4 Best Ocassions for White Gift Boxes

2025-04-05

As a jewelry packaging specialist who has designed custom pieces for brands across three continents, our company have witnessed how a meticulously crafted engraved jewelry box transforms a simple purchase into an unforgettable brand experience. The perfect jewelry box isn’t merely a container—it’s an extension of your brand identity and a crucial touchpoint in your customer’s journey. Discover how expertly engraved jewelry boxes transform packaging into a lasting brand statement—blending art, function, and personalization to captivate customers and elevate your jewelry’s perceived value.

Jewelry engraving is a specialized technique for permanently marking surfaces with designs, text, or symbols. From ancient civilizations to modern times, this art form has evolved significantly, incorporating new technologies while preserving traditional methods. This transformation has made engraved jewelry boxes more relevant than ever in today’s market where personalization is increasingly valued.

When I first entered the industry, most small-batch jewelry boxes featured simple stamp work. Today’s options range from computer-guided precision to artisanal hand-carved masterpieces. This evolution mirrors the modern consumer’s desire for personalized experiences, making engraved packaging a powerful differentiator for jewelry brands.

Before any engraving begins, selecting the right base material is crucial. Each material responds differently to engraving techniques and impacts both aesthetics and durability.

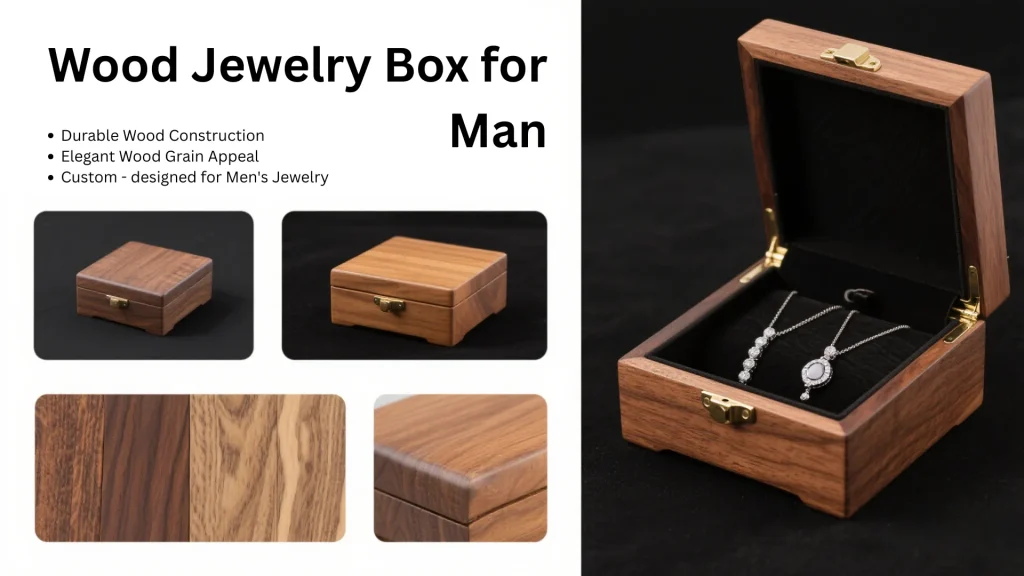

Wood remains the premium standard for high-end jewelry boxes. In our workshop, we select from exotic and domestic hardwoods to achieve different grain patterns and tones.

Hardwoods offer high density and stability. It is not easy to be chipped and deformed when carving, especially suitable for complex crafts such as relief carving, openwork carving and round carving.

Many wooden jewelry boxes feature marquetry embellishments or inlaid wood details, providing luxurious backgrounds for personalization.

Pewter provides an elegant, timeless option for smaller jewelry boxes. The classic handcrafted Southern Craftsmen pewter jewelry box, for instance, stands at 3/4″ tall with a 3″ diameter—perfect for rings and small pieces.

In recent years, we have expanded our material repertoire to include:

When advising clients on material selection, I always emphasize matching the material to both the engraving method and brand positioning. Sustainable luxury brands may prefer to use responsibly sourced hardwoods and hand-carve them, such as our FSC-certified wood, which is guaranteed to come from responsibly managed forests and supports environmentally conscious forestry practices. Contemporary fashion brands, on the other hand, may opt for laser-refined, boldly patterned pieces.

The heart of jewelry box craftsmanship lies in the engraving technique. Each method produces different aesthetic and tactile results, with important implications for production time, cost, and scalability.

Laser engraving utilizes focused light beams that heat and mark the surface material. This computer-controlled process excels at reproducing complex designs and tiny text with exceptional precision.

In our production facility, we primarily use laser engraving for small-batch premium jewelry boxes due to its clarity and scalability. The precision allows for consistent replication of intricate brand logos and detailed monograms.

Key characteristics include:

Hand engraving involves skilled artisans using specialized tools called gravers to manually cut into the material. This traditional method creates deeper marks with distinctive characteristics like varying line weights and subtle texture variations.

When I collaborated with a renowned European jewelry house, their insistence on hand-engraved packaging resulted in pieces so distinctive that customers would display the empty boxes as decorative items in their homes.

Key characteristics include:

Computer Numerical Control (CNC) carving combines computer guidance with mechanical etching. This method creates deeper, three-dimensional effects while maintaining repeatability across production runs.

Key characteristics include:

Stamp pressing uses heated die stamps for shallow imprints, creating a classic look particularly suited to leather or softwood jewelry boxes.

Key characteristics include:

| Engraving Method | Depth | Best Applications | Production Time | Unique Characteristics |

| Laser Engraving | 0.005-0.020mm | Precision logos, tiny text | Fast (24-48 hours) | Computer-precise, clean lines |

| Hand Engraving | Up to 0.5mm | Luxury pieces, artistic designs | Slow (Days to weeks) | Unique character, varying line weights |

| CNC Carving | 0.1-1.0mm | 3D textures, deep relief designs | Moderate | Deep, textural, dimensional effects |

| Stamp Pressing | 0.01-0.05mm | Vintage aesthetics, leather | Fast | Traditional look, consistent pressure |

In addition to the above common engraving methods, we also provide Pad Printing, Offset Printing, Flexo Printing, UV Printing and other common printing methods, which can bring different effects to your packaging.

Request a free sample and experience our quality workmanship for yourself. This enables you to evaluate the quality and suitability of our packaging solutions for your products.

While exterior engraving captures immediate attention, the interior craftsmanship determines functionality and lasting impression.

In our custom design practice, we have found that interior lining selection is just as important as exterior engraving. Most luxury jewelry boxes feature velvet or soft foam interiors that protect jewelry from scratches.

The process involves carving the inside dimensions to fit the foam or velvet, then adhering them with wood or craft glue. Unlike ordinary glues, Richpack’s glues meet the highest industry standards for safety, reliability and environmental compliance as certified by SGS. This careful attention to interior detail provides both protection and a luxurious feel when accessing the contents.

In addition to several common lining materials, we recommend the following options:

Creating functional compartments requires understanding jewelry types and customer usage patterns. To provide extra value, consider separating the box into compartments using dividers created from cardboard or slim wood. These dividers can be covered in cloth or painted to blend with the interior.

This specialized design creates individual segments ideal for varying kinds of jewelry pieces, allowing customers to sort their collections effectively. In our consultations with jewelry brands, we recommend:

Quality hardware elevates both functionality and perceived value. The jewelry box should have its hinges and clasps securely installed by marking positions on the back part and lid while attaching screws using a screwdriver.

Fastening a clasp at the front prevents accidental opening and makes it safer to store valuable pieces. Through my years of production experience, I’ve found that hardware quality often becomes a subconscious indicator of overall box quality for customers.

The final phase of jewelry box craftsmanship involves the details that transform a well-made container into a memorable brand touchpoint.

Beyond engraving, jewelry boxes can be enhanced with beads, rhinestones, stickers, or custom tags specific to your brand. Each box can be personalized by attaching these embellishments using a strong adhesive, ensuring they remain securely in place.

Other finishing options include:

Personalization transforms standard packaging into keepsakes. The engraving process allows for remarkable customization, including:

These personalized jewelry boxes make excellent gifts for special occasions like birthdays, weddings, anniversaries, or graduations. Our design team at Richpack leverages creativity, cutting-edge design tools, and industry-leading technology to craft custom jewelry packaging solutions that resonate with your brand’s vision. Whether you need custom jewelry packaging boxes or unique personalized jewelry packaging, we have the expertise to bring your vision to life.

According to this article, in 2025, trending personalization options include engraved initials, bridesmaid names, and birth flower designs.

Before completing any custom jewelry box, examine it for edges or areas that need improvement. Add any final touches or color adjustments to ensure it looks neat, polished, and professional. In our production plant, each engraved box is thoroughly inspected before shipment, and an automated system that monitors and adjusts production parameters in real time ensures that your goods are both beautiful and durable.

As a jewelry brand owner or packaging wholesaler, selecting the right engraving approach represents a strategic decision that impacts production capabilities, customer perception, and price positioning.

| Brand Positioning | Recommended Techniques | Material Considerations | Production Implications |

| Ultra-Luxury Artisanal | Hand engraving, Deep carving | Exotic hardwoods, Fine metals | Longer lead times, Premium pricing |

| Contemporary Premium | Laser engraving, Machine engraving | Domestic hardwoods, Leather | Moderate lead times, Scalable production |

| Accessible Luxury | Laser engraving, Stamp pressing | Sustainable woods, Quality cardboard | Faster production, Cost-effective scaling |

| Mass Market Gifting | Digital printing, Simple laser | Composite materials, Cardboard | Rapid production, Volume efficiencies |

We own and operate three plants, work with three subcontracting plants and have invested in a plant in Vietnam. We also have a 20,000 square foot warehouse in New York. This global footprint allows us to efficiently manage production and storage and meet large-scale demand.

For startup brands, We typically recommend beginning with laser engraving on quality domestic hardwoods—this provides an excellent balance of perceived value and production efficiency. We actively use automated manufacturing techniques to precisely control production speeds and material usage, minimizing waste and energy consumption. And we offer flexible MOQ and step pricing to minimize your costs. As your brand scales, consider how your engraving choices might evolve to maintain quality while meeting growing demand.

The craftsmanship involved in creating engraved jewelry boxes represents far more than packaging—it’s about creating vessels worthy of holding precious memories. The techniques we’ve explored demonstrate the rich tradition and innovation available to modern jewelry brands.

As consumer preferences continue to evolve toward meaningful experiences and personalization, investing in quality engraved packaging becomes increasingly strategic. Whether you’re a luxury jeweler seeking heirloom-quality presentation boxes or a contemporary brand looking for distinctive packaging that scales, understanding these craftsmanship techniques provides a foundation for making informed decisions.

The right jewelry box doesn’t just protect a product—it tells a story, creates an experience, and builds lasting connections with your customers. By thoughtfully selecting materials, engraving techniques, and interior designs that align with your brand values, you can create packaging that elevates both perception and customer satisfaction.

Ready to elevate your jewelry packaging with expert craftsmanship? Consider how these various engraving methods might align with your brand values and customer expectations, then contact us, we can bring your vision to life with precision and care.

Create a unique small wooden jewelry box with this guide. Learn to use basic tools and affordable materials. Customize designs with engraving, lining, and hardware.

After a late-night wipe down of his Audemars Piguet Royal Oak, the case pinched in a plain velvet box, and Mr. Lin was determined to find a “proper home” for his watch. On the advice of Richpack‘s bespoke consultants, he was able to touch the natural annual rings of the 50°N walnut – an FSC-certified… Continue reading The Art of Craftsmanship: Exploring Engraved Jewelry Box Techniques

Hey there, gift-giving gurus and presentation pros! Are you ready to transform your thoughtful presents into absolutely unforgettable experiences? Then buckle up, because we’re diving headfirst into the dazzling world of fancy gift boxes! Forget the humdrum wrapping paper – we’re talking next-level presentation that screams “You’re special!” before the lucky recipient even peeks inside.… Continue reading The Art of Craftsmanship: Exploring Engraved Jewelry Box Techniques

Personalized Leather Jewelry Box – Customizable with Name Engraving & Spacious Compartments

Affordable Jewelry Bags Wholesale for Professional Packaging – High-Quality Wholesale Jewelry Bags for Retail and Gift Solutions

Are Brown Paper Bags Recyclable – Learn About Green and Eco-Friendly Paper Recycling Bags and More Available Sustainable Options for Packaging

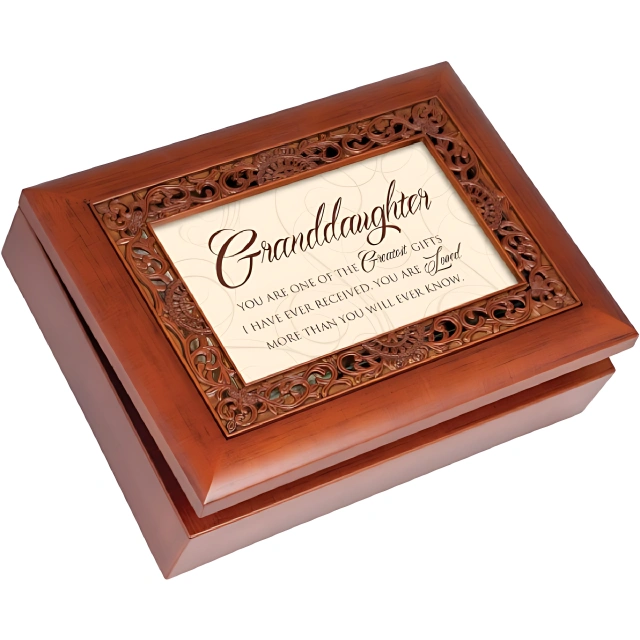

Custom-crafted Personalised Granddaughter Jewellery Box: A Cherished Heirloom in the Making

View More

Girls Jewelry Box | Unicorn Jewelry Boxes with Drawers for Little Girls & Teenagers Personalized Custom Engraved Jewelry Boxes for Girls

View More

Personalized Leather Jewelry Box – Customizable with Name Engraving & Spacious Compartments

View MoreJust submit your email to get exclusive offers (reply within 12 hours)