There’s a key rule in the jewelry e-commerce industry. The first 5 seconds when a customer opens a package usually determine 80% of their perception of a brand’s value.

You might spend weeks perfecting the design of a ring or necklace. But if a thank you card is just tossed into a jewelry gift box—and worse, falls out when the box is opened—that carefully crafted sense of luxury vanishes in an instant. This is not just an aesthetic mistake; it’s a hidden killer of customer retention.

Many brand owners mistakenly think “bundling” is just putting a card in a box. But as a premium packaging solutions provider, Richpack has learned from real-world experience that it’s a detailed process involving brand consistency and supply chain efficiency.

When a card’s size and material perfectly match a box’s structure, the card is no longer just a piece of paper. It becomes your lowest-cost, highest-ROI silent salesperson.

The real challenge is striking a balance between design aesthetics and operational needs. And strategic packaging design is where this balance happens.

If you’re looking for a solution that boosts unboxing experience and optimizes your back-end supply chain, you’re in the right place. We’ll explore how to turn these two elements into drivers of brand growth.

Many brands see packaging as nothing more than a protective container. But in the high-end jewelry industry, packaging is the only marketing channel with a 100% unboxing rate.

Strategically pairing Thank You Cards with Jewelry Gift Boxes is not an extra step. It’s a low-cost, high-return investment in your brand equity.

It’s not just about being polite. More importantly, it builds a premium brand feel through the unboxing experience, the moment a customer touches your product.

Dopamine peaks when a customer opens a box. At that moment, a thick, well-designed card instantly amplifies this emotional connection. To truly master this moment, brands must look beyond the box and focus on jewelry packaging ideas for unboxing magic. Many independent designers we’ve worked with find that a carefully designed embedded card significantly reduces return rates.

The deadliest brand mistake is a disjointed experience. A cheap, plain printed card falling out of a luxurious leather jewelry box—this inconsistency shatters consumers’ perception of a high-end brand in an instant.

As a strategic packaging partner, Richpack always emphasizes brand consistency. This means the card’s paper texture must match the box’s surface finish, and the printed CMYK values must align perfectly with your brand colors. Only when the two are delivered as a single bundle is your brand image complete and credible.

Industry Data Reference: According to research by Dotcom Distribution, over 40% of consumers say they’re more likely to repurchase if their online order comes in premium, unique packaging. This is further evidenced by the impact of custom packaging designs on retail sales, where strategic bundling directly influences long-term customer loyalty.

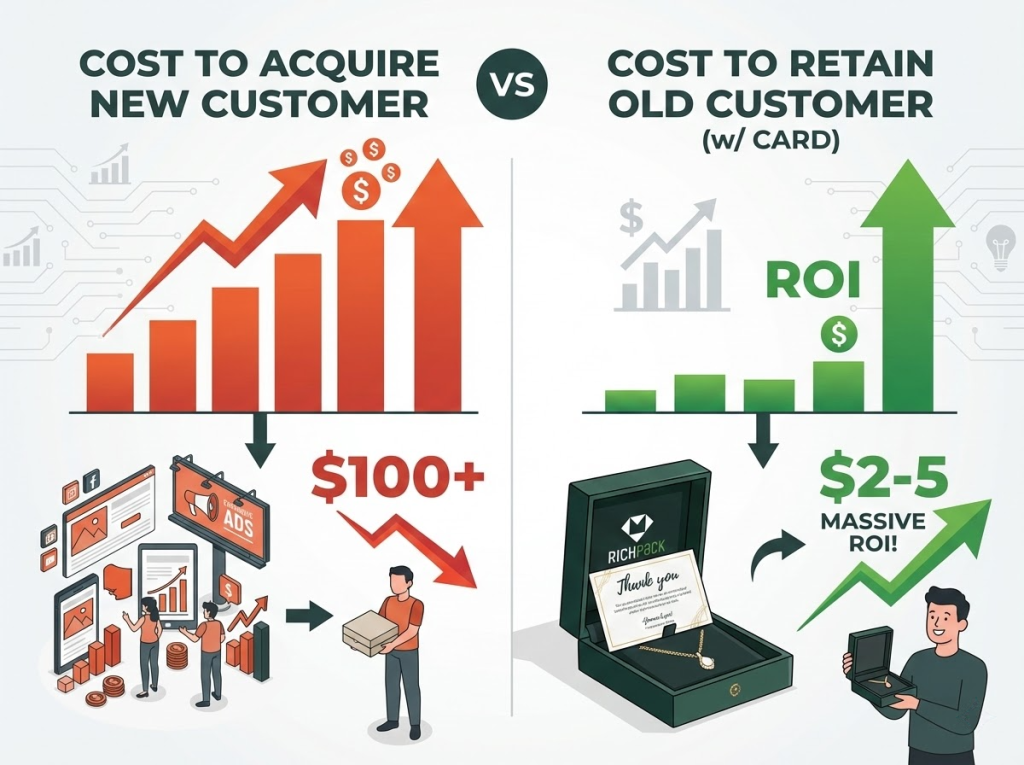

Don’t underestimate this small card—it’s your lowest-cost customer retention tool. Unlike expensive digital ads, a card in the box can trigger repeat purchases at an extremely low cost with a QR code or discount code.

It’s your silent salesperson, quietly offering an invitation to come back when the customer is in the best mood. For B2B decision-makers focused on growth, ignoring this is like leaving unclaimed cash on the table.

A fatal mistake many brands make in design is: “Produce the jewelry gift boxes first, then print the thank you cards, and finally find the cards don’t fit, or the box won’t close after putting them in.”

True fit is not just simple physical accommodation—it’s an engineering calculation measured in millimeters. If a card slides around in the box, it not only looks cheap but can also scratch delicate gold or pearl surfaces with its edges.

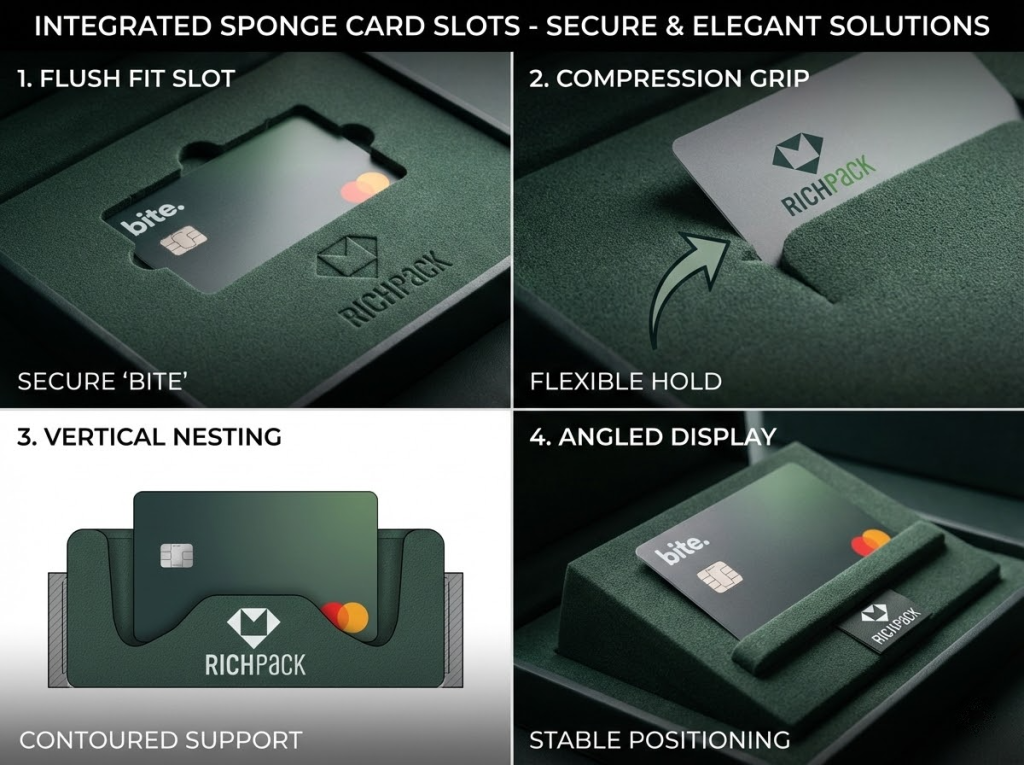

We usually advise clients to choose from these four placement options based on jewelry type and unboxing drama needs:

Card size must follow the tolerance principle. Based on our lab test data, the ideal size for insert cards should be 1.5mm to 2mm smaller on each side than the box’s inner diameter.

Too little clearance and the card edges will curl under pressure; too much and it creates a cheap, wobbly feel. For a standard 3.5″ x 3.5″ necklace box, a 3″ x 3″ square card is usually the golden ratio—it leaves enough space and is easy to pick up.

Professional Tip: Before finalizing sizes, refer to the ISO 216 paper standard or ask your supplier for a specific dieline to ensure your design is within the safe zone.

When you ship 500 orders a day, an extra folding step means significant labor costs.

When designing a card, consider not just its appearance but also how easy it is for packers to handle. For example, avoid complex double-fold card structures unless they’re delivered pre-assembled. Choosing thick single-page cardstock with a pre-designed slot can boost packing efficiency by over 30%.

Once the physical fit is solved, the next challenge is matching touch and material compatibility. Imagine a customer eagerly touching a velvet jewelry gift box, only to feel a flimsy paper like a receipt— that premium feel collapses in an instant.

Material selection is not just about aesthetics; it’s about risk control. In Richpack’s lab, we’ve seen countless costly cases of silver tarnish or pearl damage caused by the wrong paper choice.

In the high-end jewelry industry, 250gsm is the minimum, not the maximum, for thank you cards. Paper below this weight easily curls in humid environments, giving a cheap, last-minute feel.

If you use minimalist packaging, we highly recommend upgrading to 300gsm to 350gsm specialty paper. A thick card not only feels substantial in the hand but also stays stiff like a coaster—even if customers place it casually on a table, your brand message remains clear.

Professional Tip: For textured art paper, increase the weight by 10-15% to compensate for structural strength loss from embossing.

This is a detail most general printers overlook, but it is critical for jewelry brands: chemical compatibility.

Ordinary paper and cheap inks often contain acidic substances or sulfides. If your card touches pure silver or brass jewelry directly, months of storage are enough to make the jewelry tarnish and discolor.

To protect your assets, it is essential to focus on mastering jewelry packaging materials and ensuring you use acid-free, neutral-pH options. This is not just an environmental statement; it prevents chemical volatiles from reacting with precious metals.

Professional Tip: Ask your supplier for the material’s MSDS or FSC certification to confirm the paper has a neutral pH value.

Visual brand consistency requires the card’s finish to match the outer box. A glossy card looks out of place with a matte box.

Consider using soft-touch lamination or spot UV coating to make the card’s touch seamlessly match the velvet or leather of the jewelry box.

For logos, foil stamping not only adds luxury but also avoids the risk of ink touching the jewelry directly.

A beautiful jewelry gift box and high-quality paper are just the stage—the words on the card are the real lines.

Many brand owners struggle with writer’s block at this step. They worry that being too formal feels cold, while being too enthusiastic seems like begging for reviews.

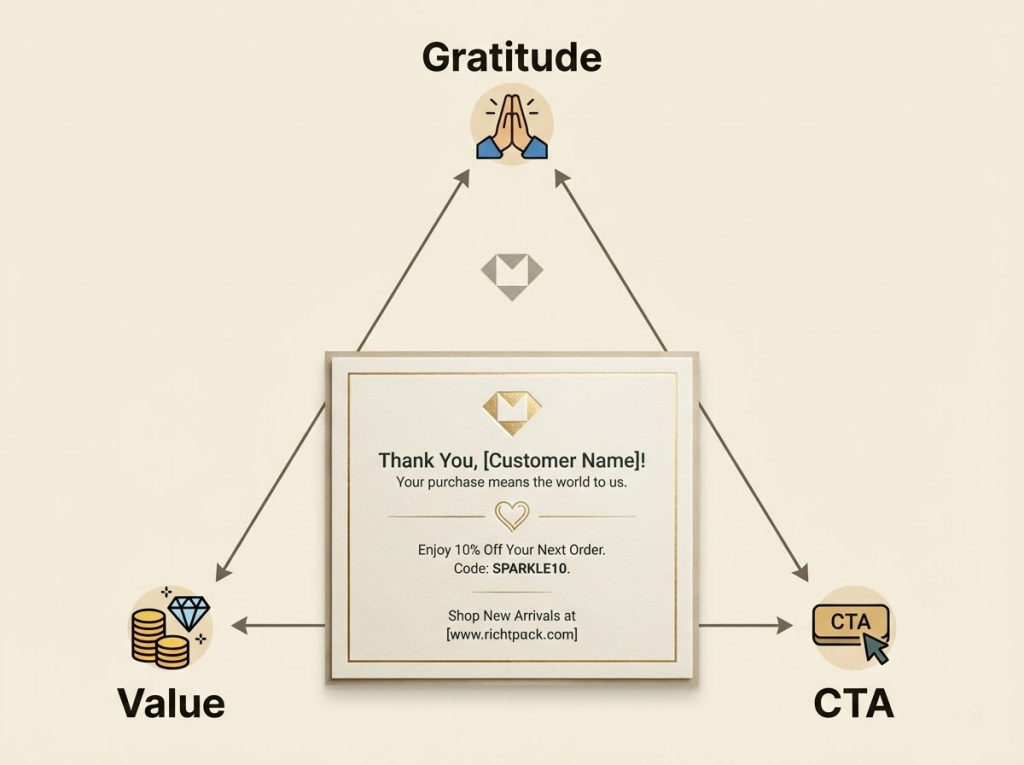

If you only print a simple “Thank You”, you’re wasting a golden opportunity to turn a one-time buyer into a lifelong customer. The core of content strategy is not literary talent, but psychology. You need to embed your brand voice at the moment of unboxing, when the customer’s dopamine is at its highest.

To break through writer’s block, we’ve developed a proven “Golden Triangle” rule for Richpack’s clients. No matter your brand style, these three elements are essential:

Different jewelry categories need different messaging. For custom jewelry, card content should be personal and emotional; for fast-fashion accessories, it should be more casual and social.

Professional Tip: While handwriting each card is impractical for brands with large shipping volumes, we’ve found that for high-ticket orders (> $500), cards with a handwritten signature or the buyer’s name boost repeat purchase rates by nearly 15%.

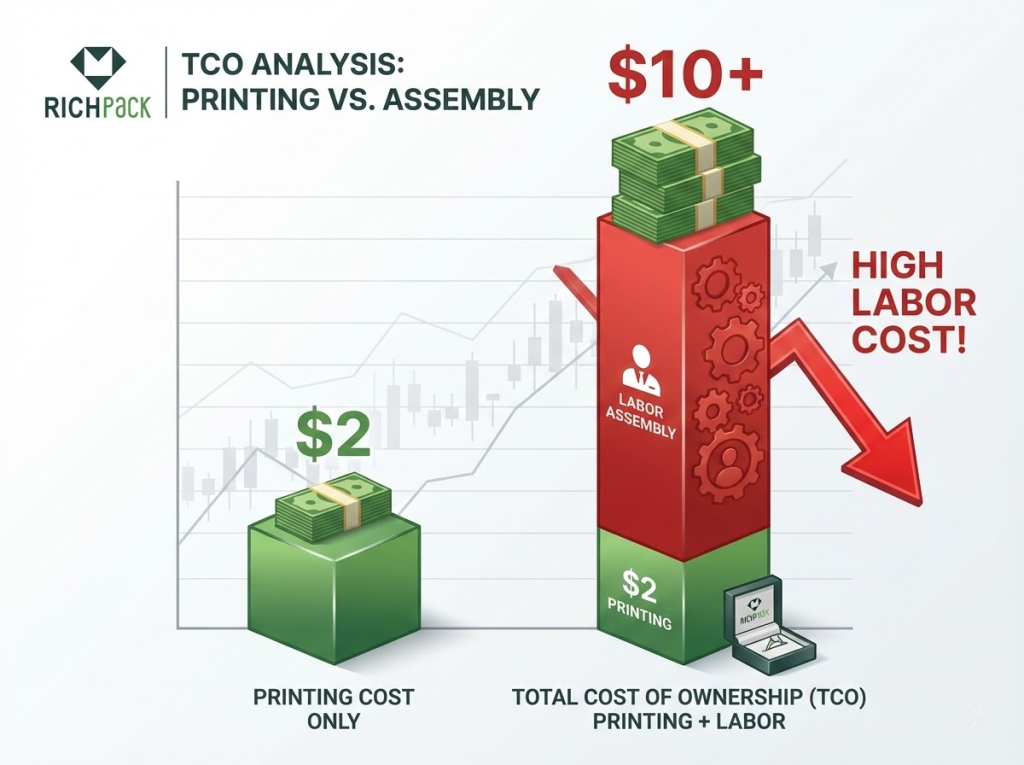

When your daily orders grow from 10 to 500, you’ll quickly find that the highest cost of thank you cards is not printing fees, but the hidden labor in the fulfillment process.

Many brands hit a “packing bottleneck” during expansion. Warehouse staff have to spend extra time folding cards, finding the right boxes, placing them carefully—and this seemingly small action, multiplied by thousands, becomes a profit-eating black hole.

We once helped a client calculate this.

If a worker spends an extra 30 seconds handling a card for each jewelry gift box, processing 10,000 orders adds nearly 83 labor hours.

This doesn’t even include error costs. During busy peak seasons, tired packers easily put the wrong card in a box (like a VIP card in a regular order) or forget to include one. These pick and pack mistakes often lead to costly customer complaints and brand damage.

To solve this supply chain pain point, Richpack offers a kitting service. We don’t just deliver boxes and cards separately—we act as your strategic partner, embedding the card perfectly into the box before it leaves the factory.

This means your warehouse receives a single ready-to-ship unit instead of two separate SKUs. This not only boosts your packing efficiency by over 40% but also eliminates the risk of missing cards.

Richpack Supply Chain Insight: Consolidating printing and packaging with a single-source supplier also avoids color-mismatch disasters. We ensure the card’s Pantone color is identical to the box’s outer packaging—something hard to achieve with separate sourcing.

Before you place a large wholesale order for custom thank you cards, establishing a standard operating procedure (SOP) is critical.

We recommend conducting a drop test before production. Simulate shipping vibrations with the box and card inside to check if the card shifts or falls out of the slot. Only structural designs that pass physical testing can withstand the real supply chain and arrive perfectly at customers.

Space is at a premium in ring boxes. For a standard 5x5cm box, we don’t recommend laying the card flat on top of the ring—it covers the product’s highlight moment. The best option is to design a tiny ribbon corner on the inner lid to hold a 4x4cm mini folded card, or use the foam pad’s elasticity to slide the card behind the ring slot as a backdrop.

While there’s no absolute industry standard, to save mold costs, we recommend business card size (3.5″ x 2″) or square (2.5″ x 2.5″). These sizes fit most necklace and bracelet boxes perfectly, and printers usually have ready-made die-cut molds, saving you about 15% on mold costs.

Technically, yes, but from an inventory flexibility perspective, we recommend separate thank you cards. Printing on the box means the message is permanent. Once you want to change the greeting for Mother’s Day or update your social media handle, the entire batch of boxes becomes useless. Cards allow you to rotate seasonal content at an extremely low cost, keeping your marketing fresh.

Don’t try to cram 5 languages on one small card—it ruins the design. Richpack recommends a “universal visuals + digital landing” strategy: use English or your brand slogan on the front of the card, and print a dynamic QR code on the back. Through backend settings, the QR code automatically redirects to a landing page in the user’s language based on their scan IP—solving language barriers and building private traffic at the same time.

Separate sourcing is often the cause of color mismatch. Different paper materials (e.g., coated paper vs. specialty paper) absorb ink differently, resulting in vastly different prints for the same Pantone color. Choosing a one-stop supplier like Richpack means we conduct unified color management on the production line, ensuring your jewelry gift boxes and cards have identical brand colors—something hard to achieve with separate suppliers, while also saving you the communication cost of coordinating two factories.

Strategically bundling Thank You Cards with Jewelry Gift Boxes is far more than just putting a piece of paper in a box. It’s the critical link connecting brand experience and supply chain efficiency.

Every detail—from using acid-free card material to protect jewelry, to designing precise die-cut slots to speed up packing—affects your brand premium and net profit. In this competitive market, consumers may forget your ads, but they’ll never forget the unboxing moment that made their heart race.

Don’t let a broken supply chain dilute your brand value. Finding a partner that offers a one-stop solution from structural design to finished product assembly frees you from tedious material coordination, allowing you to focus on what matters most—creating unforgettable jewelry pieces.

Richpack is ready to be your strategic support behind the scenes. We don’t just make packaging—we build the most intimate conversation space between you and your customers.

Just submit your email to get exclusive offers (reply within 12 hours)