Best Recyclable Packaging Solutions for Luxury & Jewelry Brands

2025-07-24

You can order custom boxes in bulk directly from a factory by simply providing your specifications. This allows you to choose the design, size, and material. You also save money by cutting out the middleman. Clear communication helps prevent mistakes and ensures the factory produces exactly what you need. When you order custom boxes, you control the quality and branding from the start.

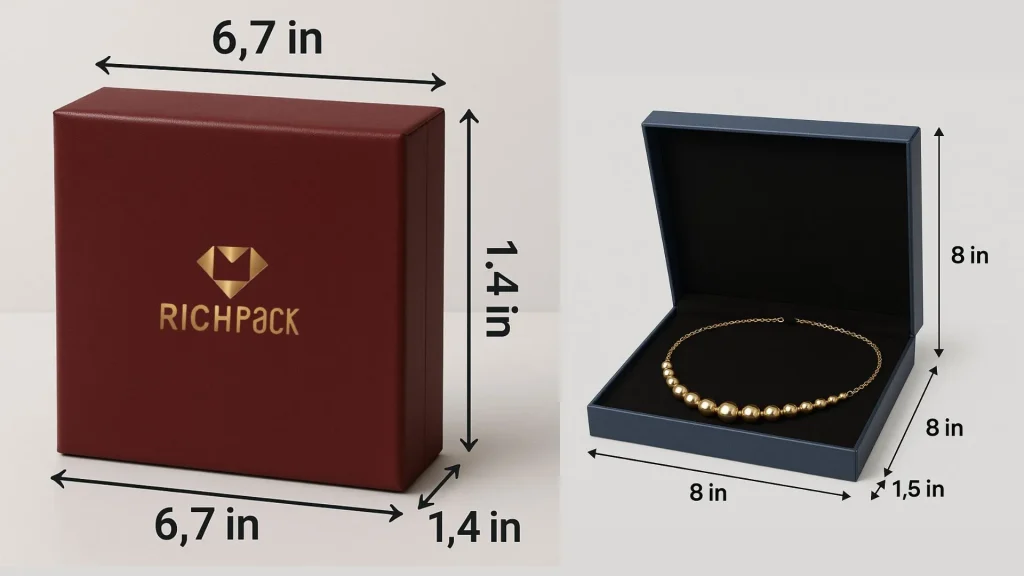

First, choose the exact size for your custom jewelry boxes. Measure the length, width, and height of your product. Write these numbers down so you don’t forget. The factory will use these numbers to build the right box. If you choose the wrong size, your product might move around, or the box may not close properly.

Tip: Always measure your product after it is packed with any internal padding or liners. This ensures the box can safely hold everything.

You can use a simple table to keep your measurements organized:

| Product Name | Length (Inches) | Width (Inches) | Height (Inches) |

| Example | 10 | 6 | 4 |

Show this table to the factory. Clear numbers help you avoid mistakes and save money.

Next, choose the best material for your box. The most common options are corrugated board, paperboard, and rigid boxes. Corrugated is strong and durable, perfect for shipping heavy items. Paperboard is better for lightweight items and retail packaging. Rigid boxes have a premium look and are often used for luxury goods.

Consider how heavy your product is and how you want the box to look. If your item is fragile, use a thicker corrugated board. If you need eco-friendly packaging, ask about recycled or biodegradable materials.

Note: Factories can provide samples of different materials. Always ask for samples before you make a final decision.

Your design is crucial for your brand image. You can choose a plain box or a printed one. You can add your logo, brand colors, and product details. Some factories offer design help and provide templates. Use these tools to create a box that matches your brand.

Tell the factory which printing method you want. You can choose from digital printing, offset printing, or flexographic printing. Each has its own price and quality. If you need special finishes, such as a glossy or matte look, or embossing, let them know.

Pro Tip: Provide your factory with high-resolution design files. This helps them print your design clearly.

When you order custom boxes, clear details about size, material, and design help you get a great price and an excellent result.

The process of ordering wholesale jewelry boxes is a perfect, practical application of all the requirements we’ve just discussed. The detailed keywords you’ve identified represent the exact specification categories a factory needs to give you an accurate quote.

Let’s break down how to use this vocabulary when communicating with a supplier.

This maps directly to the Design section of the guide. Instead of just saying you want a “printed box,” you would be highly specific.

This tells the factory you are moving beyond a generic, in-stock box and require a custom production run that includes your branding.

This is often the most important factor in cost and brand perception.

This maps directly to the Box Dimensions section. The box’s function determines its size and inserts. A factory needs to know exactly what the box is for.

This is a key Design specification.

This is where you define the “special features” mentioned in the RFQ section. These details significantly impact the price.

This maps to the Quantity section. Your language sets the factory’s expectations.

These keywords are for the Finding a Factory step. Your search terms determine your supplier pool.

Finally, many factories offer more than just boxes. You can save on shipping and ensure brand consistency by bundling your order.

By using this specific vocabulary, you are providing a complete and professional RFQ that allows a factory to give you an accurate price with no delays.

Choosing the right jewelry packaging factory is essential. You need quality custom boxes for your business. There are many ways to find a trustworthy manufacturer. Each method has its benefits and things to watch out for.

Online platforms help you find custom box factories around the world. You can check many suppliers from your computer. Some platforms are known for being safe and easy to use.

richpkg.com helps buyers connect with manufacturers from all over the world. You can find jewelry box suppliers and other box makers.

These features can help you save money and show that the platform works well.

Other good online platforms include Alibaba, Made-in-China, and Global Sources. Always read reviews and check ratings before you contact anyone.

Tip: Use the platform’s chat system to keep all conversations in one place. This makes it easy to remember deals and details.

Trade shows let you meet factory representatives face-to-face. You can check samples, ask questions, and build trust in person. Many cities host packaging or manufacturing trade shows each year. Look for events like Jewellers of America 2024 Fall Trade Show, JA New York Spring 2025, or local packaging expos.

At a trade show, you can:

Bring a notebook and business cards. Write down notes about each factory you visit. This helps you remember your options later.

Before you place an order, you need to verify the factory is legitimate. Start by asking for their business license and certifications. A good factory will show you these documents.

Here are the steps to check a factory:

Note: If you use a sourcing agent or inspection company, they can help you check the factory and review your goods before they ship.

Doing this work helps you avoid scams and find a good partner. Verifying now saves you time and money later.

When you want to get a price from a factory, you need to fill out a Request for Quote (RFQ). Most factories have these forms on their website or will email one to you. You should fill out every part of the form. This helps the factory understand what you need. If you leave out details, you might get the wrong price or a slow reply.

A typical RFQ form asks for:

Tip: Double-check your numbers before you submit the form. A mistake can lead to delays or the wrong sample.

A factory needs clear information to give you an accurate quote. You should have all your details ready before you make contact. This makes the jewelry packaging manufacturing process faster and smoother.

Here is a checklist of what you need:

You can use a table to organize your details:

| Detail | Your Information |

| Box Dimensions | 10″ x 6″ x 4″ |

| Material | Corrugated |

| Printing | Full-color, Matte finish |

| Quantity | 1,000 |

| Delivery Date | August 1st |

Note: The more details you provide, the more accurate your quote will be.

After you get quotes from different factories, you need to compare them. Don’t just look at the price. You should also check the lead time, quality, and extra services.

Make a list or a spreadsheet to compare:

Ask questions if you are unsure. Some factories have a lower price but a longer lead time. Others might offer free design help or better packaging. Choose the offer that fits your needs and budget.

Pro Tip: Save all your quotes and emails. This helps you remember what each factory promised.

Shop around to make a smart choice for your business. You can get the best value and avoid surprises when you order custom boxes.

Before you place a large order, always ask for a sample. A sample lets you check the box’s size, material, and print quality. You can see if the box fits your product and how your brand looks. Most factories will provide a sample for a small fee, or sometimes for free, if you plan to order in bulk.

When you get the sample, inspect it carefully. Check the printing. Make sure the colors are bright and the logo is clear. Test the box’s strength by folding it and pressing on it. If you need special features, like windows or handles, test them too.

Tip: Take photos of the sample with your product inside. Share these with your team or partners to get feedback before moving forward.

If you find any problems, tell the factory right away. A good supplier will fix the issues and send a new sample. This step helps you avoid mistakes on your entire order.

After you approve the sample, you need to finalize all the details. This step is very important. Clear and detailed specs help the factory produce the right boxes for you.

Here are key steps that help prevent errors and ensure you get what you expect:

Note: Put all details in your order, including box size, material, print type, finish, and quantity. Keep a copy of all proofs and emails.

Finalizing specs also means agreeing on the MOQ. The factory will tell you the minimum number of boxes you can order. Make sure you understand this before you sign anything.

Once you have approved the sample and finalized the specs, you are ready to place your order. Ask the factory for a contract or a proforma invoice (PI). This document should list all the details—box specs, quantity, price, delivery time, and payment terms.

Read the contract carefully. Make sure it matches what you discussed. If you have questions, ask before you pay. Most factories will ask for a deposit, usually 30% to 50% of the total price. The remaining balance is paid when the goods are ready to ship.

Some factories offer design support. If you need help with your artwork or want to try new features, ask about their design services. Many suppliers can adjust your files or suggest improvements.

Pro Tip: Keep all your order documents in one folder. This makes it easy to check details later if you have questions.

Clear steps and good communication help you avoid problems when ordering custom boxes. You will get the packaging you need to support your brand.

You want to know how long it will take to make your custom boxes. The production timeline (or lead time) starts after you confirm the final sample and pay the deposit. Most factories need 2 to 4 weeks to finish a bulk order. The exact time depends on your box design, the number of boxes, and how busy the factory is.

The factory follows a step-by-step process:

Tip: Ask your supplier for a clear production schedule. This helps you plan your inventory and sales.

If you need your boxes faster, some factories offer expedited or rush services. These may cost more but can help you meet a tight deadline.

Quality checks make sure your boxes look and work their best. Factories take several steps to ensure every box meets your standards. You should ask about their quality control (QC) process before you order.

Here are common quality checks:

You can ask for photos or videos of the inspection process. Some factories allow a third-party inspector to visit and check the goods before they ship.

Note: If possible, always inspect a few of the finished boxes yourself. This gives you peace of mind before the whole shipment leaves the factory.

Good communication helps prevent mistakes and delays. Stay in touch with your factory during production. Ask for updates at each stage. Most suppliers will send progress reports with photos or videos.

You should keep a record of all messages and agreements. Use email or the platform’s chat system. A clear record helps solve any problems that come up.

Pro Tip: Build a good relationship with your supplier. Friendly and clear communication often leads to better service and fewer problems.

Following these steps helps ensure your boxes arrive on time and meet your quality standards. Ordering custom boxes in bulk can be a smooth process from start to finish.

You need to choose the best shipping method for your custom boxes. Factories offer several options. Air freight is ideal for fast delivery. You can get your boxes in a few days, but it costs more. Sea freight (or ocean freight) is slower but saves money on large orders. Most businesses use sea freight for bulk shipments.

Ask your supplier about the carriers they use. Some factories work with trusted shipping companies. You can also use your own freight forwarder. Be sure to confirm if the factory offers door-to-door delivery. This means the shipment will arrive at your business address without extra handling.

Tip: Always ask for a shipping quote before you confirm your order. This helps you plan your budget and avoid surprises.

Here is a simple table to compare shipping methods:

| Shipping Method | Speed | Cost | Best For |

| Air Freight | Fastest | Highest | Urgent orders |

| Sea Freight | Slow | Lowest | Bulk shipments |

| Courier | Very Fast | High | Small samples |

When you import boxes from another country, you must go through customs clearance. Customs is the process where government agents check goods before they enter your country. You will need documents like an invoice, a packing list, and shipping details. Your supplier or freight forwarder can help with this paperwork.

Some countries charge import duties or taxes. You should ask about these fees before you ship. If you don’t pay the duties, your shipment could be delayed or sent back.

Note: Always check your country’s import rules. Each country has different requirements for packaging materials.

Working with an experienced shipping partner can make customs easier. They know the process and can handle problems quickly.

When your shipment arrives, inspect it right away. Check the packages for any damage. Open a few boxes to check the quality. Make sure the size, material, and printing match your order.

If you find any problems, take photos and contact your supplier. A good supplier will help you fix the issue or replace the damaged boxes. Keep all your shipping documents and receipts. These help resolve issues with the shipping company or customs.

Pro Tip: Create a receiving checklist. This helps you spot problems early and keep your business running smoothly.

Even with good planning, problems can happen. You might get boxes with the wrong size, colour, or print. Sometimes, boxes arrive damaged or the delivery is late. When these issues happen, act quickly. Contact your supplier immediately. Give them clear photos and a short description of the problem. Most factories want to help you fix mistakes because they value your business.

You should keep all your order records and emails. These documents can help you explain your case. If you are working with a platform or an agent, tell them about your problem. They can help you talk to the factory and find a solution. Many suppliers will offer replacements or a refund for damaged or incorrect boxes.

Tip: Always inspect your boxes as soon as they arrive. Checking early helps you find problems before you use the boxes to ship your products.

As your business grows, you will need more boxes. Reordering from the same factory saves you time and keeps your packaging consistent. Most suppliers will keep your box design and order details on file. You can ask for a reorder by giving them your last order number or design proof.

Here are steps to make reordering easy:

Some factories offer discounts for repeat customers or large orders. You can also set up a reordering schedule if you need boxes every month or quarter. This helps you avoid running out of packaging during busy times.

Your feedback helps the factory improve its service. After you receive your boxes, share your thoughts with the supplier. Tell them what you liked and what could be better. Good feedback builds a strong relationship and helps you get better results next time.

You can use a simple table to organize your feedback:

| What Worked Well | Areas for Improvement |

| Fast delivery | Print color accuracy |

| Strong material | Quality of box folding |

Note: Honest feedback helps both you and the factory. You get better boxes, and the supplier learns how to serve you better.

If you had a good experience, consider leaving a review on the supplier’s website or the platform where you ordered your custom boxes. Positive reviews help other buyers find reliable partners.

By following these steps, you can order custom boxes in bulk with confidence. Start by knowing your needs. Then, find the right supplier. Be sure to communicate clearly with them. Always check all the details before you place your order. Use a checklist to help you remember each step. This way, you can save money and reduce errors. Stay organized to make your next order with the supplier just as smooth.

Most factories require you to buy at least 500 to 1,000 boxes. Some will let you order fewer if you choose a standard style. Always ask the supplier about their rules before ordering.

Custom boxes typically take 2 to 4 weeks. This time starts after you approve the sample and pay the deposit. You can pay extra for faster service if you need it.

Yes, you can ask for a sample. Most factories will charge a small fee to let you check the size, material, and printing before you commit to a large order.

You should use high-quality files like AI (Adobe Illustrator), PDF, or EPS. These file types make your design look sharp when printed. Ask your supplier if they require a special template.

Inspect your order as soon as it arrives. If you find damage or problems, take photos and tell your supplier right away. Most factories will send new boxes or give you a refund.

Many factories now use recycled, biodegradable, or FSC-certified materials. You can ask about “green” options when you place your order. You can request samples to see if you like the quality.

Factories usually accept bank transfers, PayPal, or credit cards. Most will ask for a 30% to 50% deposit before they start making your boxes. You will pay the remaining balance before the order ships.

Yes, you can reorder the same boxes. Most factories save your design and order details. Provide your last order number or design proof to make reordering faster.

Stop searching for “wholesale jewelry boxes” and start creating with your factory-direct partner.

Contact Richpack Packaging today. Visit our website to fill out our inquiry form or email our team directly with your project details. We can’t wait to help you build your brand.

Among the many types of gift packaging available, Christmas gift boxes with lids stand out as an excellent option for both presentation and practicality. These boxes offer a convenient and elegant way to package gifts, ensuring they arrive in perfect condition while also adding a festive touch. Whether you’re wrapping a heartfelt present for a… Continue reading A Complete Guide to Ordering Custom Boxes in Bulk from the Factory

Choose optimal jewelry box structures by matching design to brand positioning and operational needs. Premium brands benefit from magnetic or drawer boxes for enhanced customer experience, while volume operations should prioritize lid-and-base or foldable designs for cost efficiency and reliable supply chains. In today’s competitive jewelry market, the wrong packaging structure choice can cost your… Continue reading A Complete Guide to Ordering Custom Boxes in Bulk from the Factory

With over 15 years of experience serving 300+ global brands—from small boutique jewelers to names like EFFY and ZARA—Richpack doesn’t just make boxes. We solve real problems our clients face every day. Last year alone, we helped a large jewelry retailer hit their Black Friday deadline, a new boutique brand launch their first collection, and a jewelry chain streamline their… Continue reading A Complete Guide to Ordering Custom Boxes in Bulk from the Factory

Compact Travel-Sized Velvet Jewelry Trays with Secure Closures | Ideal for Jewelry Sales Reps and Retailers Requiring Portable Display Solutions

Elegant Stuller Jewelry Packaging by Richpack | Premium Solutions for Fine Jewelry Presentation

High-End Jewelry Packaging for International Luxury Brands | Elegant and Custom Solutions | Premium Branding Options

Bespoke Jewelry Boxes with Personalized Branding for Jewelry Labels | Tailored Packaging Solutions for Retailers

View More

Branded Gift Boxes for Wholesale Jewelry Packaging | Customizable Packaging for High-Volume Orders | Logo Printing Available

View More

Convenient Roll-Up Travel Jewelry Cases | Space-Efficient and Protective Storage for Jewelers Needing Compact Solutions for On-the-Go Jewelry Storage

View MoreJust submit your email to get exclusive offers (reply within 12 hours)