A Comprehensive Analysis of Tiffany & Co. and Pottery Barn Jewelry Box

2025-02-14

As an industry leader in jewelry packaging, Richpack has found that shifting from extravagant packaging to sustainable, meticulously designed solutions prioritizes the “unboxing experience” and product durability. Modern consumers are increasingly conscious of product origin and ethical consumption, demanding that product presentation align with their values. Simultaneously, retailers face rising real estate costs and labor shortages, requiring back-office solutions that maximize storage density and minimize inventory loss.

This article provides a detailed analysis of the customization field. We’ll dissect the chemistry of anti-oxidation microfiber, explore the structural logic of modular vault systems, and elaborate on the ergonomic details required to showcase everything from high-value single diamonds to mass-market lab-grown fashion jewelry. Hopefully, this will provide your brand with a roadmap to transform seemingly ordinary jewelry trays into a powerful competitive advantage.

When a customer enters a high-end jewelry boutique, the environment is carefully curated to elicit a specific emotional response—usually a blend of awe, comfort, and aspiration. The lighting is tuned to specific color temperatures to flatter skin tones and gemstones; the air is often scented with subtle fragrances like vanilla or amber to induce relaxation. However, the defining moment of the interaction occurs when the sales associate reaches into the showcase and withdraws a tray.

This movement transfers the focus from the overwhelming “macro” experience of the store to the intimate “micro” experience of the specific piece. The tray serves as the stage for this performance. Research into visual merchandising suggests that the quality of this prop significantly influences the perceived value of the jewelry it holds. A tray that is scuffed, ill-fitting, or made of cheap, discordant materials breaks the spell of luxury. Conversely, a customized tray that perfectly frames the jewelry, utilizing materials that complement the brand’s color palette and textural identity, acts as a psychological primer, signaling to the customer that the object they are about to touch is precious and worthy of reverence.

Richpack’s brand philosophy, championed by founder Merry Lin, is rooted in the belief that packaging and display are emotional vessels. “The value of jewelry lies not only in its material but also in the emotions and stories it carries,” Lin asserts. Consequently, the customization of the tray—its weight, the resistance of the ring slot, the softness of the lining—becomes a direct extension of the brand’s narrative. For a heritage brand, heavy walnut wood trays with deep velvet linings communicate permanence and tradition. For a modern, direct-to-consumer brand focusing on lab-grown diamonds, sleek acrylic trays with minimalist microfiber inserts convey transparency and technological innovation.

Customization is not merely about aesthetics; it is about directing the gaze. Retail case studies have quantified the effectiveness of display placement, giving rise to the “3-Inch Rule.” This principle dictates that for the best viewing experience, the first three inches of a showcase (closest to the glass/customer) should remain clear or contain only flat trays, avoiding tall props or busts that might obscure the view of items further back.

Customized tray systems are engineered to respect this visual hierarchy. Innovations in “tiered” or “stadium” seating within trays allow for rows of rings to be displayed at graduated heights. This ensures that a ring in the third row is not hidden behind one in the second row. Furthermore, the angle of presentation is critical. Standard trays often hold rings at a 90-degree angle (straight up), which is ideal for storage density but poor for viewing from a standing position. Customized inserts can feature 45-degree angled slots that tilt the ring face toward the customer’s eye line, increasing the “sparkle factor” by capturing overhead lighting more effectively.

The color of the tray lining is a powerful, often subconscious, driver of sales. It is not simply a matter of matching the brand logo; it is about physics and psychology.

The primary function of a jewelry tray is protection. However, the definition of protection has evolved from simple physical cushioning to complex chemical preservation. Jewelry is chemically reactive; silver tarnishes when exposed to sulfur, and gold can scratch if placed on abrasive surfaces. Modern customization involves a deep dive into material science to mitigate these risks.

For decades, velvet was the undisputed king of jewelry displays. It looks expensive and feels soft. However, traditional velvet has significant downsides: it attracts dust, can be difficult to clean, and offers no chemical protection against tarnish. In fact, some cheap dyes used in velvets can release gases that accelerate tarnishing.

The industry is currently undergoing a massive shift toward high-performance microfiber (microsuede). Richpack’s research indicates that microfiber is technically superior for modern logistics and preservation.

Beneath the luxurious fabric lining lies the true workhorse of the tray: the foam insert. The customization of foam density is critical for ensuring that jewelry stays in place during transport (impact resistance) and feels substantial in the hand (tactile quality).

| Foam Type | Chemical Composition | Density & Feel | Best Application | Longevity & Archival Quality |

| PU (Polyurethane) | Open-cell polymer | Soft, low-density, “spongy.” Can be compressed easily. | Lightweight shipping, budget-friendly inserts. Good for friction-fit of very delicate items. | Low. Prone to oxidation (yellowing) and crumbling over long periods (the “cheesecake” effect). Not recommended for long-term vault storage. |

| PE (Polyethylene) | Closed-cell polymer | Firm, medium-density, rigid. Waxy texture if unlined. | Heavy items, shipping support, structural layers. Excellent shock absorption. | High. Chemically inert. Will not off-gas or degrade, making it safe for archival storage of metals. |

| EVA (Ethylene-Vinyl Acetate) | Closed-cell copolymer | High-density, smooth, rubber-like feel. Very firm. | The Luxury Standard. Precision die-cut inserts for rings, watches, and heavy sets. | Very High. Extremely durable, maintains shape indefinitely. Can be flocked directly for a seamless look. |

Insight: The trend in 2026 is moving decisively toward EVA foam. Its closed-cell structure allows for laser-cutting with micron-level precision. This enables the creation of “friction-fit” compartments where the jewelry snaps securely into the foam without the need for unsightly clips or elastic ties. This “invisible” retention system enhances the aesthetic of the display while providing superior security against drops.

The rigid base of the tray determines its weight and durability.

Jewelry is not uniform. A delicate 18-inch gold chain behaves differently from a rigid diamond bangle. Innovative tray customization requires engineering specific solutions for the unique physical properties of each jewelry type.

The single greatest operational pain point in jewelry retail is the tangling of necklaces. A tangled chain represents lost labor hours (time spent untangling) and potential damage (kinking or breaking links).

Bangles are top-heavy and prone to tipping over.

In the high-rent districts of New York, London, or Tokyo, the vault is often the most expensive square footage in the store. Efficiency here is paramount. The shift from static storage to modular, stackable systems is one of the most significant operational innovations in the industry.

Traditional jewelry trays are often stored on shelves, with wasted air space above them. Stackable trays solve this by utilizing the vertical dimension.

The “messy drawer” is a common pain point. Customization extends to the interior of the cabinetry.

As we move into 2026, the physical tray is becoming a digital node in the Internet of Things (IoT).

Inventory counts are the bane of retail operations. They are time-consuming and prone to human error. The integration of RFID (Radio Frequency Identification) into custom trays is revolutionizing this process.

Lighting is critical for selling jewelry, but showcase lighting is often blocked when a customer leans in.

By 2026, sustainability will not be an option; it will be a regulatory and consumer mandate. The “Green Commitment” is central to Richpack’s operational ethos and is a primary driver of innovation in tray manufacturing.

The European Union’s “Green Deal” and similar legislation in US states like California are pushing for the elimination of single-use plastics and the enforcement of “Right to Repair” and circular economy principles.

A major innovation in sustainable customization is designing for the end of life.

Richpack stands as a paragon of how a manufacturer evolves to meet these complex demands. Founded in 2008 by Merry Lin in Fuzhou and NewYork city, the company has grown from a family business into a global powerhouse with a “Green Rise” ethos.

Unlike “factory-direct” suppliers that simply execute orders, Richpack operates as a design consultancy. They do not just ask “What size do you want?” but “What is your brand story?”

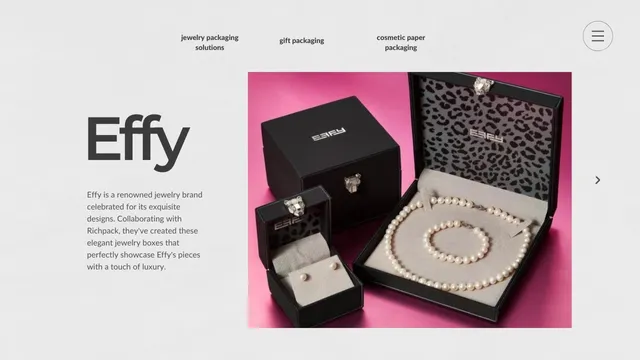

Case Study: EFFY (North America): The renowned jewelry brand EFFY needed packaging that would stand out in a saturated market. Richpack didn’t just supply boxes; they engineered “Luxury Jewelry Box Designs” that embodied the brand’s chic aesthetic. By customizing the texture and unboxing mechanics, they helped EFFY increase customer acquisition by 33.5%.

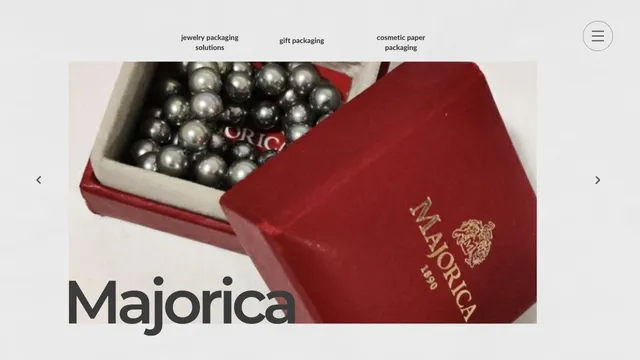

Case Study: Majorica (Spain): For Majorica, a brand associated with the Spanish Royal Family and pearls, the challenge was to balance heritage with modern conservation values. Richpack developed a packaging suite focused on “protecting the Earth while packaging beauty,” utilizing eco-friendly materials that resonated with the brand’s marine conservation philosophy. This strategic alignment boosted Majorica’s social media influence by 40%.

Innovation is useless if it cannot be delivered. Richpack has established a robust global footprint to mitigate supply chain risks.

Data indicates a market shift toward “non-luxury” or “everyday” jewelry, driven by Millennials and Gen Z. By 2026, this segment is expected to hold 75-77% of the market share.

LGDs are expected to account for 50% of all diamond sales by 2030.

Stores are becoming “experience centers.”

The jewelry tray, once a silent bystander in the retail transaction, has found its voice. It speaks of the brand’s commitment to quality through its tactile finish. It speaks of the brand’s respect for the environment through its certified materials. It speaks of operational excellence through its stackable, modular logic.

Now, the narrative deepens through the strategic process of choosing custom jewelry trays that truly reflect a brand’s soul. It is no longer just a container; it is an articulation of identity through bespoke colors and logos, combined with anti-oxidation linings that safeguard the brilliance of every gemstone. By mastering this selection, this once-simple tool evolves into a powerful bridge between the artisan’s craftsmanship and the customer’s desire.

For jewelry brands navigating the competitive landscape of 2026, the customization of the tray is a high-leverage activity. It is an investment that pays dividends in inventory accuracy, asset preservation, and, most importantly, in the emotional connection forged with the customer at the moment of truth—the moment the jewelry is revealed.

As demonstrated by industry leaders like Richpack, the future belongs to those who view the tray not as a container, but as a canvas. Whether it is through the molecular engineering of anti-tarnish microfibers or the logistical elegance of RFID-integrated stacks, the innovative solutions available today offer a clear path to elevating the entire jewelry ecosystem.

| Jewelry Category | Recommended Insert Type | Key Feature | Material Suggestion |

| Engagement Rings | Single “Floating” Clip | Elevates ring to allow light entry from bottom; maximizes sparkle. | High-Density EVA Foam with Microfiber lining. |

| Wedding Bands | Continuous Foam Roll | High density storage; allows for easy size comparison. | Velvet or Suede (Black for Platinum, Cream for Gold). |

| Fine Chains | “Tunnel” or “Straw” Insert | Prevents tangling; keeps chain completely isolated. | Soft Microfiber (Anti-tarnish treated). |

| Pendants | Ramp with Hidden Pocket | Hides excess chain for clean look; gravity keeps pendant centered. | Weighted MDF Base with Vegan Leather. |

| Stud Earrings | “Scoop” Bottom Compartment | Curved bottom allows easy retrieval without tweezers. | Flocked Plastic or EVA. |

| Hoop Earrings | Flap / Pierced Pad | Hides posts/clutches for a clean visual; secures earring from moving. | Reinforced Cardboard wrapped in Velvet. |

| Bangles/Cuffs | C-Clip or Weighted Pillow | Maintains round shape of bracelet; weighted to prevent tipping. | Memory Polymer C-Clip. |

| Watches | Adjustable C-Cuff | Fits varying wrist sizes; holds heavy watch heads upright. | Leather or Faux-Leather for durability. |

| Material | Durability | Anti-Tarnish | Eco-Friendliness | Cost | Best For |

| Velvet | Medium | Low | Low (usually synthetic) | Low-Med | Traditional Bridal |

| Microfiber | High | High (with treatment) | High (Recycled options) | Med-High | Silver, Daily Wear |

| Acrylic | Very High | N/A | Med (Recyclable) | High | Modern, LGD, Window Display |

| Wood (FSC) | High | Neutral | Very High | High | Heritage, Luxury, Eco-Brand |

| EVA Foam | Very High | Neutral | Med | Low-Med | Inserts, Tech-Luxury |

Your jewelry deserves a stage that equals its brilliance. Whether you need Custom Jewelry Trays for Drawers that maximize your vault space or bespoke display props that tell your brand story, Richpack is your partner in global luxury packaging.

Contact us today to begin your design consultation and discover how our “Design-First” philosophy can transform your retail experience.

Research indicates that 83% of the information our brains process comes through our sense of sight. It makes sense that product presentation is crucial to the success of your retail store. For jewellery retailers, it’s not enough to casually put the most beautiful, unique and attractive jewellery items in display cases and wait for the buyers.… Continue reading Innovative Solutions for Customizing Jewelry Tray to Fit Different Jewelry Types

Custom jewelry box, a timeless accessory for storing precious items, has evolved from a simple storage container to a personalized luxury item. According to a market research report by Grand View Research, the global luxury goods market, which includes custom jewelry boxes, is projected to grow at a compound annual growth rate (CAGR) of 6.8%… Continue reading Innovative Solutions for Customizing Jewelry Tray to Fit Different Jewelry Types

Let’s be honest. If you don’t understand the physical properties of velvet fabric, printing on it will be a big problem. Many people know that custom velvet ring boxes feel very high-quality. They make jewelry look more premium. But printing clear, long-lasting logos on this soft, thick fabric has always been very difficult. Over the… Continue reading Innovative Solutions for Customizing Jewelry Tray to Fit Different Jewelry Types

Customizable Jewelry Organizers with Personalized Designs for Small Orders | Ideal for Boutique Jewelers Needing Tailored and Unique Packaging in Low Quantities

Elegant and Compact Jewelry Ring Storage Case for Secure and Stylish Organization | Richpack 2025 Customizable Ring Holder Jewellery Box

Luxurious and Soft Velvet Ring Trays for Retail | Sophisticated and Durable Display Solutions for Jewelry Stores Seeking Elegant In-Store Showcases

Affordable Bespoke Jewelry Organizers with Low Minimum Order Quantities | Designed for Small-Scale Jewelry Retailers Needing Custom Packaging

View More

Cosmetic Eyeshadow Palette Packaging Hardcover Picture Frame Gift Paper Shadow Box Shadow Box

View MoreCustomizable Jewelry Organizers with Personalized Designs for Small Orders | Ideal for Boutique Jewelers Needing Tailored and Unique Packaging in Low Quantities

View MoreJust submit your email to get exclusive offers (reply within 12 hours)