4 Must-Have Jewelry Bag Styles for Jewelry Brand

2025-05-13

For any jewelry brand, creating luxurious packaging that elevates the product is essential, yet its associated high costs constantly erode profit margins. The essence of this challenge isn’t merely about cutting expenses, but about making smarter strategic decisions that balance brand prestige with profitability. This guide reveals the complete, expert-level playbook for achieving that balance, moving beyond conventional tips to delve into the core disciplines of value engineering, supplier vetting, and pre-production risk mitigation.

At the heart of every packaging decision is a fundamental conflict: the desire for a premium, unforgettable unboxing experience versus the practical need to manage expenses. Investing in high-end packaging can directly boost perceived value and customer loyalty, yet every dollar spent on a box is a dollar not spent on product development or marketing.

The immediate temptation might be to source lower-quality materials or eliminate finishing touches. This is a dangerous path. A flimsy, poorly constructed box can instantly devalue the fine jewelry inside, breaking the brand promise before it’s even fully unwrapped. The goal is not to be “cheap”; it’s to achieve value engineering for packaging. This means strategically allocating your budget to the elements that matter most to your customers—the sensory details they can see and feel, like the satisfying heft of the box, the smooth texture of the paper, and the precise fit of the insert—while relentlessly optimizing the areas they won’t notice, such as internal glue points or the exact paper grammage.

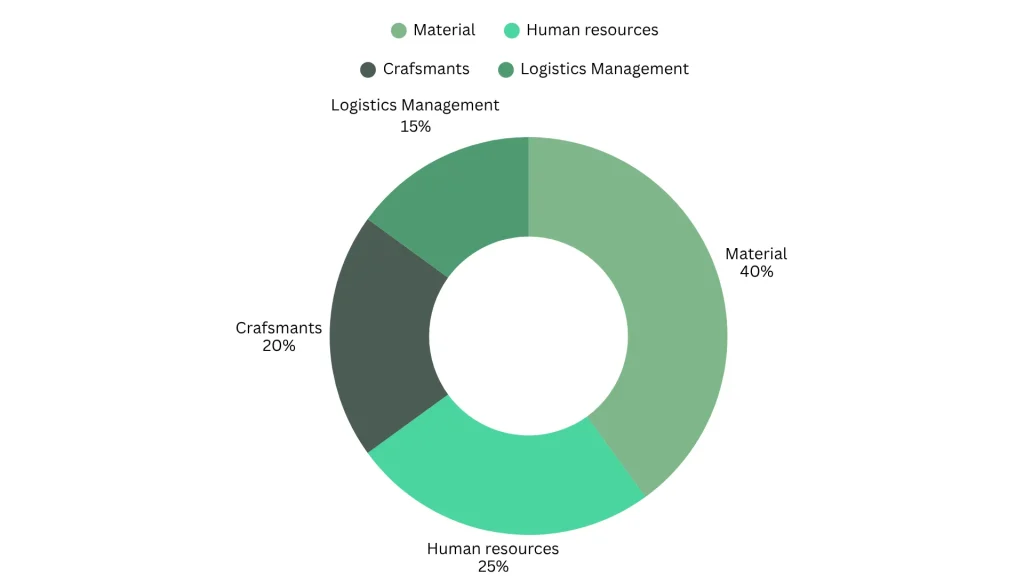

Understanding your cost breakdown is the first step toward optimization. Typically, the costs are distributed across four main areas:

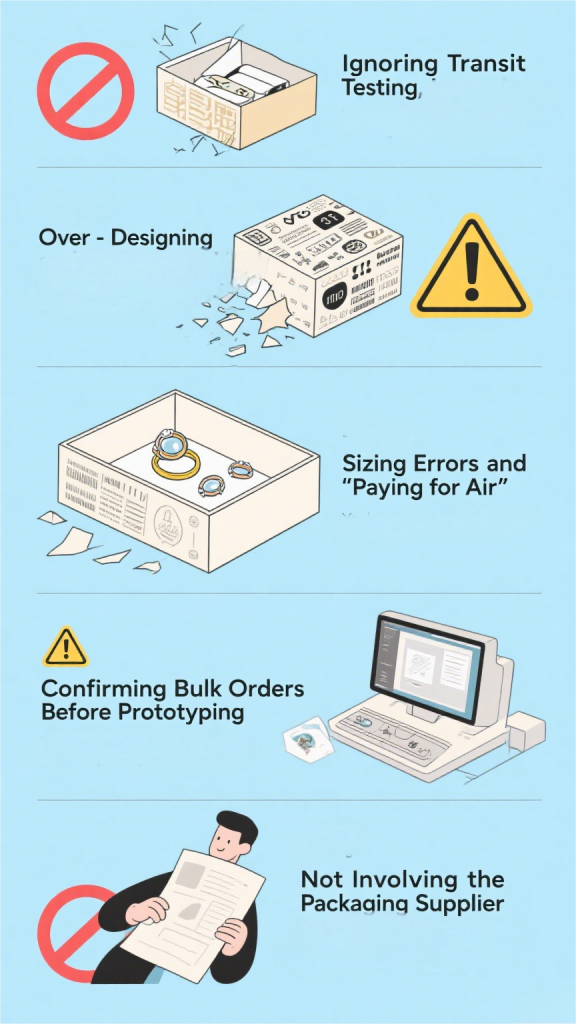

Before discussing how to “get it right,” understanding how to “get it wrong” can save you tens of thousands in trial-and-error costs. In our experience, here are some of the most common mistakes brands make, especially in the early stages:

The material is the soul of the box and the largest component of its cost. However, a high price tag doesn’t always equate to a high-perceived value. Smart material substitution is the art of choosing materials that feel luxurious but are inherently more cost-effective, always starting with your brand’s precise positioning.

While a solid wood box screams luxury, it’s often prohibitively expensive and heavy. A high-quality, dense rigid board offers a comparable sense of heft and durability at a fraction of the price. Similarly, while a custom-printed cloth bag or pouch feels premium, a well-designed paper box often provides better protection and a more structured unboxing experience at a lower cost point. The key is to compare materials not just on price, but on the perceived value and protection they offer.

Specialty papers with unique textures or embedded fibers can be beautiful but can also double your material costs. A more strategic choice is to use a high-quality, heavyweight art paper, such as a 157gsm coated art paper, which provides a premium, smooth surface ideal for high-quality printing. Its smooth, consistent surface is the perfect canvas for exquisite printing and finishing, allowing your branding and design—not the paper’s texture—to be the star of the show.

The interior of the box is where your product rests. While real velvet is the traditional choice, modern alternatives like high-density flocked foam, EVA foam, or faux suede provide a nearly identical soft, plush feel. These materials are excellent at holding jewelry securely—often better than velvet—and offer a premium tactile experience, perfectly aligning with a sustainable luxury packaging budget when using recycled foam options.

Choosing the wrong partner means that even the best design cannot be perfectly realized and may even lead to endless trouble. A good supplier is not just a manufacturer but also your cost consultant and quality guarantor.

Inquire about certifications like ISO quality systems and FSC forest certification, which reflect professionalism and social responsibility.

Check Certifications

Prototyping (or Proofing) is the process of creating a small number of samples for final confirmation before large-scale production. Skipping this step is a major cause of significant losses.

Contains no printing and is used only to verify the box’s dimensions, structure, material, and stability. You need to physically place your jewelry inside to test the fit, opening mechanism, and overall strength.

Plain Sample (White Sample)

Based on the plain sample, with digital printing applied, mainly to confirm the accuracy of printed content, colors, and positioning. Note: There may be a reasonable, slight color difference (5-10%) between a digital proof and the final offset printing of the bulk order.

Digital Sample

The sample closest to the final bulk product, made with the same materials and processes. It is the most expensive but most reliable, typically used for orders with extremely high requirements for color and craftsmanship.

Pre-Production Sample

Only after the sample has received your 100% written and signed confirmation will (and should) the supplier begin mass production.

Simplifying your packaging’s physical structure is one of the most impactful yet often overlooked areas for significant cost savings. Every fold, every glue point, and every separate component adds a step to the manufacturing process, increasing labor costs and the potential for error. By embracing a “less is more” philosophy, you can achieve remarkable efficiency.

A prime example is shifting from a complex, multi-part assembly to a classic, two-piece rigid box (lid and base) or a streamlined drawer-style box. Equally important is “right-sizing”—meticulously designing the box to fit your product with minimal empty space. This not only reduces material costs but also significantly lowers shipping fees by avoiding “dimensional weight” charges. A thorough high-end packaging cost analysis almost always reveals that complex structures and oversized boxes are major drivers of unnecessary expense.

A critical but advanced tactic is designing for flat-shipping through foldable structures. A box that can be shipped flat and assembled at its destination can reduce shipping volume by up to 70%—a statistic often highlighted in logistics optimization studies—translating into massive savings on freight and warehousing. This requires upfront engineering and a supplier with expertise in structural design, but the long-term reduction in packaging logistics costs is substantial.

For established brands, one of the most powerful moves is standardization. Instead of creating a unique box for every single SKU, develop a modular system—perhaps 3-4 core box sizes that can house different custom inserts. This allows you to leverage the luxury packaging ROI by placing larger, consolidated orders for your standard boxes, drastically lowering the per-unit cost. Crucially, this approach allows you to amortize the one-time tooling and die-cut mold costs over a much larger volume, making custom shapes far more economical. It’s a perfect example of effective packaging supply chain optimization.

Finishing touches like foil stamping and embossing are what often separate standard packaging from a luxury experience. However, they must be used with strategic precision to avoid inflating costs. This involves carefully selecting the right craftsmanship for the right purpose.

Instead of complex multi-color printing, consider a more elegant single-color print, which can dramatically reduce costs. Instead of an all-over patterned foil stamp, consider using a single, elegant foil stamp for just your logo. The contrast between the simple paper texture and the metallic accent creates a more sophisticated and confident look. Similarly, a blind deboss (an indentation without ink or foil) can add a subtle, tactile element of luxury for a much lower cost than a two-step foil-and-emboss process.

A simple, high-quality grosgrain or satin ribbon pull on a drawer-style box can be more user-friendly and significantly more cost-effective than metal clasps, magnetic closures, or other complex hardware. The key is choosing a ribbon color and texture that perfectly complements your brand identity. Attention to these small details, like the quality of a corner treatment or the smoothness of an opening mechanism, often adds more perceived value than costly, complex additions.

How you manage your purchasing process is just as important as how you design your box. Smart procurement is a cornerstone of any custom packaging price reduction strategy.

Everyone knows that bulk orders result in a lower per-unit price. But the true power lies in leveraging your volume. When you place a large order, you gain the leverage to negotiate not just on price, but also on payment terms, warehousing options, and service levels. This is where you can secure bulk custom packaging deals that go beyond the sticker price.

The number one enemy of a packaging budget is urgency. Rush orders almost always incur significant surcharges. By providing your supplier with an accurate annual forecast and placing orders well in advance of your need-by date, you allow them to schedule production during their off-peak times and optimize material sourcing, savings which they can then pass on to you. Furthermore, building a long-term, stable partnership with a reliable supplier can lead to more competitive pricing, greater flexibility, and invaluable consulting on cost-saving material or process alternatives.

Even the most cost-effective box can become expensive if shipping isn’t optimized. Logistics is a critical, often overlooked area for significant cost reduction.

Ultimately, reducing cost is only half the story. The true goal is to maximize the Return on Investment (ROI) of your packaging. A great package isn’t a cost center; it’s a marketing asset.

Reducing your luxury jewelry packaging costs is not an exercise in compromise; it’s a strategic imperative for sustainable brand growth. As we’ve explored, the path to a more manageable budget doesn’t lie in stripping away the elements that make your brand special. Instead, it lies in making smarter, more informed choices—transforming how you view materials, engineering, your supply chain, and your shipping strategy. Through professional value engineering, strict supplier management, prudent prototyping, and intelligent logistics, you move from being a price-taker to a strategic operator. For those looking to explore these topics in even greater detail, a complete guide on how to control jewelry packaging cost is available. While this article provides a detailed playbook, understanding how all these elements interconnect is key. For a comprehensive A-to-Z resource covering every challenge from initial budget to final design, we recommend exploring our ultimate jewelry packaging guide.

Call-to-Action (CTA):

Ready to implement these smart, cost-saving strategies? “Contact the experts at Richpack today for a complimentary packaging audit and discover the hidden opportunities to reduce your costs while elevating your brand.

We hope this guide has provided you with actionable insights! We’d love to hear from you. What’s the biggest packaging cost challenge your brand is currently facing? Share your thoughts in the comments below!

If you found this article helpful, please consider sharing it with your network on LinkedIn.

During Christmas, how to ensure the on-time and high-quality delivery of Christmas gift packaging while controlling costs through effective supply chain strategies has become a major challenge for enterprises. This affects their long-term reputation and market position. This article will introduce you to 5 supply chain strategies that can increase the return on investment (ROI) of… Continue reading How to Reduce Jewelry Packaging Costs Without Cheapening Your Brand

Custom jewelry packaging isn’t just making your jewelry look good. It focuses on creating the perfect mix of materials, designs, and techniques that truly represent your brand and meet your customers’ expectations. Understanding the key terms and techniques in custom packaging is crucial for any jewelry seller or brand manager. It helps you design better packaging and… Continue reading How to Reduce Jewelry Packaging Costs Without Cheapening Your Brand

White gold rings have got a story that’s been unfolding for ages. Back in the day, white gold emerged as a trendy alternative to traditional yellow gold. It quickly caught on, especially for engagement rings and fancy jewelry pieces. And since I’ve been in this factory, I’ve seen how important it is to pair these stunning… Continue reading How to Reduce Jewelry Packaging Costs Without Cheapening Your Brand

Custom Jewelry Packaging for Small Jewelry Brands | Personalized Solutions for Distinct Branding | Perfect for Niche Markets

Versatile Richpack Anniversary Gift Box – Tailored to Every Love Story’s Chapter

Zero-Waste Gift Packaging Solutions for Online Stores | Eco-Friendly and Customizable Packaging | Sustainable E-Commerce Solutions

Build Your Own Gift Box | Customizable Gift Boxes for Any Occasion Full Sizes Various Materials to Choose Richpack Packaging Supplier

View More

Convenient Roll-Up Travel Jewelry Cases | Space-Efficient and Protective Storage for Jewelers Needing Compact Solutions for On-the-Go Jewelry Storage

View More

Creative Jewelry Display Ideas by Richpack for Stunning Presentations | Unique Necklace Display Ideas for Jewelry Retail and Luxury Brands

View MoreJust submit your email to get exclusive offers (reply within 12 hours)