Over the past two years, cross-border e-commerce has shown a universal trend: faster delivery, more product varieties, and greater sensitivity to returns and exchanges.

Many brands have started using small jewelry gift boxes to enhance the unboxing experience. They also use this packaging to protect jewelry. Cotton-filled small jewelry gift boxes are particularly popular—they look elegant, and their costs are relatively manageable.

But here’s the problem: after-sales issues with jewelry rarely stem from product damage itself. Instead, they come from packaging that can’t withstand wear and tear during shipping and storage.

This leads to a series of problems:

Many brands struggle to balance two things: crush resistance and a premium look.

Overly thick packaging for protection looks like industrial packaging. Overly thin packaging can’t stand up to vibrations during logistics and shipping.

Essentially, the solution to this problem is to treat cotton-filled gift boxes as reusable protection systems, not one-time decorative items.

You can ensure consistent protection by focusing on three key steps:

This guide covers multiple aspects, including standard packaging operating procedures, size adaptation rules, and wholesale quoting tips. It shows you how to prevent jewelry scratches, tangles, and crush damage.

You use cotton-filled small jewelry gift boxes not just to look good.

They actually help you save three types of costs:

Below are the five most common risks I found when reviewing customers’ after-sales issues. All of these can be easily avoided with the right packaging process.

Scratches rarely happen from being dropped. Instead, they come from repeated friction caused by slight movement inside the box.

Cotton pads work because they prevent jewelry from hitting other metal pieces and rubbing against the box walls.

You can do this more effectively with these steps:

Vibration is the most common problem in last-mile shipping. The box won’t break, but the jewelry inside will shift around.

This damage may not show up immediately, but over time it causes scratches, loose parts, and even lost small, shifted components.

Here’s a simple yet highly effective tip:

A tangled necklace is almost the same as a terrible unboxing experience. If customers can’t untangle it or scratch the necklace while trying, it will likely lead to returns or negative reviews.

While cotton pads can’t fix the necklace chain itself, they solve the self-tangling problem caused by long, loose chains.

Here are more reliable solutions:

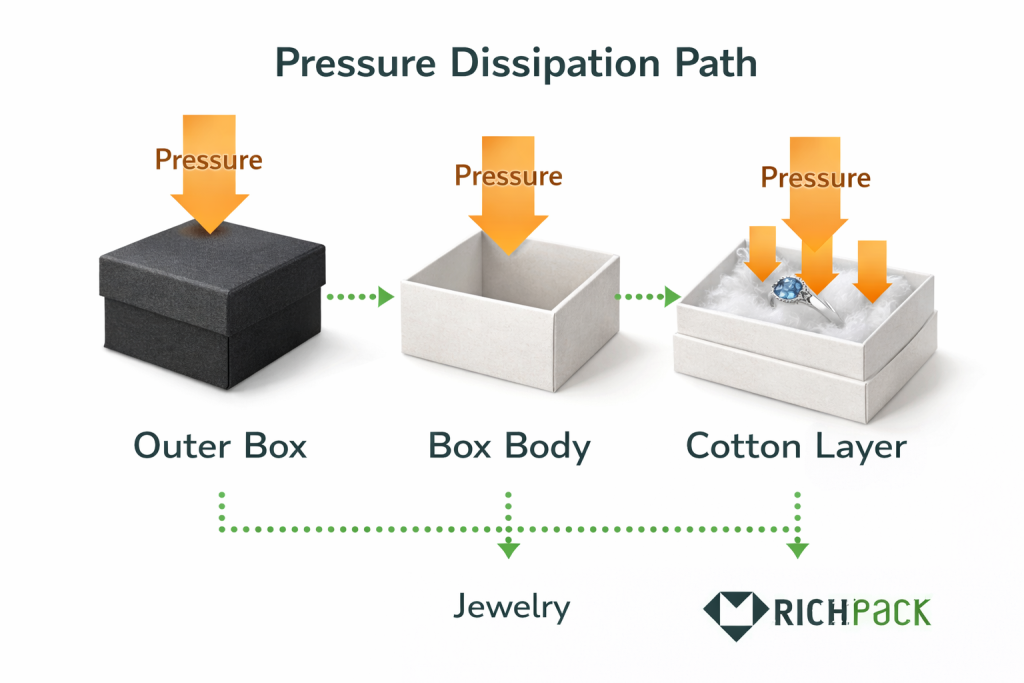

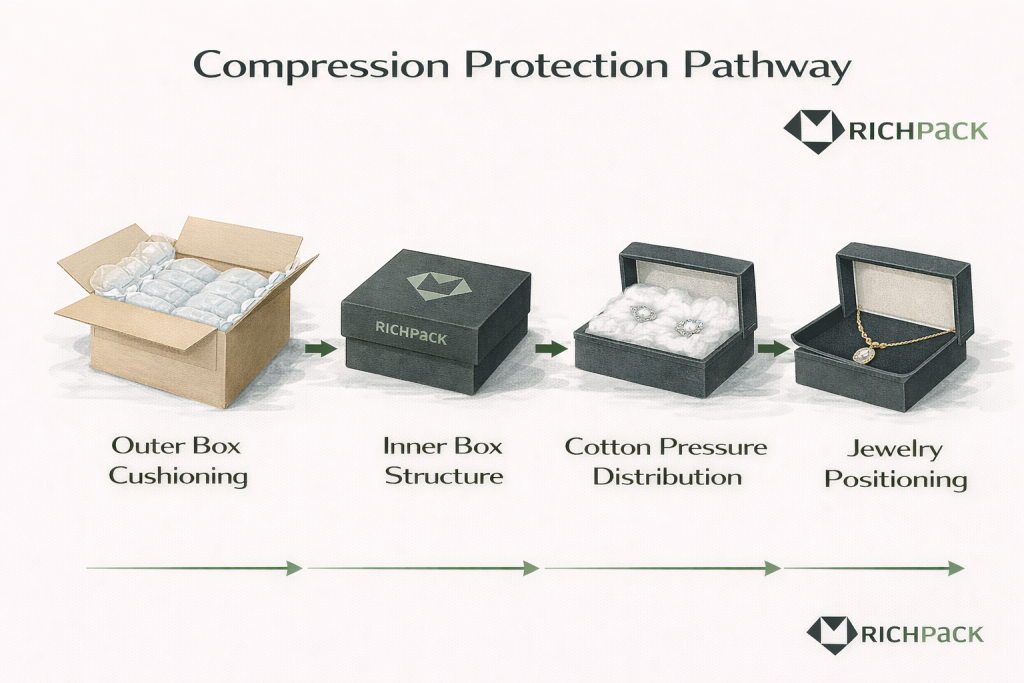

Crush resistance rarely comes from foam alone. Instead, it relies on a combination of box structure and outer box cushioning. Foam distributes pressure, preventing jewelry from being crushed at specific points or hit by hard edges.

Actionable tips:

Tarnish on inventory during storage is a major hidden loss for many sellers. It may not lead to returns, but it directly affects product display quality and customer repurchase intent.

Cotton materials carry risks because they easily absorb moisture, especially in humid environments or storage spaces with large temperature changes.

You can turn moisture protection into low-cost standard operations:

Many people choose jewelry gift box sizes just by eye.

This usually leads to two outcomes:

For cotton-filled small jewelry gift boxes, size is not just a cosmetic issue—it’s a critical factor that directly determines if jewelry gets scratched, tangled, or crushed.

When helping merchants fix jewelry damage issues, I found three main causes:

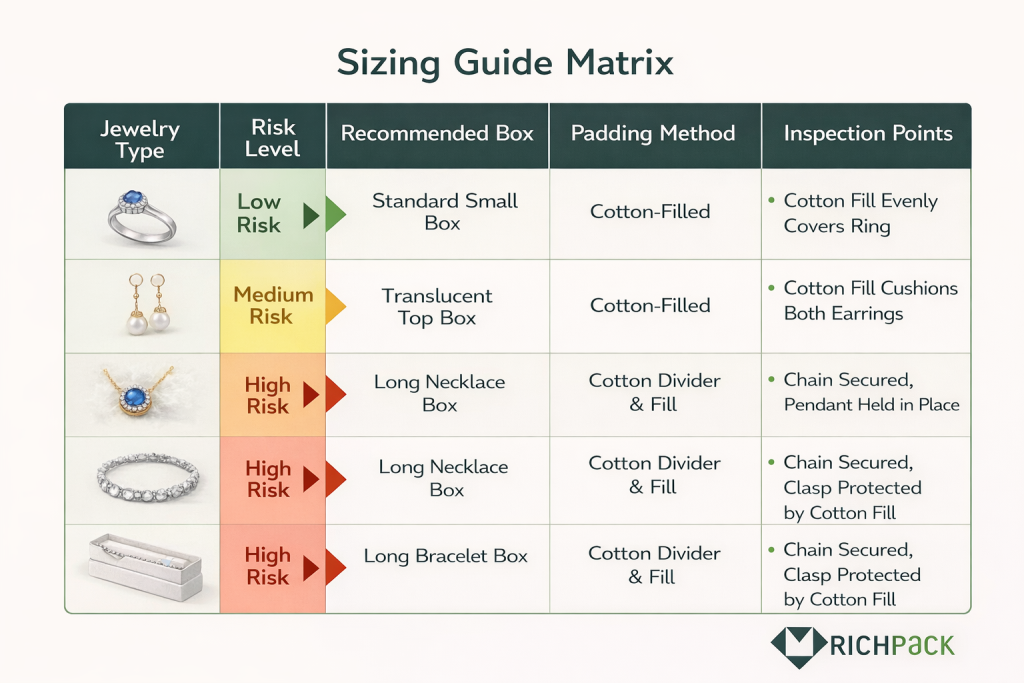

Below is a set of easy-to-master size selection rules for your team. No complex tools are needed, and it drastically reduces trial-and-error costs. The core idea is to let the jewelry determine the internal space needs first, then let the cotton filling set the allowable space range.

The biggest threats to rings are not falling out, but gem pressure and setting impacts. When choosing a size, focus on gem height and band diameter first, not just the overall ring size.

Practical steps:

The main problems with earrings are usually their sharp posts and small size. Choose boxes with dedicated earring holders to prevent the posts from sliding in the cotton and getting scratched.

Here are actionable steps:

The standard for a properly sized necklace box isn’t just fitting the necklace—it’s preventing tangling from excessive chain length.

Here are actionable steps:

The most common problems with bracelets are bending and surface scratches, especially for hard bracelets or those with inlays—closing the box and applying pressure directly increases these risks.

You can take these measures:

Many people choose extra-small boxes for a delicate look, but this actually leads to more returns.

Common issues include:

When you have a large number of SKUs and ship frequently, standardized packaging sizes drastically reduce packing errors. They also simplify future procurement through small jewelry gift boxes wholesale.

We recommend classifying your products with a simple 2×3 matrix:

Pro tip: Assign one standard box type and one cotton filling method to each grid. Then, place a quick reference chart at each packing station to drastically cut training costs.

Many sellers think all they need to do with cotton-filled small jewelry gift boxes is put the jewelry in and close the lid.

In reality, different packing methods for the same box type lead to huge differences in damage and return rates.

What you need is not a more expensive box, but a repeatable, trainable, verifiable assembly standard operating procedure (SOP).

We recommend posting this process next to every packing station.

The process has clear goals:

Each step is simple, but skipping even one can lead to customer complaints about scratches, tangles, crush damage, or lint on the jewelry.

First, determine the final display position of the jewelry, then add the filler. Keep gemstones on rings, pendant tips, and earring posts away from the box’s hard edges to reduce pressure points and friction.

Practical tip: I always ask my colleagues to pause for two seconds after placing the jewelry. They need to check where the pressure points are before adding filler. This step drastically reduces scratches from random jewelry placement.

For filling density, aim for a snug fit, not compression. Loose cotton causes jewelry to shift.

But overly tight cotton creates pressure when closing the lid, squeezing the prongs, gemstones on rings, or pendants.

Use this practical judgment: before closing the lid, gently press the cotton surface with your finger pad. The cotton should bounce back—not too quickly (which means it’s too loose) and not almost at all (which means it’s too tight).

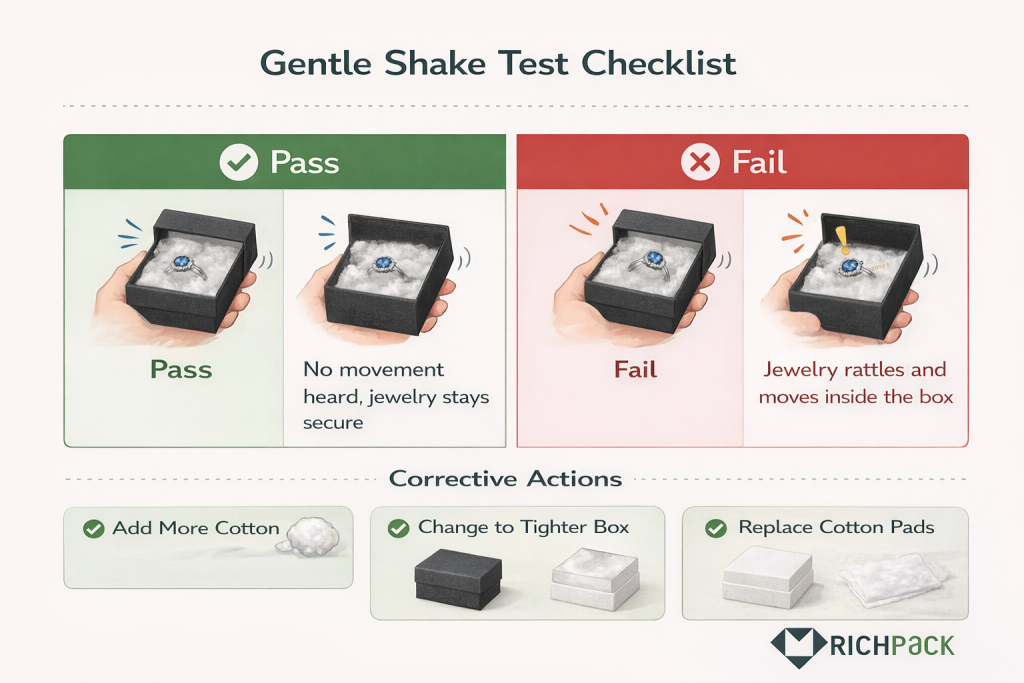

Closing the lid is not the end, but the start of inspection. After closing, do a double shake sound test:

This step quickly eliminates risks from shipping vibrations and is suitable for daily shipping checks of small gift boxes for jewelry.

Necklaces are the most prone to self-tangling during shipping. The solution is to shorten the movable length and secure the pendant.

Specific steps:

If you ship necklaces often, create a fixed folding template for your team to follow. This reduces problems from human operational differences.

Silver jewelry or oxidizable materials tarnish due to humidity during storage and shipping. Since cotton filling can absorb moisture, humidity control should be a standard operation.

Take these specific measures:

Cotton filling distributes pressure but can’t withstand all crushing force. True crush resistance comes from a combination of box structure and outer carton cushioning.

If your goods require international shipping or multiple transit steps, add this rule to your packaging guide: leave a cushioning layer around the inner box, ensuring all four sides have cushioning material.

This prevents pressure on the outer box from directly squeezing the inner box’s edges and corners.

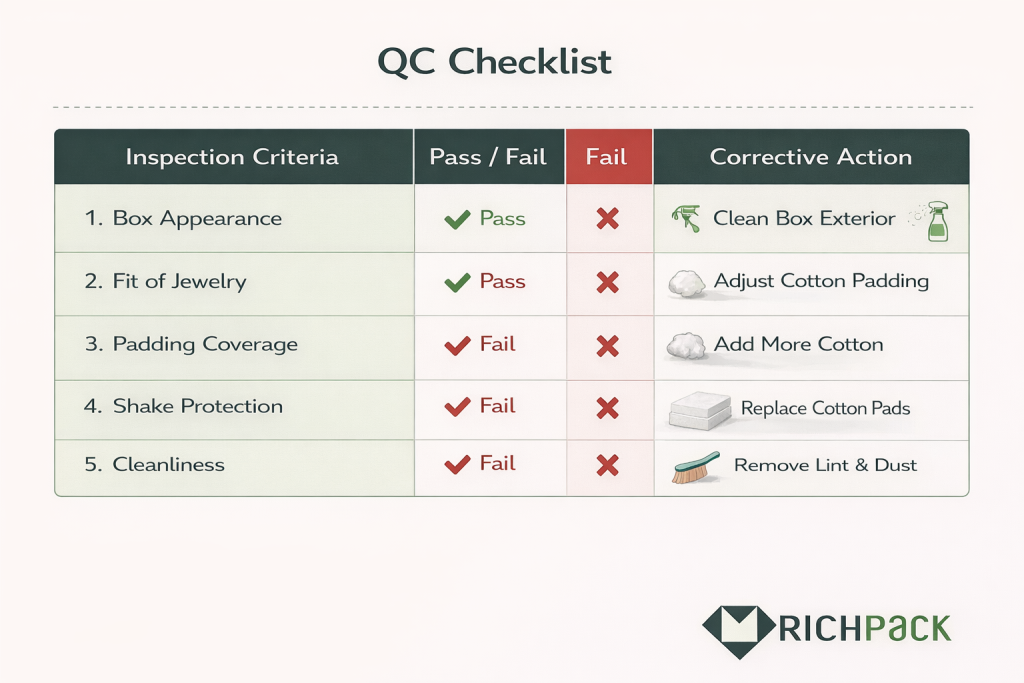

Inspection is the key to implementing the SOP. You should conduct random spot checks with a simple quality control (QC) checklist that includes:

This checklist can also be used directly as an inspection item for suppliers when you start bulk purchasing small jewelry gift boxes wholesale, reducing cases where samples pass but mass production fails.

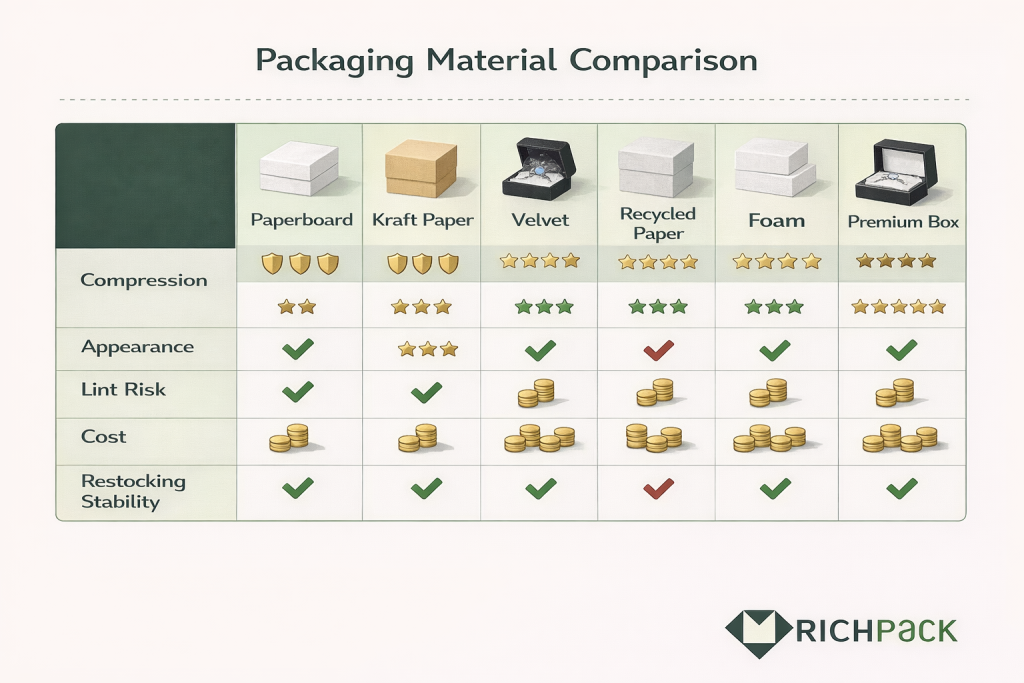

All products use cotton-filled packaging. Some sellers ship with almost no issues, while others constantly deal with scratches, dents, lint, and a cheap look.

The difference is usually not whether you use small jewelry gift boxes, but whether your chosen box material and liner style match your shipping intensity, SKU structure, and brand positioning.

The wrong material choice leads to inconsistent results, no matter how much you optimize the assembly SOP.

I recommend starting with a simple decision framework: what factor matters most to you?

Cardboard’s biggest advantage is structural control. When made sturdier, it has stable crush resistance, making it ideal for international shipping or stacked storage.

But cardboard has risks: thin cardboard bends easily, and pressure on the edges transfers directly to the inside jewelry.

If your main problem is crushed boxes, invest in box structural strength first, then improve cotton pad pressure distribution. Never do it the other way around.

Kraft paper boxes are usually more readily available, making them perfect for sellers with many SKUs, frequent restocking needs, and fast packing requirements.

They offer high efficiency and controlled costs, but you need to watch for details that make them look cheap: blurry paper, faded printing, and bent edges.

Pro tip: If you choose kraft paper, add straight edges, a tight lid closure, and a clean surface to your acceptance checklist. This works better than switching to more expensive cotton materials directly.

Velvet quickly boosts gift appeal, especially for in-store display, product photography, and unboxing experiences. But it also causes two common after-sales issues:

First, it easily attracts dust and fibers. Second, lint transfer from dark velvet to light-colored jewelry is more noticeable.

Pro tip: If you sell high-shine or light-colored jewelry, create stricter lint control processes for velvet. Additionally, use fixed cotton pads instead of loose-filling cotton to reduce fiber friction.

Recycled paper supports sustainable brand messaging, but it usually has two main problems:

These issues increase the risk of crushed and worn packaging for subscription boxes or international shipping.

Pro tip: If you need eco-friendly packaging, make load/stack performance, edge wear resistance, and batch color difference mandatory inspection items. Sustainability is not just a slogan. You need verifiable specifications and testing standards to control these risks.

Cotton filler performs well in fit and pressure distribution, but foam inserts are usually more stable for high-vibration or irregular-shaped SKUs. They offer stronger positioning and fixation.

Pro tip: If customer complaints mainly come from product shifting or vibration issues, not a lack of gift-like packaging appearance, evaluate foam insert solutions first. Then decide whether to keep cotton as the top layer for better looks.

Premium boxes—with sturdier structures and more complex production processes—don’t follow the more expensive is better rule.

They only deliver higher value in two cases: first, when your return or exchange costs are too high and hurt profits; second, when your brand positioning needs stronger perceived value to support high prices.

Pro tip: Shift your decision focus from unit price to total cost of ownership—including box unit price, return and exchange costs from damage rates, and labor hours for rework. This shift makes rational choices easier.

Once you choose materials for mass production, the biggest risk is excellent sample quality but inconsistent mass production quality. Therefore, no matter which material you choose, include these three items in your packaging procurement standards:

Many sellers struggle to balance gift appeal and protection: the more exquisite the packaging looks, the more they worry about warping from pressure during shipping; the stronger the packaging’s crush resistance, the more they fear a cheap look that ruins the unboxing experience.

In fact, you don’t have to choose between the two when gifting with cotton-filled small jewelry gift boxes.

You just need to limit decorations to areas that don’t affect the protective structure, and hide protection in invisible but noticeable details.

I recommend remembering this principle first: to make packaging gift-worthy, only modify the outer layer—never compromise the protective layer. This means cotton fit, crush resistance, and lid closure must remain stable. You can adjust the outer layer’s color, ribbons, stickers, cards, and outer packaging style. This way, you keep the protective effect while making small gift boxes for jewelry look more valuable.

The most common gift wrapping problems are ribbon pressure marks and outer box damage, which get worse, especially during last-mile shipping.

Here are actionable solutions:

A low budget doesn’t mean poor quality. The key is to reduce cheap cues and enhance visual consistency—i.e., brand consistency. You can boost perceived product value with just a few elements:

Personal experience: Many returns are not due to product issues, but because the first unboxing impression makes the product seem not worth the price. Standardizing these small details often works better than using more expensive packaging boxes.

The real holiday challenges are threefold: surging orders, temporary staff, and inconsistent packaging.

These issues lead to lower quality standards. What you need is a holiday version SOP to turn gift wrapping into repeatable steps, not trial and error.

Here are ready-to-implement steps:

When switching from sporadic restocking to small jewelry gift boxes wholesale, the real risk is not price, but uncertainties.

Samples may look good, but bulk orders can have problems like color differences, reduced hardness, more lint, and inconsistent lid tightness.

These issues force you to revise packaging SOPs, handle more returns, and disrupt restocking plans. The hidden costs from these problems are greater than those from unit price differences.

You need to add protection effect requirements to specifications, include stability indicators in inspection standards, and clarify restocking capacity clauses in contracts and processes.

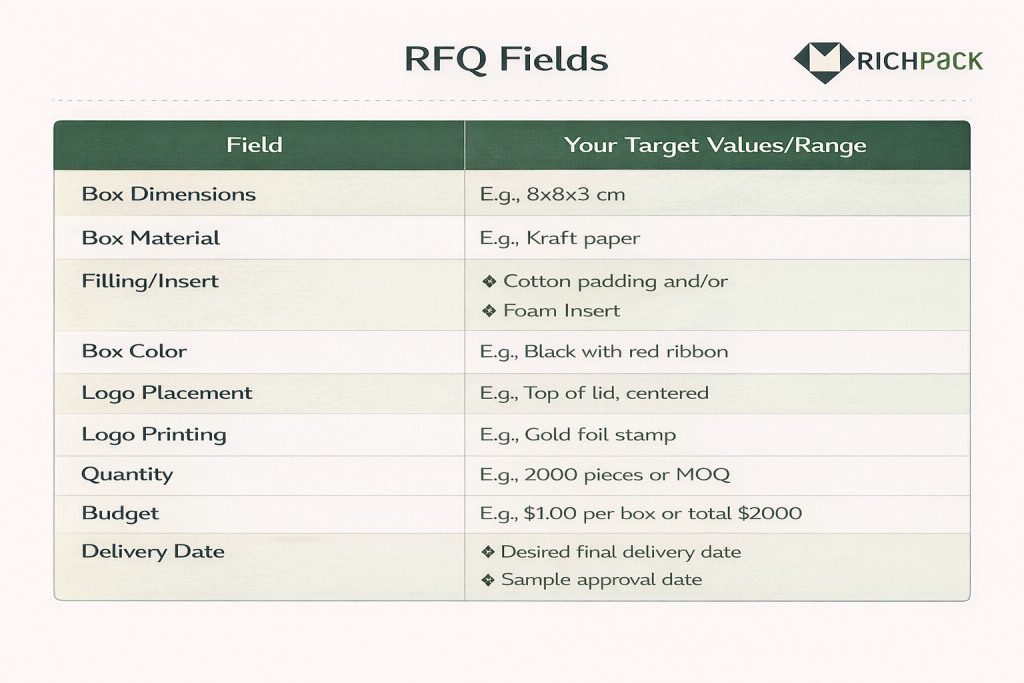

Below are the seven key areas where you’re most likely to make mistakes. You can copy these points into your request for quotation (RFQ) to reduce repeated communication.

The more your RFQ aligns with procurement norms, the less likely you are to buy bulk products with uncontrollable quality. We recommend including at least these sections to avoid receiving only per-carton unit prices:

More cotton is not better. The key is a stable shape and controllable compression. Unstable cotton density, thickness, or fiber cleanliness will render your assembly SOP ineffective.

Actionable tips:

The biggest worry in mass production is overall qualification, but poor performance of low-end products. My go-to method is to divide random sampling into three categories: appearance, structure, and protection performance.

You can write these actionable inspection steps directly into acceptance clauses:

For highly gifting-oriented products like small gift boxes for jewelry, poor color matching and texture directly reduce perceived value.

A more practical problem is restocking: you can’t make new samples every time you need to reorder.

Here are actionable tips:

Many sellers fail not because of price, but because of stockouts. Lead time is not just production time—it includes sample confirmation, raw material procurement, production scheduling, and shipping.

Actionable tips:

Custom logo projects usually generate two types of abnormal costs: more sampling times and greater batch-to-batch differences. Your job is to keep customization within manageable limits.

Here are ready-to-implement tips:

As your business scales, packaging is no longer a single item—it becomes part of your supply chain system, including specification setting, restocking, random sampling, version control, and cross-team collaboration. At this stage, you should stop managing multiple scattered suppliers and partner with an end-to-end strategic packaging partner. This brings all uncertainties into a single standard system.

You can judge if a party is a partner rather than a supplier by these questions: Can they help you integrate size grading, SOPs, QC random sampling, repeat order consistency, and restocking plans? Do they use verifiable processes to manage these links, instead of just verbally promising no quality issues?

You’ve detailed assembly SOPs, size rules, and wholesale RFQs for cotton-filled products. But real profit losses usually come from small, easy-to-ignore problems: jewelry discoloration, surface lint, and scratches or negative reviews from position shifts during shipping.

Worse, these problems rarely show up in the sample stage. They only appear in large numbers when you start bulk shipping with small jewelry gift boxes, leading to more returns and rework.

I recommend using this chapter as a reverse checklist. Every time you receive a customer complaint, first confirm which problem was not controlled, then add this detail to your SOP and QC checklist.

Each problem below includes actionable solutions that you can use directly to train your packaging team or update supplier inspection standards.

Cotton filling alone doesn’t mean moisture protection. The real cause of tarnish on silver jewelry or its plating is often the microenvironment formed after sealing: moisture is trapped inside the box, and this problem worsens with temperature changes during shipping.

Actionable tips:

The biggest damage from customer complaints about lint is to perceived value: when customers see fibers on metal or gems at first glance, they directly associate it with cheap and dirty.

Many sellers wipe products temporarily before shipping, which actually increases scratch risks.

Actionable tips:

Most scratches and dents don’t come from rough shipping—they come from oversized packaging boxes. Jewelry shifts constantly when the box vibrates. You may think cotton filling solves all problems, but cotton is better at distributing pressure. It can’t hold jewelry firmly when there’s too much empty space.

Here are actionable tips:

The opposite problem is over-compression. When cotton pads are pressed too tightly, or the lid squeezes the jewelry’s prongs or gems when closing, the jewelry warps, loses stones, or gets dents during shipping. This is very common when people try to prevent crush damage.

Actionable tips:

The most common DIY shortcut to cut costs is using a good inner box with a random outer box. But during last-mile shipping, pressure acts directly on the inner box’s edges and corners, causing it to crush, warp, and have a loose lid.

Here are actionable tips:

Even with the right protection measures, a cheap look can lead to unreasonable returns. Consumers may think the product is not worth the price, doubt its authenticity, or leave negative reviews directly.

Common signs of poor quality include inconsistent color, blurry printing, crooked stickers, loose lids, and dirty cotton surfaces.

Actionable tips:

The key is not to add more cotton, but to prevent jewelry from shifting inside the box. Follow these simple steps: first, place the jewelry in its final display position; then, gently press the cotton pad to secure it; finally, close the lid and check for a clinking sound—a sound means the jewelry is not fixed properly.

In practice, I have my team do a double light shake test. Close the lid and shake the box gently. A clinking sound means too much internal space or insufficient cotton fixation, which drastically increases the risk of scratches from jewelry movement or vibration.

If you ship in bulk with small jewelry gift boxes, add lid resistance checks and light shake tests to your quality checklist to avoid inconsistent results from different staff judgment standards.

Necklace tangling usually happens when free ends shift during shipping vibrations. Here’s the solution:

Never ball up the chain and stuff it in—that’s the key to preventing tangling.

If the box is too big, the necklace will still tangle even with lots of cotton, as the chain still has room to shift. In this case, use better-sized small gift boxes for jewelry or slotted cotton pads to fix the chain.

You can also create a separate assembly SOP for fine chain SKUs to reduce concentrated customer complaints.

There’s only one goal when choosing sizes: after closing the box, the jewelry doesn’t shift, doesn’t push the lid open, and isn’t squeezed.

Follow this principle: the box’s inner diameter should be slightly larger than the jewelry’s maximum external dimension. Then use cotton to fix the jewelry and distribute pressure, not to fill the empty space.

The practical method is simple: keep a standard piece for each jewelry type (such as a standard ring, earring, or bracelet) to test the box. A box is qualified if the lid closes smoothly, there’s no sound when shaken gently, and the jewelry stays in place when opened.

For bulk operations, set 2 to 3 standard sizes (SKU standardization). This makes small jewelry gift boxes wholesale procurement, material restocking, and staff packaging training more stable.

Cotton itself doesn’t necessarily cause metal tarnish. The real problem is trapped moisture after sealing. Silver and gold-plated jewelry are more sensitive to high humidity.

So you need to treat moisture protection as a system: control both the storage environment and the microenvironment inside the jewelry box.

You can add a silica gel barrier without direct contact with the jewelry; compress the cotton to a tight but reboundable level—don’t let the inside become a damp, stuffy space; avoid storing jewelry boxes in high-humidity areas or places with drastic temperature changes.

Add acceptable quality standards to your RFQ. Otherwise, suppliers will only deliver products that look about right. At a minimum, cover four aspects: box structure and dimensional tolerance, cotton liner shape and lint control, lid fit and crush resistance, and random sampling and non-conforming product rejection standards.

A common problem I find: samples meet standards, but mass production is inconsistent.

So add these details to the RFQ: color swatch reference, retained standard samples, and repeat order consistency requirements. Additionally, clearly list random sampling steps, such as the light shake test and the lint test, by wiping the cotton liner surface with a cloth.

To reduce communication, add the 3 most critical steps in your assembly SOP to the RFQ. This way, suppliers understand from the start that you need products with stable protection performance, not just a box.

Remember, cotton is not a one-size-fits-all protective material. What truly determines the protection effect is your ability to turn size selection, assembly operations, and quality inspection processes into a repeatable system. The right size prevents jewelry from shifting; stable assembly prevents scratching or tangling from shipping vibrations; strict quality control ensures consistent batch quality.

After talking with many sellers, I found that returns and negative reviews usually don’t come from poor materials, but from unstable processes. For example, slight differences in compression or placement when different staff assemble the same small jewelry gift box can turn jewelry from a stable state to a shifted state, which may cause scratches, warping, and even damage from crush pressure.

So what you need to do is not look for thicker filler, but post-assembly SOPs and QC checklists at every workstation to ensure everyone follows the same steps.

If you plan to buy in bulk, the key to small jewelry gift boxes wholesale is clear: specify specs clearly, make quality inspection measurable, and make restocking predictable.

In your RFQ, lock in these details: dimensional tolerance, cotton liner lint control requirements, lid fit tightness, sampling methods, and non-conforming product rejection standards. For reorders, emphasize color difference standards and require retained standard samples to ensure batch consistency. This writing style drastically reduces communication costs from sample-qualified but bulk-defective products.

Finally, here’s a practical framework to help you implement these steps directly with your team:

If you’re unsure which small gift boxes for jewelry sizes or cotton pad specs to use, or want to turn RFQ fields + assembly SOP + QC checklist into internal standard documents in one go, you can get our template pack and sample recommendation list. This helps you reach consensus with suppliers more easily, train packaging staff better, and maintain stable protection effects.

Just submit your email to get exclusive offers (reply within 12 hours)