How to Measure Jewelry Box Dimensions

2025-05-15

Industry experts and professional organizers agree: a custom-fit drawer tray is the single most effective method for protecting and organizing a valuable jewelry collection. It addresses the core failures of standard storage—wasted space and potential damage—by creating a tailored, protective environment for every piece you own.

This philosophy is increasingly being adopted by luxury jewellers themselves, who now often design their high-value presentation boxes with removable inserts that can be transferred directly into a client’s drawer. This trend, seen in packaging from brands like Cartier and Tiffany & Co., underscores the industry’s recognition that long-term care begins with proper, purpose-built storage. The transition from a retail box to a personal drawer becomes a seamless continuation of the luxury experience.

This definitive guide provides two clear paths to achieving this solution. We will detail the exact, step-by-step methodology for a professional-grade DIY project. We will also present an expert framework for evaluating and purchasing the best pre-made organizers on the market.

To understand the value of a custom tray, we must first analyze the fundamental flaws in common storage methods. Standard jewelry boxes and generic drawer dividers fail on two critical fronts: spatial efficiency and collection-specific protection. A custom tray directly solves these issues.

From a material science perspective, the primary goal of jewelry storage is the mitigation of micro-damages. High-end jewelers will attest that the cumulative effect of tiny scratches and abrasions from improper storage is the leading cause of diminished brilliance in gemstones and luster in precious metals over time. A custom tray isn’t just about organization; it’s a preventative conservation tool that actively preserves the financial and sentimental value of your collection.

Most commercial jewelry boxes utilize a one-size-fits-all design. This generic approach inevitably leads to inefficient storage, forcing long necklaces into small squares and leaving no adequate space for unique items like brooches or statement pieces. The result is organized clutter, not true organization.

This design flaw is a direct consequence of mass production, where the goal is to appeal to the broadest possible market, not to serve the specific needs of a curated collection. A prime example is the lack of consideration for modern jewelry trends, such as oversized hoop earrings or layered pendant necklaces, which are notoriously difficult to store in traditional, grid-based layouts. The inefficiency is not just spatial; it’s a functional disconnect from the very items it’s meant to protect.

Your jewelry represents a significant investment. When items are stored in loose contact, metals abrade, gemstones can chip, and delicate chains become tangled. A custom tray with fabric-lined, individual compartments isolates each piece, creating a zero-friction environment that prevents physical damage and minimizes exposure to air, thereby slowing oxidation.

The principle of isolation is paramount in archival conservation and is directly applicable here. Consider the Mohs scale of hardness; a diamond (10) will easily scratch a sapphire (9), and both will abrade softer metals like gold (2.5-3). Individual compartments, therefore, act as a physical barrier that respects the unique material properties of each item. Furthermore, by limiting airflow across surfaces, especially for sterling silver, the rate of sulphide-induced tarnishing is significantly reduced, decreasing the need for frequent, potentially abrasive polishing.

A custom solution empowers you to design a layout based on your actual collection. This means creating purpose-built compartments: long, undivided channels for necklaces; a grid of small squares for rings and earrings; and larger sections for bracelets and watches. This approach ensures immediate visual access to your entire collection.

This concept of “visual inventory” is a key principle in professional organizing. When every piece is visible and easily accessible, you are more likely to wear a wider range of your jewelry, maximizing the return on your investment. It also allows for quick condition assessments, enabling you to spot a loose stone or a damaged clasp before it becomes a critical issue. Case studies from custom closet designers show that clients report wearing up to 50% more of their accessories after implementing a tailored tray system.

Drawer space is a finite and valuable resource. A tray custom-built to the exact internal dimensions of your drawer achieves near-100% spatial efficiency. It transforms a deep, underutilized space into a structured, single-layer system where no item is hidden or buried.

In the context of luxury retail and high-end residential design, this is referred to as “optimizing the cube.” By creating a full-footprint insert, you eliminate the dead space at the perimeter where items can slide and become lost. For deeper drawers, this allows for a tiered system using stackable trays, effectively creating multiple layers of perfectly organized storage within the same footprint, a technique frequently used in the design of professional jewelers’ vaults.

With the need for a custom solution established, the next step is to select your implementation strategy. To determine the optimal path, we have developed a decision framework based on three key variables: Time, Budget, and Customization Specificity.

This decision also hinges on your long-term vision for your collection. If your collection is relatively stable, a highly specific DIY or bespoke solution is ideal. However, if you are actively acquiring new pieces, a high-quality modular system from a reputable manufacturer might offer better long-term flexibility and scalability, allowing your storage to evolve with your collection.

The DIY approach offers maximum customization for minimal material cost, but demands the highest investment in time and personal skill. Purchasing a solution is the most time-efficient and guarantees a professional finish, but carries a higher financial cost.

It’s also important to factor in the “cost of error” in a DIY project. A miscalculation in measurement or an imperfect fabric application can lead to a result that is functionally compromised or aesthetically disappointing, potentially requiring a complete restart. Commercially produced trays benefit from precision cutting machinery and standardized assembly processes, which virtually eliminate such risks.

The DIY path is the correct choice if you enjoy hands-on projects, require a solution for a non-standard drawer size, or have a highly specific layout in mind that is unavailable commercially. The process itself is rewarding and the outcome is a truly bespoke organizer.

This route is particularly well-suited for individuals with antique or heirloom furniture, where drawer dimensions are often non-standard. It also serves collectors of niche items, such as antique stick pins or charm bracelets, which require uniquely shaped compartments that are not available in the mass market. The ability to control every aspect, from the exact shade of velvet to the precise width of a divider, is the ultimate expression of personalized organization.

If your available time is limited or if you prioritize a flawless, highly durable finish, purchasing is the superior option. Professionally manufactured trays utilize materials and construction methods that ensure product longevity and a refined aesthetic.

This is the preferred path for clients who view the organizer not just as a utility, but as a piece of luxury equipment in its own right. High-end manufacturers often use proprietary construction techniques, such as heat-sealed edges on fabric and interlocking joinery for dividers, which result in a level of durability and precision that is difficult to replicate in a home workshop. This is an investment in both organization and the overall aesthetic integrity of your dressing room or closet.

This section provides the exact methodology for constructing a custom jewelry tray to a professional standard. Following these steps will ensure a functional, durable, and aesthetically pleasing result.

Correct material selection is critical to the project’s success. It dictates not only the final look and feel but also the level of protection afforded to your jewelry.

From a manufacturing standpoint, we strongly recommend Medium-Density Fiberboard (MDF). Its high density, lack of voids, and smooth surface make it the ideal substrate for fabric adhesion. Plywood is a viable, durable alternative, while foam core should only be considered for lightweight, non-permanent applications.

Professional packaging manufacturers favor MDF for its superior dimensional stability; it is less prone to warping with changes in humidity compared to plywood. This ensures the tray maintains its perfect fit within the drawer over time. Furthermore, its smooth, homogenous edge allows for a cleaner finish when wrapped with fabric, eliminating the layered texture that can sometimes show through from plywood edges.

Velvet and fabrics are the industry standard for high-end packaging and display due to their non-abrasive pile, which protects polished surfaces. We advise using a low-pile, non-stretch velvet for the cleanest application. Felt serves as a functional, budget-conscious alternative, while microsuede provides a contemporary matte finish.

In the luxury packaging industry, the material of choice is often a high-density, short-pile rayon or silk velvet. These specific types are selected because they are less likely to shed fibres that can get caught in delicate chain links or prong settings. When selecting your fabric, perform a “lint test” by rubbing it vigorously with a dark cloth to assess its shedding potential. Microsuede, while visually appealing, can sometimes have a slightly more abrasive texture, making it better suited for watches and bracelets than for delicate, high-polish items.

The required toolset includes: a measuring tape, a saw or heavy-duty utility knife appropriate for your chosen base material, a metal straight edge, and a high-tack fabric adhesive or quality spray adhesive.

For a truly professional result, consider adding a small, sharp chisel or a precision craft knife for cleaning up corner cuts in the fabric. A bone folder, a tool used in bookbinding, is also invaluable for creasing fabric into tight corners and ensuring crisp, clean lines along the edges of dividers.

Accurately measure the internal length, width, and depth of your drawer. It is a professional best practice to subtract 1/8 inch (approx. 3mm) from both the length and width measurements. This tolerance ensures the finished tray can be inserted and removed without binding.

This “tolerance gap” is a critical engineering principle in fabrication. It not only facilitates easy removal for cleaning but also accommodates the slight thickness added by the fabric lining on the exterior walls of the tray. It also allows for minor seasonal expansion or contraction of the wooden drawer itself, preventing the tray from becoming jammed.

Cut the base panel to your calculated final dimensions. Next, cut strips for the four exterior walls and all internal dividers. Bond the exterior walls to the perimeter of the base using wood glue, forming the main frame. Finalize your internal layout before permanently installing the dividers.

For superior strength, especially when using MDF, apply a thin bead of wood glue along the bottom edge of each divider before seating it against the base. Use a small square to ensure each divider is set at a perfect 90-degree angle to the base. This structural reinforcement prevents dividers from shifting or loosening over time, even with daily use.

This step requires precision. Cut a single piece of fabric significantly larger than your base. Apply adhesive evenly to the base panel, then carefully smooth the fabric from the center outwards to eliminate air bubbles. Wrap the excess fabric up the interior walls and over the top edges, making clean relief cuts at the corners to create seamless folds.

The technique for achieving perfect corners is called a “hospital corner” or a mitered fold, similar to that used in professional upholstery. This involves making a diagonal cut away from the corner before folding the flaps, which eliminates bunching and creates a sharp, tailored edge. Practice this on a scrap piece of material first, as it is the detail that most distinguishes a professional finish from an amateur one.

Prior to fixing the internal dividers, perform a dry run by arranging your entire jewelry collection within the empty frame. This allows you to map out an optimized layout, ensuring each compartment is purpose-built for its intended contents. This planning phase is crucial for a truly functional outcome.

During this stage, think in terms of “zones.” Group like items together: create a zone for daily-wear items, another for evening or statement pieces, and a separate one for valuable items worn less frequently. This ergonomic approach not only makes selection faster but also aligns the organization of your jewelry with the patterns of your real life.

For those opting to purchase a solution, a systematic evaluation is necessary. As manufacturers of high-end packaging, we assess products based on three core pillars: Material Integrity, Construction Quality, and Functional Design.

Beyond the immediate features, consider the reputation and specialty of the brand. Companies that specialize exclusively in storage solutions, as opposed to general home goods brands, typically invest more in research and development, resulting in more thoughtfully designed and durable products.

Velvet-lined trays offer superior scratch protection. Wood provides structural rigidity and a classic aesthetic. Leather adds a tactile sense of luxury. Acrylic organizers provide high visibility but lack the essential soft lining required to protect valuable, delicate items from micro-abrasions.

When evaluating materials, consider the product’s core or substrate. A high-quality tray will have a solid wood or dense MDF core, even if it is wrapped in leather or velvet. Lower-quality alternatives often use simple cardboard, which can warp or break down over time, especially in humid climates. Press firmly on the dividers and base; they should feel rigid and unyielding.

A high-quality product is identified by its details. Examine the corners—they should be sharp and perfectly aligned. The fabric seams should be tight, with no visible glue residue or fraying. These are indicators of a product engineered for durability.

Also, lift the tray and check its underside. Reputable manufacturers will either finish the bottom with the same care as the top or use a non-slip material. This detail prevents the tray from sliding within the drawer when it’s opened and closed, which is another source of potential shock and damage to the contents. The weight of the tray is also a good indicator of quality; a heavier tray suggests a more substantial core material.

If your collection is dynamic, a modular system offers the best long-term value. Stackable trays allow for vertical expansion within deep drawers. Expandable trays offer horizontal flexibility to fit various drawer widths.

The best modular systems feature a consistent “design language” and standardized dimensions, allowing you to purchase new components years later that will still fit perfectly with your original set. Look for systems with a wide variety of tray layouts—some with small compartments, some with long ones, and some with open space—as this will provide the greatest flexibility as your collection evolves from earrings to necklaces to larger statement pieces.

This product exemplifies a balance of robust construction, high-grade velvet, and a versatile layout suitable for the majority of collections. It often features a weighted base and a non-slip bottom, details that speak to a thoughtful design process.

This system is recommended for its interlocking tray design, which provides exceptional flexibility for building a multi-layered, customized solution. The trays often have a subtle lip or groove that allows them to nest securely, preventing shifting and creating a stable, unified block within the drawer.

This selection offers the best value proposition, providing essential protective features like a soft lining without a premium price tag. While the core material may be a lighter-weight composite board instead of solid MDF, the fabric quality and compartment design still meet the fundamental requirements for safe jewelry storage.

This tray is distinguished by its use of premium materials, such as solid wood frames and high-density velvet, making it an investment in both function and aesthetics. Often, these products are finished with details like genuine leather pull tabs or custom-monogrammed plaques, elevating them from a simple organizer to a piece of bespoke furniture.

For a fully bespoke solution, engage with professional custom closet firms or specialized artisans on platforms like Etsy. These services will fabricate an insert to your exact specifications, offering the highest possible level of integration and personalization.

When commissioning a custom insert, provide the maker with an inventory—or even photos—of your collection. A true artisan can then recommend specific compartment sizes and layouts tailored to your exact pieces, such as creating curved slots for specific Omega watches or deeper compartments for South Sea pearl necklaces. This collaborative process ensures the final product is not just custom-fit to the drawer, but custom-designed for the jewelry itself.

Proper maintenance preserves the integrity of your organizer and the condition of your jewelry. This is not a one-time task but an ongoing practice of care.

For routine dust removal, a soft-bristled brush or a lint roller is the most effective and least abrasive method. For minor stains, use a microfiber cloth lightly dampened with water, but always test on a hidden area first to ensure colorfastness. Avoid any harsh chemical cleaners.

For more persistent debris caught in the velvet pile, a vacuum cleaner with a soft brush attachment on its lowest setting can be highly effective. This method lifts dust from the base of the fibers without causing abrasion. For luxury trays with leather elements, use a dedicated leather cleaner and conditioner sparingly to prevent the material from drying out.

Long-term organization is a function of habit. Make it standard practice to return each item to its designated compartment daily. Periodically audit your collection and reconfigure modular trays as your needs evolve.

A professional organizer’s tip is the “one-in, one-out” rule. When you acquire a new piece, take a moment to assess if there is an older, unworn item you can sell, gift, or store elsewhere. This prevents the collection from outgrowing its dedicated space and maintains the curated, uncluttered feel of your tray. Schedule a bi-annual “collection review” to polish pieces and re-evaluate your layout.

The path to perfect jewelry organization is now clear. Whether you choose the hands-on precision of a DIY project or the guaranteed quality of a professionally crafted tray, you are investing in a system that protects, preserves, and beautifully displays your collection. This is the foundation of a truly organized and elegant space.

Ultimately, the goal is to transform the daily act of selecting jewelry from a search into a ritual. A well-designed tray presents your collection like a curated gallery, allowing you to appreciate the beauty of each piece and make your choice with intention and pleasure. This elevated experience is the true return on your investment in proper organization.

Stackable jewelry trays for drawers, they have become an essential item for jewelry brand owners, retailers, and wholesalers. In the early days, jewelry storage was often a box or a basic tray. But as the jewelry industry boomed, and consumers demanded more efficient ways to store their precious baubles, the concept of stackable jewelry trays… Continue reading Custom Jewelry Trays for Drawers: Ultimate Organization Guide

When Emily’s grandmother’s teacup arrived broken, she discovered our luxury keepsake boxes – where heirlooms get the protection they deserve. That’s why we craft each unique keepsake box with museum-grade materials and precision fits, because 73% of treasures last generations in proper storage. Clients like Mark use our best keepsake boxes to transform military dog tags into legacy gifts, proving these aren’t… Continue reading Custom Jewelry Trays for Drawers: Ultimate Organization Guide

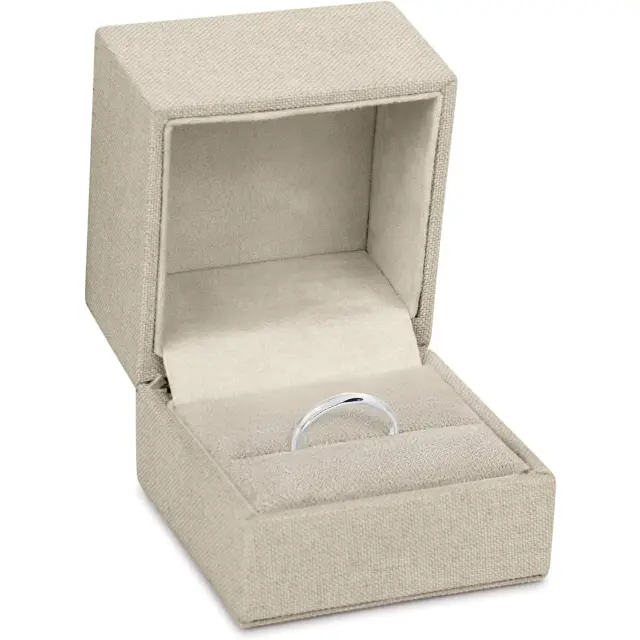

A jewellery box for rings is the perfect gift, combining practicality and sentiment. It safeguards rings, keeps them organized, and holds emotional value.

Eco Linen Ring Box Wholesale | Custom Jewelry Box Manufacturer – Richpack

Bespoke Custom Jewelry Display Cases for Small Retail Businesses | Tailored for Jewelers Needing Custom Branding with Compact and Elegant Solutions

Biodegradable Jewelry Packaging with Personalized Designs for Retailers | Ideal for Jewelers Needing Green and Branded Packaging Solutions

Custom Jewelry Display Solutions for Retail and Personal Use – Elegant Jewelry Displays, Stackable Plastic Trays, and Display Stands

View More

Durable Leather Multi-Tier Jewelry Boxes | Space-Saving Storage Solutions for Jewelers Needing Organized and Stylish Display Options

View More

Exquisite Luxury Jewelry Boxes and Cases | Designer Jewelry Box and Tray in 2025 Trend Elegant Jewelry Storage Solutions by Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)