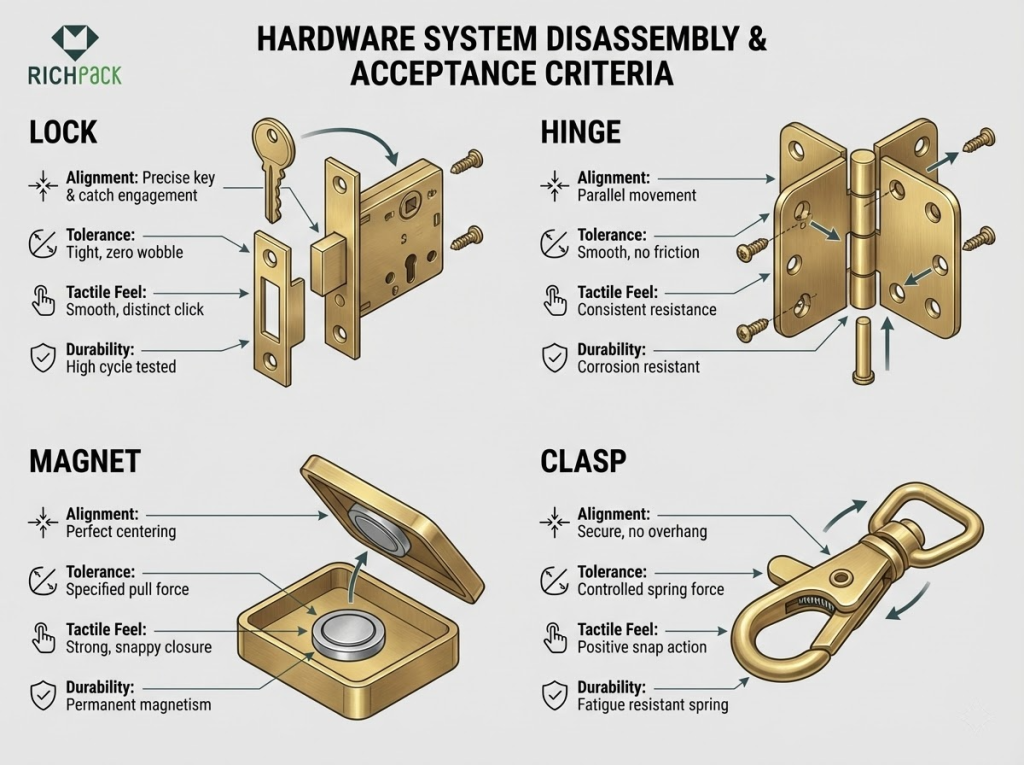

For many buyers and brands, having a lock symbolizes high quality.

But what truly determines the user experience are three things:

A leather jewelry box with a lock may look expensive, but if it feels loose when opened/closed, the hardware fades, or the hinges are misaligned, consumers will immediately link this unreliability to the expected value of the jewelry inside.

So this section isn’t about listing different types of hardware—it’s about giving you a set of standards you can use directly when inspecting samples and mass-produced products.

When inspecting samples, I do a simple but effective test: open and close the box with one hand 30 times. At the 10th and 20th times, I shake the lid gently to check if the lock is still aligned, if there’s any abnormal noise, and if the click feel of closing is consistent every time.

This test quickly uncovers problems that worsen in mass production, like poor assembly, spring aging, or uneven stress on hinges. After all, inspecting a box isn’t just about its appearance.

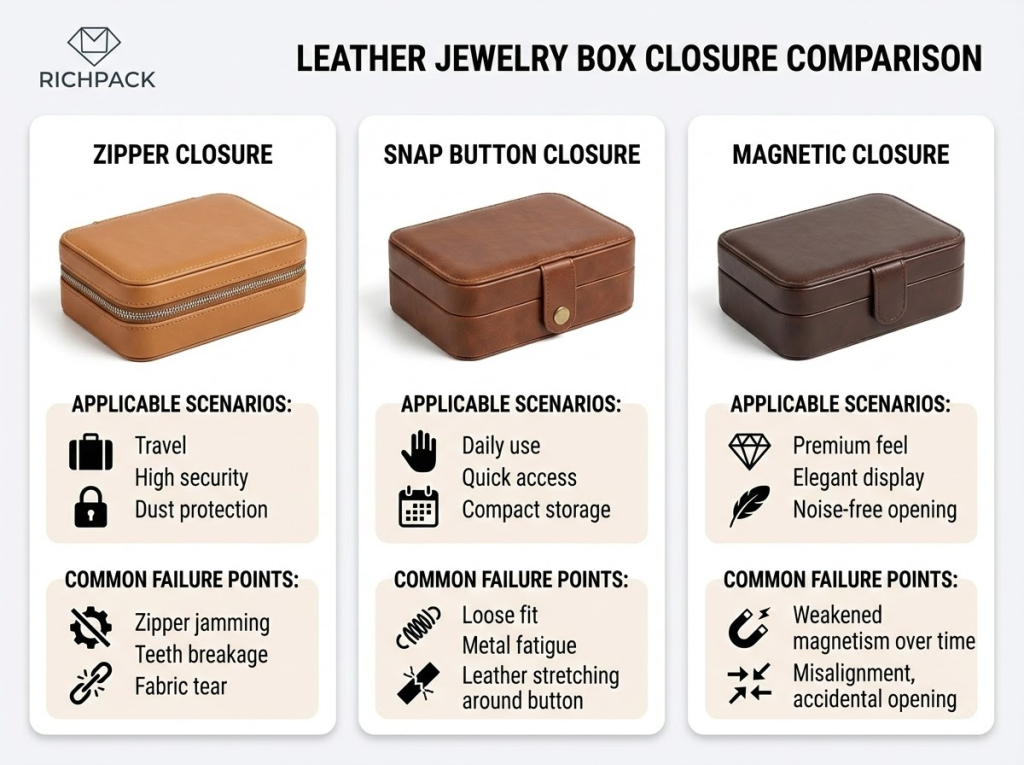

Locks have two main values: security and a sense of ceremony. You first need to figure out which one fits your use case. Otherwise, you may end up with a lock that’s installed but ruins the user experience.

Gift projects usually prioritize a smooth, stable feel when opening and closing. Retail display cases or high-priced items may focus more on preventing accidental opening and structural reliability.

Actionable acceptance tips:

Professional tip: For more rigorous compliance statements, refer to standard documents or industry guidelines on hardware/lock durability testing methods. Use terms like durability test/cycle count/acceptance criteria instead of never loosens.

Hinges are the structural core—and the most prone to problems in mass production. The hinges on your sample may turn smoothly, but poor tolerance control leads to issues in mass-produced products: the lid tilts left or right, gets stuck when opening/closing, and edge wear from uneven stress (wear points).

Practical inspection methods:

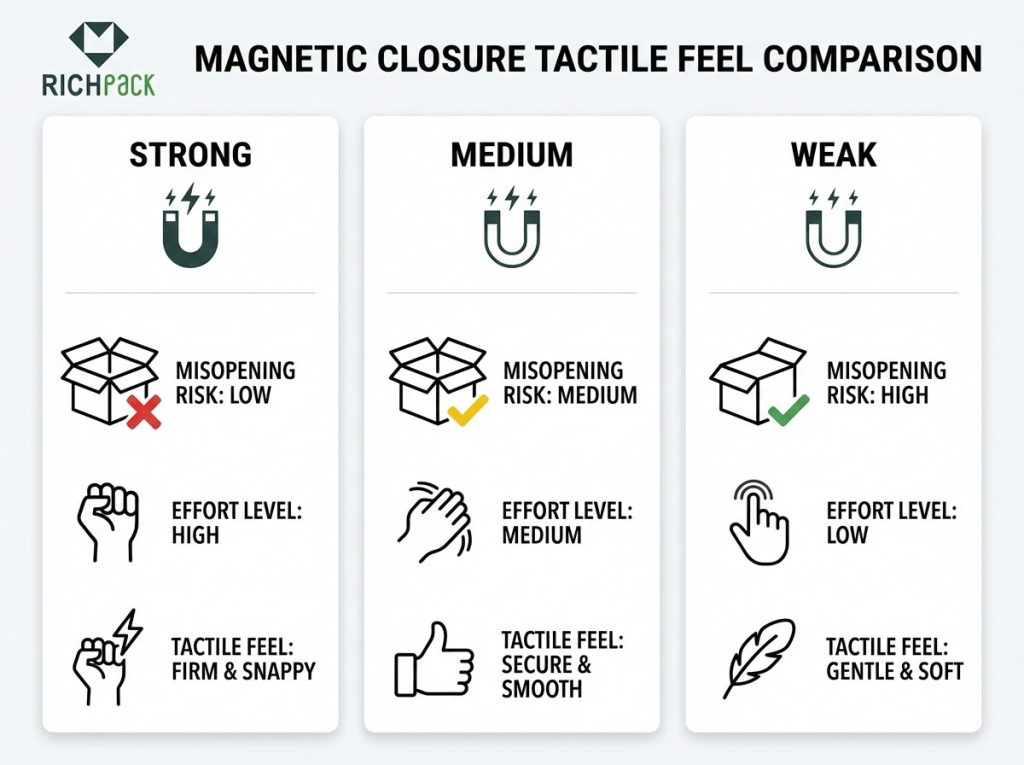

The key to magnetic closures isn’t the stronger the magnet, the better—it’s the right strength.

A weak magnet may cause the structure to open accidentally during shipping or daily use. A magnet that’s too strong makes the box hard to open, even damaging the outer leather and inner lining.

Luxury quality is usually reflected in a clear, crisp click feel and a sense of certainty when closing (closure stability).

Here are practical testing methods:

The color and surface treatment of metal hardware determine if your entire packaging looks like it’s from the same brand.

The most common problem: samples have uniform color, but mass-produced products turn yellow, red, or dull.

These products may also show obvious fingerprints easily or scratch quickly (this refers to the durability of the surface treatment).

For boutique buyers, this directly impacts display effects. For corporate gifts, it impacts whether the gift is presentable when given.

Practical tips for ensuring consistency:

If you plan to buy repeatedly for the long term or purchase leather jewelry boxes in bulk, you must inspect their durability at the prototyping stage. Don’t wait for customer complaints to solve problems.

Hardware is usually prone to wear at these parts: lock contact surfaces, hinge axles, magnetic contact plates, and handles attached to opening/closing edges.

These parts share one common feature: initial wear is not obvious, but differences show up quickly after a few weeks of use.

Here’s a low-cost durability check checklist you can implement:

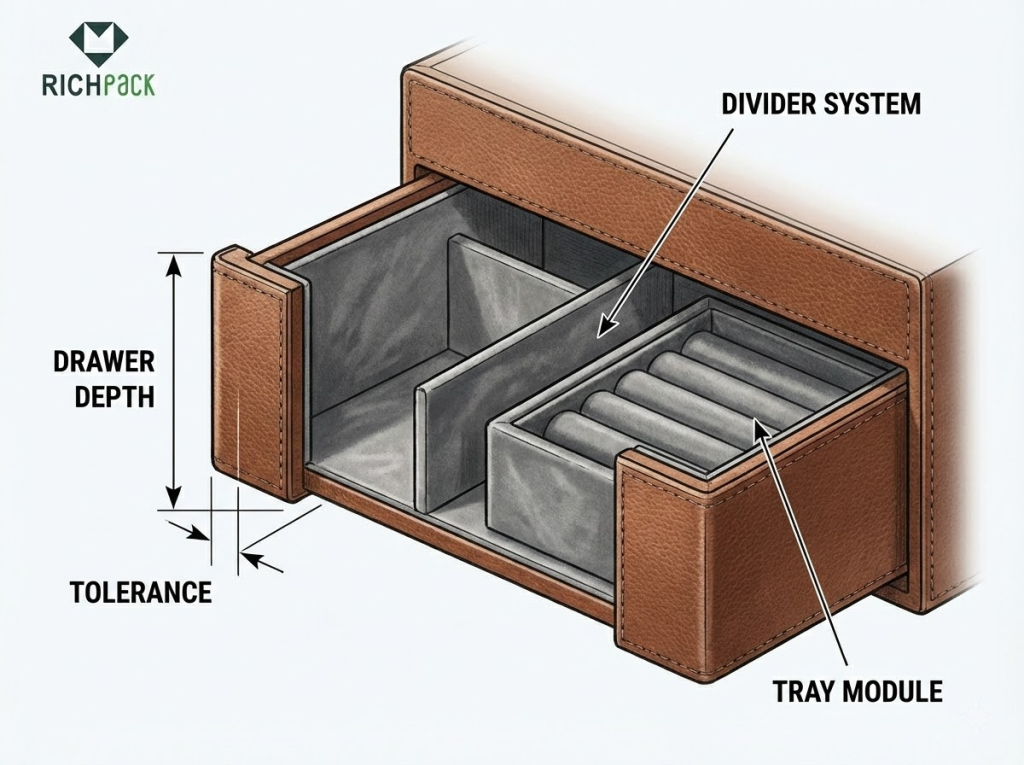

Drawer-style structures are considered luxury not because they’re more complex, but because they’re more in line with actual usage needs. You can access items easily, store them by category, find what you need quickly every day, and prevent jewelry from rubbing against each other in a pile.

For buyers and brands, a leather jewelry box with drawers is more like a daily item that can sit on a dresser for years, not a disposable gift box (this reflects daily practicality).

But there’s a hidden problem: poor tolerance, material, and internal support structure design for the drawer system leads to jamming, looseness, abnormal noise, and wear in mass production. In the end, consumers blame the brand for this cheap feel.

When inspecting samples of drawer-style structures, I first do an extreme test: fully pull out the drawer and hold it, then lift the front edge gently to feel for obvious shaking; then push the drawer back quickly to see if it rebounds or pinches fingers (this tests drawer tolerance).

This simple action lets me quickly judge if the slides/structure are stable, if the damping is uniform, and predict if the drawer will become looser with long-term use.

The key to a drawer-style jewelry box isn’t more compartments, but better—it’s compartments designed for your product categories.

Ring slots need to accommodate rings of different band thicknesses and gem heights.

Necklace compartments must prevent tangling.

Earring areas must be easy to access while avoiding scratching jewelry.

These details determine if customers will actually use the box for storage, instead of putting jewelry back in its original packaging.

Actionable compartment inspection tips:

The luxury feel of using a drawer comes from three things: smooth sliding, stable positioning when open, and neat alignment when closed.

Insufficient drawer depth causes items to rub against each other when stacked. Excessive depth makes it hard to organize different areas. Too narrow gaps lead to jamming; too wide gaps cause shaking and abnormal noise. If the stress point of the drawer handle is not firm, the leather surface cracks, and the metal parts loosen after long-term use.

You can set inspection standards simply and practically like this:

Many brands overlook replaceability, but this feature actually determines the service life of a drawer-style storage box.

If dividers are fixed, consumers find the box completely useless when they update their jewelry collection. But if dividers are too soft or easy to bend, they lose their partitioning function quickly (this feature is called modularity).

For corporate gift solutions, replaceable dividers let the same box fit different gift combinations, reducing SKU complexity.

Actionable tips:

Professional tip: To build more trust, recommend referring to industry guidelines or testing methods for packaging durability and material compatibility. Develop a logical argument around how replaceable parts reduce long-term maintenance costs.

Once drawer-style products enter retail or warehousing scenarios, stackability becomes a key factor affecting operational efficiency: stacked products are neater, restocked faster, and space utilization is more controllable (higher space efficiency).

But without considering stress points in the stacking structure, stacking easily leads to drawer misalignment, slide pressure, and appearance deformation. These problems ultimately impact in-store display effects.

Actionable verification methods:

Finding it too small to hold jewelry after taking it home is one of the most troublesome complaints about drawer storage products. Capacity isn’t just a number—it’s about helping customers quickly judge if the box is right for them (this concept is called decision clarity).

This is especially important in B2B procurement. Buyers need to choose products for a group of people, and enterprises need to select items for gift sets. Both need clear capacity standards and compatibility limits.

Practical capacity planning tips:

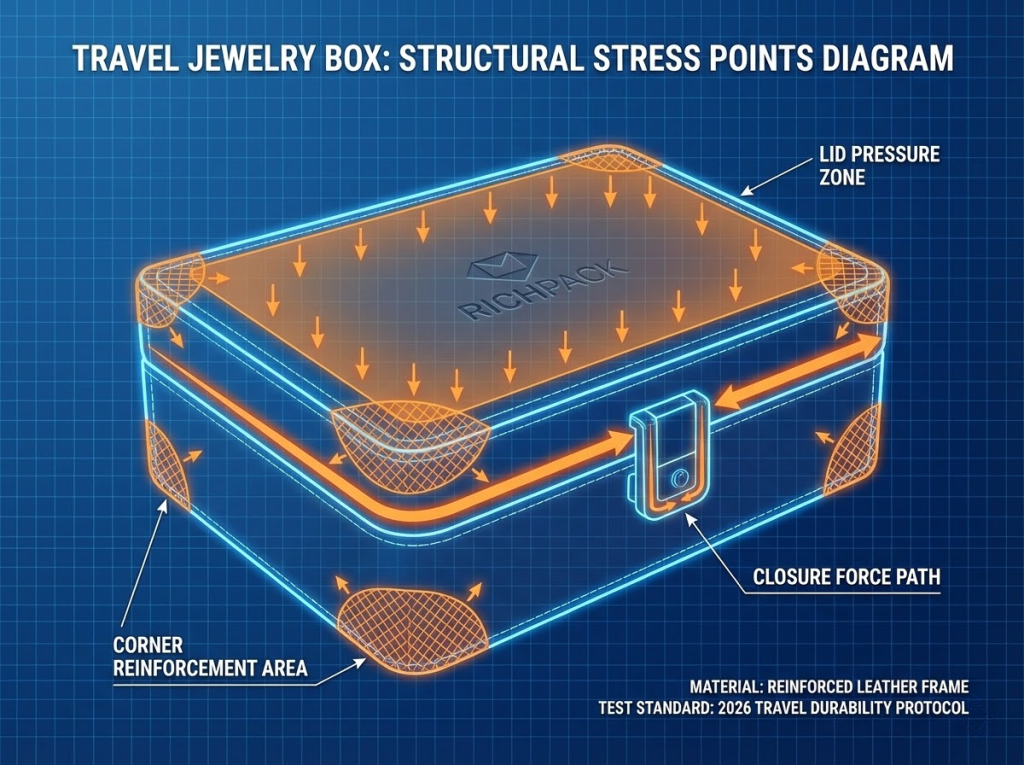

Travel products are hard to make well. The problem isn’t appearance—it’s too many variables: users stuff them into carry-ons, checked luggage, and gym bags. They open, close, pull, and squeeze these products repeatedly.

To make a high-quality leather travel jewelry box, you can’t just focus on the leather surface and lining. You must design and test it as a small, durable item. Otherwise, common problems arise: deformation during shipping, broken zippers or snaps in a month or two, and jewelry scratching each other inside. After that, returns and negative reviews surge quickly.

When inspecting samples of travel products, I don’t start by feeling the texture. Instead, I do three controlled destructive tests: first, place weight equivalents (like metal blocks or test weights) inside the box to simulate jewelry; then pull the box in and out of a standard-sized carry-on 10 times; next, open and close the box quickly 30 times with one hand; finally, press the lid gently to check if it rebounds and retains its shape (compression deformation).

These three tests quickly uncover structural weak points and reflect the product’s actual usage performance far more effectively than just inspecting appearance.

The durability of a travel jewelry box includes two key parts: compression resistance (not deforming when squeezed in luggage) and impact resistance (not damaging the jewelry inside when dropped or hit).

A too-soft casing causes jewelry to deform under pressure. Insufficient internal filling may leave the box looking undamaged, but the jewelry inside may be scratched. These after-sales problems are the most troublesome to handle.

Actionable inspection tips:

Professional tip: To make durability more verifiable, refer to shipping test guidelines or standard documents as acceptance criteria. For example, the ISTA shipping test framework and ASTM/ISO wear and tensile test methods. No need to list standard numbers—the key is to make acceptance criteria traceable.

The biggest problems with travel bags aren’t the leather surface—but closure parts: stiff zippers, zipper teeth that scratch the lining, weakened magnetic snaps, and loose press studs.

For retailers and buyers, these problems translate directly to return and exchange costs; for corporate gift projects, they become an unreliable delivery experience.

Actionable tips (can be added directly to the quality inspection checklist):

The size strategy for travel products isn’t the smaller the better—it’s fitting common bag types without sacrificing protection performance. A too-thin box crushes jewelry. A too-large box never gets taken along. A too-heavy box reduces people’s willingness to carry it (carry compliance).

Practical methods for choosing the right size:

Roll-up pouches are lighter and save more space. But they have higher requirements for compression resistance and preventing jewelry movement.

Hard cases are more stable but more expensive and bulky. The key isn’t the type—it’s whether the internal structure achieves fixation + partitioning + quick access (access convenience).

You can compare them from the following aspects:

Many teams only test the product itself, ignoring the product + outer packaging combination.

The reality is this: shipping damage often happens at the packaging stage. You don’t have to promise to pass a specific test, but you must at least explain the testing methods clearly. This helps procurement and supply chain managers understand how to reduce unpredictable risks.

Practical implementation steps:

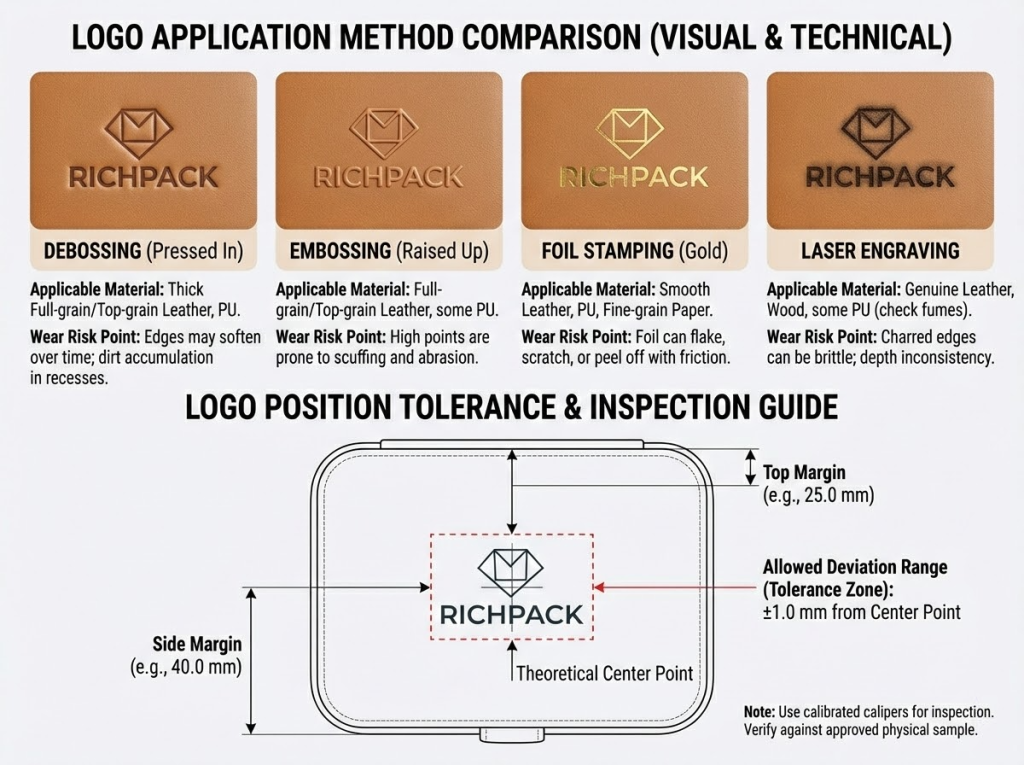

Many teams think personalization is just adding a logo. But in mass production, the real challenge is making every batch of products look like they’re from the same brand. Your job is to turn the personalization of custom leather jewelry boxes from design renderings into repeatable process parameters. At the same time, you need to control delivery times, yield rates, and cost fluctuations—this is what we call batch consistency.

Doing this well directly boosts unboxing experiences and repeat customer purchase rates. Doing it poorly leads to common problems: misaligned logos, fading foil stamping, blurry embossing, and uncontrollable color differences. In the end, these problems cause rework and delivery delays.

When reviewing custom samples, I require factories to provide three things: process sampling records, positioning jigs or line drawings, and comparison samples from at least two different batches.

The reason is simple: a single perfect sample can’t prove mass production stability. Only by clearly defining positioning methods and process ranges can you avoid problems during peak seasons or when working with multiple factories.

Different logo processes aren’t about being expensive or cheap—they differ in feel, durability, and mass production fault tolerance.

You can use a practical selection logic: choose embossing/debossing for a premium feel, foil stamping for high visibility, laser engraving, or metal nameplates for in-depth customization.

Common process options and matching tips:

Embossing/debossing failures usually have two causes: unstable depth and unstable positioning.

This is especially common with grained or corrected-grain leather. The embossed pattern seems visible during initial testing, but fades once mass production starts and speed increases. In the end, the logo looks like it was never embossed at all.

Practical implementation steps:

The biggest problem with foil stamping isn’t looking good at first—it’s the edges starting to peel off a week later. In B2B projects, this directly ruins the gifting experience and makes return costs uncontrollable.

You can avoid these risks in advance with the following methods:

Professional tip: For more verifiable color and surface quality standards, refer to Brand Guidelines, printing/foil stamping process specifications, and color management standards/color card systems (e.g., Pantone and related color management processes). Turn looking good into traceable acceptance language.

Lasers are perfect for engraving names, numbers, and limited-edition event logos. But they have high requirements for leather coating and color.

You definitely don’t want to face these problems: some items are too dark, some too light, or edges are charred with a smoky smell (edge charring).

Practical tips (can directly guide prototyping and mass production):

For retail buyers and brands, color differences are never a small issue. These differences make products from the same product line look like they’re from different suppliers. What you need to control isn’t getting one sample right—it’s keeping every batch within the same color tolerance range.

Actionable control checklist:

Make pre-production samples (PP samples) before peak seasons or collaborate with multiple factories. Use these samples as the standard for mass production.

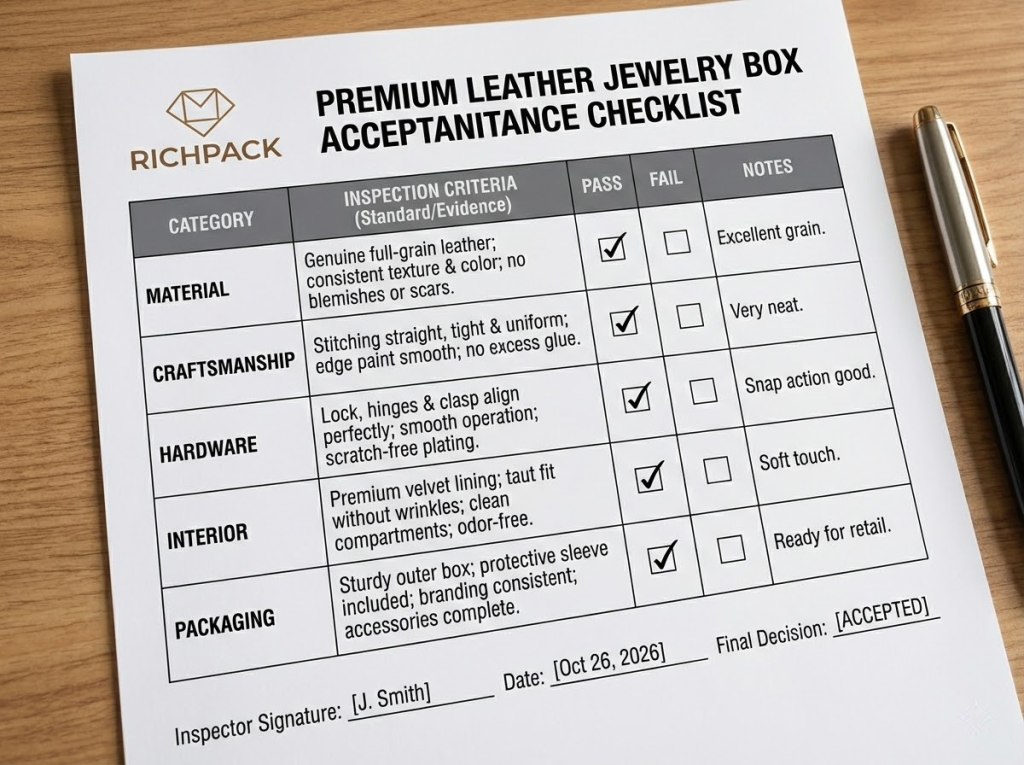

You’ve probably faced this problem: samples look luxurious at the sample stage, but mass-produced products have color differences, excess glue on edges, a loose lock feel, and even lint-shedding lining that scratches jewelry surfaces.

The solution isn’t to make quality checks stricter—it’s to turn acceptance standards into a set of repeatable, measurable rules with clear responsibilities (acceptance criteria). At the same time, require suppliers to self-inspect according to the same standards before shipping.

This checklist can be used as a purchase order attachment + incoming quality inspection process: first, identify critical defects; then, control risks with AQL sampling; finally, include packaging and shipping in the acceptance process. This way, you avoid all your previous work being wasted in the logistics stage.

Materials are the foundation of creating a luxury feel, but they’re also the easiest part to replace. You can’t judge just by feel—instead, you need to ensure every batch matches the master sample (the one you confirmed earlier) and the pre-determined material specifications (including detailed material information).

After goods arrive, you should first do these 6 quick checks:

Practical detail (I use this often in projects): Pick 3 samples to do a corner fold test—press the four corners with your thumb for 5 to 8 seconds. Check if the edge paint whitens, cracks, or feels sticky. This area is the most likely to expose problems with edge paint or coating formulas, and also the most prone to issues in mass production.

Luxury feel is often compromised by small details: crooked stitching, rough edge paint, and excess glue at seams.

These problems become more obvious under retail store lighting. You need to break down craftsmanship checks into items that can be judged at a glance to reduce subjective disputes.

Check these items in the following order:

Leather jewelry boxes with locks often fail to make a good first impression on touch: misaligned locks, stiff hinges, weak magnetic suction. Hardware problems not only impact the user experience but also increase repair and after-sales costs.

When inspecting, focus on both appearance matching and functional reliability:

Professional tip: If planning to include opening/closing life/wear resistance requirements in the contract, adopt industry standard hardware durability testing methods or third-party laboratory report formats (e.g., opening/closing cycle, salt spray/wear resistance test templates). No need to fabricate data, but ensure requirements are testable and reportable.

Lining is the invisible part that most impacts reputation: loose fibers stick to the prongs of ring settings. Overly hard lining scratches mirror-polished metal. Poorly designed areas cause necklace tangling.

For luxury customers, these usage experience problems are more damaging than appearance issues.

You need to focus on checking the following items carefully:

Many perfect products fail due to poor logistics. Their boxes get crushed, metal parts get scratched, and edge paint peels off. You need to check the packaging as part of the product, not just an extra item.

Here are the items you need to check and record:

If you sell luxury jewelry as an experiential product, a leather jewelry box is essentially the first touched and most memorable link in your brand experience chain. It not only needs to look luxurious but also stand up to the repeated tests of mass production, shipping, in-store display, and long-term use. Otherwise, the disappointment in that single unboxing moment will directly negate all the investment you’ve made in products, marketing, and channels.

Turning luxury into a replicable outcome hinges on three key things: whether the materials you choose can be delivered consistently (material disclosure); whether the structure and hardware can maintain a consistent feel through frequent opening and closing (hardware durability); and whether you have an actionable acceptance and sampling mechanism to align every batch with your golden sample. The most common pitfall I see in projects is that brands only focus on making samples look perfect, but fail to write tolerances, defect classification, and packaging drop risks into purchase orders. As a result, when mass production issues arise, it’s hard for both parties to define responsibility and remediation costs.

If you’re ready to mass-produce custom leather jewelry boxes or screen stable suppliers for wholesale leather jewelry boxes, make your next steps more concrete:

A great leather jewelry box is never just a container. It’s a silent brand ambassador that speaks to your customers every time they open it, store their jewelry, or pass the box on to someone else. Invest in getting it right, and it will pay off in higher customer loyalty, fewer after-sales headaches, and a brand image that truly lives up to your luxury positioning.

Just submit your email to get exclusive offers (reply within 12 hours)