5 Luxury Watch & Perfume Packaging Ideas: Gifts for 50 Year Old Man

2025-03-27

The 10×10 gift box has transcended its role as a mere container to become a global phenomenon and a cornerstone of the packaging industry. This comprehensive analysis explores why this specific dimension has become the gold standard for logistics and branding, examines the latest trends in the jewelry packaging sector, and provides a detailed look at market forecasts through 2035. From the psychology of unboxing to the integration of smart technology and sustainable materials, the humble 10×10 box represents a convergence of efficiency, consumer desire, and manufacturing innovation.

The dominance of the 10×10 inch gift box is not a coincidence but the result of four converging forces that have solidified its position as the preferred specification for manufacturers and logistics providers worldwide. The primary driver is the perfection of logistical and shipping compatibility. The 10x10x5 inch specification aligns flawlessly with the standard classification systems used by major carriers such as USPS, UPS, and FedEx. Furthermore, these dimensions allow for optimal stacking efficiency on standard 48×40 inch shipping pallets, maximizing warehouse utilization. This size has become the “golden ratio” for economic shipping, allowing brands to avoid the surcharges often applied to oversized items while maximizing the volume of goods transported per vehicle.

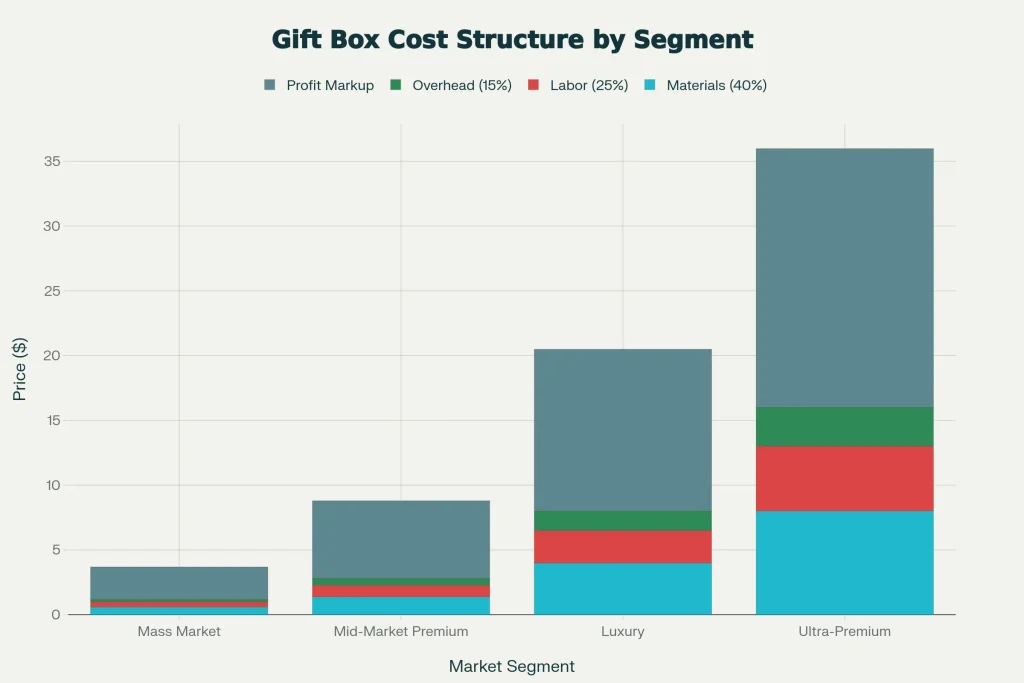

Beyond logistics, the cost-benefit ratio of the 10×10 box is unrivaled in the manufacturing sector like custom ring boxes wholesale field. In terms of material costs, it sits in a sweet spot between small jewelry boxes and large appliance packaging, offering the lowest unit cost for its volumetric capacity. The surface area, which offers approximately 500 square centimeters of printable space, allows printing machinery to operate at peak efficiency, minimizing waste and setup times. Global manufacturers have optimized their production lines around these dimensions, resulting in the lowest Minimum Order Quantities (MOQs) and the fastest turnaround times in the industry. This production scalability creates a barrier to entry for non-standard sizes that require custom tooling and generate higher material waste.

Consumer psychology plays a massive, often underestimated role in the standardization of this gift box size for jewelry. Visually, a 10×10 box presents a substantial presence that immediately signals to the recipient that they are receiving a significant and valuable gift. Studies indicate that this specific size increases the perceived value of the contents by 40 to 50% compared to smaller alternatives. It provides ample space for a multi-layered unboxing experience, which is crucial in the age of social media where unboxing videos on TikTok and Instagram drive brand visibility. Additionally, the internal volume allows for thick, high-quality cushioning materials, giving consumers a heightened sense of security regarding the protection of their purchase.

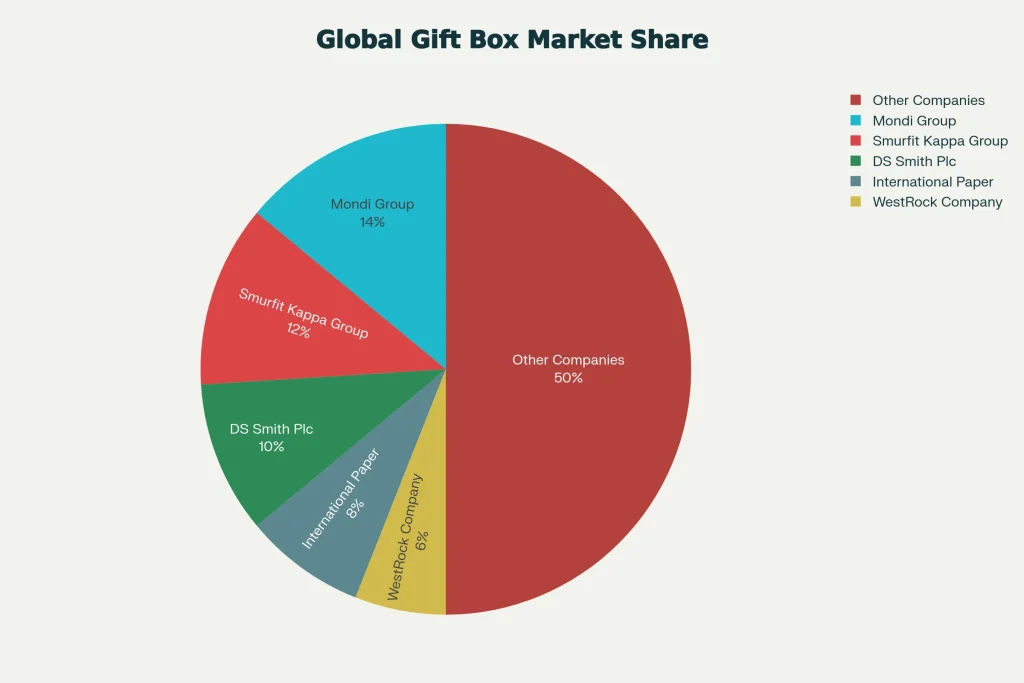

Finally, the industry has experienced a powerful network effect that reinforces the status of the 10×10 box. Major global packaging leaders like Mondi and Smurfit Kappa have adopted this size as a flagship specification, influencing the entire supply chain. From pulp suppliers to cardboard manufacturers and printing houses, the entire ecosystem is configured to support this standard. This integration creates a positive feedback loop where the widespread availability of raw materials and tooling for 10×10 boxes lowers costs further, encouraging more brands to adopt the size, which in turn solidifies the supply chain’s focus on this specific form factor.

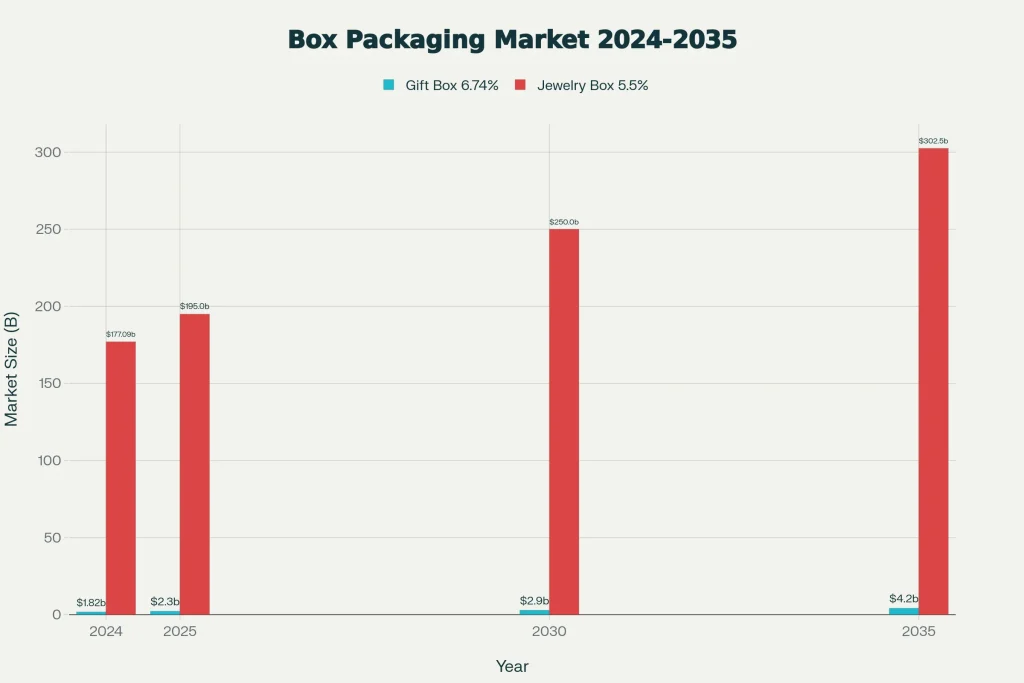

The financial trajectory of the packaging industry reveals a robust growth pattern for the next decade. The general global gift box market, valued at 1.82 billion dollars in 2024, is projected to nearly double to 3.50 billion dollars by 2034, growing at a compound annual growth rate of 6.74%. However, the true economic powerhouse lies in the specialized jewelry packaging segment. This high-end niche is valued at a staggering 177.09 billion dollars in 2024, nearly 100 times the size of the general gift box market, and is expected to reach 302.50 billion dollars by 2034. This growth is driven by the booming e-commerce sector, where US online sales reached 272.6 billion dollars in 2023, and a global resurgence in gifting culture, exemplified by rising wedding expenditures in Canada and festival spending in China.

Regional preferences dictate the design and function of packaging across the globe. North America currently commands 37% of the market, driven by a demand for high-end, personalized, and sustainable solutions that cater to a strong culture of gift-giving. The European market, holding a 25% share, is heavily influenced by strict environmental regulations such as GDPR and a consumer preference for minimalism, craftsmanship, and verified sustainability. The Asia-Pacific region is the fastest-growing sector with 23% market share, fueled by an expanding middle class growing at over 15% annually. China plays a unique dual role, serving as a massive consumption hub during festivals while also acting as the world’s factory, responsible for 17 billion dollars in jewelry packaging exports.

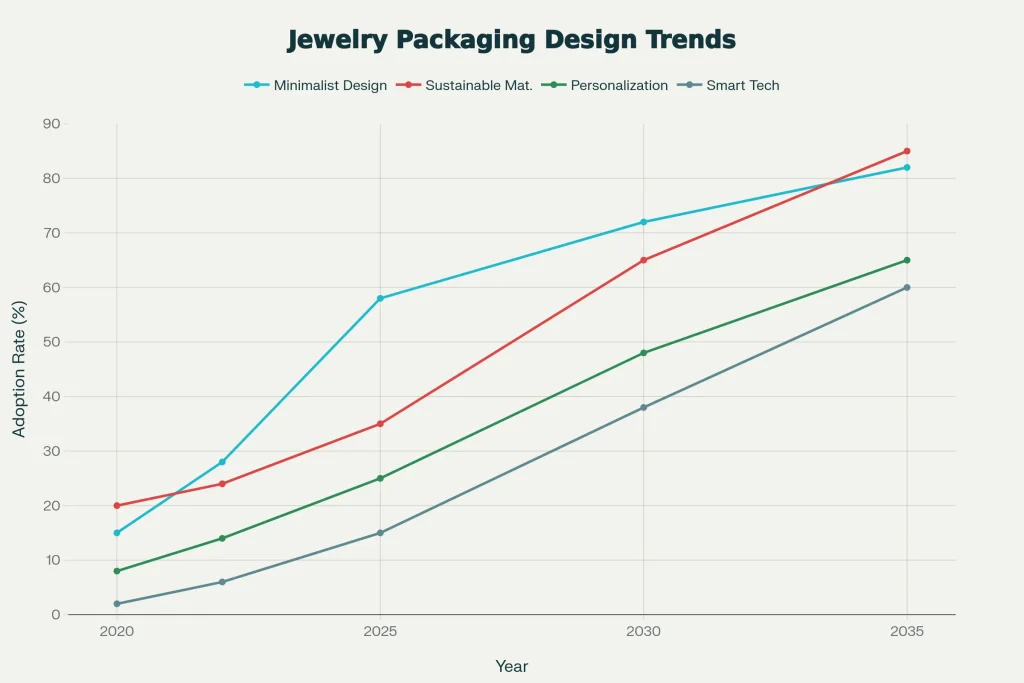

The industry is currently undergoing a sustainability revolution that is fundamentally reshaping manufacturing processes. Data shows that 75% of consumers now prioritize eco-friendly brands and are willing to pay a premium of 15 to 20% for sustainable packaging. This has spurred innovation in materials, such as the adoption of mushroom-based mycelium materials which turn agricultural waste into sturdy packaging. While currently costing 10 to 15% more than traditional cardboard, costs are expected to reach parity within five years. Innovative companies like ITIS Packaging have successfully leveraged these materials, achieving a 42% revenue increase by marketing the sustainability of their mushroom-based jewelry boxes.

Parallel to sustainability is the rapid rise of personalization and customization. Modern consumers demand uniqueness, with 52% expressing a desire for personalized packaging options. The industry is evolving from a model that required minimum orders of 1000 units with six-week lead times to a more agile approach. Current capabilities allow for orders as low as 500 units delivered in four weeks, with a future target of 100-unit runs delivered in two weeks. While customization adds 8 to 15% to design costs, consumers are willing to accept price premiums of up to 40% for packaging that feels exclusively made for them.

Technology is also finding its way into cardboard and paper through smart packaging integration. The adoption of NFC and RFID tags is expected to grow from 15% in 2025 to over 60% by 2035. These technologies allow brands to embed digital certificates, authentication verification, and brand stories directly into the box. A prime example is the brand Anartxy, which embedded NFC chips in their boxes, allowing customers to verify authenticity with a smartphone tap. This integration not only enhanced trust but also improved customer repeat purchase rates by 45%.

Navigating the market for 10×10 inch gift boxes reveals a variety of styles designed to meet specific functional and aesthetic needs. One of the most popular configurations is the magnetic closure box.

These units feature a sturdy construction with integrated magnets that snap the lid shut, eliminating the need for adhesive tape or external wrapping. They are favored by luxury brands because they often ship flat to save storage space and can be assembled in seconds. Many of these magnetic boxes come with accompanying ribbons, adding an extra layer of elegance that appeals to high-end consumers.

Another staple of the industry is the classic two-piece box, consisting of a separate lid and base. This style offers versatility as retailers can mix and match colors for the top and bottom to create contrast or match specific branding palettes. These are typically manufactured from high-quality chipboard to ensure durability and are the preferred choice for rigid retail packaging. For products that require visibility, such as baked goods or artisanal sets, window boxes feature a transparent film on the lid, allowing the product to serve as its own display. Conversely, plain kraft paper boxes remain a best-seller for the DIY market, providing a blank canvas for artistic personalization with stamps, drawings, or stickers.

While the 10×10 inch footprint is standard, the depth of the box varies significantly to accommodate different product categories. A depth of 4.5 inches is commonly found in high-gloss finishes for premium apparel. The 5-inch depth is the industry workhorse, suitable for books, multiple small items, or medium-sized accessories, and is widely available on major platforms like Amazon. For bulkier items, depths extend to 5.5 inches and 6 inches, often referred to as high-wall options. The cubic 10x10x10 inch box represents the maximum capacity in this category, ideal for large gifts or bulk sets that require significant internal volume.

Looking toward the next decade, the packaging landscape will be defined by the ubiquity of sustainable materials and the normalization of smart technology. By 2035, it is projected that 85 to 90% of all packaging materials will be fully sustainable or circular, moving away from virgin plastics entirely. The cost of smart integration, such as NFC tagging, is expected to drop from 40 cents per unit to roughly 10 cents, making digital interactivity a standard feature rather than a luxury add-on. Design trends will continue to favor minimalism, but with a shift toward “biomimetic” textures and shapes that imitate nature, alongside a growing appreciation for multicultural aesthetic fusion.

For manufacturers, the path forward involves a critical pivot from being simple production facilities to becoming design partners. Successful suppliers will need to invest in digital printing and AI-driven design tools to facilitate the micro-batch customization that brands will demand. For jewelry and retail brands, the advice is to view packaging as a core component of the product itself. Creating a signature unboxing experience, much like Cartier’s iconic octagon or Meadowlark’s hexagon, can drive social media engagement and justify higher price points. The winners of the next decade will be those who can seamlessly blend ecological responsibility with technological innovation and personalized luxury.

As the global standard for 10×10 gift boxes and jewelry packaging continues to evolve, finding a manufacturing partner who understands both the logistics of mass production and the nuances of brand storytelling is essential. Whether you are looking to launch a sustainable jewelry line, require high-end magnetic closure boxes for corporate gifting, or need a completely custom structural design to stand out and become an industry leader, Richpack packaging has the expertise to bring your vision to life. We specialize in providing comprehensive packaging solutions that balance cost-efficiency with premium quality.

If you are ready to elevate your brand with professional, industry-standard, or fully customized packaging, we invite you to contact us today. Richpack packaging team is ready to assist you with bulk orders, material selection, and design optimization to ensure your packaging not only protects your products but enhances your brand value.

Contact Richpack today to start your custom packaging inquiry.

The 10x10x5 inch specification aligns perfectly with standard carrier classifications used by USPS, UPS, and FedEx. It allows for optimal stacking on standard 48×40 inch shipping pallets, which maximizes warehouse utilization. This size helps brands avoid surcharges often applied to oversized items while ensuring the highest volume of goods can be transported per vehicle, making it the most cost-effective standard for global logistics.

Research indicates that the specific 10×10 box size increases the perceived value of the contents by 40% to 50% compared to smaller alternatives. Visually, it presents a substantial presence that signals a valuable gift. It also provides enough internal volume for a multi-layered unboxing experience and high-quality cushioning, which drives social media engagement and gives consumers a heightened sense of security regarding their purchase.

The industry is undergoing a sustainability revolution, with a shift toward circular materials like mushroom-based mycelium that utilize agricultural waste. By 2035, it is projected that 85% to 90% of packaging will be fully sustainable, moving away from virgin plastics. Although these materials currently carry a slight cost premium, data shows that 75% of consumers prioritize eco-friendly brands and are willing to pay up to 20% more for sustainable packaging.

The integration of NFC and RFID tags into cardboard and paper packaging is expected to grow from 15% in 2025 to over 60% by 2035. These technologies allow brands to embed digital certificates, authentication verification, and brand stories directly into the box. This “smart packaging” not only enhances consumer trust but has been shown to improve repeat purchase rates significantly by connecting the physical unboxing experience with digital interaction.

Richpack · Choosing the Right Hinged Box A Comprehensive Guide Hinged boxes have become a sustainable packaging solution, prized for their versatility and adaptability. According to the latest industry analysis, the global sustainable packaging market is experiencing robust growth, driven by innovations like plant-based plastics and materials. This guide examines the various types of hinged… Continue reading Deep Industry Analysis of 10×10 Gift Boxes

Do leather jewelry boxes appeal to men? Explore how leather’s durability, masculine aesthetics, and premium feel meet men’s storage needs.

When you picture a white paper box, you might just see a simple container. But what if that box could tell your brand’s story before it’s even opened? That’s the magic of die-cutting. This precision technique transforms a humble white paper box into a powerful tool for engagement and an unforgettable part of your product’s journey.… Continue reading Deep Industry Analysis of 10×10 Gift Boxes

Anniversary-Themed Jewelry Boxes: With Romantic Designs, Ideal for Anniversary Gifts

View More

Bamboo Wooden Jewelry Organizer Boxes with Multiple Compartments | Eco-Friendly and Functional Storage for Eco-Concious Brands

View More

Best Jewelry Box with Lock | Elegant & Secure Jewelry Storage for Your Precious Collection | Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)