2026 Your Definitive Guide to Necklace Packaging Ideas

2025-07-11

Packaging, especially custom made jewelry boxes, has evolved from a simple protective container into a core pillar of brand strategy and a significant revenue driver. It is no longer an operational cost but a critical brand investment.

Market data clearly reveals this trend: the global jewelry box and packaging market shows a stable compound annual growth rate (CAGR) of 5.4% to 7%. The jewelry box market alone is projected to approach $10 billion by 2033, with the entire jewelry packaging market valued in the hundreds of billions. This strong growth trajectory proves that custom packaging, reflecting the latest jewelry packaging trends, is an undeniable focus for the industry.

Three core drivers are fueling this market expansion:

On a deeper level, this market shift reflects a fundamental change in consumer expectations. Modern consumers, especially high-net-worth individuals and the younger generation, are purchasing not just a product, but a personalized experience and a validation of their values. Packaging is the most effective vehicle for conveying a brand’s craftsmanship, sustainability commitments, and unique story.

In the digital wave, where product differentiation is increasingly difficult, the competitive focus has shifted to the experience. As the most impactful and controllable part of the post-purchase experience, packaging’s strategic position is irreplaceable. Therefore, investing in custom packaging is no longer an optional marketing expense; it is an indivisible part of the product’s value. Brands that view packaging as secondary will be left behind, while those that understand its power as a key differentiator will lead the market.

The “unboxing experience” is the customer’s first physical interaction with a brand after an online purchase—a critical moment filled with anticipation and emotion. A well-orchestrated unboxing can transform a simple transaction into a memorable brand ritual.

This experience, which a high-quality custom made jewelry box delivers, provides tangible business returns:

A successful unboxing is not an accident; it is the result of meticulous design. It combines high-quality materials, personalized details (like thank-you cards or handwritten notes), rich sensory elements (unique textures, the crisp sound of a magnetic closure), and a unified brand story told through design language.

This is a multidimensional brand communication channel. When a customer touches textured specialty paper, feels the reassuring weight of rigid greyboard, hears the precise “click” of a magnetic closure, and sees the jewelry resting securely in a velvet lining, every sensory input reinforces the brand message. Without a word, the brand has proven its commitment to quality, precision, and detail through physical touch. If the packaging uses FSC-certified paper, it also subtly communicates the brand’s social responsibility.

Therefore, the unboxing experience is the most intimate and effective channel for a brand to convey its core values to the customer.

Choosing the right materials for your jewelry boxes is the starting point for any custom made jewelry box. This decision not only concerns protection but also directly defines the brand’s image, the customer’s tactile experience, and the overall perception of value.

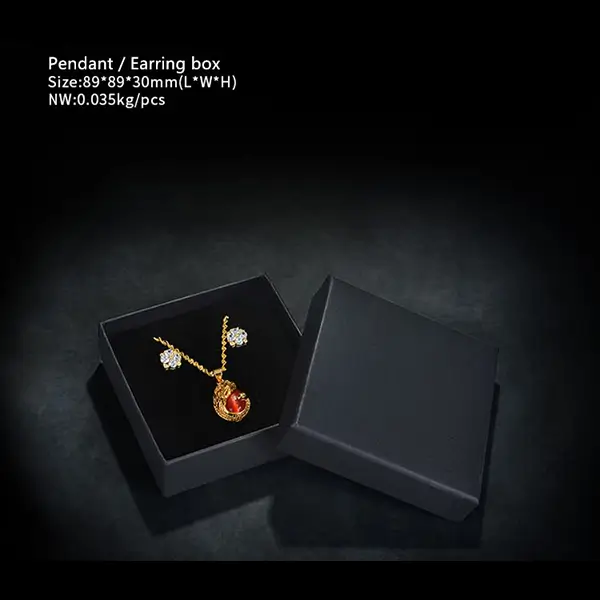

A high-end jewelry box typically consists of three parts: the core structure, the exterior wrap, and the interior lining.

The box’s structure determines the opening method and interactive experience. As this jewelry box structure comparison shows, different styles convey different brand languages.

To help brands make the best strategic choice for their positioning, the following decision matrix matches brand positioning with recommended materials and structures.

| Brand Positioning | Recommended Box Style | Recommended Exterior Wrap | Recommended Interior Lining | Perceived Value / Price Point |

| Luxury Classic | Magnetic Closure / Lift-Off Lid | Specialty Paper / PU Leather | Velvet / Silk | High |

| Modern Minimalist | Drawer Box / Magnetic Closure | Matte Art Paper / Specialty Paper | EVA Foam Insert | Medium-High |

| Eco-Conscious / Artisan | Drawer Box / Lift-Off Lid | Kraft Paper / Recycled Paper | Recycled Cardboard / EVA Foam | Medium |

| Young / Fashion-Forward | Drawer Box / Lift-Off Lid | Glossy Art Paper / Colored Specialty Paper | Colored EVA Foam | Medium-Low |

A perfect custom made jewelry box is the crystallization of art and precision manufacturing. Understanding the production process not only allows brands to better control quality but also to grasp the true value of “customization.” This section goes deep into the workshop to reveal the manufacturing process for two typical high-end custom products: a heart-shaped rigid box and a jewelry tray insert.

Compared to standard square boxes, manufacturing non-standard shapes like a heart-shaped box presents an exponential challenge in precision and craft, serving as a litmus test for a factory’s technical capabilities.

Material Prep & Precision Cutting: Production begins with large sheets of high-density greyboard. An automatic grooving or slitting machine precisely cuts the greyboard into the components needed for the heart-shaped base and lid.

V-Grooving: This is the key step that determines the quality of a rigid box. An automatic grooving machine cuts V-shaped or U-shaped grooves along the heart-shaped curve without cutting through. This process allows the greyboard to form sharp, clean 90-degree edges when folded—unlike the rounded edges of cheap folding cartons—giving the box a crisp, premium look.

Corner Taping & Forming: The grooved greyboard flat is folded up. An automatic corner-taping machine applies hot-melt tape to each corner, rapidly transforming the 2D flat into a sturdy 3D heart-shaped box embryo.

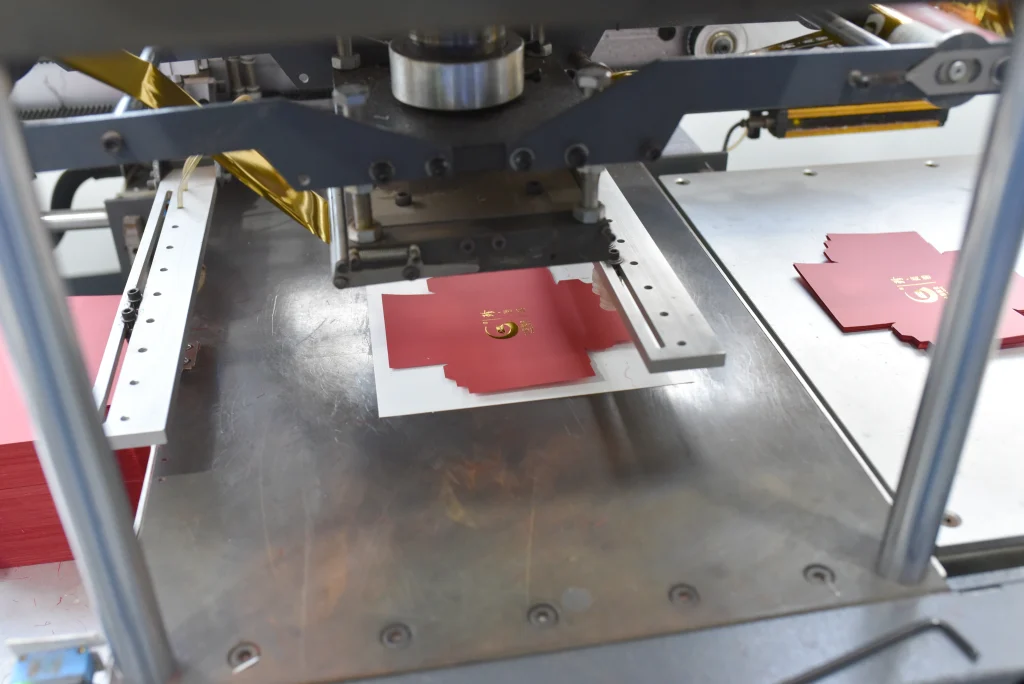

Wrap Prep & Gluing: Simultaneously, the exterior wrapping paper, which has already been printed and finished, is cut to the exact shape needed to wrap the heart box, leaving an allowance for the edges. A uniform layer of glue is then applied to the back of the wrap.

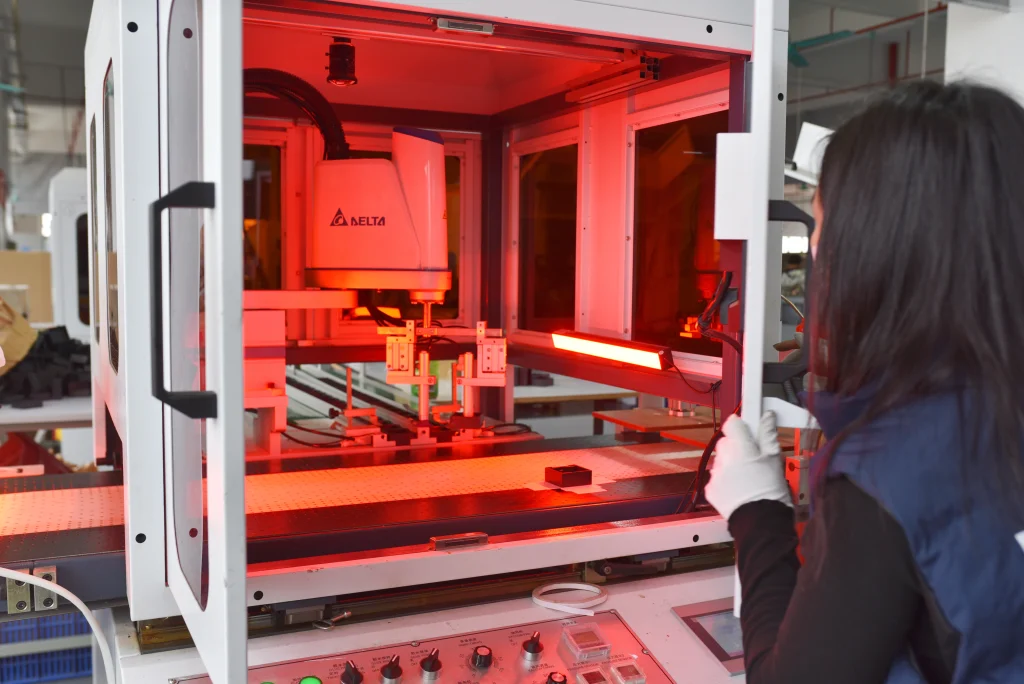

Robotic Arm Spotting: This is the most precision-critical part of the process. The formed heart-shaped box embryo must be placed perfectly onto the glued wrap. Top-tier factories like Richpack use robotic arm positioning systems equipped with cameras and sensors, achieving an astonishing positioning accuracy of ±0.1mm. This ensures the printed design on the wrap aligns perfectly with the box edges, without deviation.

Automatic Wrapping & Finishing: The positioned box and wrap are fed into an automatic box-making machine. Sophisticated mechanical arms perform a series of complex actions—tucking, bubble-pressing, folding, and wrapping—to smoothly and tightly adhere the wrap to the box, folding the excess edges inward to create a seamless, clean final product.

The insert is not just filler; it’s a custom-designed stage for the jewelry, integrating protection, stabilization, and display. A poor-quality insert can destroy the entire luxury experience, which is why understanding foam inserts for jewelry boxes is so critical.

Core Material Analysis: Choosing the Right Foam

Protective Foam Insert Decision Matrix

| Feature | PU Foam | PE Foam | EVA Foam |

| Feel & Density | Soft, spongy, low-density | Firm, rigid, medium-density | Dense, smooth, high-density |

| Protection Level | Good (for light items) | Excellent (shock-resistant) | Excellent (shock-resistant & display) |

| Best Use | Lightweight, fragile items; short-term display | Heavy items, shipping protection | Luxury items, high-end display |

| Perceived Value | Standard | Utilitarian | Luxurious, Premium |

| Long-Term Storage Safety | Not recommended (can degrade) | Excellent (chemically inert) | Good (with no additives) |

| Cost Factor | Low | Medium | High |

Achieving the Velvet Touch: Electrostatic Flocking

Flocking is a high-end process that applies short fibers to a substrate to create a velvet-like texture.

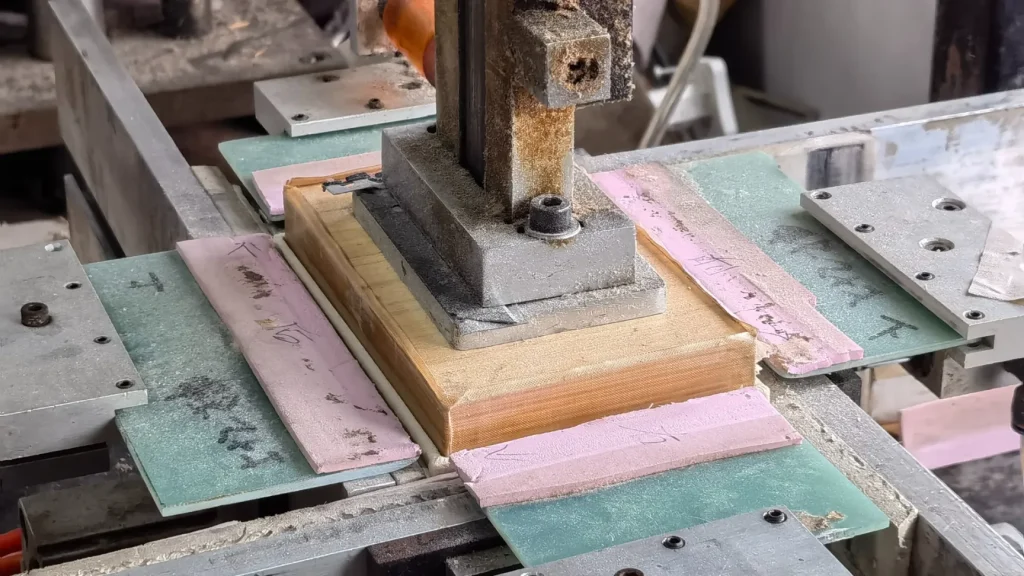

The Perfect Fit: The Die-Cutting Process

Die-cutting uses a custom-made “die” (a steel rule blade) to precisely cut materials, which is key to ensuring the insert perfectly matches the jewelry.

This process uses a steel die customized to the exact contour and size of the jewelry (like a ring or pendant). A high-pressure press stamps the die through the foam sheet, cutting out the required shape and internal cavities in one go. This method is not only highly accurate but also ensures that thousands, or even tens of thousands, of inserts are identical in size and shape, providing the most secure and snug protection for the jewelry.

Successful customization for custom made boxes for jewelry with logo for business is far more than just printing a logo. It’s a complete visual system that tells a coherent brand story through color, typography, and finishing details.

Color directly evokes emotion and shapes brand perception.

Font choice is equally important, defining the brand’s tone.

These details are what separate standard packaging from a true luxury experience.

When a customer runs their finger over an embossed logo, the physical, tactile feedback leaves a deeper, more “real” impression in the brain than a purely visual signal. The brain subconsciously associates this rich tactile feel with high quality, fine craftsmanship, and attention to detail. Therefore, investing in these finishes is, in effect, raising the product’s value in the customer’s mind before they even see the jewelry.

For many jewelry brands, the procurement process for jewelry containers wholesale can seem complex. Following a clear roadmap and choosing the right partner is key to ensuring a successful project.

When selecting a manufacturer for custom made jewelry boxes wholesale, you shouldn’t just focus on price.

You should seek a strategic partner who can provide long-term value. Key criteria to evaluate include:

Choosing a packaging supplier is a key strategic decision that impacts brand image, customer loyalty, and market returns. After fully understanding the strategic importance, design elements, and manufacturing complexity of custom made jewelry boxes, it is crucial to select a partner who can execute it all perfectly.

Richpack is not just a manufacturer; as detailed on our about page, we are a strategic partner with over 15 years of industry experience, serving more than 300 jewelry brands worldwide. We deeply understand that your packaging needs to be as precious as the jewelry it holds.

Your brand deserves exceptional packaging to match. The journey from a concept to a stunning unboxing experience begins with a simple conversation.

Contact the Richpack expert team today to discuss your project needs. Let us provide you with a free quote and a physical sample to demonstrate our commitment to excellence. Click here to submit your wholesale inquiry and begin your brand’s upgrade.

Great packaging enhances the unboxing experience and influences buying decisions. Discover how small paper bags can elevate your jewelry brand today.

Die-cutting is a specialized manufacturing process that transforms packaging materials into unique shapes and designs using custom molds. It’s an indispensable technique in the jewelry industry, allowing brands to move beyond standard boxes and create truly custom packaging. By precisely cutting, scoring, and shaping materials, die-cutting ensures every fold and tab fits perfectly, resulting in… Continue reading A Comprehensive Analysis of Custom Made Jewelry Boxes

The heart-shaped box is a timeless symbol of affection, perfect for Valentine’s Day, anniversaries, and presenting fine jewelry. While a handmade box is perfect for a personal, one-time gift, a business requires a packaging solution that communicates quality, ensures product safety, and can be produced consistently at scale. The fundamental challenge, therefore, is not simply… Continue reading A Comprehensive Analysis of Custom Made Jewelry Boxes

Biodegradable Jewelry Boxes for Eco-Conscious Brands | Environmentally Friendly Packaging Solutions for Jewelry Businesses Focused on Green Initiatives

Custom-Printed Jewelry Gift Boxes for Corporate Gifts | Tailored Packaging Solutions for Jewelry Brands Offering Elegant and Branded Corporate Presentation

Elegant Earrings Stand for Showcasing Jewelry – Customizable Jewellery Earring Stand for Retail Displays from Richpack Innovative Display Solutions

Artistic Embroidered Quilted Boxes | Embellished with Embroidery for Artistic Gift Packaging

View More

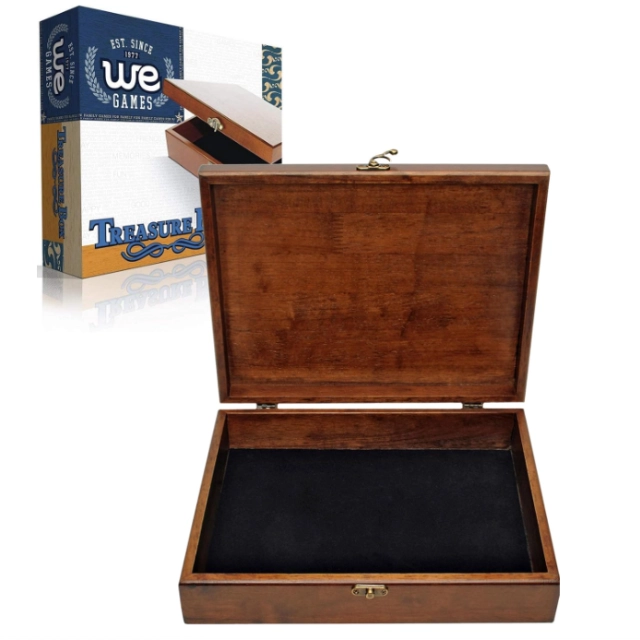

Charming Wooden Keepsake Box – Crafted with Care, Treasured Memories Holder

View More

Creative Personalized Packaging for Handmade Goods Marketplaces | Perfect for Artisans and Craft Retailers Needing Custom Branding and Memorable Packaging

View MoreJust submit your email to get exclusive offers (reply within 12 hours)