How to Choose the Best Gift Box with Lid for Your Brand: The Essential Guide

2025-04-15

Do you want to know why the price of 500 custom jewelry boxes is the same as that of 100? In this article, we will uncover the truth behind the minimum order quantity, hidden setup fees and production restrictions. As a jewelry packaging supplier that collaborates with over 300 high-end jewelry brands worldwide, Richpack Packaging will analyze your capital flow in detail in this article and guide you on how to achieve the best return on investment.

MOQs for wholesale jewelry boxes differ significantly among suppliers and are largely determined by production efficiency and customization requirements.

1.1 Low MOQs (1-100 units)

Some suppliers, particularly online marketplaces or those catering to small businesses, offer MOQs as low as 1 to 48 units for stock items or basic customization. This is ideal for startups or testing new products.

1.2 Standard MOQs (100-500 units)

Many suppliers, especially for custom logo printing on standard jewelry box structures (like cardboard drawer boxes), have MOQs in this range.

1.3 High MOQs (500-1,000+ units)

For fully custom-designed boxes (unique shapes, complex structures, specific finishes), the typical MOQ is 500 to 1,000 units or more. Larger volumes allow manufacturers to spread fixed costs like molds and tooling over more units, making it more cost-effective for them.

It is the most common friction point in the packaging industry: A brand wants 200 custom rigid boxes to test a new men’s jewelry line, but the factory quotes a Minimum Order Quantity (MOQ) of 1,000. Or worse, the price for 200 boxes is astronomically high—almost the same total cost as ordering 500.

Is the factory simply refusing small orders? Not quite.

The reality lies in the physics of industrial manufacturing.

In this guide, Richpack breaks down the hidden “Fixed Costs” that dictate wholesale pricing. We will show you exactly where your money goes and how to manipulate the variables—Material, Labor, and Logistics—to get the best ROI for your brand.

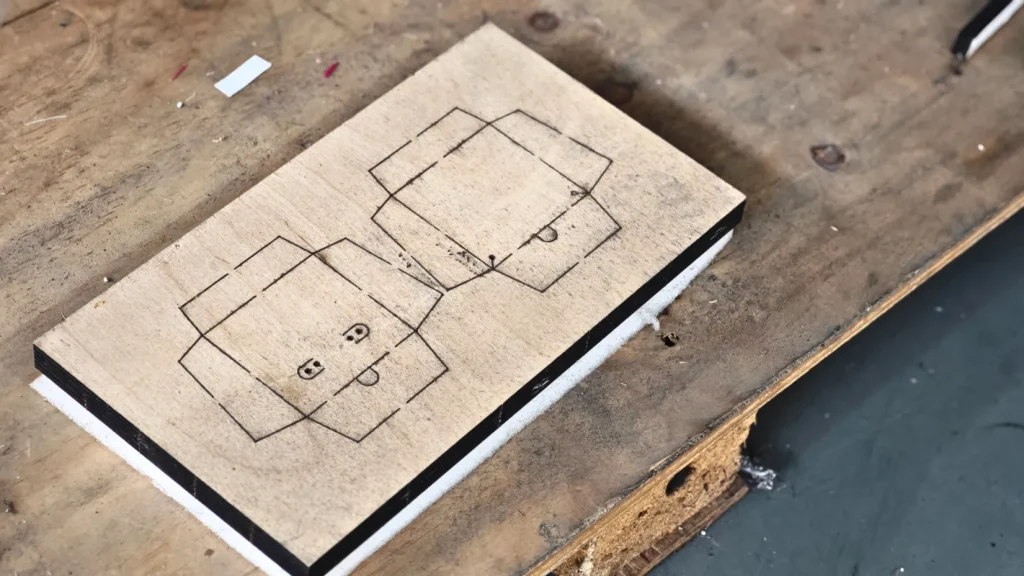

To understand why customized packaging has a high entry threshold, you must understand “Make-Ready” (the industry term for machine setup).

Unlike digital printing (which is click-and-print), producing a high-quality rigid jewelry box involves a chain of industrial equipment: offset printers, die-cutting machines, foil stampers, and lamination rollers.

Before a single box is produced, the factory incurs Fixed Costs:

The Mathematical Reality:

Imagine these fixed setup costs total $400.

High MOQs are not arbitrary; they are the break-even point where the setup cost becomes negligible per unit.

Here is an insider detail most suppliers won’t tell you: Often, the MOQ is not set by the box factory, but by the paper mill.

If you choose a standard black art paper, we likely have tons of it in stock. However, if you demand a custom-dyed “Midnight Blue” textured paper, we cannot buy just 50 sheets.

Expert Advice:

To lower costs on smaller runs, ask us for our “Stock Paper Swatch Book.” Using a premium paper we already have in the warehouse avoids the mill’s MOQ entirely.

Let’s analyze the cost structure of a standard Hinged Lid Rigid Box (Watch/Cufflink style) to see how volume transforms the unit economics.

| Cost Component | At 500 Units (Small Batch) | At 3,000 Units (Mass Production) | Why? |

| Material Cost | High | Medium | Bulk buying power reduces raw material rates. |

| Labor Cost | High | Low | Critical Factor: At 3,000 units, we can set up a semi-automated flow line. At 500 units, boxes are often hand-wrapped, which is slow and expensive. |

| Setup Amortization | Very High | Negligible | Fixed costs are spread over more units. |

| Unit Price | $3.50 – $5.00 | $1.80 – $2.50 | ~50% Cost Reduction |

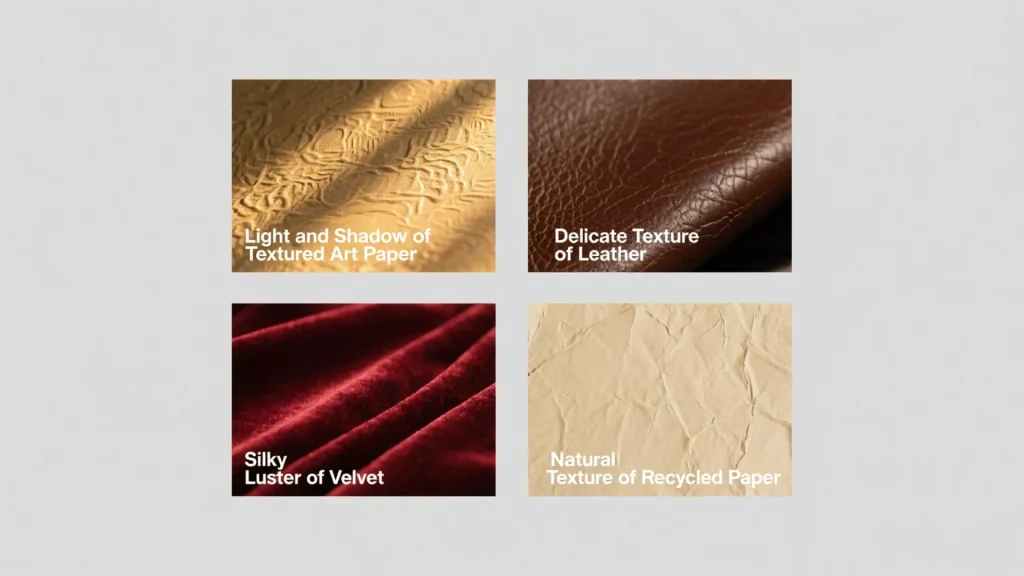

Materials like cardboard are generally less expensive than velvet, wood, or high-end PU leather. To understand the cost and aesthetic differences between these premium options, read our in-depth comparison: Leather vs. Wood vs. Velvet: Men’s Jewelry Box Guide.

Complex designs, unique shapes, and specific finishes (like foil stamping) increase both the per-unit cost and the MOQ.

International suppliers, particularly from places like China, often have very competitive pricing but may involve import regulations and longer lead times (typically 4-8 weeks for custom orders).

The most significant factor in achieving lower per-unit pricing is the total quantity ordered.

If you cannot increase your volume, you can still optimize your costs by “Designing for Manufacturing” (DFM).

Instead of a custom size, ask for our “Existing Mold List.”

If we have an existing knife mold that is 10cm x 10cm x 5cm, and you use it instead of creating a 10.5cm box, you immediately save the Die-Cut Mold Fee (approx. $100-$200). You can still customize the print and insert, but the structure is free.

Do you sell rings, cufflinks, and tie clips?

Instead of ordering 500 Ring Boxes, 500 Cufflink Boxes, and 500 Tie Clip boxes (three separate setups), design one universal box with a clever foam insert cut to hold any of these items.

Rigid boxes are essentially “shipping air.”

Many manufacturers will simply quote you a high price and walk away. At Richpack packaging, we act as your packaging consultants.

Stop overpaying for inefficiency.

Contact our engineering team today. We will review your design and suggest specific tweaks to lower your MOQ threshold and unit price.

Get a Strategic Quote Analysis

No. Mold and plate fees are one-time costs. If you re-order the same design (even months later), you only pay the unit price. The tools are stored in our factory dedicated to your brand.

Generally, no. If you want 500 boxes, and you want 250 Blue and 250 Red, that requires cleaning the ink fountains and making new plates, which triggers a new Setup Cost. However, if you just change the hot foil color, it is cheaper than changing the ink color.

Finish techniques like Hot Foil Stamping or Debossing is often more cost-effective for small runs than full-color printing, as it avoids complex ink calibration.

A collapsible box is made of the same greyboard and paper materials, so it feels just as premium and heavy. The only difference is the corner construction, which allows it to fold flat.

Yes. Once you confirm the dimensions, our engineers provide a free, production-ready die-line file for your designer to work on.

In this digitally-driven world, we crave authentic touches and thoughtful surprises more than ever. Monthly gift boxes, with their carefully curated themes, high-quality products, and constant freshness, have become the perfect medium for conveying emotion. For businesses, monthly gift boxes are an excellent way to build brand loyalty and enhance the customer experience. Customized gift… Continue reading Wholesale Jewelry Boxes: MOQ & Pricing Guide

Nowadays, the continued rise in raw material prices, coupled with the increased demand for environmentally friendly and sustainable packaging, makes procurement more complicated. At the same time, importing from overseas may also face additional tariffs and shipping costs, further pushing up the overall expenses. In this situation, wholesalers and bulk buyers in the United States… Continue reading Wholesale Jewelry Boxes: MOQ & Pricing Guide

Implementing the right packaging strategies can lead to significant cost savings in a relatively short period.

Functional and Adorable Small Jewelry Box for Necklaces – Protect and Organize Your Treasures

Light Up Gift Boxes for Christmas | Creative Lighted Gift Boxes Set Of 3 Illuminated Holiday Packaging and Gift Box Decorations

Personalized Luxury Packaging for Premium Skincare Products | Bespoke Packaging Solutions for High-End Beauty Merchants Needing Branded Appeal

Durable Magnetic Closure Rigid Boxes with Silk Inserts for Premium Gifts | Tailored for Luxury Brands Seeking High-End Presentation for Corporate Gifting

View More

Elegant Stackable Gift Boxes for Stylish Gifting | Nesting and Stackable Boxes for Gifts with Customizable Designs and Sizes by Richpack

View More

Elegant Jewelry Boxes for Women | Practical Women’s Jewelry Box for Mom & Wife Spacious and Stylish Storage Solutions for Ladies’ Precious Collections

View MoreJust submit your email to get exclusive offers (reply within 12 hours)