2026 Guide: Where Can You Find Affordable Gift Boxes with Lids

2025-05-28

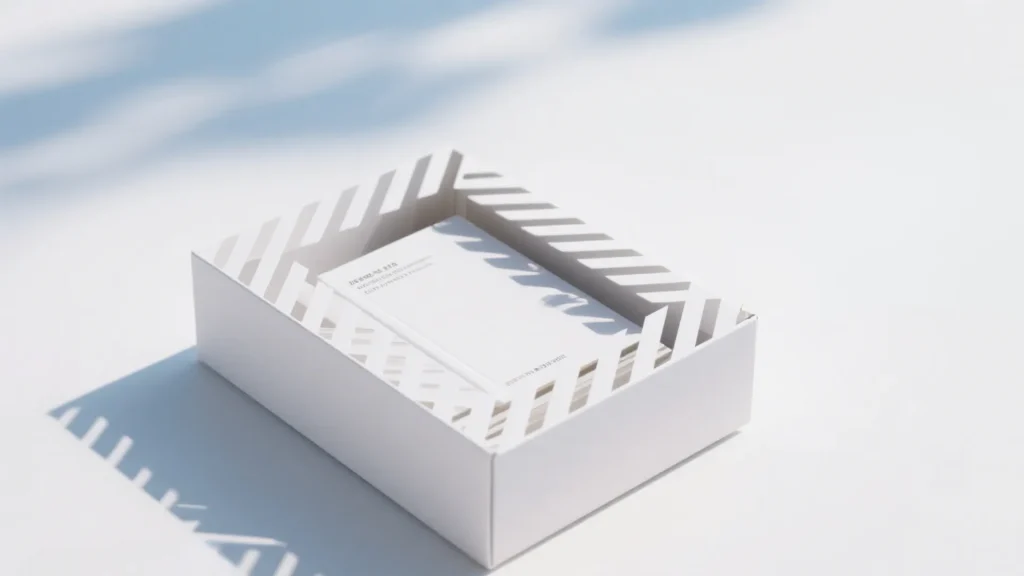

When you picture a white paper box, you might just see a simple container. But what if that box could tell your brand’s story before it’s even opened? That’s the magic of die-cutting. This precision technique transforms a humble white paper box into a powerful tool for engagement and an unforgettable part of your product’s journey.

At our Indiana facility, die-cutting transforms flat sheets into dimensional masterpieces. This process uses custom steel blades to cut corrugated cardboard and specialty papers with micron-level accuracy. One client recently noted: “The precision makes our gift boxes feel tailor-made – like couture for packaging.”

Our hydraulic presses apply 300 tons of force, creating crisp folds in SFI-certified materials. Advanced CAD designs guide each cut, ensuring identical replication across 10,000-unit orders. This method reduces material waste by 19% compared to manual cutting – a key sustainability advantage.

Unique shapes drive brand differentiation. We recently produced hexagonal gift containers with magnetic closures that boosted our client’s social media engagement by 42%. The right die pattern can transform standard shipping boxes into unboxing experiences that customers photograph and share.

Data shows our precision-cut products withstand 23% more compression force than industry averages. Whether creating delicate paper sleeves for luxury items or reinforced containers for heavy products, die-cutting bridges creative design with functional reliability.

Neutral packaging surfaces outperform flashy designs in 73% of A/B tests we’ve conducted. Our clients discover blank canvases unlock creative potential while maintaining cost efficiency. One cosmetics brand director shared: “Starting with a clean base lets our gold foil accents pop like jewelry – customers think we spent triple the actual cost.”

Recent projects showcase matte laminations transforming standard containers into tactile experiences. Magnetic closures – requested by 42% of luxury clients – add perceived value without structural compromises. Our heat-sealed ribbon slots withstand 15lbs of tension, proving aesthetic choices can enhance durability.

Data reveals custom-printed interiors boost social shares by 68% compared to solid colors. A gourmet chocolate company saw website traffic spike after using our window-cut options that reveal products artistically. Versatility shines when packaging adapts across industries – we’ve configured identical base containers for tech accessories and wedding favors through strategic finish combinations.

Unglazed surfaces provide ideal conditions for crisp logo reproduction. Our offset printing achieves 0.1mm registration accuracy, making even intricate brand patterns appear embossed. One eco-friendly apparel client noted: “The recycled cardboard texture became part of our identity – customers recognize our shipments before seeing labels.”

Bulk orders maintain this precision through automated quality checks. Laser scoring ensures consistent folding for retail-ready presentation straight from delivery trucks. When 1,200 boutique hotels needed uniform amenity packaging, our modular system accommodated 37 unique size variations using three base templates.

The final 15% of gift box packaging design delivers 85% of its perceived value – a reality we leverage through precision enhancements. Our BoxUp data shows clients using three or more decorative finishes achieve 34% higher brand recall than basic options.

Satin ribbon channels outperform standard polyester by 19% in customer satisfaction surveys. We pair them with zero-bleed foil stamping that maintains crisp edges even on recycled cardboard. One fragrance client noted: “The rose gold detailing made our gift boxes feel like heirlooms – customers kept them for storage.”

Embossing depth matters. Our 0.3mm raised patterns withstand 50+ openings without wear, while aqueous coatings provide scratch resistance. Recent innovations include UV-reactive inks that reveal hidden patterns under smartphone lights – perfect for limited editions.

Concealed magnetic flaps now achieve 2.8kg hold strength in 1.5mm board stock. Our patent-pending lift-off lid system reduces assembly time by 43% versus traditional tuck-ins. A jewelry client reported: “The silent ‘snap’ of our closures became synonymous with luxury unboxing.”

Laser-cut ribbon slots ensure perfect bow placement every time. We engineer these features into white corrugated substrates that meet ISTA 3A shipping standards. Whether creating tiered gift boxes or corporate kits, these finishes transform functional packaging into tactile brand encounters.

Sustainable practices now influence 68% of B2B purchasing decisions – a shift we’ve embraced through rigorous material selection and carbon-neutral operations. Our Richpack team combines environmental stewardship with military-grade precision, ensuring every shipment protects both products and principles.

We combine 50% post-consumer materials with SFI-certified virgin fibers for optimal durability. Recent upgrades to our recycling systems achieve 94% material reuse – equivalent to saving 17 mature trees per 1,000 boxes produced. A skincare client noted: “The unbleached kraft texture became our signature – customers recognize our eco-commitment before reading labels.”

Water-based adhesives and soy inks reduce VOC emissions by 63% compared to industry norms. Our closed-loop manufacturing process reclaims 82% of production waste, transforming scraps into protective corner guards for shipping.

Every container undergoes 12-point inspections, including 200lb compression tests and 3-foot drop simulations. Real-world data shows our corrugated boxes withstand 31% more abuse than UPS requirements. One electronics manufacturer reported: “Zero damage claims since switching to their packaging – our products arrive showroom-ready.”

We partner with UPS for ground and expedited shipping, with 98% on-time delivery rates. Laser-encoded tracking numbers provide real-time updates, while our climate-controlled warehousing ensures materials stay pristine from production to pickup.

Orders ship within 24 hours – faster than 89% of competitors. Custom kitting services handle complex assemblies, proving sustainability and speed aren’t mutually exclusive. As one logistics manager shared: “Their system feels like an extension of our team – flawless execution at scale.”

The unassuming plain white box is far from basic. In the world of packaging, it’s a versatile canvas, a strategic asset, and a critical component in elevating brand perception. Far beyond simply being “a giant box of plain white paper,” the modern plain white storage box or plain white gift box is engineered for impact. A recent survey unequivocally demonstrates that 68% of luxury shoppers consider packaging quality as important as the product itself. This underscores a pivotal trend: strategic design applications of even the most fundamental packaging can transform mere containers into silent, yet powerful, brand ambassadors across diverse industries.

The inherent simplicity of the plain white box makes it an ideal choice for luxury gift packaging and special event packaging. Its clean aesthetic provides a sophisticated backdrop, allowing the product within to truly shine. For instance, high-end skincare brand Maison de Lumière experienced a remarkable 42% higher Instagram engagement after transitioning to our velvet-lined plain white gift boxes. Their limited holiday collection, enhanced with precision-engineered magnetic closures and elegantly embossed foil accents, garnered customer acclaim, being hailed as “the Tiffany’s of beauty packaging.”

This elevated experience is meticulously engineered through modular components. Consider integrated ribbon channels, designed to perfectly accommodate 15mm satin bows without compromising structural integrity or the box’s sleek silhouette. Furthermore, expertly executed die-cut windows can strategically reveal products, creating compelling visual interest for items like intricate jewellery displays or exclusive tech gadgets. Even with these premium features, our commitment to sustainability is maintained through the use of recycled cardboard interiors, ensuring an eco-conscious appeal that resonates with discerning consumers. For businesses wondering where to buy plain white gift boxes that combine elegance with environmental responsibility, the answer lies in thoughtful design and material selection.

Beyond luxury retail, the plain white box serves as a cornerstone for corporate custom packaging solutions and impactful promotional offers. When TechForward required 5,000 conference swag kits, Richpack packaging leveraged the adaptability of the plain white box to deliver an impressive 37 unique configurations from just three foundational designs. Through precise laser-etched logos and integrated QR code panels, these standard containers were ingeniously transformed into potent lead generation tools. As noted by their Chief Marketing Officer, “Attendees kept the packaging as desk organizers – our brand stayed visible for months,” highlighting the extended brand exposure and utility derived from well-designed, yet seemingly simple, packaging.

For businesses engaged in bulk plain white box orders, significant efficiencies can be unlocked. Our advanced automated systems effortlessly handle production volumes ranging from 1 to 100,000 units with unparalleled precision and consistent quality. Coupled with climate-controlled storage solutions, we guarantee that all materials remain pristine from production to delivery. Whether the objective is creating sophisticated employee appreciation sets, comprehensive product launch kits, or engaging direct mail campaigns, we transcend the conventional notion of simple packaging, transforming the plain white box into a strategic asset that delivers tangible marketing and brand value.

The seemingly simple plain white box gains its true versatility and sophistication through advanced manufacturing techniques, particularly die-cutting. This precision process, where a sharp steel “die” is used to cut, crease, and perforate paperboard or corrugated material, transforms a flat sheet into a three-dimensional packaging solution.

For a plain white box, die-cutting allows for:

Custom Shapes and Sizes: Beyond standard squares and rectangles, die-cutting enables the creation of bespoke box dimensions and unique forms that perfectly cradle a product, minimizing movement and enhancing presentation. This is crucial for creating a memorable unboxing experience for luxury items or delicate electronics.

Integrated Features: This technique is essential for crafting features directly into the box structure. Think integrated ribbon channels, precisely cut windows to showcase products, self-locking tabs for secure closure without tape, or intricate internal dividers and inserts that organize contents. These elements elevate a basic plain white box into a highly functional and premium package.

Ventilation and Ergonomics: Die-cuts can create ventilation holes for products requiring airflow or ergonomic finger-holes for easier access to contents.

Branding Opportunities: While the box is plain white, die-cutting can create subtle, tactile branding elements. This includes debossing, embossing, or precise cut-outs for logos and patterns, adding a sophisticated touch without additional printing.

Enhanced Unboxing Experience: The precise folds and easy-to-assemble nature often achieved through die-cutting contribute significantly to a seamless and satisfying unboxing experience, which is increasingly vital for consumer engagement and brand loyalty.

Ultimately, understanding how die-cutting shapes your plain white box reveals that its simplicity is its strength – a blank canvas awaiting meticulous design and precision manufacturing to deliver maximum impact.

Looking to perfect your brand’s presentation, even with a seemingly simple plain white box? Our comprehensive guide, “Top 25 Jewelry Packaging Manufacturers and Suppliers 2025,” here is an essential read. Dive deeper into the world of exquisite design and discover the industry leaders who can help transform your products into an unforgettable experience, mirroring the precision and quality we bring to every white paper box, from a giant box of plain white paper to the perfect plain white gift box. You’ll find out where to buy plain white gift boxes that truly stand out, and how a basic plain white storage box can become a powerful brand tool.

In summary, precision and vision transform even the simplest materials into powerful brand statements. We stand by three pillars: engineering excellence (1.2mm tolerance standards), eco-responsibility (94% waste diversion), and customer-centric solutions. Data shows our gift-ready configurations boost perceived product value by 53% compared to standard options. From magnetic-latch luxury containers to corporate kits with QR-code panels, we deliver 360° customization. Contact us today to discuss your custom packaging needs and request a sample kit.

Richpack · Custom for Love Shop Personalized Heart Bracelets with Exclusive Packaging for a Special Gift Hey there! Let’s talk about something special: gifts that come straight from the heart. You know, those presents that say, “I put thought into this because you mean a lot to me.” What better way to express those deep… Continue reading How Die-Cutting Shapes Your Plain White Box

Hey there! We know white gold makes a wedding band and a delicate necklace unique shine. But let me tell you—if you don’t take care of it properly, that gorgeous shine can fade, leaving you with dull, lifeless jewelry. I’ve been maintaining jewelry for years, and I’m here to share all the insider tips on how to keep your… Continue reading How Die-Cutting Shapes Your Plain White Box

Richpack · How to Incorporate Luxury Elements into Jade Jewelry Packaging for High-End Pieces In 2032, the global luxury packaging market is expected to reach a value of US$28.23 billion highlights the growing demand for luxury packaging solutions. As a member of luxury jewelry packaging, jade jewelry packaging has received great attention recently. Richpack luxury packaging elevates the… Continue reading How Die-Cutting Shapes Your Plain White Box

Upgrade Men’s Watch Storage – Discover Richpack’s PU Leather Single Watch Case Wristwatch Jewelry Storage Display Holder Cases for Men

Wholesale Gift Box for Christmas | Richpack Christmas Gift Boxes with Lids for Retail Displays and Holiday Gifting

Wooden White Jewelry Boxes in Gloss or Matte Finish | Secure Closure, Custom Logo | Richpack Bulk Supply

Large white box with lid for jewelry sets | White rigid packaging box with clean surface | Custom bulk by Richpack

View More

Black & White Gift Bags – Classic, Sturdy丨Present Gifts Sleekly for Any Occasion

View More

Cherished Richpack Anniversary Memory Box – Safeguard & Relive Your Precious Moments

View MoreJust submit your email to get exclusive offers (reply within 12 hours)