22 Marketing Tricks with Heat-Activated Color-Changing Coatings

2025-02-25

Have you ever wondered what makes the packaging of a luxury jewelry box so captivating? It all comes down to the printing process. Before diving into the technicalities, it’s essential to grasp the basics of printing. Discover how printing processes shape the allure of luxury jewelry packaging. This includes three main stages: prepress, press, and postpress. In this guide, Richpack shows printing techniques, from traditional methods like screen printing to modern solutions like inkjet technology. By the end of this article, you’ll be equipped with the knowledge to make informed decisions and optimize your printing processes for stunning, professional-grade jewelry packaging.

The world of printing is fascinating, especially when it comes to creating stunning jewelry boxes. At the heart of every beautiful packaging design lies a deep understanding of the printing process.

Printing methods are broadly categorized into direct and indirect techniques. Direct printing, such as screen printing, applies ink straight onto the material. This method is great for bold designs and textures. On the other hand, indirect printing uses an intermediate step, like a blanket cylinder in offset lithography, to transfer the image. This approach is known for its high-quality results and versatility.

Image carriers are essential in printing, holding the design that gets transferred onto the material. The main types include:

| Type | Characteristics | Common Use |

| Relief | Raised surfaces transfer ink | Flexography, letterpress |

| Planographic | Flat surfaces with chemical treatment | Lithography |

| Intaglio | Etched metal plates | Gravure printing |

| Screen | Mesh screens with stencils | Screen printing |

Each type has unique properties that make it suitable for different applications. For instance, flexography uses relief plates for packaging, while gravure printing relies on intaglio for high-volume projects.

Understanding these basics is crucial before diving into optimization. By grasping direct vs indirect methods and image carriers, you’ll be better equipped to make informed decisions for your jewelry box designs.

When it comes to creating exquisite jewelry packaging, understanding the right printing techniques is essential. Each method offers unique benefits, making some more suitable for specific designs than others.

Offset lithography stands out for its high-quality image transfer. It uses metal plates to transfer designs onto rubber blankets, which then apply the image to the material. This method is ideal for large-scale production and offers crisp, detailed results. On the other hand, screen printing is highly versatile, working well on uneven surfaces and offering bold textures. It’s perfect for intricate designs and smaller batches.

Flexography, a modern version of letterpress, excels in label and packaging printing with its raised surfaces. Digital printing, utilizing inkjet heads, provides quick customization and is eco-friendly, reducing waste and setup times. For high-volume needs, gravure printing offers precise, large-scale solutions, commonly used in industries like cosmetics for vibrant packaging.

| Technique | Description | Best Use Case |

| Offset Lithography | Uses metal plates and rubber blankets for high-quality images | Large-scale production, detailed designs |

| Screen Printing | Applies ink through porous screens for bold textures | Uneven surfaces, intricate designs |

| Digital Printing | Inkjet technology for quick, customized prints | Small batches, eco-friendly solutions |

Each technique has its strengths, ensuring there’s a method to suit every jewelry box design. Whether you prioritize detail, versatility, or efficiency, the right printing technique will elevate your packaging to new heights.

Creating stunning jewelry packaging involves more than just selecting a method. It requires a deep understanding of how to fine-tune your approach to achieve exceptional results. Whether you’re aiming for intricate designs or high-volume production, the right optimization strategies can make all the difference.

Evaluating your design needs is the first step. If your design features detailed graphics, consider offset lithography for its crisp results. For bold textures on uneven surfaces, screen printing is ideal. Digital printing, on the other hand, offers flexibility for small batches and customization.

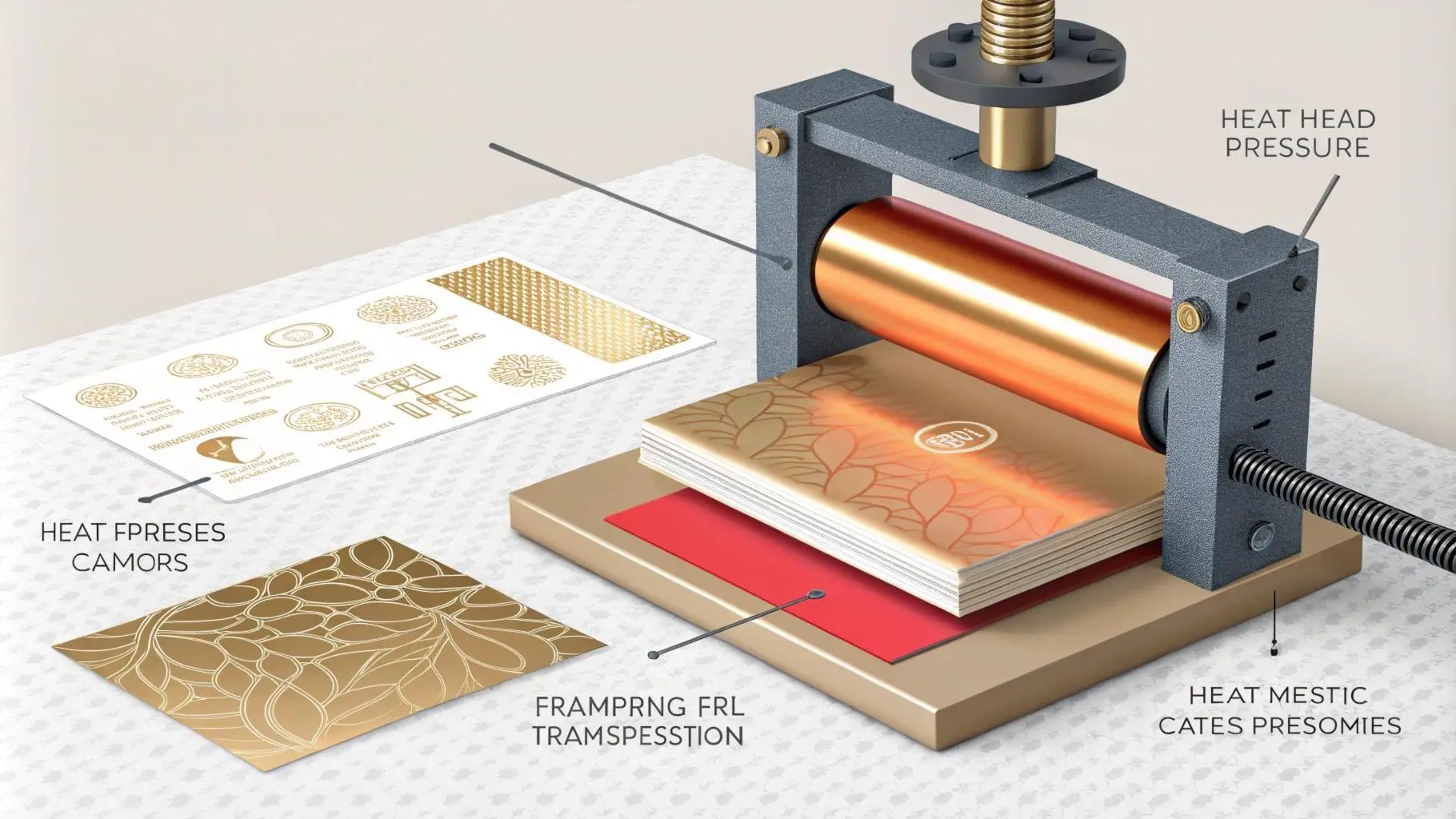

Add a personal touch with special finishes like varnishing or embossing. These enhancements can elevate your packaging, making it stand out. For instance, combining flexography with foil stamping creates a luxurious look, perfect for high-end jewelry.

Consider your budget and production scale. Offset lithography excels in large volumes but may be costly for small batches. Digital printing is more budget-friendly for smaller runs. Flexography offers a middle ground, suitable for consistent, high-quality output in moderate volumes.

| Technique | Best Use Case | Cost | Quality |

| Offset Lithography | Large-scale production with detailed designs | High | Premium |

| Screen Printing | Textured, uneven surfaces | Medium | Good |

| Digital Printing | Small batches, customization | Low | High |

By understanding these factors, you can select the optimal method for your jewelry boxes, ensuring a balance between cost, quality, and production needs. This strategic approach will help you create packaging that not only impresses but also aligns with your business goals.

Optimizing print quality and finish is essential for creating stunning jewelry packaging. Whether you’re focusing on prepress strategies or postpress finishing, every step matters. Let’s explore expert tips to help you achieve top-tier results.

A successful printing process begins with solid prepress strategies. Start by ensuring your digital files are crisp and high-resolution. Using files with at least 300 DPI will prevent pixelation and ensure sharp images. High-quality inks and toners can improve print quality by up to 30%, making your designs stand out.

Setting up your equipment properly is also crucial. Calibrate your presses regularly to maintain color accuracy, and use premium paper types that enhance color absorption. For instance, metallic paper can add a luxurious feel, perfect for high-end jewelry boxes.

Postpress finishing can elevate your packaging from good to great. Techniques like varnishing or embossing add a premium touch. Binding and adhesive application should be handled with care to ensure durability and a polished look.

Quality control is non-negotiable. Regular inspections and maintaining equipment can prevent issues like blurry images. Using automation in your workflow reduces waste and labor costs, ensuring consistency and efficiency in your production process.

| Aspect | Prepress | Postpress |

| Key Focus | File preparation, ink selection, plate setup | Finishing techniques, binding, quality checks |

| Tools | High-resolution files, calibration tools | Varnish, embossing tools, binding machines |

| Benefits | Sharp images, accurate colors | Premium feel, durability |

By mastering both prepress and postpress strategies, you can create jewelry packaging that captivates and impresses. Remember, attention to detail and the right techniques make all the difference.

Innovative technologies are revolutionizing the way jewelry boxes are printed, blending efficiency with eco-conscious practices. This section explores how advanced solutions like LED UV printing and sustainable materials are shaping the future of jewelry packaging.

LED UV printing is a game-changer, offering fast drying times and reduced energy consumption. This technology not only speeds up production but also minimizes environmental impact. Advanced digital printing solutions enhance customization and reduce waste, making them ideal for small batches and intricate designs.

Eco-friendly practices are becoming integral to the printing industry. Sustainable materials like recycled polyester and plant-based leathers are gaining popularity for their durability and luxurious feel. These materials reduce hazardous chemicals and promote greener operations, aligning with consumer demand for sustainable luxury options.

Businesses are increasingly adopting these innovative methods to produce superior packaging. By integrating new technologies with traditional methods, companies can achieve high-quality, sustainable products. For instance, combining flexography with foil stamping creates a luxurious look while maintaining eco-friendly practices.

Examples of companies utilizing LED UV and digital printing highlight the benefits of these technologies. They achieve greener operations while maintaining high standards of quality. This balance between innovation and sustainability gives businesses a competitive edge in the market.

When it comes to crafting captivating jewelry packaging, the right printing techniques can make all the difference. From the crisp details of offset lithography to the versatility of screen printing, each method offers unique benefits. Digital printing stands out for its customization and eco-friendly approach, ideal for small batches and intricate designs. For any inquiries or to discuss your jewelry packaging needs, feel free to contact us. We’re looking forward to helping you create the perfect packaging for your jewelry products.

Smithers flagship report in 2023 shows that over the five years to 2028, the global packaging market is forecast to grow from $1.17 trillion to $1.42 trillion. With hot foil stamping being a key driver of this growth due to its ability to enhance the perceived value of products. In this blog, we will explore… Continue reading How to Choose and Optimize Printing Processes for Jewelry Boxes

It is important to understand the functions and differences of various jewelry packaging materials. Whether for packaging professional or a designer of an independent jewelry brand. When purchasing or customizing jewellery packaging, it is necessary to choose good packaging to add colour to the product and brand. In addition, different materials play a unique role… Continue reading How to Choose and Optimize Printing Processes for Jewelry Boxes

72% of American consumers now consider price the most important factor when shopping online, even more important than product quality. For example, Temu, the low-price strategy-based app, is popular in the US market. For the jewelry packaging industry, this may not be a good thing. Because it makes people wonder whether the quality can be as… Continue reading How to Choose and Optimize Printing Processes for Jewelry Boxes

Customizable Sustainable Box Packaging for Eco-Friendly Branding – Guide You Find Innovative Eco Friendly Packaging Design and Box Materials

Customizable Wholesale Perfume Packaging with Personalized Branding | Ideal for Distributors Needing Unique and High-Impact Packaging

Customizable Wholesale Perfume Boxes with Bulk Discounts | Ideal for Distributors and Brands Looking for Cost-Effective Packaging Solutions

Branded Gift Boxes for Wholesale Jewelry Packaging | Customizable Packaging for High-Volume Orders | Logo Printing Available

View More

Bespoke Wholesale Custom Printed Cosmetic Boxes for Beauty Brands | Ideal Packaging Solutions for Merchants Requiring Bulk Custom Orders

View More

Custom and Artistic Branded Paper Bags with Unique Patterns | Tailored Packaging for Jewelry Merchants and Luxury Brand Marketing

View MoreJust submit your email to get exclusive offers (reply within 12 hours)