How to Choose the Right Packaging Solution for Different Jewelry Materials

2024-11-08

Hinged boxes have become a sustainable packaging solution, prized for their versatility and adaptability. According to the latest industry analysis, the global sustainable packaging market is experiencing robust growth, driven by innovations like plant-based plastics and materials. This guide examines the various types of hinged boxes , their inherent advantages, crucial factors to consider during the selection process, and emerging trends.

There is a rich tapestry of hinged box styles, each tailored to meet specific jewellery packaging requirements and sales and transportation applications. Understanding the nuances of each type is essential for making informed packaging decisions.

Known for their resilience, reusability, and optical clarity, plastic hinged boxes present a pragmatic solution for product display and storage. Their transparency allows for unobstructed product visibility, enhancing shelf appeal and facilitating inventory management.

Composed of a lid, base, and an optional insert, magnetic lid boxes employ strategically placed magnets to ensure a secure closure. The magnetic mechanism not only enhances security but also contributes to a tactilely satisfying “pop” sound upon closure, elevating the overall user experience. Their sleek makes them well-suited for premium products such as chocolates and corporate gifts. For luxury packaging like this, you can learn more about jewelry boxes with magnetic closure here.

Characterised by a thick, hollow rim, these robust boxes consist of three primary components: a lid, a base, and an insert. This structural design significantly enhances stability and protection, making them ideal for safeguarding delicate items. Their inherent elegance lends itself well to gift packaging and housing premium products. If you’re considering Richpack for your packaging needs, our custom solutions can be tailored to your exact specifications. Visit here for more details.

Beyond the common types, certain industries necessitate specialised hinged box designs to accommodate specific product requirements.

Protecting sensitive electronic components from the detrimental effects of electrostatic discharge is paramount, and ESD hinged boxes are engineered precisely for this purpose. Typically constructed from black conductive polypropylene, these boxes incorporate foam lining to provide both ESD and mechanical protection.

The pervasive popularity of hinged boxes is firmly rooted in their manifold advantages, positioning them as a superior choice compared to alternative packaging formats.

Hinged boxes excel in safeguarding their contents, utilising secure closure mechanisms such as hinges, magnets, or tuck-in flaps. These features effectively mitigate the risk of product damage during transit and handling. To learn more about how technology is enhancing security features, read more here.

The intrinsic elegance and sophisticated design of hinged boxes elevate the perceived value of the enclosed products. They contribute to a premium unboxing experience, leaving a positive and lasting impression on the recipient.

The availability of hinged boxes in an expansive array of sizes, shapes, and materials caters to diverse product and branding requirements. This adaptability transcends industry boundaries, solidifying their position as a truly versatile packaging solution.

The customisable nature of hinged boxes empowers businesses to leverage them as potent branding tools. Printing options facilitate the seamless integration of brand logos, messaging, and colour schemes, effectively reinforcing brand identity.

The growing emphasis on environmentally responsible packaging has led to the emergence of eco-conscious hinged box options. The utilisation of recycled materials and the inherent recyclability of certain box types contribute to minimising environmental impact. Richpack is committed to corporate social responsibility, offering solutions like eco-friendly jewelry pouches here. You can also read about sustainable jewelry packaging trends and materials in this article.

The selection of plastic hinged boxes significantly impacts jewellery protection, presentation, and user experience. This comparison focuses on common hinge mechanisms specifically engineered for jewellery presentations, incorporating both technical specifications and practical application considerations.

| Hinge Type | Application | Opening Experience | Protection Level | Presentation Value | Typical Usage | Durability Rating |

| Magnetic Clamshell | Ring, Earrings | Smooth, Controlled | Premium | High | Retail Luxury | 25,000+ cycles |

| Piano Hinge | Necklace, Sets | Professional, Stable | Ultra-High | Premium | High-End Brands | 50,000+ cycles |

| Spring-Loaded | Engagement Rings | Automated Pop-up | High | Luxury | Premium Retail | 20,000+ cycles |

| Classic Book | Bracelets, Chains | Traditional | Standard | Classic | Daily Retail | 15,000+ cycles |

| Double-Action | Watch, Sets | Multi-stage | Premium | Ultra-High | Collector Edition | 30,000+ cycles |

The manufacturing process begins with rigorous material selection and preparation.

Raw materials undergo comprehensive testing to verify physical properties including :

Simultaneously, tooling preparation involves systematic inspection of mold components, including thorough cleaning of cooling channels, verification of gate systems, and precise alignment of ejector mechanisms. The mold temperature is regulated between 70-80°C to ensure optimal processing conditions.

Injection molding represents the core production process, operating under strictly controlled parameters. The system maintains injection pressure between 80-100 MPa while the mold temperature is stabilized at 70-80°C. Material is processed at melting temperatures of 220-240°C, with injection speeds carefully controlled at 50-70 mm/s. The process incorporates a cooling cycle of 15-20 seconds and holding pressure of 60-70 MPa to ensure dimensional stability and surface quality.

Following the molding cycle, each component undergoes immediate post-production processing. This phase encompasses comprehensive dimensional verification maintaining tolerances of ±0.1mm across all critical dimensions.

.flow-container { width: calc(100% – 40px); max-width: 760px; margin: 10px auto; padding: 20px; background: #f5f6f8; } .flow-path { display: flex; flex-wrap: wrap; gap: 15px; justify-content: center; } .flow-step { width: 220px; background: #fff; border: 1px solid #e4e7eb; border-radius: 4px; padding: 15px; transition: all 0.3s ease; cursor: pointer; position: relative; } .flow-step:hover { transform: translateY(-3px); box-shadow: 0 4px 12px rgba(0,0,0,0.08); border-color: #2196f3; } .step-number { position: absolute; top: -10px; left: -10px; width: 24px; height: 24px; background: #2196f3; color: white; border-radius: 4px; display: flex; align-items: center; justify-content: center; font-size: 12px; font-weight: 500; box-shadow: 0 2px 4px rgba(33,150,243,0.3); } .step-title { font-size: 14px; font-weight: 600; color: #1e88e5; margin-bottom: 10px; padding-left: 15px; text-transform: uppercase; } .step-details { font-size: 12px; color: #546e7a; line-height: 1.4; } .key-param { margin-top: 8px; padding-top: 8px; border-top: 1px solid #eceff1; font-size: 11px; } .param-item { display: flex; justify-content: space-between; margin-top: 4px; padding: 3px 6px; background: #f8fafc; border-radius: 2px; } .param-label { color: #455a64; font-weight: 500; } .param-value { color: #0d47a1; font-weight: 600; font-family: monospace; }Surface quality inspection is performed under controlled lighting conditions, followed by precision gate removal and structural integrity testing. Components then undergo surface treatment including static elimination, compressed air cleaning, and application of specialized UV-protective coatings under controlled environmental conditions.

The assembly phase integrates all components into the final product structure. Metal hinge pins of Ø1.5±0.05mm are precisely inserted and subjected to torque testing at 1.5-2.0 N⋅m. Each assembled unit undergoes movement verification through 100 test cycles. Interior fitting proceeds with precision cutting and placement of velvet or fabric liners, utilizing adhesive application at 120-150 g/m², followed by foam insert integration and corner reinforcement installation.

Quality assurance incorporates comprehensive physical testing protocols including standardized drop testing from 1m height, extended durability cycling through 1000 operations, and detailed closure force measurements. Environmental stress testing evaluates product performance under varied conditions, while aesthetic inspection addresses surface finish quality, color consistency, and assembly precision under standardized lighting conditions.

The final production stage encompasses systematic packaging preparation, ensuring each unit receives appropriate protective wrapping and correct insert placement. Products are individually coded for traceability, with proper documentation and certification materials included. This stage maintains strict quality control standards while preparing products for safe transport and storage.

The production process concludes with compilation of comprehensive documentation. This includes detailed material certifications, complete production batch records, quality inspection reports, and relevant compliance certificates. This documentation ensures full traceability and verification of quality standards throughout the production process, maintaining transparency and accountability in manufacturing operations.

Choosing the optimal hinged box for a specific application necessitates a thoughtful evaluation of several key factors.

Choosing the optimal hinged box for a specific application necessitates a thoughtful evaluation of several key factors.

Accurately determining the dimensions and weight of the product is paramount for selecting a box with appropriate structural integrity and capacity.

Delicate items warrant boxes with enhanced protective features, such as inserts, thicker walls, or specialised cushioning materials.

Products intended for retail display often benefit from transparent plastic boxes, while those requiring a premium aesthetic may be better suited to magnetic lid boxes with luxurious finishes.

Certain industries, such as the food and pharmaceutical sectors, mandate compliance with stringent regulations, including the use of food-safe or medical-grade materials.

Understanding the properties and characteristics of various materials is crucial for choosing a box that aligns with both product needs and sustainability goals.

.materials-container { width: calc(100% – 40px); max-width: 760px; margin: 10px auto; background: #f5f6f8; padding: 20px; } .materials-grid { display: grid; grid-template-columns: repeat(2, 1fr); gap: 15px; } .material-card { background: white; border: 1px solid #e4e7eb; border-left: 4px solid #2196f3; padding: 15px; transition: all 0.3s ease; cursor: pointer; position: relative; } .material-card:hover { transform: translateY(-2px); box-shadow: 0 4px 8px rgba(0,0,0,0.08); } .material-title { display: flex; align-items: center; gap: 10px; margin-bottom: 12px; } .icon { width: 32px; height: 32px; background: #e3f2fd; border-radius: 4px; display: flex; align-items: center; justify-content: center; font-size: 16px; } .title-text { font-size: 16px; font-weight: 600; color: #1e88e5; text-transform: uppercase; } .material-desc { color: #546e7a; font-size: 13px; line-height: 1.5; } .features { margin-top: 10px; padding-top: 10px; border-top: 1px solid #eceff1; } .feature-tag { display: inline-block; padding: 4px 8px; margin: 2px; background: #f8fafc; border: 1px solid #e3f2fd; border-radius: 3px; font-size: 11px; color: #0d47a1; } @media (max-width: 600px) { .materials-grid { grid-template-columns: 1fr; } }Cost-effective, lightweight, and readily recyclable, cardboard remains a popular choice for hinged boxes. Its printability and versatility make it suitable for a wide range of applications.

Durability, reusability, and transparency are hallmarks of plastic hinged boxes. They offer a practical solution for showcasing products while ensuring their protection.

Protecting sensitive electronic components from electrostatic discharge necessitates the use of specialised ESD-safe materials.

Opting for recycled content, sustainably sourced materials, and recyclable box designs underscores a commitment to environmental responsibility. Richpack offers a variety of sustainable material options for your packaging.

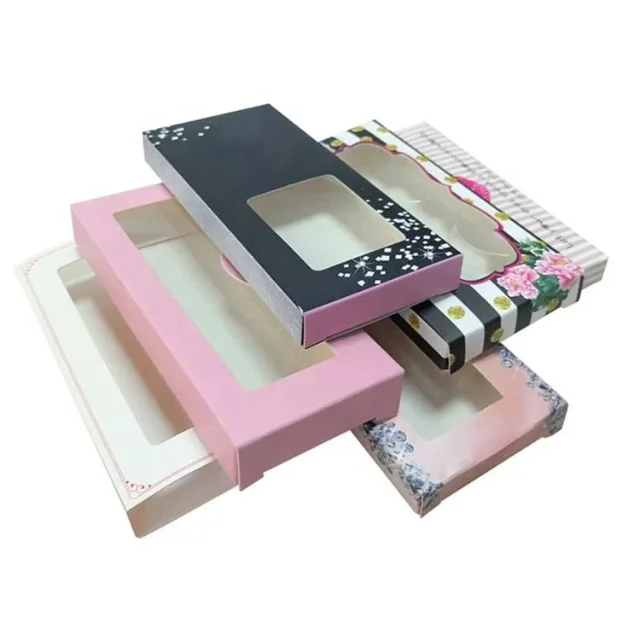

Elevating hinged boxes’ visual appeal and branding impact often involves exploring various customisation options.

A diverse array of printing methods, including offset, digital, and screen printing, along with various finishes and colour palettes, allows for creating bespoke designs that align with brand aesthetics.

Foam, cardboard, and vacuum-formed trays offer varying levels of protection and presentation for different products. Custom inserts can be tailored to hold and showcase specific items securely.

Deviating from conventional box shapes can enhance brand recognition and create a distinctive identity for a product.

Selecting the ideal hinged box involves a meticulous evaluation of the product’s attributes, material properties, and available customisation options. This comprehensive approach ensures optimal functionality, visual appeal, and brand consistency. To explore custom packaging solutions for your brand, contact us.

Hinged boxes offer a secure, elegant, and sustainable packaging solution, meeting the growing demand for high-quality presentation. If you’re ready to enhance your packaging with a sustainable touch, Richpack’s custom jewelry packaging solutions offer a wide range of designs to meet your specific needs. Explore our offerings from eco-friendly materials to personalized designs and take your brand’s packaging to the next level now!

Did you know that 72% of consumers say that packaging design influences their purchase decisions? In the jewelry industry, where brand image and uniqueness are paramount, packaging can make all the difference. In this article, we will delve into the top 10 customizable jewelry packaging options. These options will enable your brand to convey its… Continue reading Choosing the Right Hinged Box for Jewellery: A Comprehensive Guide

Fragrance focuses on classics, fragrance packaging may be the opposite, sustainability, customization, and smart technology are shaping the future of packaging. Facing the perfume packaging market with increasing environmental awareness and obvious advantages of intelligent packaging, perfume packaging design should pay attention to market trends, consumer preferences, and in-depth research on innovation in the industry. In… Continue reading Choosing the Right Hinged Box for Jewellery: A Comprehensive Guide

Many jewellery packaging businesses have quality concerns about custom card printing. You should solve custom card printing issues by using the DMAIC method to optimize printing parameters and choose the right printing technology and high-quality card materials you can select appropriate materials such as glass-like cardboard for high gloss, adjusting the coating type and formulation. 1. Understand… Continue reading Choosing the Right Hinged Box for Jewellery: A Comprehensive Guide

Cost-Saving Bulk Order Discounts on Custom Jewelry Display Units | Perfect for Wholesalers Seeking High-Volume, Branded Display Solutions at Competitive Rates

Custom Logo Embossed Black Cardboard Beauty Products Box With Window Pink Art Paper Packaging

Customizable Velvet Jewelry Pouches with Custom Colors | Tailored Packaging Solutions for Jewelry Retailers Needing Bespoke and Stylish Storage

Exquisite Jade Jewelry Packaging | Custom Creations by Richpack for Timeless Elegance

View More

Richpack High-End Earring Boxes with Secure Clasps | Luxury Earring Packaging for Retailers and Collectors Trade Pricing

View More

Richpack Versatile and Recherché Small Containers with Lids – Durable and Secure Jewelry Display Solutions for Organized Storage and Beauty Amplification

View MoreJust submit your email to get exclusive offers (reply within 12 hours)