Essential Custom Jewelry Packaging Terms You Need to Know

2024-10-28

The technique of hot foil stamping, such as holographic foil stamping, which requires the use of a hot stamping machine, is commonly used in the design of hot foil stamping logos for Jewellery packaging. This technique adds a sophisticated metallic ornamental appearance to ordinary luxury jewellery packaging. In the field of automobile jewellery packaging, Richpack is an expert in the hot stamping process.

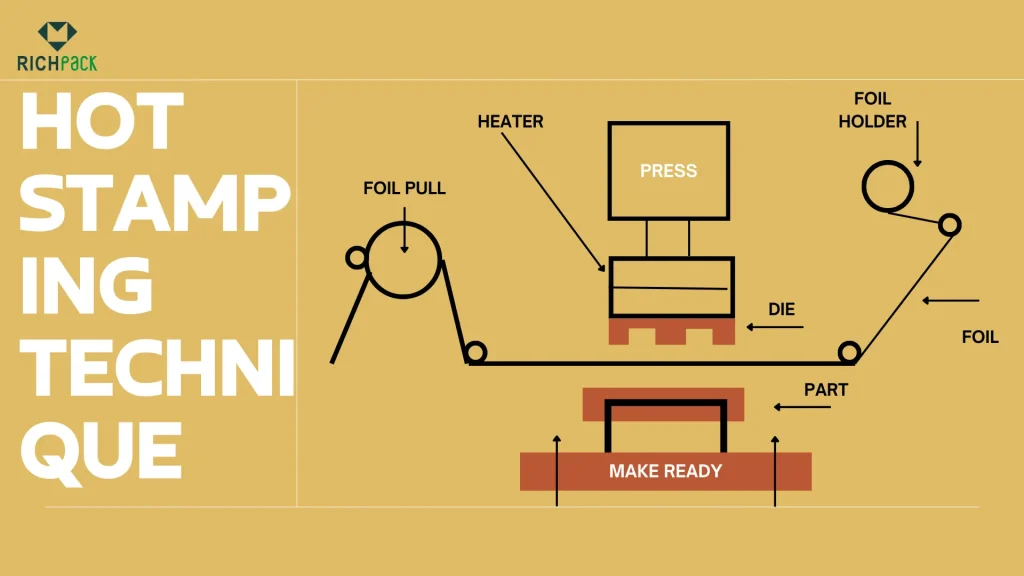

According to the Foil Stamping and Embossing Association (FSEA) studies, The process is achieved when a die is mounted on a platen and heated. Foil is then placed between the die and the material to be imprinted. When the die presses against the foil, the heat releases the colouring layer from the foil roll and binds it to the end product

The substrates used for foil hot stamping are diverse and include paper, leather, plastic, and more. It can be applied to leather-cover notebooks to give them an elegant and luxurious look. Common notebooks can also be enhanced with foil hot stamping steel, making them more visually appealing.

Here is a visualization diagram of the hot stamping principle.

Hot stamping is an important processing method for decorating the surface of plastic objects. It is used for paper and often for electronic and electrical consumer products, such as hot stamping logo names. Paper objects such as certificates, greeting cards, business cards, gift boxes, desk calendars, etc. can be reprocessed by hot stamping.

Richpack’s customized jewelry packaging or gift box packaging offers the luxurious texture brought by a customized hot stamping logo. Hot stamping can also be performed in the printing factory on other mobile phone cases, textiles, and coated objects.

Foil hot stamping offers several advantages. It provides a high-quality finish with a shiny, metallic look that catches the eye. It can also add a sense of luxury to the printed item. It is a durable printing method that can withstand normal handling and use.

Hot foil stamping for logo is an innovative printing technique that employs heat and pressure in a highly effective manner to transfer metallic or pigmented foil onto a diverse range of substrates. These substrates can include paper, which provides a smooth surface for the foil to adhere to and create an eye-catching effect.

Let’s explore these materials with Richpack. Zinc is no longer popular because the byproducts of zinc color production contain arsenic and cyanide, both of which are harmful to the environment. Most people choose magnesium. Copper or brass dyes, on the other hand, are a choice for large print runs, such as 500,000 or a million objects. They provide greater resolution but come at much higher prices.

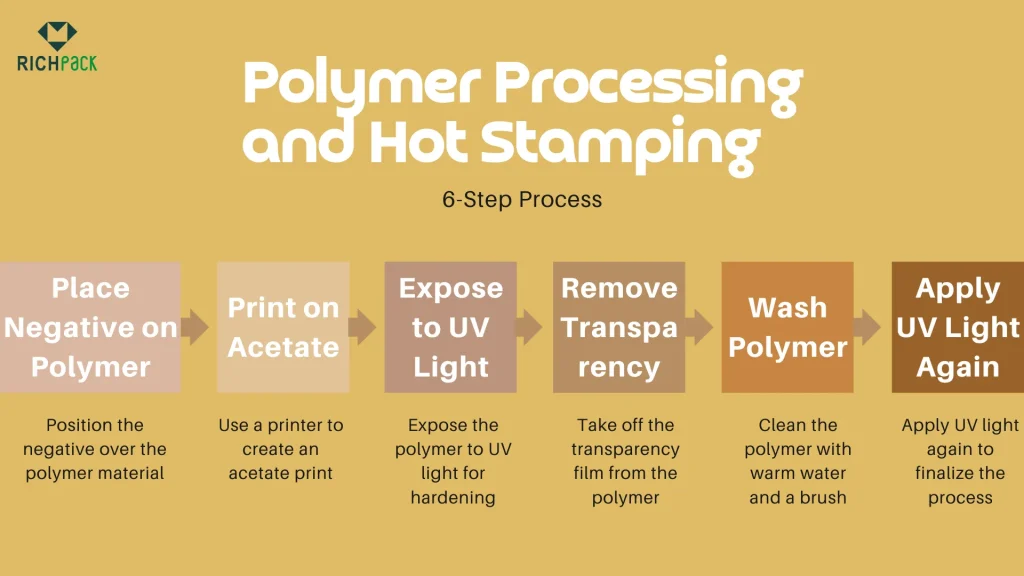

Plates made of polymer are available in a standard thickness known as the sixteenth gauge, which is a comparatively thin thickness. It is necessary to have a polymer plate maker in order to construct a polymer plate, and the following is a brief overview of the process:

The material made of polymer is packaged in a leather-like black bag; A negative should be placed on top of the material, and it can be printed on acetate using either a laser or an inkjet printer; A UV light box should be used to expose the substance after the negative has been placed over it. The areas that are subjected to ultraviolet light will toughen. After ten to fifteen seconds, please remove it from the UV light box, remove the transparency, and wash it with warm water and a gentle brush; this will complete the process. Last, UV light should be applied once more to solidify the polymer. It is important to remember that printing tips with hot foil require a specialised polymer plate that can withstand high temperatures. We exhibit exceptional professionalism and a profound understanding of pertinent topics due to our proficiency in the hot stamping process on plastic or the hot stamping logo for jewellery packaging such as this. Therefore, we can assess compliance.

The following are some of the differences that can be found between the various plate thicknesses: In the world of plates, there are three distinct categories. Steel with a gauge of 16 is used to make the narrow plate, which is the most cost-effective option. Both bending and flexing are not difficult for it to accomplish. Prices for the centre plate with an 8-gauge gauge are not prohibitively expensive. It is not only reusable but also resistant to bending. The quarter-gauge plate, which is the thickest, is the most expensive of all the plates. It is extremely long-lasting and is an excellent choice for use in automated machines.

The cost-effectiveness of thinner plates is increased. Plates that are thinner, on the other hand, are more likely to sustain damage. It is frequently more efficient to utilise an 8-gauge plate or thicker in a corporate context, despite the fact that a 16-gauge plate could be enticing for one-time jobs due to its low cost.

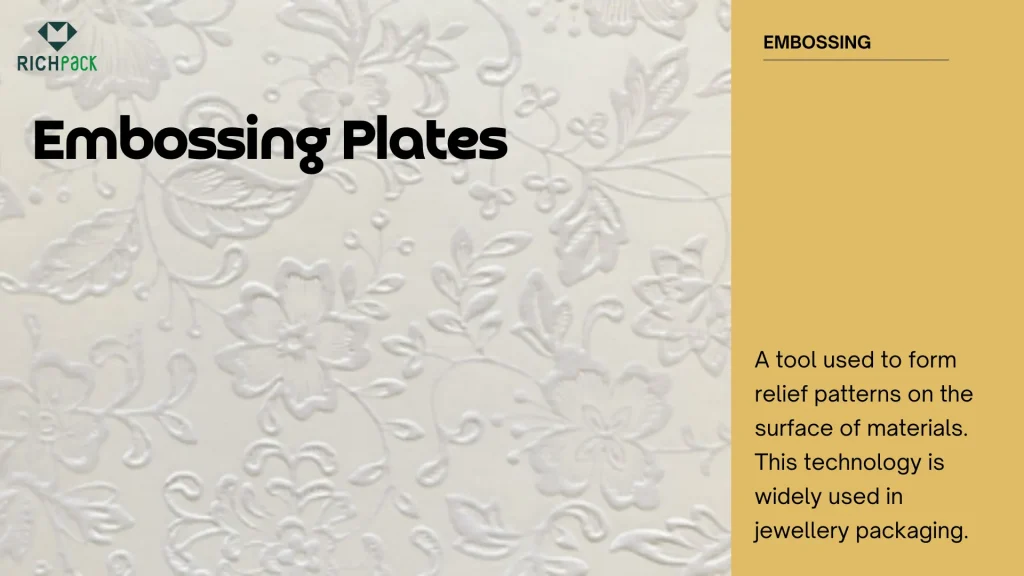

Embossing Plates is a tool used to form relief patterns on the surface of materials. This technology is widely used in jewellery packaging. Embossed sheets can be made from different materials, such as metals, plastics, and photopolymers, and can be manufactured using different processes, such as heat embossing, cold embossing, and roll embossing.

We frequently receive enquiries concerning embossing, which is distinct from the conventional dye printing process. There are two plates that are required for an embossing plate: a male plate that is etched into the material and a female plate that is protruding from the material. In order to make an emboss, you must first align both plates. When you do this, you will notice that the male plate protrudes from the paper while the female plate is forced into the paper.

This page covers hot stamping. Jewellery packaging typically has holographic foil printing for a luxurious look. It may mark many surfaces. Magnesium and copper/brass dyes are used for large print runs. Polymer plates in sixteenth gauge thickness are made a certain way. We examine numerous plate thicknesses: 8-gauge is reusable and cheap, 16-gauge is cheap but fragile, and quarter-gauge is pricey but strong. Relief embossing requires two plates. Hot stamping and embossing have several innovations.

Mastering hot stamping is an important step in enhancing the tactile and visual appeal of packaging, but it is only one of the many tools we employ in the journey toward excellent packaging design and manufacturing. To discover how we integrate multiple techniques into a complete brand experience, we recommend reading our in-depth guide.

We possess a comprehensive understanding of the materials and standards used in hot foil stamping logo, which enables us to accurately determine whether they meet the specifications. In the event that a client encounters an issue, we promptly provide explicit advice to assist them in the collection of persuasive evidence regarding the matter.

We trust that this information will assist you in gaining a more comprehensive understanding of heated foil stamping. At Richpack, we are specialists in the automotive industry’s hot stamping procedure for jewellery packaging. Contact us here if you have any hot foil stamping logo requests.

Today, the importance of having custom jewellery packaging box design is acknowledged across industries. This is especially significant for the jewelry industry where building connections with customers is significant. Personalized packaging is a powerful tool to add a brand’s value, through enhancing the unboxing experience and interaction with customers. And how can you craft your jewellery box… Continue reading Everything You Need to Know About the Hot Stamping

Sustainable packaging has gradually become a hot spot in the jewelry packaging industry. Sustainability is not only about strategic thinking but also about the responsible dimension of supply chain cooperation, and global regional development. In today’s case, we will focus on the sustainable and environmentally friendly packaging practices of Vivienne Westwood, and understand how to optimize… Continue reading Everything You Need to Know About the Hot Stamping

Today’s customers don’t just look at the product itself; they seek a memorable buying experience. How can an e-commerce jewelry brand stand out? The answer is making a lasting impression starts with custom packaging. For e-commerce, the product packaging is not merely for protecting a product but also a tool to advertise the brand and… Continue reading Everything You Need to Know About the Hot Stamping

Durable and Secure Recycled Paper Bags with Reinforced Bottoms for Heavy Items | Reliable Packaging Solutions for Jewelry Stores and Retailers

Personalized and Branded Recycled Paper Bags with Brand Logos | Eco-Friendly Packaging for Jewelry Merchants and Retail Storefronts

Richpack Halloween Paper Bag Treat Bags for Festive Trick-or-Treat Gifting | Fun and Sturdy Paper Treat Bags for Halloween Parties and Crafts

Affordable Jewelry Bags Wholesale for Professional Packaging – High-Quality Wholesale Jewelry Bags for Retail and Gift Solutions

View More

Are Brown Paper Bags Recyclable – Learn About Green and Eco-Friendly Paper Recycling Bags and More Available Sustainable Options for Packaging

View More

Bespoke and Durable Custom-Printed Paper Bags for Retail Stores with Logos | Perfect Branding Solutions for Jewelers Needing Eye-Catching Retail Packaging

View MoreJust submit your email to get exclusive offers (reply within 12 hours)