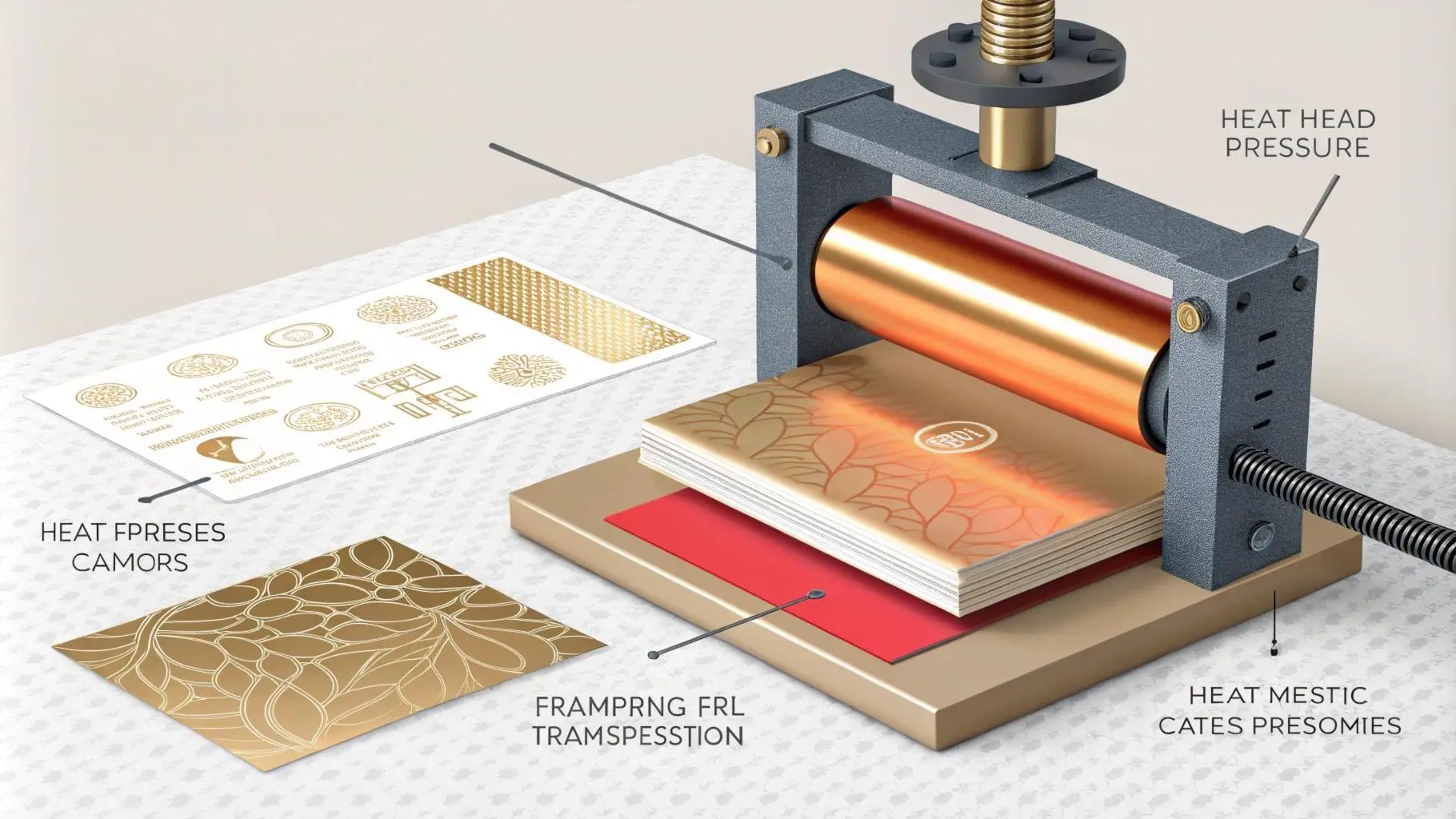

How Does Hot Foil Stamping Elevate Your Packaging Branding

2024-12-05

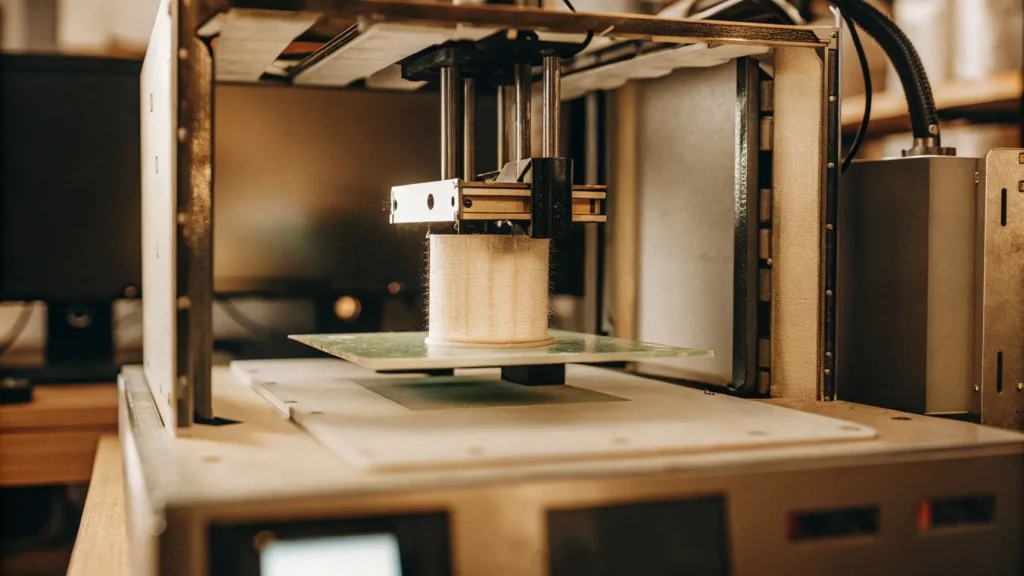

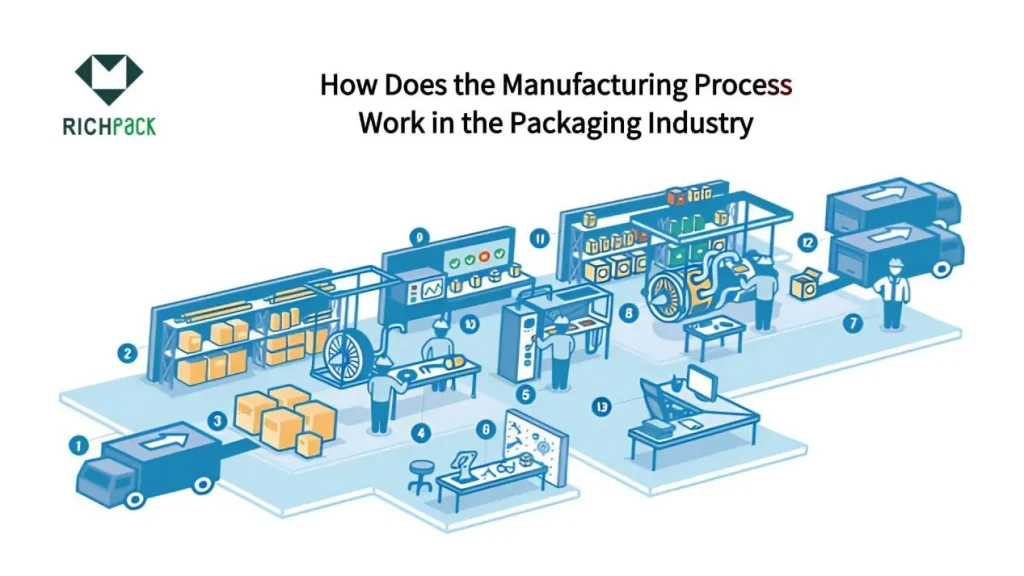

Traditional jewelry packaging manufacturers are facing a staggering 30% collapse rate, and although 3D printing has brought about changes, it struggles to dominate due to aesthetic and quality issues. Against this backdrop, Richpack’s hybrid model has emerged as a promising solution. This article will delve deep into its collaborative production system that combines digital molds with traditional lacquer art. From material innovation, cost-effectiveness, to production process optimization, it will present how this model resolves industry challenges and leads the new development trend.

As we stand at the crossroads of the jewelry packaging industry’s transformation, a deep-dive into the historical context becomes essential. The clash between centuries-old craftsmanship and the disruptive force of digital technology has been the backdrop against which the current industry challenges and innovations unfold.

| Process | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Geometry | Limitations | No limitations, flexible and complex parts, infill options |

| Number of processes needed to get to final shape | One or more | One |

| Stocks needed | Yes | No |

| Profitability | Based on large batches | Independent of number of units |

| Goal | Mass production | Mass customization |

For 500 years, jewelry boxes relied on:

Yet by 2020:

Key milestones:

But pure 3D solutions failed:

Now that we’ve established the context of the industry’s transformation and the challenges faced by both traditional and digital manufacturing, it’s time to zero in on the solution that is revolutionizing the game: Richpack’s Hybrid Blueprint. This innovative approach holds the promise of bridging the gap between past and present, combining the best of traditional craftsmanship with the precision and efficiency of modern technology.

As we begin to dissect Richpack’s hybrid blueprint, the first crucial aspect to explore is Technical Integration. This is the foundation upon which the entire hybrid model stands, seamlessly fusing advanced digital processes with age-old artisanal techniques.

Richpack’s use of advanced materials in its hybrid system is a key differentiator.

| Material | CO2 Impact (kg/kg) | Tensile Strength (MPa) | Key Feature |

| Algae-Based Resin | -1.2 (carbon sink) | 45 | Self-healing microcracks |

| Recycled Nylon 12 | 1.8 | 55 | 98% post-industrial waste |

| Ceramic-Infused PLA | 2.1 | 65 | Heat-resistant up to 120°C |

These materials, combined with the digital mold production, provide a solid foundation for the high-quality jewelry boxes.

A crucial aspect of evaluating any business model is its economic impact, which can make or break its viability in the market. For Richpack’s hybrid approach to jewelry box production, understanding the financial implications is essential for both the company and its clients.

| Cost Factor | Traditional | Pure 3D | Hybrid |

| Mold Fee | $8,000 | $0 | $0 |

| Labor | $12,000 | $1,200 | $3,800 |

| Material | $2,400 | $900 | $1,500 |

| Total | $22,400 | $2,100 | $5,300 |

Richpack’s hand-painted lacquer boxes are a prime example of the value of the hybrid approach. They command a $120/unit premium, which is a 220% markup over 3D-printed bases. This shows that consumers are willing to pay a premium for the artisanal touch combined with modern technology. If you’re interested in more luxury jewelry packaging designs, read here to learn more.

Having explored the technical and economic dimensions of Richpack’s hybrid model, theory must now meet practice. What better way to illustrate the real-world impact of this innovative approach than through a case study? Enter Pierre Cardin Jewelry, a brand that has successfully harnessed the power of Richpack’s hybrid system.

The changes brought about by Richpack’s hybrid system aren’t just about one brand’s success; they’re heralding the new industry order, a new era defined by technological integration, cost-efficiency, and a reimagined balance between traditional craftsmanship and digital disruption.

The Delphi Group predicts that a staggering 40% of mold-dependent factories will close by 2024. The inability to adapt to the changing market demands and the rise of 3D printing and hybrid manufacturing are the main reasons.

In this rapidly evolving industry, the choice is clear: embrace the hybrid model or risk being left behind. The future of jewelry packaging belongs to those who can seamlessly blend the best of traditional craftsmanship with the innovation of 3D printing technology. If you have any questions or want to explore further, don’t hesitate to contact us.

Richpack · Rook Piercing Jewellery Packaging Tips for Attracting Piercing Lovers The rook piercing has surged in popularity in recent years, becoming a staple in the world of ear adornment. The number of searches for “Rook Piercing” on search engines has been increasing annually for the past five years, averaging about 15% per year. In… Continue reading Is 3D Printing Technology Killing Traditional Packaging? The Bitter Lessons of Industry Veterans

The wine glass gift box serves as a presentation vehicle that elevates the act of gifting. It can increase the perceived value of products, attract more customers, and differentiate their offerings from competitors. Moreover, in an era where consumers are increasingly focused on the quality of the entire purchasing and gifting experience, the wine glass gift… Continue reading Is 3D Printing Technology Killing Traditional Packaging? The Bitter Lessons of Industry Veterans

Richpack · What You Need To Learn About Moonstone Jewelry Packaging From rainbow moonstone jewellery to pieces crafted with chalcedony and moonstone, moonstone jewellery symbolizes magic, love, and healing. As demand for authentic moonstone jewellery rises, especially in niches like moonstone jewellery for men and moonstones jewelry enthusiasts, businesses need to focus on one critical… Continue reading Is 3D Printing Technology Killing Traditional Packaging? The Bitter Lessons of Industry Veterans

Customizable Wholesale Perfume Packaging with Personalized Branding | Ideal for Distributors Needing Unique and High-Impact Packaging

Eco-Friendly Cosmetic Packaging for Small Beauty Retailers | Tailored for Brands Committed to Green Solutions with Low Minimum Orders

Joyful Yellow Goodie Bags | Made of Thin Paper With Twisted Handles for Joy-Spreading Gift-Carrying

Branded Gift Boxes for Wholesale Jewelry Packaging | Customizable Packaging for High-Volume Orders | Logo Printing Available

View More

Corporate Gift Packaging with Logo Printing | Tailored for Jewelry Businesses and Corporate Clients Needing High-End, Branded Gift Presentation

View More

Affordable Bespoke Jewelry Organizers with Low Minimum Order Quantities | Designed for Small-Scale Jewelry Retailers Needing Custom Packaging

View MoreJust submit your email to get exclusive offers (reply within 12 hours)