6 Packaging Strategies for Napier Jewelry

2024-12-13

As a brand, have you ever searched for the ‘best jewelry box‘ only to find results for personal storage? This is a core problem for businesses: consumer search terms rarely lead to strategic business solutions. This guide is designed to solve that problem, providing a framework for businesses to define what “best” truly means and how to find a packaging partner who can deliver that strategic asset.

The “best” jewelry box is not a one-size-fits-all product. It’s a custom packaging solution designed for your specific business goals, operational scale, and brand identity. Understanding your core drivers is the first step in identifying the right packaging partner. A supplier with over 15 years of experience, for example, has likely encountered and solved challenges for all types of businesses. Which of these profiles sounds most like you?

| Business Profile | Primary Goal | Core Pain Point | “Best” Solution is… |

| Enterprise | Reliability & Scale | Supply chain disruption | A system built for predictability and zero defects. |

| Startup | Design & Innovation | Lack of expertise, high costs | A collaborative, guided creation. |

| Pragmatist | ROI & Optimization | Inefficient spending | A clear balance of cost and value. |

For large, established retailers like ZARA or Marks & Spencer, “best” means reliability is the primary requirement. Your main concern is a predictable supply chain where every step, from material sourcing to final delivery, is coordinated to prevent delays. A missed deadline can jeopardize a national product launch or a critical holiday sales season.

You need a packaging partner who operates with defined processes and has a documented, high-volume production capacity—for instance, the ability to produce up to 3 million pieces per month. This partner must maintain consistent quality control across continents and manage complex logistics. For you, the best jewelry box is the one that arrives on time, on budget, every single time. This allows you to focus on sales and marketing, not on managing your packaging supplier.

For new and emerging brands, “best” means a product developed with a partner that helps you make a strong first impression. You are not just buying a box; you are investing in your brand identity. You need a packaging partner who acts as a guide, providing expert advice on packaging materials, explaining current design trends, and helping you achieve a premium look without the burden of large order quantities.

This is especially true for brands targeting specific niches, whether it’s creating the best kids jewelry box for a younger audience or a sentimental best wishes jewelry box for the gifting market. Specific packaging solutions like custom rigid paperboard boxes, for example, can offer a luxurious feel with accessible low MOQs (Minimum Order Quantities). This approach addresses a major concern for new businesses, allowing a jewelry box for startups to compete with established players in the unboxing arena.

For the pragmatic brand manager or seasoned business owner, “best” is defined by a clear balance of cost and value. You understand the effect of custom packaging, but every dollar must be justified. You need a supplier who doesn’t just take orders but actively seeks to improve them.

This packaging partner analyzes your initial concept and offers specific alternatives—like a different material that reduces weight and shipping costs, or a design that is faster to assemble—potentially reducing labor costs by up to 15% per unit.. This wholesale jewelry packaging approach ensures every investment in luxury packaging yields a clear return.

No matter your business goal, a successful jewelry packaging strategy is built on three core pillars. A focus on these will ensure your final product is not only beautiful but also functional and strategic. An experienced, one-stop-shop supplier can provide specific advice across all three areas.

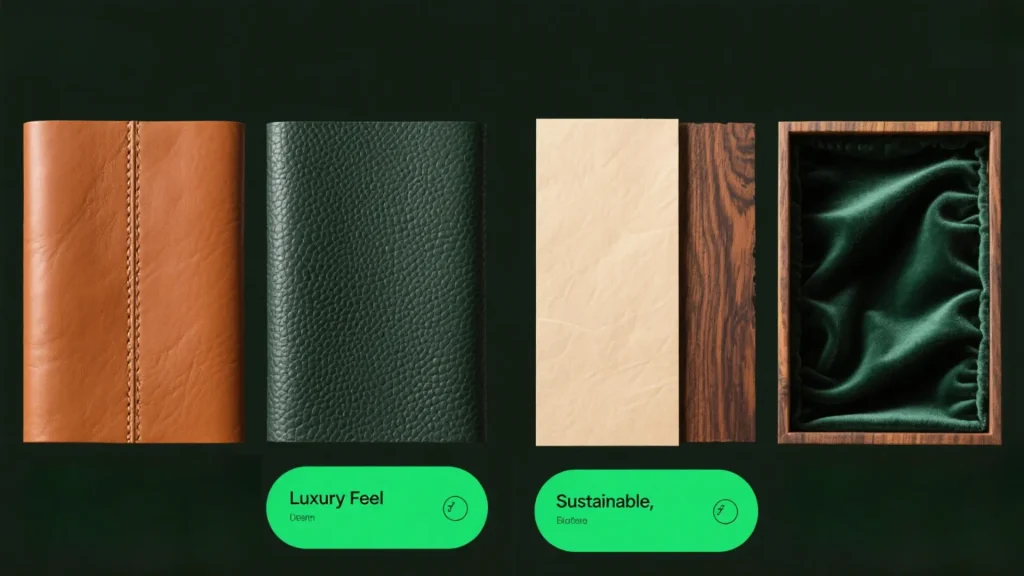

The packaging materials you choose are the foundation of what the customer feels and a reflection of your brand’s values. While options like rigid paperboard, wood, and leatherette all have their place, a strategic choice considers perceived value, durability for shipping, cost at scale, and sustainability. For brands aiming to create the best wooden jewelry box, the conversation goes deeper.

They must consider what consumers perceive as the best wood for jewelry box construction—be it the classic appeal of mahogany or the sustainable choice of bamboo. Furthermore, the best finish for jewelry box design, whether a high-gloss lacquer or a natural matte oil, directly affects the perceived luxury and durability. A supplier committed to high-standard, non-fading materials is essential to protect the jewelry inside and preserve the brand’s image.

This focus extends to the interior. End-consumers consistently look for high-quality linings like soft felt or plush velvet to protect their treasured items. Ensuring your jewelry packaging meets this expectation is a required part of a premium experience. The choice of a velvet lining over a standard paper insert can increase the perceived value of the piece within.

Your packaging is an effective marketing tool that communicates your brand identity long after the sale. Customization details turn a simple box into a brand story. To see these principles in action and explore a range of possibilities, you can view our jewelry box collection page. This goes beyond simply printing a logo. Techniques like hot stamping, debossing, foil stamping, or spot UV can add texture and visual appeal. The structure itself, from magnetic closures to ribbon pulls, contributes to the customer’s experience.

Understanding the specific design language needed to create the best jewelry box for girls, or even the best jewelry box for little girl, opens up specific market segments that require certain customizations. For high-value items, security is part of the brand identity, making the development of the best locking jewelry box a feature that adds value by protecting the customer’s purchase.

Consider every layer: a branded outer shipping box, custom tissue paper, the primary jewelry box, a perfectly die-cut insert holding the product securely, and perhaps a personalized thank-you card. Each step is an opportunity to reinforce your brand and increase the likelihood of customer loyalty and social media shares.

Ultimately, the “who” is more important than the “what.” The best box comes from the best packaging partner. This is a supplier who not only understands your strategic goals but also possesses the technical manufacturing knowledge to produce your design accurately and within budget. A great idea is worthless if your packaging supplier cannot execute it.

They should be able to foresee potential production issues with a design, suggest viable alternatives, and manage the entire process from prototyping to final delivery. This “design-to-delivery” or “one-stop” service model is what separates a simple order-taker from a true partner. To see who the industry leaders are, you can consult our list of the Top 25 Jewelry Packaging Manufacturers and Suppliers (2025). A partner trusted by over 300 global brands brings a level of experience and reliability that is hard to replicate.

Give yourself clarity and confidence in your selection process. A true packaging partner will welcome these questions. Use this checklist to vet any potential supplier and ensure you find a partner aligned with your needs for luxury packaging.

The search for the “best jewelry box” isn’t about finding a product in a catalog. It’s a strategic journey that ends when you find the right packaging partner—one who understands your business, anticipates your needs, and has the knowledge to deliver a packaging solution that supports your brand’s growth.

Whether your goal is to find inspiration from the Top 10 Luxury Jewelry Packaging Designs to Impress Your Clients or to build a practical, durable solution for travel, the core principles remain the same. By focusing on the three pillars of materials, customization, and supplier quality, you can make an informed decision that results in customer loyalty, a stronger brand perception, and smoother operations. For a complete overview of the entire process, our The Ultimate Jewelry Packaging Guide: From Budget to Design, Solving Every Challenge is the perfect next step.

A partner like Richpack, which offers a one-stop procurement experience from design to delivery, demonstrates these principles. With over 15 years of dedicated experience in high-quality custom packaging for the jewelry, apparel, and cosmetics industries, they provide the reliability, design knowledge, and competitive pricing needed to produce your packaging concept.

Ready to find a packaging solution that fits your business goals? Whether you’re an enterprise, a startup, or an optimizer, contact our team for a tailored strategy consultation.

Recyclable packaging that merges luxury with sustainability. Our efficient, low-energy process delivers premium quality that protects your brand and your bottom line. A streamlined system proven to reduce material waste by up to 15% and cut lead times by an average of 10% compared to traditional production models. We engineer solutions that solve the core conflict between… Continue reading What Makes a Jewelry Box the “Best”? A Strategic Guide for Brands

Do leather jewelry boxes appeal to men? Explore how leather’s durability, masculine aesthetics, and premium feel meet men’s storage needs.

Richpack · From Design to Production The Whole Process of Julie Vos Jewellery Packaging The global jewellery market is experiencing remarkable growth. It is estimated that the market size will reach 35.326 billion US dollars by 2030, with a compound annual growth rate of 4.6%. Despite the fierce competition in the market, Julie Vos has… Continue reading What Makes a Jewelry Box the “Best”? A Strategic Guide for Brands

Elegant and Compact Jewelry Ring Storage Case for Secure and Stylish Organization | Richpack 2025 Customizable Ring Holder Jewellery Box

Luxurious Jewelry Display Bust for Showcasing Necklaces and Accessories – Customizable Jewelry Bust Displays Perfect for Retail Stores and Exhibitions

Artistic Embroidered Quilted Boxes | Embellished with Embroidery for Artistic Gift Packaging

Best Jewelry Box with Lock | Elegant & Secure Jewelry Storage for Your Precious Collection | Richpack

View More

Christmas Gift Wrap – Gorgeous Wraps Infused with Christmas Enchantment for Memorable Gifts

View More

Custom Earring Storage Boxes for Travel Durable and Stylish Solutions for Jewelry on-the-go with Trade Pricing Richpack Manufacturer Direct

View MoreJust submit your email to get exclusive offers (reply within 12 hours)