5 Male Gift Box Designs That Increase Repeat Orders by 40%

2025-03-27

For large-scale jewellery retailers, an unreliable packaging supply chain poses a direct threat to revenue and brand reputation. The fundamental purpose of a successful jewellery packaging supply chain is to ensure every product is presented to the customer with absolute consistency and on schedule—an operational necessity for protecting profits and brand equity. This case study details the precise strategies implemented for EverLuxe Jewellers, a national retail chain, to solve these critical challenges. We will analyse how their volatile supply chain was transformed into a reliable asset, resulting in a 15% cost reduction and a 99.9% on-time delivery rate.

Before our engagement, EverLuxe Jewellers, a national retailer with over 200 stores, faced significant operational friction from its packaging supplier. Their supply chain was not an asset but a quantifiable liability that drained resources and directly impacted their bottom line.

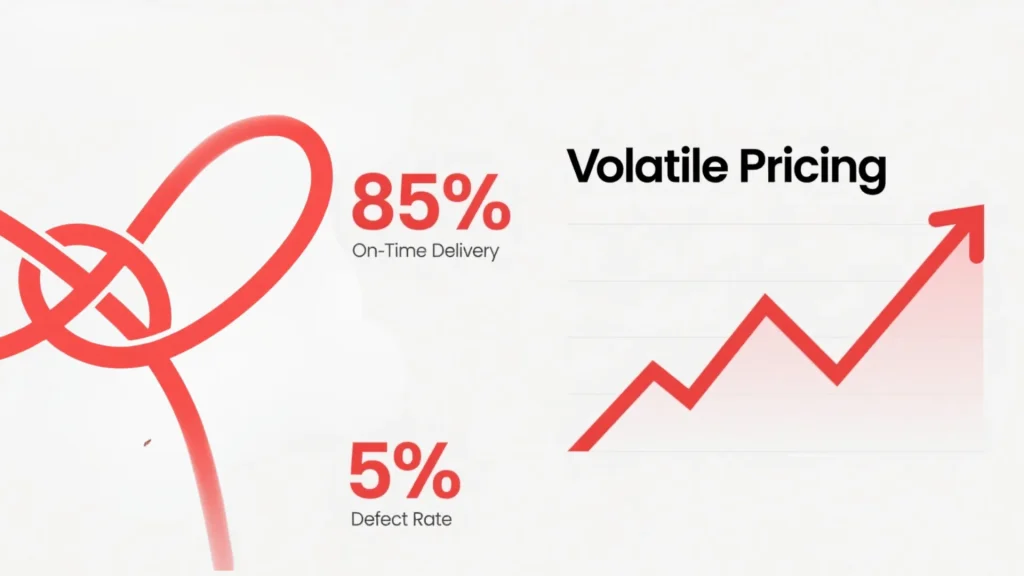

The most critical issue was an unreliable delivery schedule. This is not a trivial matter; according to a report by McKinsey & Company, major supply chain disruptions can erase nearly 40% of a decade’s worth of a company’s EBITDA growth. For EverLuxe, with an on-time delivery rate of approximately 85%, this risk became a reality. They experienced frequent packaging stockouts at key retail locations, a problem that was amplified during the peak Q4 holiday season, leading to significant lost sales opportunities. The inability to move products to the sales floor due to packaging shortages represented a direct and substantial revenue loss—a clear symptom of a flawed high-volume jewellery packaging strategy.

For a brand like EverLuxe, consistency is non-negotiable. However, they faced noticeable quality variations between production batches from their former supplier. These defects included colour discrepancies that deviated from their brand standards and structural weaknesses that diminished the perceived value of the product. Consequently, store managers were forced to discard up to 5% of delivered boxes, which increased waste and diluted the premium customer experience, a stark contrast to the standards expected from luxury jewelry packaging designs.

The absence of a long-term, stable pricing agreement exposed EverLuxe to sudden cost increases in materials and transport. This price volatility made accurate financial forecasting nearly impossible for their procurement department. The search for effective packaging cost reduction strategies was ongoing, but without a predictable cost structure, their budget was frequently compromised, affecting overall profitability.

“Our operations were in a constant state of reaction,” stated the VP of Operations at EverLuxe Jewelers.

“The packaging supply chain was creating significant friction, not facilitating our business. We were losing revenue during our most critical sales periods and our brand integrity was at risk.

It was clear we required a strategic partner, not merely a vendor.”

Drawing on our 15+ years of experience serving over 300 global brands, including leaders like ZARA, Marks & Spencer, and EFFY, we addressed EverLuxe’s challenges with a proven methodology. For enterprise clients, we believe packaging is an exercise in reliability, consistency, and efficiency. We replaced their unpredictable system with a strategic framework built on three pillars, designed to deliver a seamless and predictable enterprise packaging solution.

Our first step was a deep understanding, not a simple reaction. Our logistics team held a series of joint workshops with EverLuxe’s procurement and store operations managers to map out their complete workflow, from purchase order to in-store delivery. The objective was clear: to transform their passive “order-and-wait” model into our proactive, data-driven “forecast-and-stock” system.

Based on this, we implemented the Vendor-Managed Inventory (VMI) system. We no longer waited passively for purchase orders. Instead, based on their last three years of sales data and seasonal fluctuations, we proactively stocked safety inventory for EverLuxe in our regional warehouses. For EverLuxe’s operations team, this was a game-changer. They could view their inventory levels held at our warehouses and our production line progress in real-time through a shared online portal. The era of anxious phone calls to chase order statuses was definitively over.

Our packaging engineers conducted a forensic-level audit of EverLuxe’s existing packaging suite. We deconstructed every element—from the paper’s grammage and specific adhesives to the box’s internal structure. We discovered that by making millimetre-level adjustments to the box dimensions (an alteration completely imperceptible to the end consumer), the number of loadable units per shipping pallet increased by 8%, resulting in a direct 5% reduction in logistics costs.

| Optimization Area | Implementation Strategy | Cost Savings |

| Logistics Costs | Optimized packaging dimensions to increase pallet load rate | 5% |

| Material Costs | Strategic supplier sourcing | 10% |

| Total | 15% |

Furthermore, we leveraged our vast procurement network and economies of scale to match them with a new paper supplier. This supplier not only provided premium, eco-friendly paper with more stable colour and texture but also offered it at a more advantageous price. This was not a simple replacement, but a re-engineering of value, ensuring their packaging reflected the latest jewelry box design trends. We presented EverLuxe with two options: one that optimised existing materials for a 10% cost reduction, and another that used fully FSC-certified sustainable materials for only a 2% cost increase. This ultimately helped them achieve a perfect balance between their corporate social responsibility goals and cost control. This is a core practice within the 8 strategies for reducing jewelry packaging costs we provide for our clients.

To free the EverLuxe team from tedious supplier management, we assigned a senior Account Manager as their single point of contact. This manager became deeply integrated into their weekly operations meetings, proactively reporting on inventory levels, forecasting future demand, and handling all inquiries, becoming a seamless “external member” of their team.

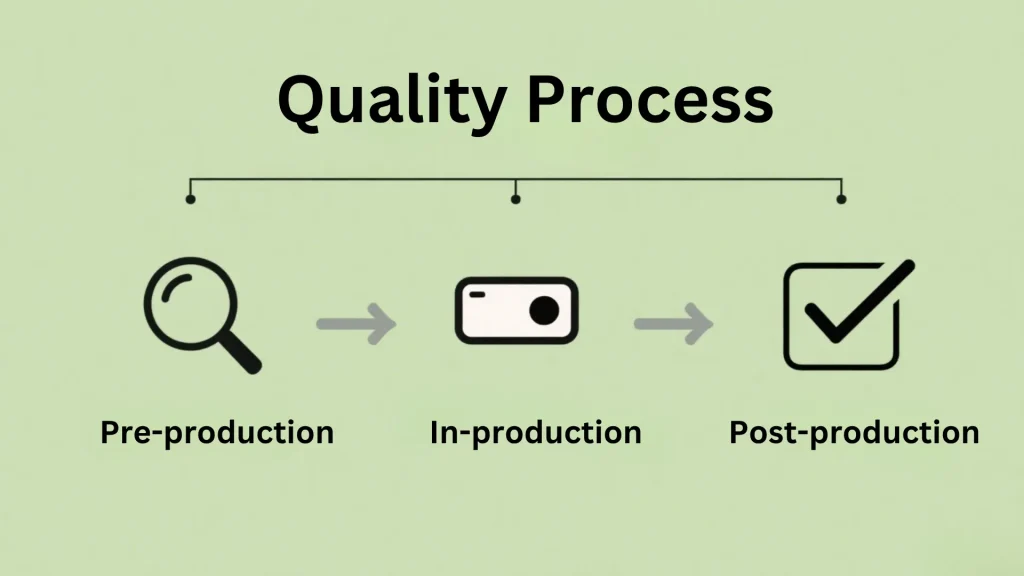

Behind the scenes, our commitment as an ISO certified packaging company was rigorously executed. We initiated a stringent three-stage

Pre-production:

All raw materials had to pass physical tests, compared against the client-approved “golden sample” for color difference and thickness. Any non-conforming materials were rejected.

In production:

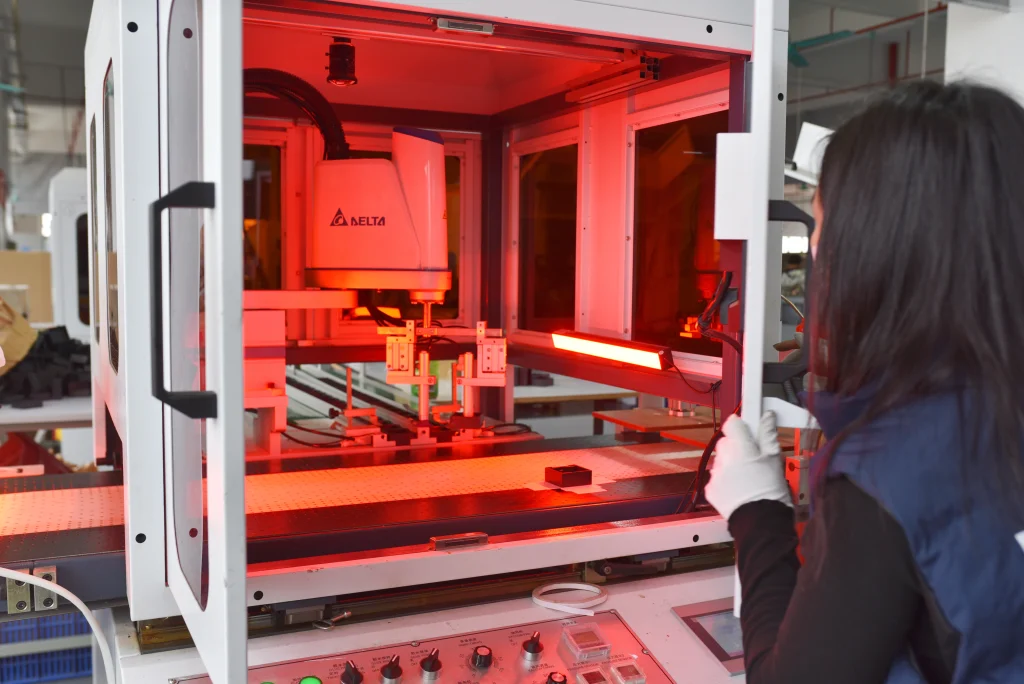

Automated optical scanners on the production line monitored dimensional accuracy and structural defects in real-time.

Post-production:

Before shipment, a dedicated specialist would randomly select 5% of each batch for stress and friction tests.

It is this quality control system, proven effective across our monthly production capacity of over 3 million units, that ensured every single box delivered to EverLuxe’s 200+ stores was a perfect physical representation of their brand.

The implementation of our 3-Pillar Solution transformed EverLuxe’s packaging supply chain from a source of operational friction into a measurable competitive advantage. The outcomes were not merely numbers on a report; they represented fundamental improvements to their business operations, directly addressing the challenges they faced.

This 15% cost reduction was not a result of sacrificing quality, but a direct outcome of our value engineering process. The 5% savings from logistics optimisation (by increasing units per pallet) and the 10% savings from strategic material sourcing were tangible gains passed directly to EverLuxe. For their finance department, this meant a more predictable and lower cost of goods sold (COGS), which in turn directly improved the profit margins on every piece of jewellery sold.

Achieving a 99.9% OTIF rate was a direct consequence of the VMI system and our proactive inventory management. This metric meant that across four consecutive quarters—including their most critical Black Friday and Christmas sales periods—EverLuxe’s 200+ stores no longer experienced stockouts due to packaging unavailability. Their store managers could confidently plan promotions and displays, knowing the necessary packaging was already in our regional warehouse, ready for immediate dispatch, rather than waiting on uncertain production schedules.

The dramatic drop in defect rate from 5% to less than 0.1% was the direct result of our stringent, three-stage QC process. This number represents more than just saved material; it represents the restoration of brand consistency. It meant that every customer, whether in New York or California, received the same premium unboxing experience. For the operations team, it eliminated the time-consuming and wasteful process of inspecting and discarding faulty boxes, allowing them to reallocate that time to more productive activities.

The implementation of our 3-Pillar Solution transformed EverLuxe’s packaging supply chain from a source of operational friction into a measurable competitive advantage. The outcomes were not merely numbers on a report; they represented fundamental improvements to their business operations, directly addressing the challenges they faced.

This 15% cost reduction was not a result of sacrificing quality, but a direct outcome of our value engineering process. The 5% savings from logistics optimisation (by increasing units per pallet) and the 10% savings from strategic material sourcing were tangible gains passed directly to EverLuxe. For their finance department, this meant a more predictable and lower cost of goods sold (COGS), which in turn directly improved the profit margins on every piece of jewellery sold.

Achieving a 99.9% OTIF rate was a direct consequence of the VMI system and our proactive inventory management. This metric meant that across four consecutive quarters—including their most critical Black Friday and Christmas sales periods—EverLuxe’s 200+ stores no longer experienced stockouts due to packaging unavailability. Their store managers could confidently plan promotions and displays, knowing the necessary packaging was already in our regional warehouse, ready for immediate dispatch, rather than waiting on uncertain production schedules.

The dramatic drop in defect rate from 5% to less than 0.1% was the direct result of our stringent, three-stage QC process. This number represents more than just saved material; it represents the restoration of brand consistency. It meant that every customer, whether in New York or California, received the same premium unboxing experience. For the operations team, it eliminated the time-consuming and wasteful process of inspecting and discarding faulty boxes, allowing them to reallocate that time to more productive activities.

The engagement with EverLuxe Jewelers demonstrates a core truth: for a large-scale retailer, the right packaging partner provides a seamless, predictable, and profitable operational system through a fully integrated, design-to-delivery service. By integrating logistics, engineering value, and guaranteeing quality, a significant liability was converted into a strategic asset. Your jewelry boxes and packaging supply chain should be a source of strength and stability, not operational friction.

Is your business facing similar challenges with supply chain reliability and cost control? Contact our Enterprise Solutions team for a complimentary, no-obligation audit of your current packaging supply chain.

Moonstone jewelry has fascinated jewelry customers for centuries with its mysterious allure. But competition is fierce for brands to keep these customers interested. In fact, A Study shows increasing customer retention rates by 5% increases profits by 25% to 95%. So brands must pay attention to their packaging design. One way to achieve this is to… Continue reading How We Cut Packaging Costs by 15% & Achieved 99.9% On-Time Delivery for EverLuxe Jewelers

Opting for them showcases brand charm through details, strengthening the bond with customers.

During Christmas, how to ensure the on-time and high-quality delivery of Christmas gift packaging while controlling costs through effective supply chain strategies has become a major challenge for enterprises. This affects their long-term reputation and market position. This article will introduce you to 5 supply chain strategies that can increase the return on investment (ROI) of… Continue reading How We Cut Packaging Costs by 15% & Achieved 99.9% On-Time Delivery for EverLuxe Jewelers

Eco-Friendly Affordable Sustainable Packaging Solutions for Small Jewelry Shops | Perfect for Independent Jewelers Seeking Green Packaging

View More

Quick Turnaround Personalized Gift Boxes for Jewelry Retailers | Fast Production and Custom Branding | Tailored for Small Orders

View More

Quince Jewelry Box – Elegant Ring Box for Luxury Jewelry Packaging | Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)