4 Must-Have Jewelry Bag Styles for Jewelry Brand

2025-05-13

Your product is premium, but if your packaging arrives crushed or covered in lint, you’ve lost the luxury experience before the customer even sees the jewelry.

Deciding between Microfiber vs Velvet Jewelry Pouches is a strategic choice between traditional aesthetics and modern technical performance. In today’s competitive market, the right material must do more than look good—it must prevent tarnish and survive global shipping.

Backed by Richpack’s 15 years of manufacturing expertise, this guide compares both fabrics on anti-tarnish chemistry, shipping ROI, and branding precision. We cut through the marketing fluff to show you which material truly protects your bottom line and your brand prestige. Read on to discover which pouch style will elevate your unboxing experience in 2026.

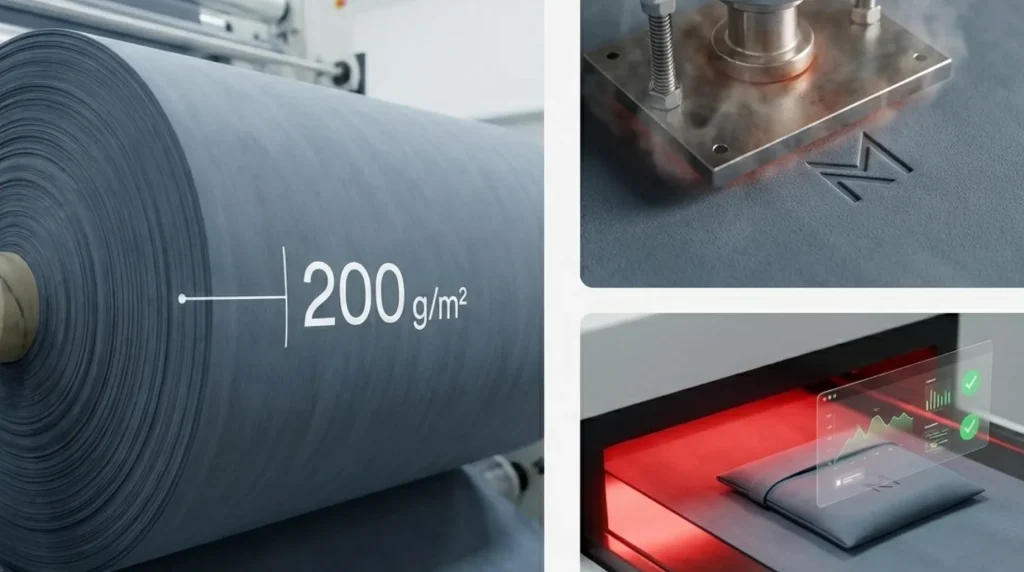

Microfiber is a high-performance synthetic textile, typically composed of a blend of polyester and polyamide. The defining feature is the fineness of its threads, engineered to be less than 10 micrometres in diameter. Microfiber is valued for its low-friction, ultra-soft surface and its ability to block environmental contaminants. High-quality microfiber density should range from 150 g/㎡ to 200 g/㎡to ensure adequate protection against pilling and tearing.

Velvet is characterized by its short, dense pile or nap, a structural feature that delivers natural cushioning and a significant increase in perceived value. Modern velvet is commonly composed of viscose or polyester blends. Velvet conveys a sense of traditional luxury, opulence, and emotional value. It is widely used for high-end pieces and delicate items like pearls.

Microfiber is technically superior for protecting polished surfaces against abrasion due to its dense, low-friction environment, which minimizes the movement of the jewelry piece inside the pouch. Microfiber is also effective at absorbing oils and moisture from handling, preventing these substances from accelerating oxidation.

While custom velvet pouches offer excellent cushioning, it is susceptible to crushing and may shed fibres/lint onto polished metals. Microfiber’s superior resilience makes it the more cost-effective choice for e-commerce, as it resists permanent creasing when flat-packed for shipping.

Tarnishing is unequivocally a chemical change (sulfidation) that alters the metal’s composition, forming compounds like silver sulfide ($Ag_2S$). The reaction is triggered by environmental factors such as sulfur compounds, oxygen, and moisture/humidity.

Microfiber is the preferred substrate for anti-tarnish treatments. Advanced linings in microfiber pouches are infused with colloidal metal particles (silver, zinc, or copper) that act as “scavengers,” neutralizing sulfur gases before they react with the jewelry. The tight weave of the microfiber fabric is highly efficient at maintaining the enclosed environment necessary for these chemical scavengers to function over time. To better understand the long-term chemical preservation of precious metals, you can explore our comprehensive manufacturer’s guide on how to keep jewelry from tarnishing.

Utilizing microfiber pouches with certified anti-tarnish lining has been shown to reduce the tarnish rate by up to 40% compared to non-treated velvet bags in high-humidity shipping conditions.

In high-humidity shipping conditions, certified anti-tarnish lining significantly outperforms standard materials.

| Feature | Velvet | Microfiber (Microsuede) |

| Primary Vibe | Traditional Luxury | Modern Sophistication |

| Tarnish Protection | Moderate | Superior (Anti-tarnish Treated) |

| Shipping Weight | Heavier | Ultra-light (Flat-packable) |

| Durability | Delicate | High (Stain-resistant) |

Yes, for modern brands focused on technical performance and logistics.

While velvet offers a classic look that communicates luxury and tradition, Microfiber jewelry pouches are technically superior for long-term functionality, anti-tarnish protection, and durability. Microfiber is the preferred material for long-lasting chemical preservation, and its tight weave allows for sharp, permanent logos through debossing.

Compliance with chemical safety standards is a mandatory requirement for market entry. Suppliers must be rigorously vetted to confirm adherence to the EU’s REACH regulation and California’s Prop 65.

Manufacturers should use XRF (X-ray Fluorescence) machines to verify exact metal composition and plating thickness. Furthermore, for gemstones and precious metals, brands must request documentation proving materials are certified as recycled or adhere to standards like the Kimberley Process for conflict-free sourcing.

Sustainability is a primary driver in the jewelry market. 73% of Gen Z consumers are willing to pay more for sustainable products.

Eco-Solutions:

Packaging should prioritize materials that are recyclable, biodegradable, or reusable. Preferred options include Recycled PET (rPET) microfiber (made from post-consumer plastic bottles), organic cotton, and recycled paper.

Verification:

Legitimacy is verified through certifications such as GOTS (Global Organic Textile Standard) and FSC(Forest Stewardship Council) to ensure ethical and sustainable sourcing.

Microplastic Concern:

Both microfiber and synthetic velvet are typically made from petroleum-based synthetic fibres (polyester, nylon) that do not biodegrade and are a source of microplastic pollution.

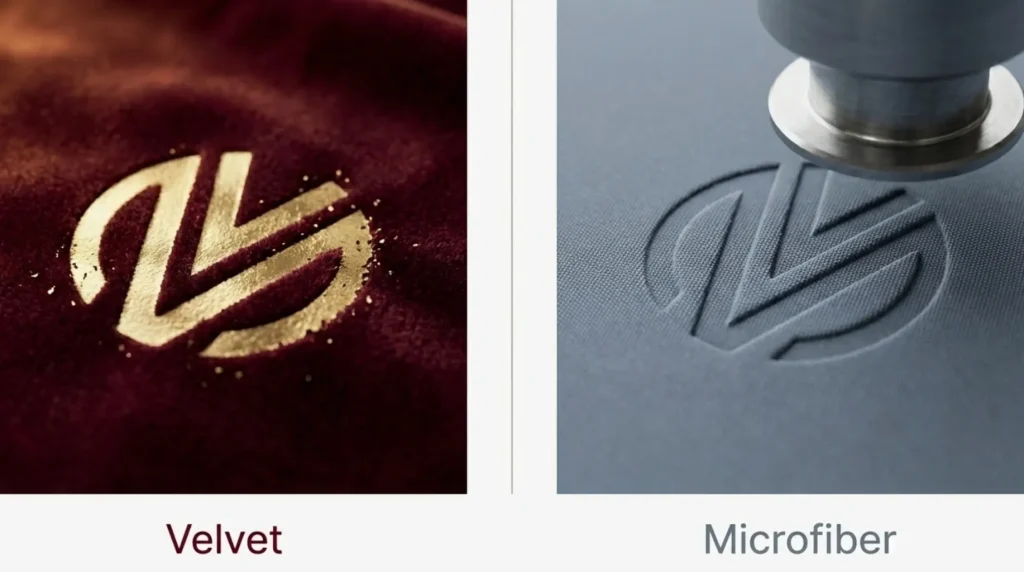

The choice of pouch material directly impacts the quality, permanence, and perceived sophistication of the logo application.

| Printing Method | Velvet Suitability | Microfiber Suitability | Durability Ranking |

| Hot Stamping | High (Metallic) | Moderate | Medium (Can flake) |

| Debossing | Low (Pile hides detail) | High (Sharp edges) | High (Permanent) |

| Embroidery | High (Textured) | Moderate | High (Indestructible) |

| Screen Printing | High (Bold) | High (Vibrant) | Medium/High |

| Heat Transfer | Low (Texture issues) | High (Detailed) | High (Permanent) |

Debossing:

Highly effective on microfiber and synthetic suede, as the tight weave results in a sharp, permanent imprint that does not rebound like velvet pile.

Hot Stamping:

Most popular on velvet for a clean metallic sheen.

However, these applications are considered temporary and are prone to flaking with wear.

Embroidery:

Adds a tactile, upscale finish that is highly durable and ideal for professional appearances on thicker fabrics.

Design Rule:

Logos must adhere to the “three B’s”: BIG, BOLD, AND BRASSY.

Small details or characters smaller than 3/8″ may be obscured by the pile of the fabric.

While no fabric can stop oxidation forever, microfiber pouches infused with anti-tarnish scavengers (like silver or copper particles) neutralize sulphur gases. In our tests, this reduces the tarnish rate by up to 40% compared to traditional velvet in high-humidity environments.

Microfiber often provides better long-term value. While the unit price may be comparable to high-grade velvet, its durability and lower shipping volume (due to flat-packing) result in a lower Total Cost of Ownership (TCO) for e-commerce brands.

For professional quality, ensure a fabric density of 150–200 g/m². Anything lower may feel thin, lack structural integrity, and be prone to pilling after only a few uses.

For maximum durability, we recommend blind debossing on microfiber. Because the logo is heat-branded into the tight weave of the fabric, it is permanent. Hot stamping on velvet, while beautiful, is a surface application and may flake with frequent handling.

Standard microfiber is petroleum-based, but modern brands should opt for rPET (Recycled Polyester) options. This turns post-consumer plastic waste into high-end packaging, aligning your brand with global sustainability certifications like GOTS and OEKO-TEX®.

The choice between microfiber and velvet jewelry pouches is a strategic decision that impacts product safety, brand perception, and logistical efficiency.

Implementing a routine cleaning schedule extends the life of your premium packaging. For a deeper dive into extending the lifecycle of your brand’s assets, refer to our expert tips on how to properly care for and maintain your jewelry packaging.

Richpack offers modular, travel-friendly boxes. Discover the ideal storage solution for your watch collection here.

I still remember the first time I visited New York, wandering through a small handmade market where delicate mini jewelry boxes with logo of “Richpack” were displayed on wooden stalls. I was instantly mesmerized—like finding a “hidden gem.” That moment of love at first sight led me on a journey to explore different jewelry boxes, from… Continue reading Microfiber vs. Velvet Jewelry Pouches: Which is Best for Your Brand? (2026 Guide)

An analysis of global jewellery consumer trends shows that 14k jewellery is gaining more traction in the face of rising gold prices, and retailers are driving sales of these high-margin products through aggressive marketing strategies: the jewellery industry is witnessing a surge in the popularity of 14k gold-plated jewellery. This trend is driven by the desire for high-quality pieces… Continue reading Microfiber vs. Velvet Jewelry Pouches: Which is Best for Your Brand? (2026 Guide)

Cost-Effective Bulk Packaging Solutions for Jewelry Brands | Perfect for Wholesalers Needing Scalable and Customizable High-Volume Packaging

View More

Velvet Jewelry Pouches | Custom Luxury Pouches – Richpack

View More

Richpack Large Necklace Boxes with Custom Sizes and Colors | Big Necklace Boxes with LED Light for Gold and Statement Pieces

View MoreJust submit your email to get exclusive offers (reply within 12 hours)