10 Best Alternatives to Plastic Packaging for High-End Jewelry

2024-11-19

The selection of packaging materials directly impacts a jewelry brand’s image, cost structure, and consumer perception. Kraft paper and Art paper are the two most prevalent materials for jewelry boxes, each offering distinct advantages and notable drawbacks. This article provides a detailed comparative analysis, supported by real-world case studies and industry data, to help jewelry brands formulate the optimal packaging strategy.

Kraft Paper, named after the German word for “strength,” is a high-durability paper produced from chemical pulp in the kraft process. Known for its original brown appearance and superior tear resistance, it is a staple in eco-conscious packaging. In jewelry applications, Kraft paper generally falls into four categories:

Natural Kraft (Unbleached), which retains the fiber texture and ranges from 45 GSM (flexible) to 80 GSM (rigid enough for box structures);

Bleached Kraft, which offers a cleaner, creamy white look;

Coated Kraft, treated with clay or polyethylene for better printability;

and Colored Kraft, dyed during manufacturing for varied aesthetic options.

The core advantage of Kraft paper lies in its structural integrity. Its interlaced fiber structure can withstand high tension and pressure, making it excellent for lightweight yet bulky jewelry packaging. Furthermore, its natural composition ensures it is fully biodegradable and recyclable, aligning perfectly with the environmental expectations of modern consumers.

Art Paper refers to paper stocks that have been coated to create a smooth surface, typically available as C1S (Coated One Side) or C2S (Coated Two Sides). The surface is treated with a white pigment layer and binders, resulting in a canvas that is highly receptive to printing. In terms of specifications, Art paper used in packaging generally ranges from 190 GSM for folding cartons to 400+ GSM for ultra-luxury rigid boxes. The 300–350 GSM range is the industry standard for wrapping magnetic rigid boxes.

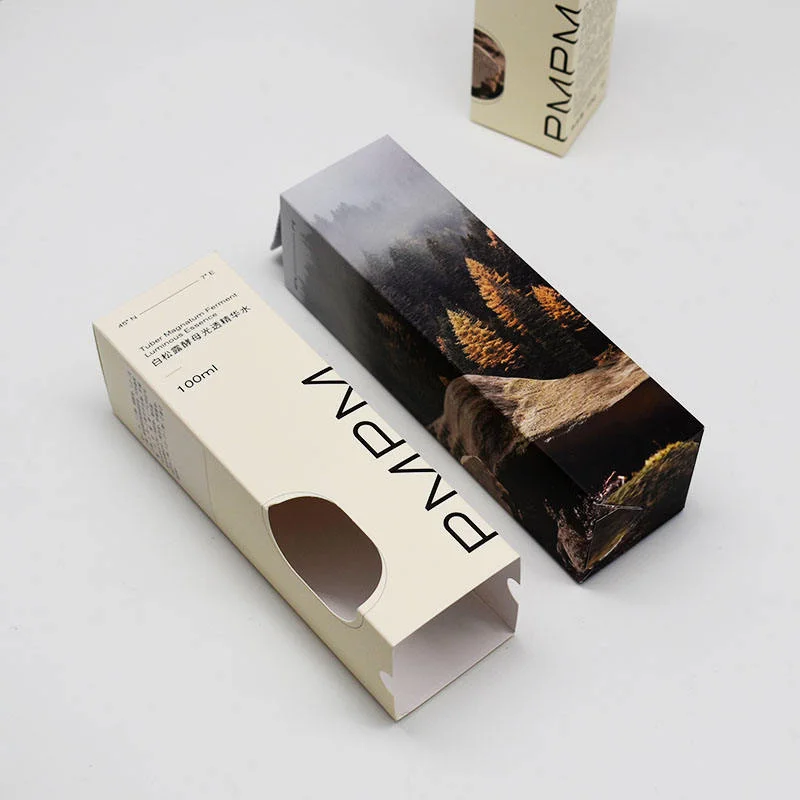

The defining characteristic of Art paper is its ultra-smooth surface and high color fidelity. The coating ensures perfect ink adhesion, allowing CMYK offset printing to achieve near-perfect color accuracy. This makes it the ideal choice for brands requiring full-color photography, complex gradients, or detailed textures. While it excels in compatibility with high-end finishes like hot stamping and embossing, its glossy nature makes it susceptible to fingerprints and scratches.

Paper selection is not merely an aesthetic choice; it is a strategic business decision involving cost, brand positioning, and sustainability.

For high-volume orders (exceeding 10,000 units/month), the cost difference between Kraft and Art paper significantly impacts the bottom line (up to 40–50%).

Cost Implications:

For high-volume orders (exceeding 10,000 units/month), the cost difference between Kraft and Art paper can be as high as 40–50%. While Kraft paper generally costs between $0.15–$0.25 per unit, Art paper ranges from $0.30–$0.50. For a jewelry wholesaler producing 20,000 units monthly, choosing Kraft paper over Art paper can result in annual savings of $15,000 to $25,000.

According to Harvard Business School research, consumers associate packaging quality with craftsmanship.

Brand Perception & Sustainability:

According to Harvard Business School research, consumers closely associate high-quality packaging with product craftsmanship. Art paper conveys traditional luxury, while Kraft paper communicates authenticity and an eco-friendly promise. With over two-thirds of consumers prioritizing sustainable packaging, Kraft paper holds a natural marketing advantage, particularly among Millennials and Gen Z demographics.

Kraft paper’s most significant competitive edge is its environmental credentials. Unlike Art paper, which requires multiple coatings and chemical additives, Kraft paper is essentially a pure cellulose product that is fully recyclable and compostable. Lifecycle assessment studies indicate that new biodegradable paper configurations can reduce environmental impact by 10–35% compared to traditional options. By utilizing FSC-certified Kraft paper, brands can send a powerful message of responsible sourcing.

Case Study: EFFY Jewelry: This Mediterranean brand successfully rebranded to attract Millennial consumers by switching to 100% recyclable paper and vegetable-based inks. In eco-conscious markets like North America and Europe, the new packaging was praised for being “modern and responsible,” leading to a tangible increase in sales.

The natural brown texture of Kraft paper conveys authenticity and artisan craftsmanship, aligning perfectly with the current minimalist design trend where “less is more.” The material offers a unique tactile quality—rough yet soft—that adds a sensory dimension to the unboxing experience. In an era where sustainability and transparency are core brand values, choosing Kraft paper is a statement in itself. Brands can forgo excessive decoration, relying instead on the material’s texture and structural precision to convey value.

Physically, Kraft paper offers high tensile strength, allowing it to withstand the rigors of shipping, folding, and friction without tearing. Specifically, 60–80 GSM Kraft paper can withstand significant pressure (up to 300 N) and resists cracking or delamination during repeated opening and closing. This durability is crucial for logistics; while Art paper coatings may crack or peel under stress, Kraft paper maintains its integrity, ensuring the product arrives in pristine condition.

From a financial perspective, Kraft paper is the clear winner for large-scale operations. Beyond the lower material cost ($1,500 vs. $3,500 for 10,000 units), Kraft paper is significantly lighter, reducing shipping costs. For a wholesaler moving 20,000 units, the weight difference can save $3,000–$5,000 annually in logistics. Additionally, the consistency of Kraft paper reduces quality control costs, as it is less prone to the batch-to-batch color variations or coating defects often seen with Art paper.

The primary drawback of Kraft paper is its printing limitations. The rough, uncoated surface absorbs ink unevenly, leading to lower color saturation and “dot gain,” where small ink dots spread and blur. Consequently, photographic details, subtle gradients, and fine text can appear dull or fuzzy. If a brand relies on showcasing intricate product photos or complex illustrations on the box, Kraft paper will struggle to achieve the vibrancy and sharpness possible with Art paper.

Kraft paper’s matte finish contradicts the high-gloss aesthetic often associated with traditional luxury. High-end finishes like hot stamping and embossing lose their sharpness on Kraft paper, and metallic effects often lack luster. Furthermore, UV coatings do not pop against the absorbent surface. For brands aiming for “ultimate luxury”—such as high-end watches or exclusive gemstone collections—Kraft paper may be perceived as a downgrade, potentially diluting the premium image.

Art paper’s greatest asset is its unrivaled smoothness. The C2S (Coated Two Sides) variants provide a mirror-like white canvas ideal for high-resolution printing. Whether using CMYK offset printing for photo-realistic color accuracy or digital printing for customization, Art paper captures the sparkle of diamonds and the warmth of gold with precision. This visual consistency between the packaging and the retail display builds brand trust and heightens purchase desire.

The specialized coating on Art paper ensures uniform ink distribution and adhesion. This allows for microscopic precision in texture registration (up to 0.02mm) and high dot fidelity. Top-tier brands like Missoma utilize Art paper wrapped around rigid boxes to achieve a sophisticated, modern look. The ability to render smooth gradients and sharp contrasts makes Art paper the standard for brands that treat their packaging as a visual extension of their jewelry.

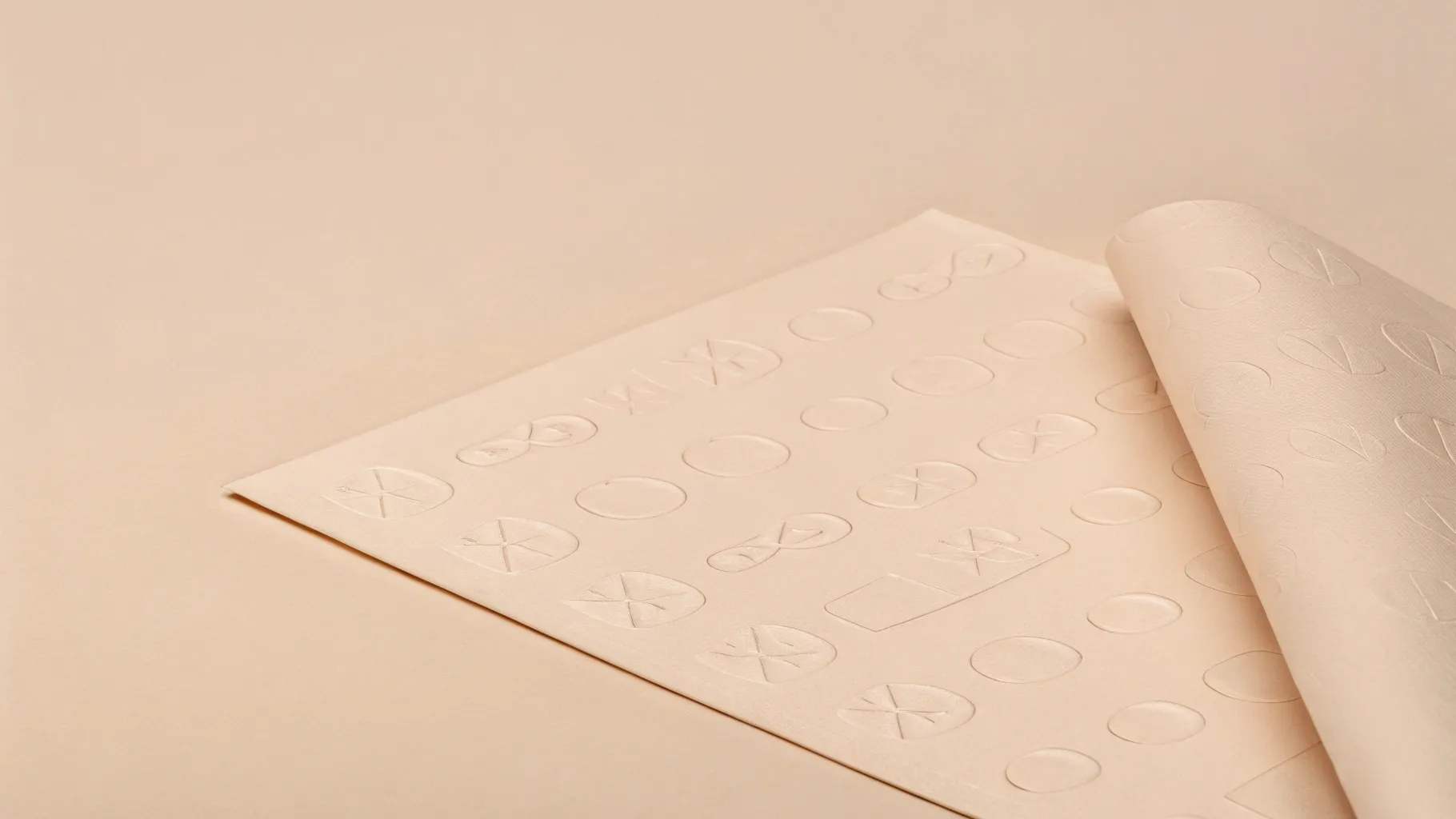

Art paper is the optimal foundation for luxury post-processing. Hot stamping (gold or silver foil) produces crisp, brilliant lines, while embossing and debossing can achieve deep, defined architectural effects. Spot UV coatings create a striking contrast between matte and gloss areas, highlighting logos or patterns effectively. These complex combinations of visual and tactile elements are difficult to replicate on Kraft paper.

The versatility of Art paper offers immense customization potential. Brands can choose from Pearl Paper for a subtle iridescent shimmer, Metallic Foil Paper for high-impact gold or silver finishes, or Matte Art Paper for a modern, fingerprint-resistant look. In a retail environment, the high contrast and saturation of Art paper packaging capture consumer attention more effectively than the muted tones of Kraft paper.

Despite the availability of recycled or FSC-certified Art paper, many consumers still associate the material with chemical processing. The coatings—comprising pigments and binders—are often viewed as “additives” rather than natural materials. For brands positioning themselves as strictly “green” or “eco-responsible,” Art paper can dilute the message. In environmentally sensitive markets like Europe, Art paper may be viewed by younger demographics as “outdated luxury” rather than “modern responsibility.”

While visually stunning, Art paper is physically fragile. The glossy coatings attract fingerprints and smudges, particularly on dark backgrounds like navy or black. Unlike Kraft paper, the surface is easily scratched by fingernails or keys, and prolonged exposure to sunlight can cause fading or discoloration. Since jewelry boxes are often kept for years, the tendency of Art paper to look worn or “shabby” over time contradicts the concept of “timeless jewelry.”

Analysis: While Art paper wins on immediate shelf appeal, Kraft paper excels in “shareability” on social media due to its authentic, trendy aesthetic.

| Feature / Metric | Kraft Paper (The Natural Choice) | Art Paper (The Canvas Choice) |

| Haptic Feedback | Coarse & Warm: Fibrous texture creates friction; feels organic and “dry” to the touch. | Slick & Cool: Clay coating creates a frictionless, glass-like surface; feels sterile and premium. |

| Ink Absorption | High Absorption: Inks soak into fibers. Colors appear muted, darker, and matte. Cannot print white ink easily. | Low Absorption: Inks sit on the surface. Colors appear vibrant, sharp, and glossy. Supports pure white ink printing. |

| “The Fingerprint Test” | Excellent: Hides oils and skin residues completely due to matte, porous surface. Ideal for high-handling retail. | Poor: High-gloss or satin finishes act like a mirror for fingerprints. Often requires a matte lamination to mitigate. |

| Best Logo Technique | Depressive: Debossing, Laser Engraving, or heavy Ink Stamping looks best (plays with shadow). | Additive: Hot Foil Stamping, Spot UV, or 3D Embossing looks best (plays with light reflection). |

| Recommended Pairings | Hemp cord, cotton ribbons, dried flowers, tissue paper interior. | Satin ribbons, magnetic closures, velvet inserts, foam padding. |

| Moisture Reaction | Hygroscopic: Absorbs ambient moisture; box may feel “soft” in high humidity (70%+ RH). | Resistant: Coating acts as a mild barrier; maintains structural rigidity better in damp climates. |

Recommendation: Art Paper (C2S 300–400 GSM). For diamonds, rare gemstones, and luxury watches (e.g., Cartier or Van Cleef & Arpels style), the packaging must signal excellence. Consumers expect the box to match the price tag. Art paper allows for photo-grade printing and complex foil stamping that communicates prestige. The cost of packaging is negligible compared to the product value, making Art paper the logical choice.

Recommendation: Kraft Paper (FSC Certified 60–80 GSM). For handmade jewelry, sustainable startups, and designer brands, Kraft paper aligns the packaging with the brand story. It offers a 50% cost reduction—vital for cash flow—and appeals directly to the values of Millennial and Gen Z consumers. Simple branding techniques, like laser engraving or single-color printing, look sophisticated on Kraft without breaking the bank.

Recommendation: Greyboard or Kraft Paper (250–300 GSM). For mid-range jewelry and high-volume online retailers, the priority is a balance of protection and cost. Greyboard offers “medium luxury” at a reasonable price point and is robust enough for shipping. It supports decent printing quality and, when combined with optimized thickness, provides a satisfying unboxing weight without inflating logistics costs.

Recommendation: Specialty Art Paper (Pearl, Soft-Touch, Metallic). For engagement rings, anniversaries, or limited runs, packaging plays an emotional role. Specialty papers like “Soft-Touch” (velvet feel) or Pearl paper create a unique sensory experience. Although the material cost is higher, the small production volume (e.g., 500 units) keeps the total investment manageable while maximizing the “collectible” feel of the box.

To choose the right paper, brands must define their core values. If your brand stands for Sustainability and Authenticity, Kraft paper is the natural choice. If you represent Precision and Opulence, Art paper is non-negotiable. For brands focused on Value and Utility, Greyboard offers the best middle ground.

Pro-Tip: Start small. Order 500–1,000 sample units to test market reaction before committing to a large run. If scaling up to high volumes, negotiate long-term contracts (6–12 months) to lock in paper prices.

It is rarely possible to maximize all three factors simultaneously.

Whether you choose the eco-authentic look of Kraft Paper or the high-definition luxury of Art Paper, Richpack provides expert, high-volume custom packaging solutions tailored to your specific needs.

Get a Custom Quote NowIn the jewelry industry, packaging is the physical embodiment of your brand strategy. Whether you choose the raw authenticity of Kraft paper or the refined perfection of Art paper, ensure your choice tells the right story to the right customer.

Yes, natural Kraft paper can accelerate tarnishing. Standard unbleached Kraft paper often contains trace amounts of sulfur and lignin, which are natural byproducts of the pulping process. These elements react with Sterling Silver, causing it to oxidize (blacken) more quickly. Art paper, being bleached and coated, is generally pH-neutral and sulfur-free. Solution: If using Kraft boxes for silver jewelry, always use “anti-tarnish” tissue paper or a sealed plastic bag as an internal barrier.

Generally, no. Art paper is not suitable for standard hand-stamping. Because Art paper (especially C2S) has a clay coating that seals the fibers, standard water-based or pigment inks will sit on the surface rather than absorbing, leading to smearing and long drying times. Kraft paper, being porous, absorbs ink instantly and is ideal for DIY rubber stamping. If you must stamp Art paper, you require specialized solvent-based (StazOn) quick-dry inks.

Yes, they offer distinct olfactory experiences. Kraft paper usually carries a subtle “earthy” or “woody” scent, which reinforces the natural, organic brand story. Art paper, particularly when heavily printed or coated, can retain a faint chemical smell from the clay coating, UV varnishes, or offset inks (off-gassing). For sensitive luxury consumers, the chemical scent of fresh Art paper packaging can be a deterrent unless allowed to air out properly before assembly.

Art paper generally resists humidity better than Kraft paper. Kraft paper is highly hygroscopic, meaning it acts like a sponge and absorbs moisture from the air. In very humid storage conditions, thin Kraft boxes can become soft, warp, or lose structural rigidity. The coating on Art paper acts as a mild moisture barrier, helping the box maintain its sharp edges and shape longer in tropical or damp warehouse environments.

Board thickness for rigid lid and base boxes typically ranges from 40PT to 120PT, with 80PT being the optimal choice for most jewelry packaging applications. The right thickness balances protection, presentation, and cost-effectiveness while meeting your brand’s specific requirements and customer expectations. When I first started as a workshop supervisor at Richpack fifteen years ago, I… Continue reading Kraft Paper vs. Art Paper: A Comprehensive Comparison for Jewelry Box Packaging

Die-cutting is a specialized manufacturing process that transforms packaging materials into unique shapes and designs using custom molds. It’s an indispensable technique in the jewelry industry, allowing brands to move beyond standard boxes and create truly custom packaging. By precisely cutting, scoring, and shaping materials, die-cutting ensures every fold and tab fits perfectly, resulting in… Continue reading Kraft Paper vs. Art Paper: A Comprehensive Comparison for Jewelry Box Packaging

North American market for high-end smart jewelry box is expected to grow at a CAGR of 18.3% from 2025 to 2030. Napier Jewelry custom boxes also made this waves in the North American market. This article delves into how Napier Jewelry achieves this through five key elements of its custom box design, transforming packaging into a powerful brand ambassador.… Continue reading Kraft Paper vs. Art Paper: A Comprehensive Comparison for Jewelry Box Packaging

Custom Logo Printing Bottle Card Cardboard Package Luxury Packaging Gift Cosmetic Box

Custom Printed Perfume Boxes with Eco-Friendly Materials | Ideal for Fragrance Brands Focused on Sustainability and Personalized Branding

Eco Friendly Cosmetic Packaging Solutions | Designed for Beauty Brands Focused on Green and Ethical Packaging for Cosmetic Product

Adorable and Practical Travel Jewelry Case Mini – Keep Your Jewels Safe on Trips

View More

Bulk Gift Bag Packaging Solutions for Retail and Events Ocassions | Richpack Customizable Mini Gift Bags Bulk for All Occasions

View More

Cardboard Chocolate Box: Three-Tiered Tempting Treats for All Occasions

View MoreJust submit your email to get exclusive offers (reply within 12 hours)