Our research data shows that 72% of consumers admit that jewelry packaging design directly affects their purchase decisions.

However, choosing the wrong wholesale jewelry boxes often leads to higher hidden costs. For example, more returns happen because products get damaged. Or plain unboxing experiences slow down brand growth.

In fact, you don’t have to guess to find a strategic packaging solution.

In this guide, Richpack will leverage its 15+ years of custom production experience to clarify the confusion. Here, we will bridge the gap between high-end beauty and practical logistics. We will help you find a solution that protects your jewelry and safeguards your profit margins.

Before customers see the diamonds in your product, they first touch the packaging box. Over the years, as I’ve helped many brands grow, I’ve learned that packaging is more than just a container—it’s a physical representation of your brand’s promise.

If a customer spends $500 on a necklace but receives it in a thin, crushed cardboard box, the value of that purchase will drop sharply in their mind right away.

Working with professional packaging strategy experts ensures this moment builds trust for you, not loses it. We don’t just offer wholesale jewelry boxes. We also help you create a consistent brand image. This way, customers will be sure they made the right choice before they even open the box lid.

In today’s market, if your packaging isn’t good for Instagram, you’re wasting free marketing resources. I’ve seen firsthand how a well-designed unboxing process can turn one-time buyers into loyal brand fans.

When customers film unboxing videos for TikTok or Instagram, your packaging becomes the star. It should have that satisfying resistance when opened. The inner padding should feel soft. And it needs visual “highlights” that look great on camera.

Key elements that push users to share on social platforms include:

Balancing appearance and safety is the most common challenge I see for brand owners. High-end jewelry and costume jewelry require very different packaging strategies. Get this wrong, and the costs can be high.

For high-end jewelry, preventing tarnish and scratches is a must. I often advise clients to use special microfiber or velvet linings. These linings hold jewelry securely and stop it from moving during shipping. Nothing is worse than a customer opening a luxury jewelry box only to find a tangled necklace or a silver ring discolored by the smell of cheap glue.

On the other hand, for fast fashion or costume jewelry, the focus may shift to display appeal and packaging speed. You might prioritize boxes with clear windows or unique designs that stand out on retail shelves.

A professional packaging partner can help you manage these trade-offs effectively in the following ways:

Choosing the right material is the most important decision you’ll make in this process. From my experience working with hundreds of brands in the past, I’ve found that materials set customers’ price expectations even before they see the actual price tag.

If you put a $5,000 diamond ring in a foldable paper box, you’re basically telling customers it’s only worth $50—without them even realizing it. On the other hand, using heavy wooden boxes to overpackage affordable fake jewelry will eat into your profit margins.

To help you understand this better, at Richpack, I’ve sorted the four most common types of wholesale jewelry boxes we handle. I’ve also compared them in terms of cost, luxury feel, and sustainability.

| Material Type | Cost Efficiency | Luxury Level | Eco-Rating | Best For |

| Kraft / Cardboard | High | Medium | Five stars | Subscription boxes, Eco-conscious brands, Shipping efficiency |

| Rigid Box (2-Piece) | Medium | High | Four stars | Mid-to-High end retail, Gift sets, “Apple-style” unboxing |

| Velvet / Leatherette | Medium | Classic | Two stars | Engagement rings, Pearls, Traditional luxury |

| Wood | Low | Premium | Three stars | Heirloom pieces, High-ticket items, Keepsakes |

Pro Tip: Don’t just look at the unit price. Consider the landed cost. Cardboard boxes can ship flat. Compared to bulky wooden boxes, this can save you thousands of dollars in shipping fees.

Many new businesses make mistakes. They think cardboard means low cost. But this idea is no longer true. As the concept of sustainability grows, kraft paper jewelry boxes have become a status symbol for modern, eco-friendly brands.

The secret to avoiding a cheap look lies in grammage (grams per square meter). When we mass-produce cardboard jewelry boxes, I always advise clients to choose paper with a grammage of at least 300-350 grams. This ensures the boxes feel solid in hand and won’t deform when squeezed.

How to upgrade simple paper boxes:

If you want that solid unboxing feel like Apple products, you need sturdy, rigid boxes. Unlike folding cartons, these boxes are made of thick grayboard (usually 800-1200 grams per square meter) wrapped in high-quality paper. They won’t collapse.

This structure creates a much higher perceived value. When customers lift the lid of a rigid box, the friction and vacuum-seal effect subtly build a sense of anticipation.

For brands that position themselves as “affordable luxury,” this is the perfect choice. You get the structural integrity of a high-end box without the high manufacturing costs of wood.

Plus, they provide an excellent base for luxury processes like gold stamping and spot UV, common in wholesale jewelry box production.

Wholesale velvet jewelry boxes remain a top choice for engagement rings—and for good reason. They represent “classic romance.” The soft texture of velvet or the smooth feel of leatherette (faux leather) immediately gives a sense of durability and protection.

But pay attention to material quality. Poor-quality velvet may shed or look uneven. I always suggest testing this fabric under bright retail lights to ensure it has an even, rich sheen.

Best Use Scenarios:

At the top end of the market, nothing beats wholesale wooden jewelry boxes. These are not just packaging. They are keepsakes that customers will keep on their dressers for years.

Wood stands for fine craftsmanship. If you sell “heirloom-quality” jewelry, your packaging must match this idea. We usually see two very different finishes leading the market:

A beautiful box is useless if the jewelry inside looks messy when it arrives. In logistics, we call this the “shake test.” If you shake the box and hear movement inside, the item could get damaged.

Inserts are the unsung heroes of wholesale jewelry boxes. They hold the jewelry at the right angle, keep it safe during shipping, and even protect it from chemical damage. I always tell my clients: Customers buy jewelry, but they judge the brand by how the jewelry is presented.

Finding the right size can be tricky. To help you understand better, here’s a quick reference guide that Richpack uses to match box sizes with different types of jewelry.

Choosing the right base material depends entirely on the weight and structure of your jewelry.

If you sell pure silver products, tarnish is your worst nightmare. I’ve seen some brands lose thousands of dollars to returns. The only reason? The glue in their cheap packaging released sulfur. This made the silver turn black before it even reached customers.

That’s why a strategic packaging partner becomes so critical. We can design your packaging liners using special anti-tarnish fabric. This fabric soaks up sulfur and other pollutants.

It may cost a few extra cents per unit. But it saves you hours of polishing time. It also prevents the terrible situation where a customer opens a brand-new box—only to find the item inside has already tarnished.

Do you want to increase your Average Order Value (AOV)? Then sell jewelry sets. But you don’t need to double your packaging inventory for this.

We often design “universal” inserts for our clients. Imagine one insert with a cutout for a necklace, a slot for a ring, and holes for earrings.

This method greatly simplifies your SKU (Stock Keeping Unit) management. You only need to stock fewer types of boxes, but you can cover more product combinations.

A regular box might protect your jewelry, but it won’t help your business grow. In the competitive jewelry market, your logo on the box is often the only thing that sets you apart from dropshippers.

I have worked with hundreds of brands. They all hesitated to customize because they worried about the complexity or cost. But the truth is, custom jewelry boxes with printed logos are the most cost-effective way to boost your brand’s perceived value.

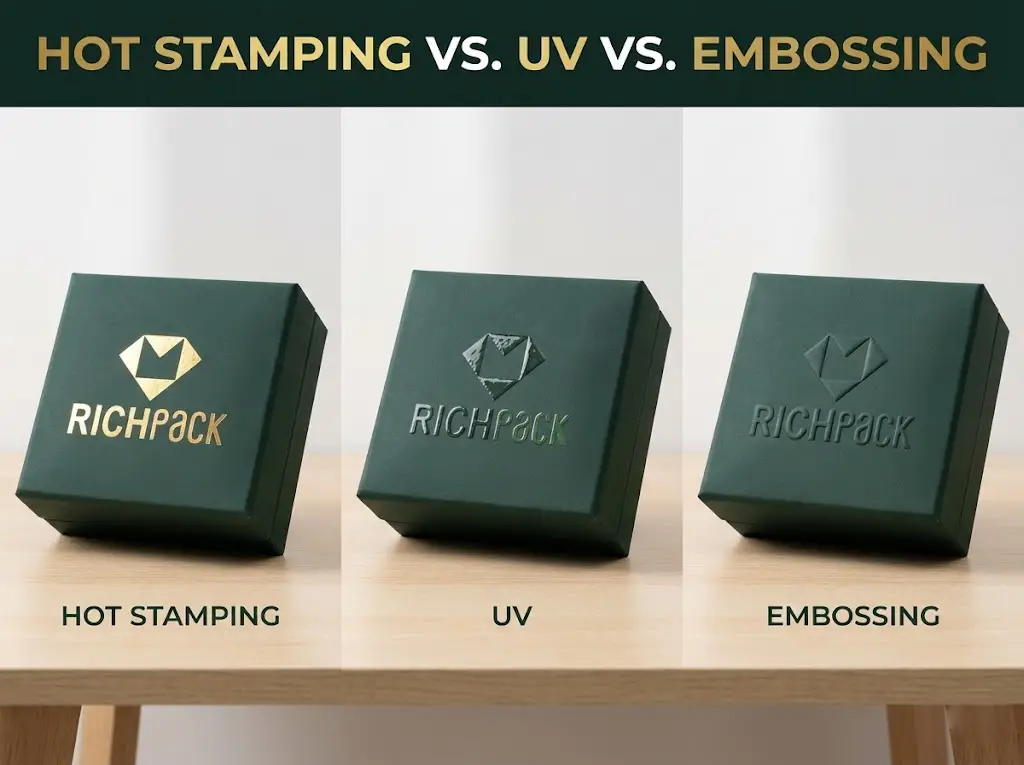

The key isn’t just slapping any logo on the box. You need to choose the right technique that matches your brand’s style. At Richpack, we guide you through these technical challenges. We make sure the final product fits your vision perfectly.

Choosing a printing method can feel like learning a new language. Simply put, I usually categorize them based on the “vibe” you want to create:

Pro Tip: For textured cardboard boxes, I almost always recommend hot stamping. Ink can sometimes sink into the paper’s texture, but metallic foil stays on the surface, keeping your design clear and easy to read.

Nothing is more heartbreaking than opening 5,000 product packages only to find your signature “Tiffany Blue” looks more like “Smurf Blue.”

This happens because there’s a difference between your screen and your printer. Your computer uses RGB (light), while printers use CMYK (ink). When converting between the two, the color tone often shifts.

What’s the solution? The Pantone Color Matching System (PMS). When you work with a professional partner like Richpack, we will ask you for your PMS color code. Unlike CMYK, where colors are mixed from inks, Pantone colors are pre-mixed, standardized colors.

Never, and I mean never, put a new design straight into mass production.

I see the sampling stage as an insurance measure. At Richpack, our process is built to find mistakes before they turn into costly problems:

Spending one week reviewing samples can help you avoid the nightmare of receiving a whole container of boxes that are 2 millimeters too small.

After working in this industry for decades, I’ve learned a harsh truth: The most expensive part of packaging is usually not the box itself. It’s the bad decisions made about logistics and quantity.

Many brands come to me wanting to cut the unit cost by $0.05 by choosing cheaper paper. But then they lose $2 per unit because of inefficient shipping. This is a strategy that isn’t worth it.

You don’t have to lower your brand’s quality to save money. What you need is a smarter design. As a strategic partner, Richpack helps you look at the big picture. We optimize your supply chain so you can afford high-quality wholesale jewelry boxes without going over budget.

The acronym “MOQ” scares many small businesses. But you should see it as a tool to boost profitability, not a barrier.

Making custom packaging involves high fixed setup costs (like creating molds and setting up printing plates). Whether we make 500 boxes or 5,000 boxes, the initial setup cost stays the same.

At Richpack, we tailor our solutions to your growth stage:

Standard Custom Orders (MOQ 500): For clients requiring fully bespoke packaging (any specific shape, color, or material), our standard MOQ is 500 pieces.

US Local Express Orders (MOQ 100): For clients who need speed, we offer a low MOQ of 100 pieces on select premium styles stocked in our US warehouse. These orders ship in 3-7 days and come with free logo printing. For more about Richpack’s MOQ, please contact us.

My Advice: If you have storage space and cash flow, aim for the next price tier. Buying 6 months of inventory at once is almost always cheaper than placing three urgent orders.

This is the biggest money-saving trick no one talks about. If you import wholesale jewelry boxes from other countries, you pay for volume—not just weight.

Shipping fully assembled rigid boxes is basically paying to move air across the ocean.

By switching to smart flat-pack designs, I’ve seen clients save so much on shipping costs that they could upgrade their logos to gold foil stamping—still staying within budget in the end.

Don’t fixate on the “FOB price” (the price at the factory gate). That number is misleading. To make profitable business decisions, you need to calculate the total landed cost.

I use this simple formula to help clients see the real picture: Total Landed Cost = (Unit Price + Mold Fees + Shipping Costs + Duties + Storage Fees) ÷ Total Quantity

Sometimes, a supplier like Richpack—with a slightly higher unit price but a better logistics network—can offer a lower landed cost. This is better than those “cheap” factories that leave you to deal with expensive shipping problems on your own.

It’s easy to find a supplier, but hard to find a partner. I’ve heard countless horror stories from business owners who chose a supplier just because of the lowest price on Alibaba. In the end, they faced silent delays and disasters when opening the boxes.

In the B2B world, your supplier is an extension of your team. If they fail, you fail too.

When I evaluate potential partners for my clients, I look at more than just the unit price. A strategic packaging partner should be stable, scalable, and trustworthy. Below is the checklist I use to tell the professionals from the pretenders.

Anyone can give you a perfect “golden sample.” The real test is whether they can replicate that perfection 10,000 times in a row.

Don’t just ask, “Do you have quality control?” Be specific: “What’s your Acceptable Quality Level (AQL) standard?”

Professional manufacturers like Richpack follow AQL protocols strictly during production. This means we don’t just glance at the boxes. We do statistical sampling to make sure the color consistency, glue adhesion, and dimensions meet the pre-agreed standards. If a supplier doesn’t even know what AQL is, don’t work with them.

Time zones are no excuse for poor communication. You need a partner who speaks your language—not just English, but the language of design and branding too.

I often see brands struggle with “yes-man” suppliers. These suppliers agree to everything but solve no problems. A real partner should act as a consultant. If a design has structural flaws, they should push back and offer better engineering solutions.

Look for these positive signs:

Modern consumers care where their products come from. If your wholesale jewelry boxes are made in sweatshops or with illegal wood, you—not the factory—will bear the reputational risk.

Transparency is non-negotiable. Always ask for relevant certifications for your products. For example, paper products need FSC (Forest Stewardship Council) certification. This proves the materials come from well-managed forests.

At Richpack, we see ethical sourcing as the backbone of modern luxury. Offering eco-friendly wholesale jewelry boxes isn’t just a trend. It’s a promise to protect your brand’s integrity in a market that cares more and more about environmental awareness.

If your top priority is pure protection during shipping, cardboard (gray board) excels at maintaining structural integrity. It won’t easily collapse under the weight of other packages. However, if you ship directly to consumers (DTC), the box inside the mail package also matters. For maximum safety, I recommend using a corrugated carton as the outer package. Inside it, place a rigid jewelry box with a die-cut foam insert. This “box-in-a-box” strategy is the industry’s gold standard for preventing damage.

Yes, absolutely. In the custom packaging industry, sample fees aren’t charged for profit. They’re used to filter out serious inquiries. At Richpack, we see samples as the first step in a partnership. If you approve the sample and place a bulk production order (usually meeting our standard minimum order quantity), we’ll deduct the sample cost from your final invoice. This lets you verify our product quality with zero risk.

Air freight is the easiest way to drain your budget. Logistics companies charge based on “dimensional weight” (volume), not just actual weight. So bulky, rigid boxes cost a lot to ship.

Here are two strategies I use to save clients money:

If you sell jewelry priced above $50, the answer is yes. The “click” sound when a magnetic lid closes triggers a psychological response. This feeling creates an impression of durability, luxury, and satisfaction. From my experience, this subtle tactile cue boosts the perceived value of the jewelry inside. It lets you keep a healthy profit margin. However, for lower-priced costume jewelry, a regular two-piece lid is usually enough.

High-quality packaging takes time. So don’t wait until October to order for Christmas.

My Advice: Always leave a 4-week buffer in your launch schedule. Quality control should never be rushed.

Choosing the right wholesale jewelry boxes is more than just a routine task. It is a strategic brand decision that affects your profits and losses.

If you take one thing away from this guide, let it be this: Your packaging must match the quality of the jewelry inside. A mismatch here creates a “value gap” in customers’ minds, and this gap is hard to fix.

You don’t need an unlimited budget to create a luxurious unboxing experience. You just need the right design. Whether you choose eco-friendly kraft paper boxes or wooden boxes that feel like family heirlooms, the secret is to balance protection, display appeal, and delivery costs.

Ready to elevate your jewelry brand? Contact Richpack’s packaging experts now. Get free consulting and digital models for custom boxes. Let’s work together to create packaging that makes customers say “wow” even before they open the lid.

Just submit your email to get exclusive offers (reply within 12 hours)