When assisting numerous jewelry brands in optimizing their supply chains, Richpack discovered that wholesale magnetic gift boxes are not just containers—they are strategic assets that boost brand perceived value.

However, bulk purchasing is fraught with hidden pitfalls. We have seen many cases where weak magnetism ruined customer experiences, as well as successful turnarounds where optimizing packaging logistics cut shipping costs by 30%.

In this guide, we go beyond basic parameters to explore how custom magnetic gift boxes can drive supply chain optimization.

Whether you want to resolve manufacturing consistency issues or seek a more cost-efficient solution, this practical guide will help you avoid costly trial-and-error expenses.

For most jewelry brands, custom magnetic gift boxes are no longer mere consumables—they are strategic assets that enhance brand perceived value.

But this is not the only reason they dominate the B2B market.

For procurement or operations managers like you, the real killer advantage of custom magnetic gift boxes is that they perfectly balance premium quality and logistics costs—especially with the advent of foldable designs.

In traditional rigid packaging procurement, our biggest pain point is often paying exorbitant shipping fees just to transport containers full of space.

When helping clients with supply chain optimization, Richpack compared logistics data between traditionally assembled boxes and foldable magnetic boxes.

The results were staggering:

| Key Metrics | Traditional Rigid Box | Foldable/Collapsible Box | Your Benefit |

| Shipping Volume | 100% (fully occupied) | 20% – 30% | Saves about 75% of container space |

| Warehouse Space | A large warehouse is needed | Compact stacking | Significantly reduce warehouse rental costs |

| Shipping Cost/Unit | High | Low | Directly increase your net profit |

| Assembly Time | Ready to use (no assembly required) | 3-5 seconds per piece/unit | Adds almost no labor costs |

[Read our in-depth comparison of foldable vs. rigid jewelry packaging]

Beyond cost considerations, user experience is also key.

Ordinary folding cartons are cheap but often feel disposable and low-quality.

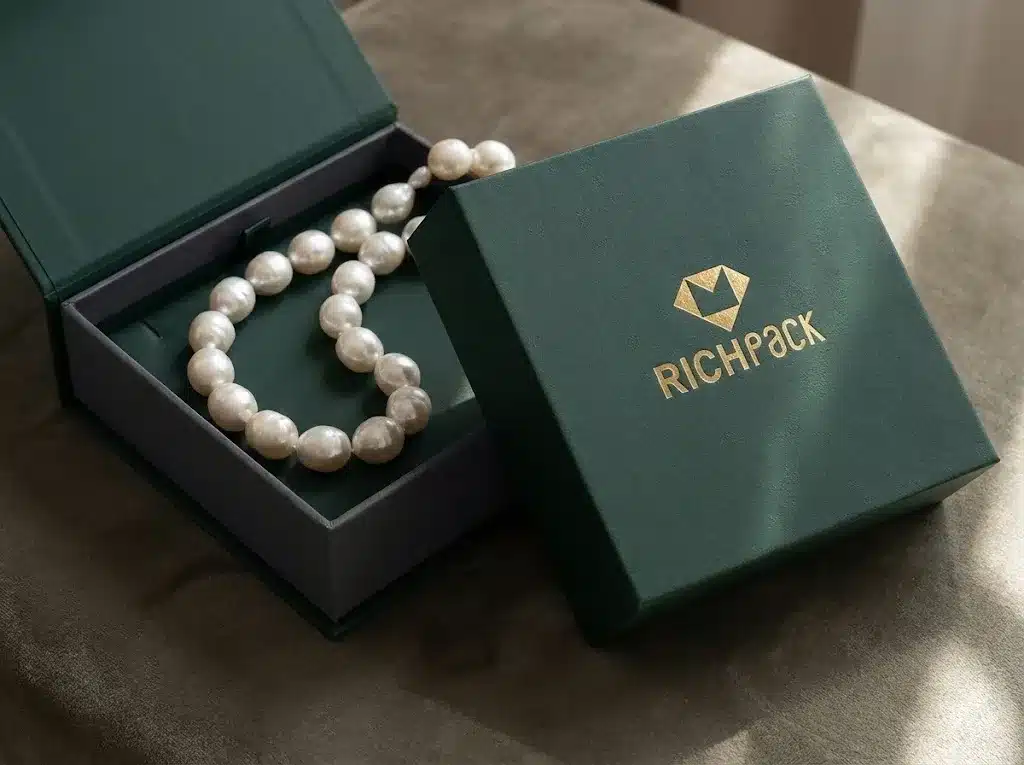

In contrast, the controlled damping and crisp “snap” of a magnetic box closing deliver a strong premium feel to customers.

In the jewelry industry, this sense of security is crucial. It sends a subconscious message to your customers: “The item inside is valuable, and we’ve protected it well.” This plays an undeniable role in reducing e-commerce return rates and boosting repurchase rates.

So when we talk about wholesale magnetic gift boxes, we are not just buying containers—we are investing in a brand asset that drives high conversion rates at minimal logistics cost.

Choosing the right box style is often more important than choosing the color.

It is not just about aesthetics; it directly determines your logistics costs and the end customer’s unboxing experience.

After handling hundreds of custom magnetic gift box orders, Richpack has compiled the most popular styles on the market.

This is the classic box-and-lid structure, usually consisting of a separate lid and base with magnets embedded along the edges for a tight seal.

Resembling a drawer, this box features an outer sleeve with a magnetic closure and an inner tray that holds the product.

Also known as book-style boxes, the lid is connected to the base by a spine and opens like a book.

A transparent PET or PVC window is embedded in the lid to showcase the product prominently.

This is currently the most strategically valuable option in B2B procurement. It combines the texture of rigid boxes with the logistics advantages of flexible boxes.

Featuring two layers like a jewelry case, the top layer usually holds the main product while the bottom layer stores certificates or accessories.

Two doors open sideways, just like pushing open a pair of luxurious gates.

Based on the traditional flip-top design, it adds an extended flap (usually triangular or semicircular).

Before partnering with new buyers, almost all of them have shared the same issue with us: “The samples we received looked perfect, but after storing the batch of custom magnetic gift boxes in the warehouse for three months, the lids started warping.”

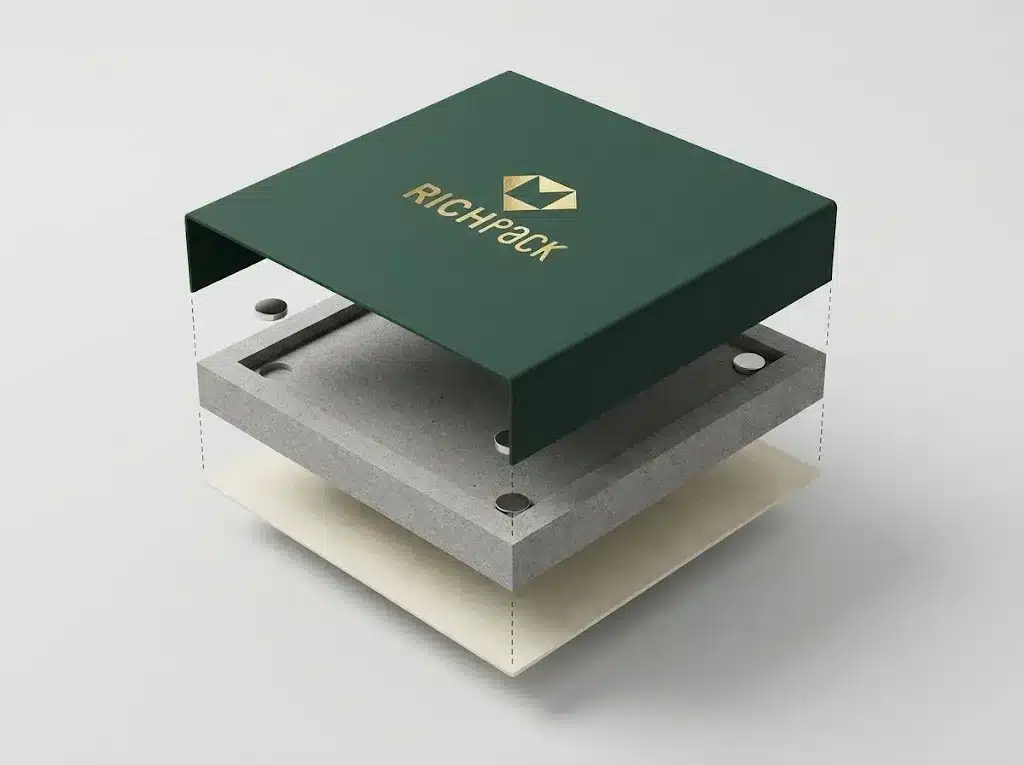

This is usually not bad luck—it is the result of choosing the wrong materials. A high-quality magnetic box is like a sandwich: the core support layer and surface decorative layer are equally important.

When planning your magnetic gift box solution, we ensure durability from three key aspects.

Cheap boxes on the market usually use low-density recycled cardboard. Although thick enough, it is as brittle as a biscuit.

For jewelry packaging, I highly recommend using high-density greyboard, typically ranging from 1000gsm to 1500gsm (about 2mm – 2.5mm thick).

Expert Tip: If you are unsure whether your current boxes meet standards, try pressing the center of the lid. If it dents easily, the greyboard density is insufficient (<800gsm). [The master guide to rigid box packaging for jewelry]

Greyboard determines strength, while exterior wrapping paper defines brand image and tactile feel.

This is the soul of a magnetic box. To achieve that crisp “snap” when closing the lid, we need to embed hidden iron sheets between greyboard layers.

The key to this process is concealment. We use precision die-cutting technology to ensure iron sheets are fully embedded inside the cardboard with a smooth, seamless surface. [Learn more about the mechanics and benefits of magnetic closure jewelry boxes]

Many suppliers use ordinary ferrite magnets to save costs, resulting in weak magnetism and loose lids.

At Richpack, we insist on using neodymium magnets for all high-end orders.

Neodymium magnets are currently the strongest permanent magnet material available. Two small neodymium magnets with a diameter of just 10mm can securely hold a lid weighing up to 2kg.

Have you ever encountered this situation: “The gold foil logo looked high-end on the design draft, but when you received the physical product, the edges were fuzzy and even peeled off with a light scratch?”

The magic of wholesale custom magnetic gift boxes lies in the details. As silent brand ambassadors, every finishing choice on the box communicates quality to customers.

Through assisting clients with sample production, I have summarized five essential customization considerations to help you strike the perfect balance between brand aesthetics and production feasibility.

Many first-time buyers choose ready-made factory sizes to save mold costs, but this is often a mistake.

In cross-border procurement, color consistency is the biggest nightmare. The Tiffany Blue on your screen may turn out turquoise when printed.

Visual appeal creates the first impression, while surface finishes enhance the tactile experience and highlight the logo. For understated luxury, try black foil on black paper for a stunning effect.

Inner trays are not just for securing products—they are also a stage for display.

A growing number of European and American consumers check if packaging is eco-friendly.

Faced with thousands of wholesale magnetic gift box options, it is normal to feel overwhelmed.

But making the wrong choice can cost you more than just a few dozen samples—it could lead to a full-quarter marketing disaster.

When helping a high-end jewelry brand redesign its packaging line, we developed a three-step decision-making model.

This model helped them cut through messy requirements and pinpoint the perfect solution that aligns with brand identity and controls operational costs.

Everything starts with your product. Don’t let the box define the product—let the box serve the product.

If your product is a solid gold bracelet, a standard 800gsm board won’t suffice—you need to upgrade to a rigid board of 1200gsm or higher.

First, measure the product’s three dimensions, then add a 15mm buffer zone to each side. A box that is too large looks empty; one that is too small risks squeezing and deforming the product.

If you only sell standardized stud earrings, universal flocked foam inserts may be sufficient.

But for products with complex shapes like pendants, only custom-molded EVA foam inserts can ensure they stay intact during cross-border shipping.

This is the most challenging part for most buyers—they want an attractive design but fear high shipping costs.

Minimalist brands may only need an elegant debossed logo, while vintage brands might opt for full-surface pattern printing. Ensure packaging aligns with your jewelry’s design language.

If your products are primarily displayed in physical stores, windowed magnetic boxes can significantly boost conversion rates.

If warehouse space is limited or you want to avoid expensive sea freight costs, foldable magnetic gift boxes are your savior. They reduce shipping volume by up to 75%.

For e-commerce brands with high daily order volumes, choose structures with self-adhesive corners to double packaging efficiency.

A perfect concept requires a reliable partner to bring it to life.

For direct e-commerce shipping, consider adding a translucent tracing paper with your brand story. This low-cost detail delivers an unexpected premium feel.

It is important to understand that customization is not always cheaper with smaller quantities. Usually, 1000 pieces mark the cost-effectiveness tipping point. Below this quantity, unit prices skyrocket due to mold cost allocation.

A good supplier won’t just say “yes”—they will advise you: “This printing method may cause fading; we recommend using another technique instead.”

Look for partners who provide consultative advice, not just order-takers.

This is a tricky question. Custom magnetic gift boxes themselves are made of cardboard and biodegradable, but embedded magnets do pose recycling challenges.

Don’t be misled by the term “standard magnetism.” Magnet strength must be selected based on lid weight and paper thickness.

Color variation is the biggest trust-killer in cross-border procurement. On-screen colors never perfectly match printed colors.

Many boxes look perfect when first received, but collapse after two months of storage. To avoid this pitfall, you can perform two simple tests yourself:

Choosing the perfect wholesale magnetic gift boxes for your brand is more than just selecting containers—it is a balancing act between brand premium and supply chain costs.

Throughout this guide, we have revealed how high-density rigid board is critical to durability, demonstrated how foldable structures can cut shipping costs by up to 75%, and explored how custom magnetic gift box details determine customer unboxing experiences.

In this highly competitive jewelry market, you need more than just a supplier—you need a strategic partner who understands design, craftsmanship, and most importantly, logistics cost control.

If this guide has answered your questions, you are ready to take the next step.

Instead of blindly trial-and-error with dozens of factories, let professional data guide your decision. Whether you need a logistics cost analysis or want to request pre-production samples that deliver that perfect “snap” sound, the Richpack team is ready to assist.

Don’t let poor packaging become the weak link in your brand story.

Just submit your email to get exclusive offers (reply within 12 hours)