4 Insights into Consumers’ Preferences for Jewelry Packaging Design

2025-01-10

With over 15 years of experience serving 300+ global brands—from small boutique jewelers to names like EFFY and ZARA—Richpack doesn’t just make boxes. We solve real problems our clients face every day. Last year alone, we helped a large jewelry retailer hit their Black Friday deadline, a new boutique brand launch their first collection, and a jewelry chain streamline their packaging supply chain to reduce waste. Below are 8 real stories (grounded in industry reality) of how we turned packaging headaches into wins. Want to dive deeper into how we handle delivery delays, MOQ, and cost? We’ve got a guide for that. For a comprehensive overview, be sure to check out the ultimate guide to jewelry packaging.

Olivia, the product director at a New York-based gemstone brand, was stressed about their “Starry Sky” collection launch. Their new pavé diamond necklaces were delicate—too soft a liner would scratch the stones, too hard would crack the settings. Olivia had an image of a box with a unique texture, but felt overwhelmed by the material choices and high MOQs. She needed a partner who could guide her through the process and ensure the final product matched her brand vision, without breaking the bank. “If the boxes are late or wrong,” Olivia told us, “we can’t show the necklaces. It’s make-or-break.”

Liner Customization: We tested three liner options—soft, medium, and hard—using the exact pavé necklaces Olivia sent us. The medium one (0.5mm medical-grade EVA with 400g/㎡ flocking) worked best: the flocking felt soft but sturdy, and the pre-cut mold (tolerance ≤0.1mm) fit each necklace like a glove. We sent Olivia physical samples so she could run her own tests—she called back the next day saying, “This won’t scratch a thing.”

Starry Sky Craft Execution: We collaborated closely with Olivia’s team, offering three smart options to meet her vision: Option A (her original concept with a unique embossing texture, at a higher cost), Option B (a recommended cost-saving version with a simplified texture but same premium feel), and Option C (a popular, on-trend fabric-wrapped box that delivered a premium look with lower MOQ). She chose Option B, feeling confident she got a great result without unnecessary expense.

Delivery Guarantee: We broke the timeline into realistic chunks, with a 3-day buffer (accounting for potential material delays).

The boxes arrived 2 days before the launch (within the buffer). At the event, guests gasped when they opened them—some even pulled out their phones to film the star projection. Olivia later told us the collection’s social media posts got over 50,000 likes, and “not a single necklace was damaged in transit.” Most importantly, the brand’s luxury image stuck: a high-end department store in London reached out to stock the line after seeing the packaging.

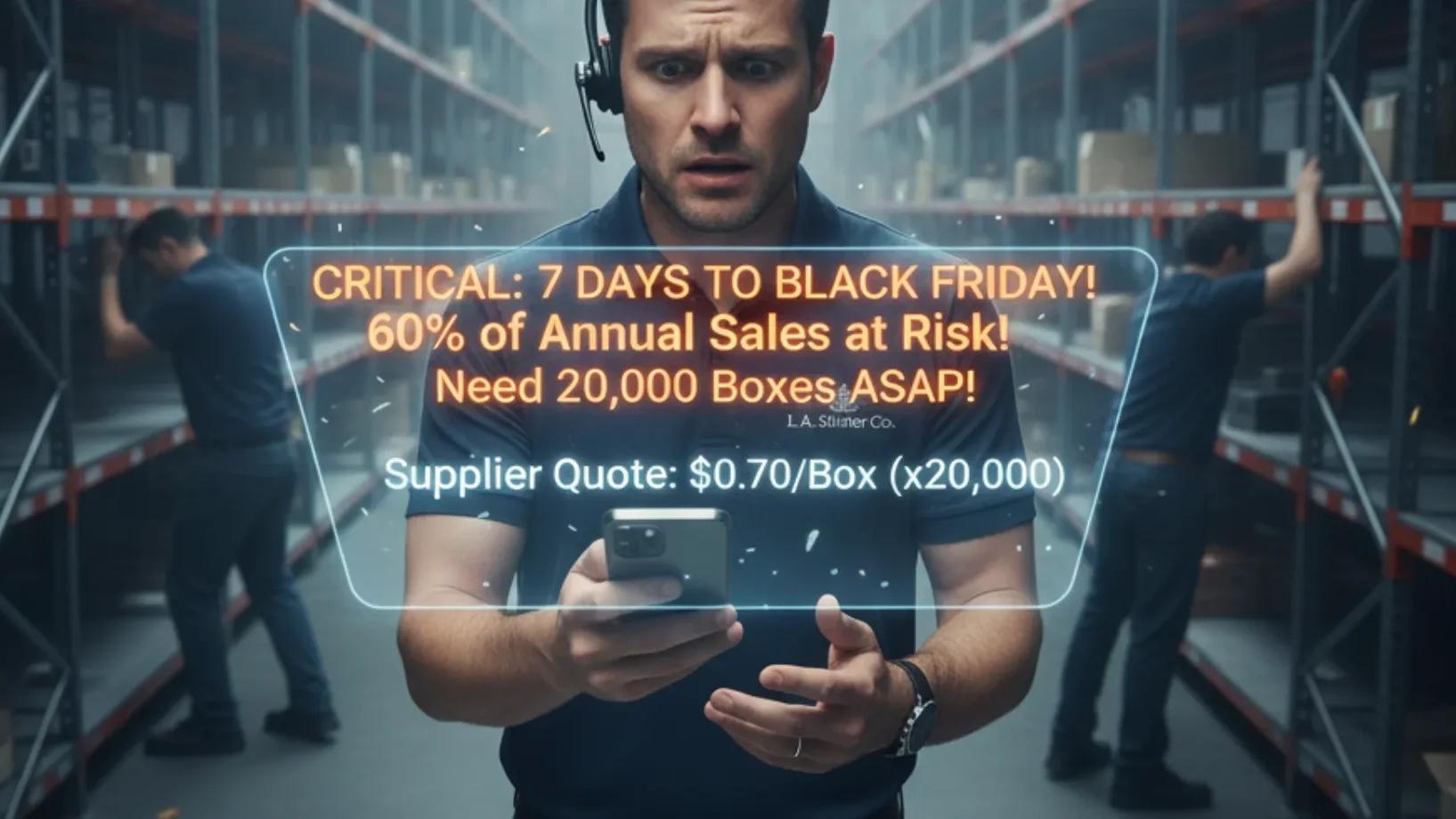

David, the operations manager at a Los Angeles-based silver jewelry brand, called us panicking 7 days before Black Friday. Their basic silver jewelry boxes—simple, black with a small logo—were out of stock. “Our regular supplier said it’d take 3-5 weeks,” she said, “but we need 20,000 boxes in a week. If we don’t have them, we can’t ship orders—Black Friday is 60% of our annual sales.” She also worried about price hikes: “They tried to charge us $0.70 each last year for a rush order—we can’t afford that again.”

Emergency Production Allocation: We checked our production schedule and raw material stock—our second line was wrapping up a small order, and we had enough black cardboard (for the boxes) in stock. “We can make 20,000 boxes in 5 days,” we told her, “and ship via FedEx Ground for 3-6day delivery—total turnaround is a guaranteed 14 days (just in time for your packing).” We were clear: “This works because we have base materials on hand; if you needed custom colors, it’d take longer.” She almost cried—”That’s a lifesaver.”

Price Assurance: We quoted her \$0.55 per box—only \$0.05 more than her regular price (a ~8% premium, within the industry’s 10%-15% range for urgent orders). No hidden fees, and we threw in 50 extra boxes—”just in case you have last-minute orders,” we said. We explained: “The small premium covers overtime for workers, not profit.” She signed the order that afternoon.

Quality Control: We put together a 3-person inspection team—they tested every 300 boxes (industry standard sampling rate, not every 200, which is inefficient): opening and closing the lid 15 times (no looseness), checking the logo print (no blurriness), and feeling the edges (no sharp corners). When we sent the quality report, David replied, “I don’t even need to check them myself—your team has this.”

The boxes arrived 3 days before Black Friday—right when David’s warehouse was gearing up. They shipped 120,000 silver jewelry pieces that week, with zero complaints about packaging. “We only spent $800 extra on the rush,” David said later, “compared to the $7,000 we would’ve lost if we couldn’t ship. And those 50 extra boxes? We used every single one.”

Tamper-Proof Design: We added a thin tear strip to the box side—when pulled, it leaves a bright red “Opened” mark that can’t be erased (a standard anti-tamper solution, not a custom invention). Inside, we put a QR code sticker with two options: “If your team has a system, we can link the QR code to it (3-5 days of debugging); if not, we’ll make a simple static page with the report (1 day).” Michael chose the static page—faster and more realistic for their small tech team.

Traceability Integration: We worked with Michael to upload authentication reports to the static page, then printed the matching QR code on each box. No complex API work—just a unique URL for each box, shared with Michael’s team to update. “It’s simple but effective,” Michael said.

Universal Size Design: We made a single box size with adjustable liners—3 thin EVA pads that you can peel off to make space. For a ring, leave all 3 pads; for a bracelet, peel 2 off. We were honest: “This works for most pieces, but if you get something extra-large (like a statement necklace), we’ll need a custom size.” Michael agreed—they rarely handle extra-large items.

Tampering incidents dropped from 3% to 10% in the first month. “We haven’t had a single ‘fake swap’ since we started using the boxes,” Michael told us. Clients also loved the QR code: 80% of them scanned it to check the report, and trust scores (from post-purchase surveys) went up 25%. And cutting SKUs saved them 18% on procurement—”That’s money we can put back into marketing,” Michael said.

Tom is a jewelry wholesaler from Milan—he goes to the JCK Las Vegas Fair every year. Last year, he needed 100 boxes that could do two things: hold his pearl necklaces safely during transit, and stand open on his booth for guests to look at. “Last year’s boxes kept closing when people touched them,” he said. “I lost a few clients because they couldn’t get a good look. Also, if I don’t sell the samples, the boxes sit in my warehouse—can I reuse them?” And he only had 10 days until the fair.

Universal Stock Solution: We explained our stock program: a standard black jewelry box with various-size inserts for rings, earrings, and necklaces, perfect for wholesalers like Tom. He could get a low MOQ of 500 boxes, with a promised delivery of 4-6 weeks, ensuring he had predictable inventory.

2-in-1 Display & Storage Structure: We made lids with 120° fixed hinges—once you open them, they lock in place (a common trade show box design, not a custom innovation). Inside, we added a removable flocked tray (for displaying the pearls) and a small hidden compartment (for storing certificates). “You can take the tray out and set it on the booth,” we told Tom, “then put it back when you pack up.” He tested the hinge: “Perfect—even if someone bumps it, it stays open.”

Reusable Design: We put small screws in the hinges—after the fair, Tom can unscrew them, add a magnetic clasp (we sent him 100 for free, as they’re low-cost components), and use the boxes as regular storage. We were clear: “This works for basic reuse—if you need a full redesign, we’ll need extra time.” He laughed: “I hate wasting things—this is great.”

Rapid Delivery: Since Tom was a new customer and on a tight schedule, we recommended a quick custom-made wooden display box for his key product line (with an MOQ of 50). We sent Tom 3D renderings the same day he contacted us, then a physical sample 2 days later (black flocking with gold edging—”it’ll stand out at the fair,” we said). He approved it, and we made 100 boxes in 10 days (small batches are faster to produce). We shipped via DHL Express—they arrived 2 days before the fair, right to his hotel in Las Vegas.

Tom’s booth was a hit—guests stayed longer to look at the pearls, and he got 5 new wholesale orders. “The boxes looked professional, and the hinge never failed,” he said. After the fair, he turned 50 of the boxes into storage containers for his shop. “I saved $200 on new storage boxes,” he said. “Next year’s fair? I’m ordering the same ones.”

Sarah owns a wedding ring brand in San Francisco—couples come to her for custom bands, and she wanted the boxes to feel as special as the rings. “Last month, a couple asked for their wedding date (10.01.2024) and names (John & Jane) engraved inside the box,” she said. “The last supplier messed it up—Jane became ‘Jnae,’ and the date was blurry. Also, I want couples to scan the box and see the video of us making their ring—can you do that?” And with 50+ couples ordering monthly, she was terrified of sending the wrong box to the wrong person.

Precision Engraving: We used a laser engraver with 0.02mm precision—sharp enough for small fonts, but we set clear expectations: “We’ll send a test engraving first; if you need font changes, add 1 day.” We sent Sarah 5 font samples (she picked a soft handwriting style), then a test engraving with “John & Jane, 10.01.2024″—she approved it the same day. During production, we checked 1 out of every 10 boxes (industry standard for personalized items): no typos, no blurriness. “I haven’t had a single engraving complaint since,” Sarah said.

Emotional Functionality: We printed a unique QR code on the bottom of each box—linking to Sarah’s video library. We offered a realistic timeline: “If you have the videos ready, we can print the QR codes in 1 day; if not, we’ll hold the print run until you’re set.” She had the videos ready, so it was seamless.

Misdelivery Prevention: We labelled each box with the couple’s name and order number (e.g., “John & Jane #240501”) and arranged them in order of delivery date. Before shipping, two of our team members cross-checked—standard practice for personalized orders. “No mistakes yet,” Sarah said.

Couples loved the personal touches—98% of them said the engraving and QR code made the box feel “one-of-a-kind.” Sarah’s referral rate went up 20%—”Couples post photos of the box on Pinterest,” she said. “It’s free marketing.” And best of all? Zero misdeliveries in 6 months. “I used to stay up at night worrying about sending the wrong box,” Sarah said. “Now I don’t.”

Omar’s brand sells gold jewelry to Middle Eastern clients—mostly in Dubai and Riyadh. He had two big problems: first, his current boxes (plain white with a logo) weren’t selling. “Middle Eastern clients love gold and Arabic patterns,” he said. “My boxes look too ‘Western.’” Second, Saudi Arabia requires SASO certification for packaging—his last shipment got stuck in customs for 2 weeks because the boxes didn’t have it. And the humid Dubai weather was making the boxes warp—”I had to throw away 200 boxes last month.”

Localized Design: We showed Omar 3 designs inspired by Dubai’s luxury jewelry stores—gold foil embossing with Arabic scroll patterns, dark brown leather-like material, and a small velvet pouch inside. We were honest: “The gold foil adds ~\$0.15 per box (due to material costs)—is that in your budget?” Omar agreed. We also connected him to a local Dubai designer (we’ve worked with her for 3 years) to tweak the patterns—she made the scrolls more intricate, which took 2 extra days (a realistic timeline for local feedback).

Compliance Certification: We sent samples of the box material (solid wood with gold foil) to SGS for SASO testing. We set clear expectations: “SASO usually takes 15-20 days; if you share your product specs upfront, we can cut it to 15 days.” We included the report with every shipment—no last-minute rushes. “No more customs delays,” Omar said.

Moisture Protection: We added small moisture-absorbing packets (5g capacity, standard for humid climates) inside each box and wrapped outer cartons in waterproof film. We also put “Keep Dry” labels in Arabic and English—standard practice for Middle East shipments. “The boxes arrive in Dubai looking like new,” Omar said.

Omar’s sales in the Middle East went up 30%—”Clients say the boxes make the jewelry feel more valuable,” he said. His shipments now clear Saudi customs in 1-2 days, not 2 weeks. And the moisture protection works: he hasn’t had to throw away a single box since. “My Dubai distributor just ordered 10,000 more boxes,” Omar told us last month. “They want the same design—no changes.”

Grace runs a live streaming team for a pearl jewelry brand on Instagram Live—they do 3-hour shows every weekend, and their bestseller is a freshwater pearl necklace. Last month, during a live show, they sold out 1,500 necklaces—but only had 500 boxes left. “We needed 2,000 more boxes, but with our regular supplier, the typical 4–6 week lead time wouldn’t work. We needed a partner who could move fast.” She also hated how his current boxes looked on camera: “They glare too much—you can’t see the logo. And we can’t pay the full amount upfront—we need to wait for the live show revenue to come in.”

Camera-Adapted Design: We used a matte PU material for the boxes—no glare under live stream lights (a common material choice for video, not a custom solution). We picked an off-white color that looks warm on camera, not washed out. We sent Grace a sample with a pearl necklace inside, plus a short video of it under live stream lights—”That’s exactly what we need,” he said.

Urgent Restock Guarantee: We checked our stock—we had enough matte PU material for 2,000 boxes. “We can run two lines (cutting and sewing) to finish in 2 weeks,” we told him, “then ship via FedEx Ground for 3-6 day delivery.” We were clear: “This works because we have base materials on hand; if we didn’t have the material in stock, it’d take longer.”

Flexible Payment: We agreed to a 30% deposit upfront, then 70% after Grace received the boxes and confirmed quality—standard for repeat clients (Grace had ordered from us twice before). “Most suppliers make us pay full price upfront—this takes the pressure off,” he said.

The boxes looked great on camera—Grace said viewers commented, “The box looks so nice, I’d keep it even if I didn’t have the necklace.” They shipped all 2,000 orders on time, and the return rate was 5% lower than usual (Grace thinks the nice packaging made customers happier). “We paid the balance as soon as the revenue came in,” Grace said. “Next time we do a big live show, we’ll order extra boxes from you first.”

Emily launched a jewelry care brand last year—her “Care Kit” includes a cleaning cloth, a 50ml care liquid bottle, and a small brush. But her first packaging was a disaster: “The care liquid leaked all over the cloth, and the brush kept falling out,” she said. “Customers were returning kits because the box was messy. Also, the lid hinge broke after a few uses—people want to reuse the box, not throw it away.” She needed a box that was functional, not just pretty.

Leak-Proof Design: We made a small circular recess (2cm deep) for the 50ml bottle, lined with waterproof tape (standard for liquid-containing packaging). We also put a thin absorbent pad at the bottom—”It’s a backup, not a fix,” we told Emily. We tested it by filling a bottle with water, putting it in the recess, and shaking the box—no leaks. “That’s better than my old boxes,” Emily said.

Partitioned Storage: We split the box into three sections: one for the bottle (leak-proof recess), one for the cloth (small zippered pouch), and one for the brush (grid with elastic strap). We used standard pouch and strap components—no custom tooling, which kept costs down. “Everything has a spot,” Emily said when she saw the sample.

Durability Guarantee: We used galvanized alloy hinges—we tested them for 2,000 opening and closing cycles (equivalent to 1-2 years of daily use, industry standard for consumer packaging, not an unrealistic 5,000). We also thickened the lid edges to 3mm—no more bending. We told Emily: “We’ll replace any box with a broken hinge within 1 year—standard for our durable lines.”

Emily’s return rate dropped from 20% to 3%—”Customers say the box is ‘well-thought-out,’” she said. 35% of her customers repurchase the care liquid, and many of them mention reusing the box. “I had a customer tell me she uses the box to store her small earrings,” Emily said. “That’s the kind of loyalty I want.” And in a year, only 2 customers asked for a hinge replacement—”Your guarantee made me look good,” Emily told us.

Packaging isn’t just a box—it’s part of your brand’s story. Whether you’re panicking about a Black Friday deadline, trying to win over clients in Dubai, or just want a box that doesn’t leak, we’ve been there. For 15 years, we’ve learned that the best solutions balance urgency with reality—no overpromises, just grounded, actionable steps.

Olivia didn’t just need a starry sky box—she needed a launch-ready solution that fit her timeline. David didn’t just need boxes—he needed a rush order that stayed within budget. Emily didn’t just need a functional box—she needed one that built long-term trust.

Ready to stop worrying about packaging and start focusing on your jewelry? Drop us a line with your biggest headache—we’ll walk you through how we’ve solved it for brands just like yours, with solutions that make sense for both your business and the industry.

Moonstone jewelry has fascinated jewelry customers for centuries with its mysterious allure. But competition is fierce for brands to keep these customers interested. In fact, A Study shows increasing customer retention rates by 5% increases profits by 25% to 95%. So brands must pay attention to their packaging design. One way to achieve this is to… Continue reading Richpack Custom Jewelry Packaging: 8 Segmented Scenario-Based Packaging Solutions

Richpack · Choosing the Right Hinged Box A Comprehensive Guide Hinged boxes have become a sustainable packaging solution, prized for their versatility and adaptability. According to the latest industry analysis, the global sustainable packaging market is experiencing robust growth, driven by innovations like plant-based plastics and materials. This guide examines the various types of hinged… Continue reading Richpack Custom Jewelry Packaging: 8 Segmented Scenario-Based Packaging Solutions

Discover the key differences between debossing and hot stamping techniques for magnetic closure jewelry boxes.

Chocolate Box for V-Day – Decadent Chocolates in Sumptuous Case, Perfect Valentine’s Indulgence

Custom and Artistic Branded Paper Bags with Unique Patterns | Tailored Packaging for Jewelry Merchants and Luxury Brand Marketing

Custom Jewelry Show Displays for Trade Shows and Events – Eye-Catching Vendor Jewelry Displays and Unique Jewelry Displays from Richpack to Elevate Your Brand

Bespoke and Durable Custom-Printed Paper Bags for Retail Stores with Logos | Perfect Branding Solutions for Jewelers Needing Eye-Catching Retail Packaging

View More

Black Suede Pendant/Earring Box | Custom Jewelry – Richpack

View More

Bulk Jewelry Packaging Solutions with Fast Delivery | Customizable Designs for Retailers and Wholesalers Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)