I’ve seen too many independent watch brands pour money into watch dials only to mess up their custom watch box packaging.

Sample boxes may look premium, but once mass-produced units hit the warehouse, corner dents, color mismatches, and loose inserts start popping up.

The worst part? You can’t blame anyone. Because the problem rarely lies with the boxes themselves—it lies in your failure to treat packaging as a replicable delivery system.

This guide breaks down structure selection, process costs, shipping damage prevention, and sampling lead times. You can use it directly to make decisions, instead of just nodding along and thinking “that makes sense.”

If you’re running a custom watch boxes wholesale business or launching a custom watch gift box project, you won’t regret reading this.

Let me be blunt: You’re not selling a box. You’re selling the certainty customers feel when they pull out their wallets.

Most custom watch box packaging projects fail—not because of poor aesthetics, but because mass production leads to color discrepancies, inconsistent insert tightness, scuffed edges, and fluctuating magnetic strength.

When customers receive the goods, their first thought isn’t “this is premium.” It’s “Is this thing reliable?”

On the flip side, truly iconic packaging is a system that can be consistently replicated in wholesale custom watch boxes scenarios.

It looks great on store counters, is easy to manage in warehouses, and holds up during international shipping. What’s more, it turns a custom watch gift box into a meaningful promise when presented as a gift.

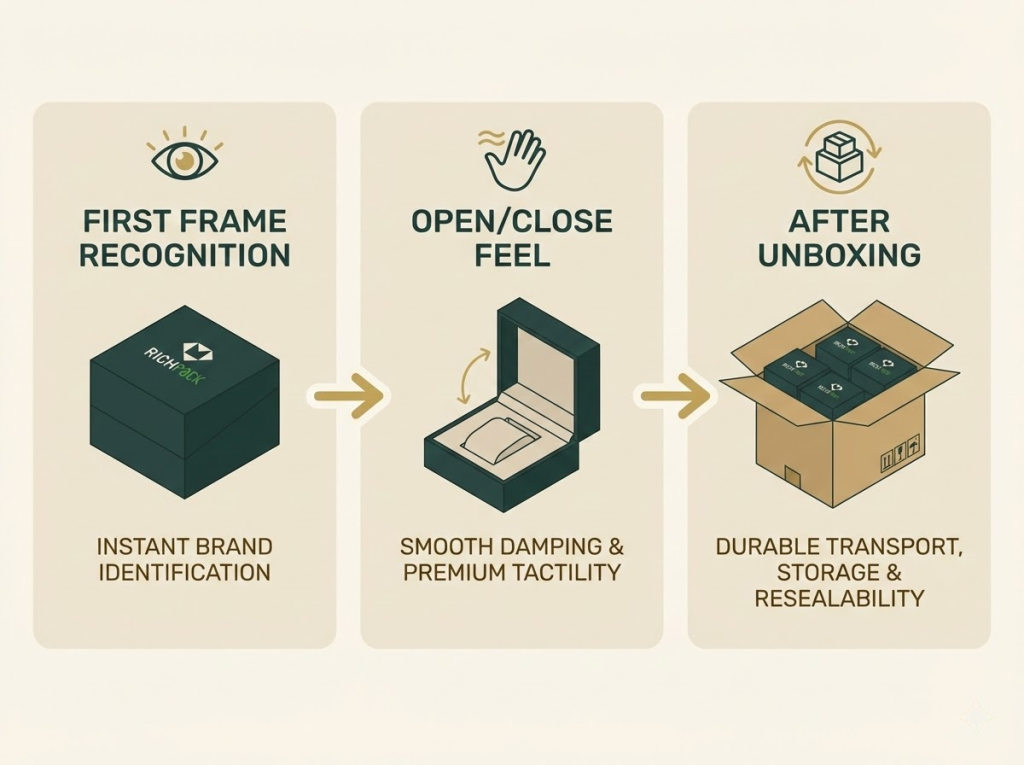

When I judge if a watch box is iconic, I never rely on vague claims like “it looks high-end.” Instead, I check four specific criteria that buyers can use to inspect products from suppliers:

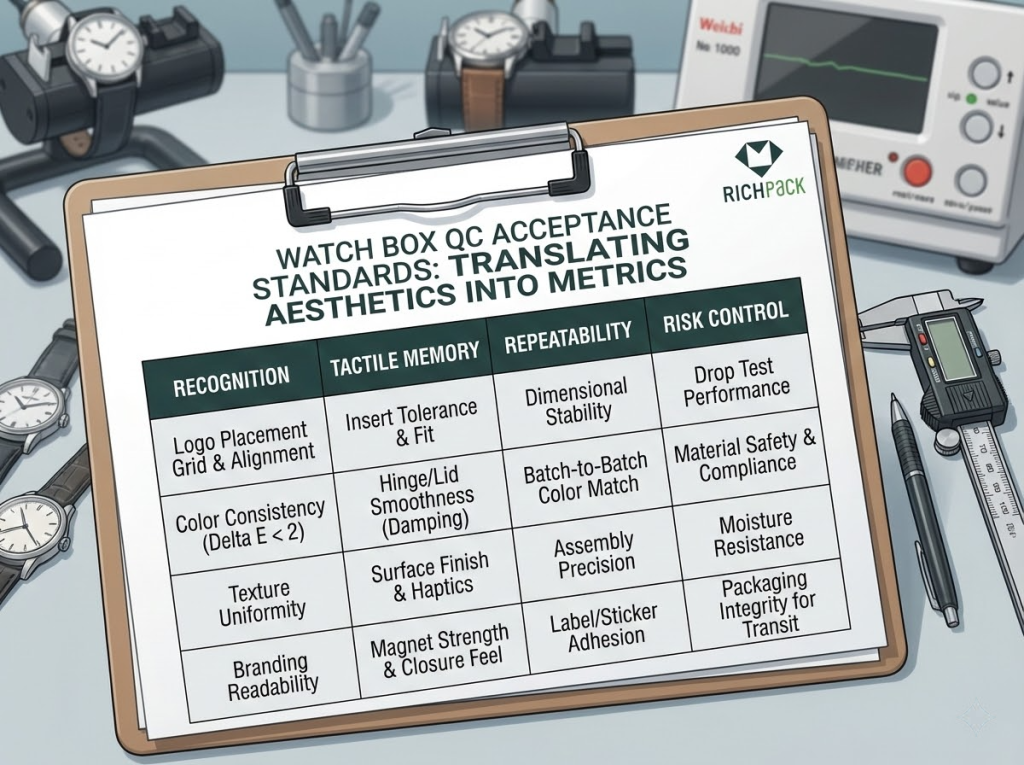

Here, I use some “hard standards” to help teams align their expectations:

For example, to ensure shipping durability, I recommend conducting drop and compression tests following ISTA guidelines. To ensure batch consistency, I require using color difference metrics (commonly ΔE) instead of relying on subjective judgments like “it looks about the same.”

These standards aren’t meant to make you look professional. They’re intended to prevent finger-pointing during mass production.

Imagine a customer standing at your counter. A clerk pulls the box out of a drawer. Under the lights, if the logo glares too brightly or sits crookedly, the entire product feels cheap instantly.

I always tell clients to take a photo of the box under real store lighting, then ask themselves: Can I recognize the brand from this image without reading any text?

Too many people underestimate the importance of how a box opens and closes. Magnetic closures, hinges, and drawer resistance—these are the most tangible experiences customers have with your product.

I once saw an independent brand whose sample boxes had crisp magnetic closures. But during mass production, inconsistent magnet specifications made the opening feel either too loose or too tight. When customers posted unboxing videos, the box sounded like a cheap plastic container—and the comment section erupted with criticism.

So when choosing a box structure, follow this simple rule:

If your packaging only looks good for the first minute after opening, but is hard to stack in warehouses, gets dented during shipping, and can’t match replacement inserts for reorders, it becomes a liability for custom watch boxes wholesale operations.

I often say this to e-commerce operations directors: Returns aren’t just a logistics problem. More often than not, they stem from packaging design flaws like being non-resealable or non-restorable.

You can do three small, low-cost things right now to drastically reduce future disputes:

Based on these three key moments, you’ll realize this: Being “iconic” doesn’t mean being more complex or expensive. It means every step of the process is explainable, and every batch is replicable.

If you’re willing, my advice for your next step is to create an inspection checklist covering structure, inserts, craftsmanship, and shipping protection. Use it to align expectations with your supplier—it’ll save you more time than staring at renderings over and over again.

When choosing a watch box, don’t start with “which one looks best.” Start with “Can this structure be consistently replicated for custom watch boxes wholesale?”

Once you enter mass production, you’ll face three challenges at the same time:

Choose the wrong structure, and fixing it later with better materials or craftsmanship will usually cost you more money.

If you’re stuck between choosing a flip cover or drawer-style box, I suggest writing down two lines of requirements first:

Once you have these written down, selecting a watch box structure will be much faster.

People love magnetic flip covers because they deliver a consistent sense of ceremony.

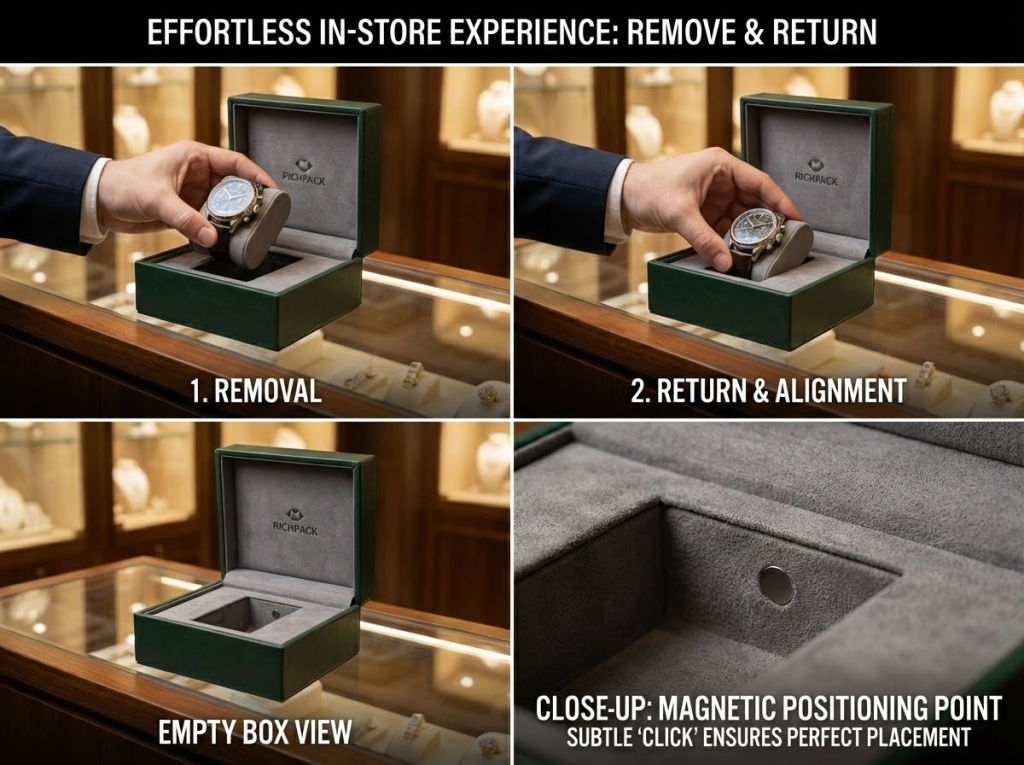

In the 2–3 seconds customers linger at your counter, the smooth flip motion and satisfying “click” sound are often more effective than adding an extra UV coating.

But mass production pitfalls are obvious:

Costs and Risks (Here’s how I usually explain it to buyers):

I often recommend drawer-style boxes to two groups: brands with many stores and frequent new product launches, and teams that handle distribution.

The reason? They’re easy to reset. Clerks can pull them out and put them back smoothly, ensuring consistent display efficiency.

Mass production risks usually don’t involve appearance—they involve durability:

I once had an e-commerce client with beautiful drawer-style boxes. But without a drawer lock, the drawers slid halfway open during international shipping. Return rates skyrocketed. Later, they added a simple stopper—and the problem disappeared.

The advantage of book-style boxes isn’t that they’re more premium. It’s that they’re perfect for building a cohesive brand story: the outer cover looks like a book, and the inner pages make it easy to arrange story content and accessory slots.

When making custom watch gift boxes, this structure makes it simple to establish clear information hierarchies.

But it’s more demanding for mass production:

Professional Tip: When mass-producing book-style boxes, prioritize outer cover sturdiness and opening/closing alignment as key inspection items—not just color and logo placement.

Travel zip boxes are more like complementary accessories than main packaging. Their tactile feel leans functional, and customers see them as storage items.

If you use them as the main gift box packaging, you’ll face common issues:

Professional Tip: Position them as “add-on purchases/member gifts/travel sets” instead of core SKU gift boxes. This way, you can sell their functionality without compromising your core product line’s brand consistency.

I’ll admit it—special-shaped boxes are eye-catching. They stand out from a sea of square boxes in e-commerce product photos.

But when clients place mass production orders, I always warn them: Special-shaped structures come with hidden costs that warehouses will make you pay for.

Watch out for three hidden expenses:

If you insist on a special shape, I suggest a split design: a stackable main box paired with a decorative outer sleeve. This way, you can have both visual appeal and practical delivery efficiency.

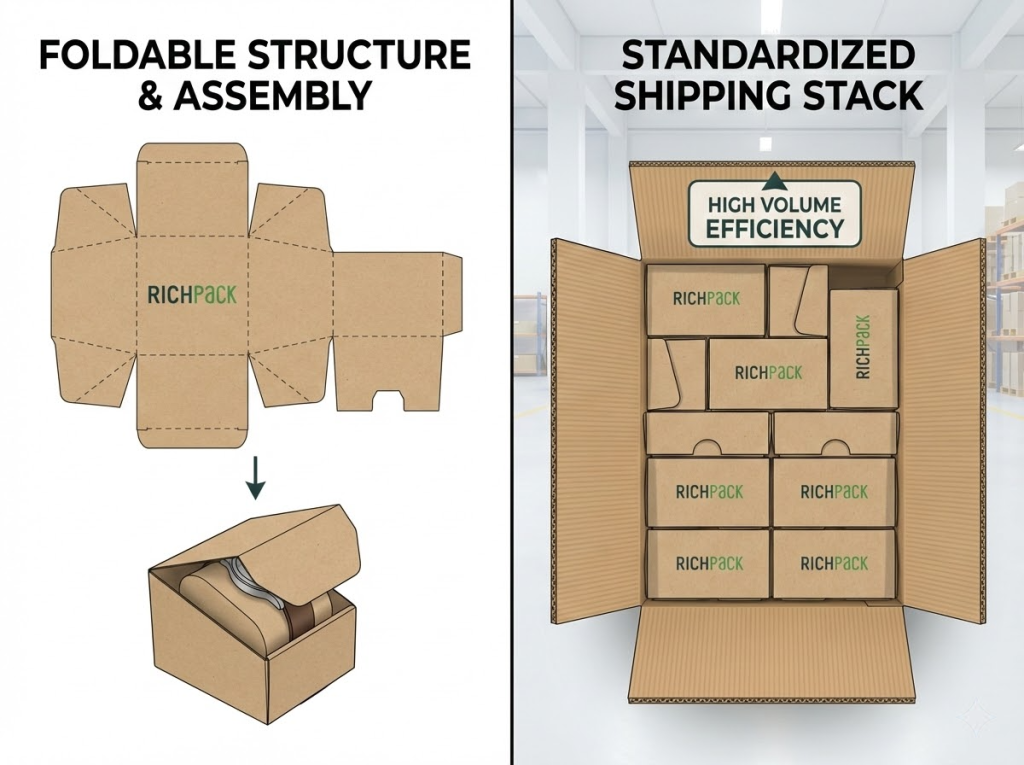

Folding and airplane boxes have clear advantages: space-saving, easy to ship, and low warehouse storage pressure. They’re popular with cross-border and e-commerce teams.

But if you’re chasing a high-end gift box ceremony, they fall short by nature. You’ll need to compensate with better inserts, premium surface materials, and thoughtful opening/closing details.

I once advised a distribution client to use folding boxes to control costs for main packaging, then upgrade the inserts with higher-tactile materials (like microfiber or high-density velvet) and add a small opening mechanism to boost the unboxing experience. Costs stayed manageable, but the customer experience improved significantly.

Shipping Damage Prevention Tips (Take these and use them):

| Structure | Who is it most suitable for | The most common risks in bulk production | The acceptance points you need to monitor |

| Magnetic Flip Cover | Gift-giving/store high-end display | Inconsistent magnetic force, misalignment | magnet strength、lid alignment |

| Drawer-style | Many stores/distribution/frequent resetting | inconsistent damping, tray misalignment | drawer resistance、insert positioning |

| Book-style | Serialized narrative/high-end gift box | Corner wear and insufficient stiffness | corner abrasion、rigidity |

| Travel zip | Travel/Storage Additional Purchase | Variations in stitching/hardware batches | stitching、hardware consistency |

| Special-shaped | E-commerce visual differentiation | Freight, protection, yield rate | carton efficiency、abrasion points |

| Folding/Mailer | E-commerce/international shipping cost control | Insufficient texture, insufficient protection | unboxing feel、corner reinforcement |

I’ve seen too many teams led astray by fancy inspiration photos. The boxes look amazing in pictures and samples, but once they enter custom watch boxes wholesale production, everything falls apart—color mismatches, scuffs, inconsistent insert tightness, and slow assembly times.

That’s why I prefer communicating with “design languages.” A design language isn’t a flashy shape—it’s a set of rules you can replicate consistently.

You can treat the following five design languages as an “executable menu.” For each one, I’ll break down visual anchors, structural implementation, cost drivers, and mass production risks. After reading, you’ll be able to choose a direction, write a brief, and negotiate with suppliers confidently.

The core of this language is simple: Give your packaging a fixed “recognition frame.” Customers will recognize your brand at a glance, even if they only stop at your counter for a second.

I often use this for independent brands’ custom watch gift boxes because it builds strong brand identity without relying on complex craftsmanship.

You can implement it with three actionable steps:

Mass Production Risks (Control these upfront):

This language doesn’t rely on visual shock—it relies on touch. Use materials like leather, microfiber, and matte specialty paper to create a clean, premium tactile experience.

I’ve found it works especially well for high-end e-commerce brands because cameras can lie, but touch never does.

Implementation is straightforward:

Costs and Risks (In plain language):

This is my go-to language for projects with tight budgets that still need to feel premium.

Because the opening/closing motion itself creates value. Drawer resistance, the “click” of a flip cover, and the unveiling experience of a book-style box—customers remember these small mechanical details.

Here’s how to do it:

I once saw a project with perfect drawer resistance in samples. But during mass production, material rebound differences made some drawers stick. In customer unboxing videos, the awkward jamming made the box look like a cheap storage bin. This wasn’t a craftsmanship issue—it was a failure to make drawer resistance consistency an inspection standard.

Many brands overlook a harsh reality: Store clerks aren’t artists, and warehouse teams won’t spend extra time arranging your boxes nicely.

This design language is built for “fast sales, fast restocking, and fast replenishment.” It’s perfect for custom watch boxes wholesale distribution scenarios.

Focus on three key points:

I usually use “reset time” as a key metric—aim for 10–15 seconds per box. Stores won’t find it a hassle. If resetting takes more than 30 seconds, clerks will cut corners, displays will get messy, and your brand image will suffer.

When people talk about sustainability, they usually think of switching to eco-friendly paper. But what matters more is this: Can you build a better system using fewer materials?

The core of this language is modularity—standardized outer boxes, replaceable inserts, and expandable accessory slots. This makes reorders, product line changes, and distribution SKU management much easier.

Actionable steps:

If you want to highlight sustainability, I recommend citing verifiable systems—like FSC-certified paper supply chains—and clearly stating your traceability processes. Don’t claim “eco-friendly” without proof; “traceable” is a safer and more credible alternative.

Many custom watch box packaging projects fail not because of wrong structure choices, but because materials and craftsmanship that look and feel the same in samples turn out inconsistent in mass production.

Once you enter mass production, batch variations get amplified—leading to color mismatches, scuffs, odors, lint, and pressure marks that instantly kill the premium feel.

Solid wood’s advantages are its natural look and the psychological value of its weight. But it’s sensitive to environmental changes—temperature and humidity fluctuations, coating wear, and corner impacts all affect its appearance.

MDF veneer is easier to produce with a consistent appearance and batch uniformity. Especially for cross-batch reorders, it acts like a reliable engineering material.

If you’re making gift-oriented custom watch gift boxes, first ask yourself: Do you want the emotional value of natural wood grain, or the consistent brand standard color of MDF veneer?

Three Inspection Points for Buyers (Take these and use them):

In my years in the industry, I’ve seen a project that used solid wood with a high-gloss finish. The samples looked stunning under office lights. But after international shipping, when the warehouse opened the cartons, minor friction had turned all the corners cloudy. Customers thought they were receiving worn display samples. This wasn’t a wood problem—it was a failure to include wear resistance and shipping protection requirements in the design plan.

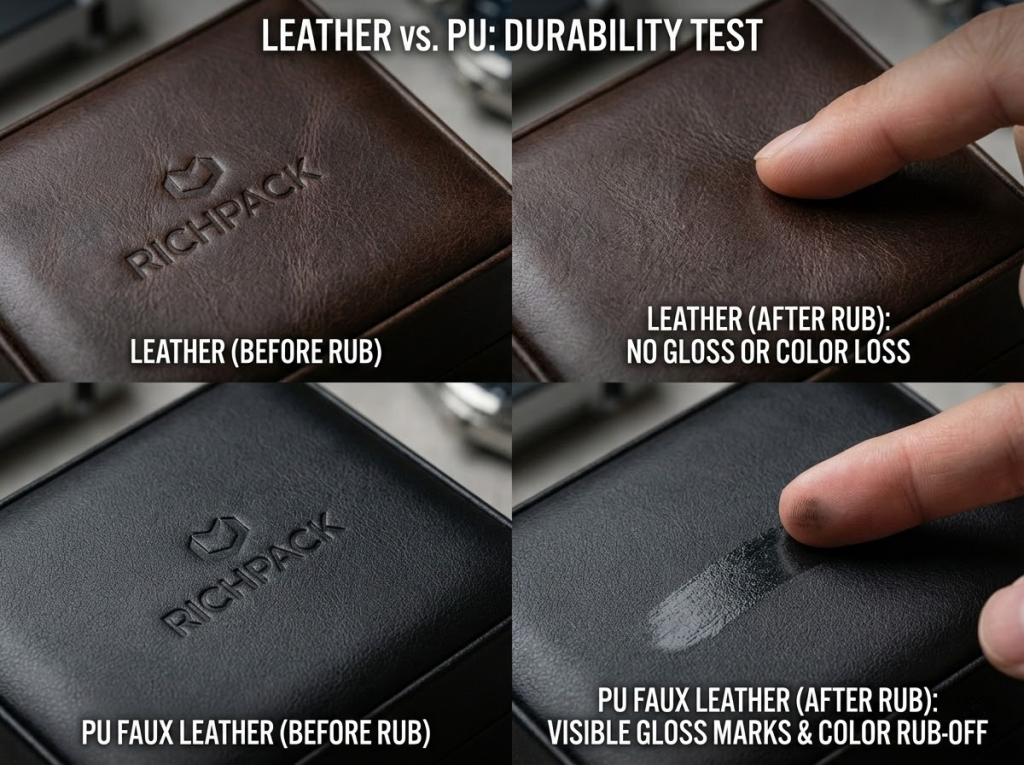

Well-made leather or PU creates a tactile feel and smooth resistance that instantly conveys premium quality.

But the most common mass production complaints aren’t about appearance—they’re about odor, color transfer, and pressure marks, which get worse after sealed shipping.

I usually do a 10-second fingertip test: Rub the material back and forth with your finger to check for powdering, color transfer, and obvious shiny scuffs. This is more effective than listening to suppliers claim they use “high-end leather.”

Write “odor control/material compliance” as mandatory requirements for suppliers—not just a vague “eco-friendly” statement. If you want to talk about sustainability, prioritize traceable systems like FSC Chain of Custody that can be verified.

Sustainable packaging is often misunderstood as simply switching to a different type of paper. What actually matters for B2B operations is this: material traceability, material reduction design, ease of disassembly, and long-term stable supply capability.

I suggest breaking down sustainability into three actionable steps on your product page—instead of just writing vague value statements:

Remember: Warehouse staff won’t applaud your environmental slogans. They’ll only care about three things: Are these outer boxes the same size? Can they be stacked stably? Will reorders use the same materials to avoid color mismatches?

Getting inserts wrong doesn’t just make the box look mediocre—it causes watches to rattle inside, leaves pressure marks on watch pillows, and makes lint stick to watch surfaces.

I usually treat insert trays like mechanical parts. Write tolerance requirements for insert tray key dimensions, and specify inspection standards for watch pillow compression and rebound performance.

If you’ve ever asked how to avoid loose inserts, here’s a data-driven answer: Control tolerances to ±0.5mm. This small change usually leads to a huge drop in rattling and pressure mark complaints.

Damage Prevention Tips:

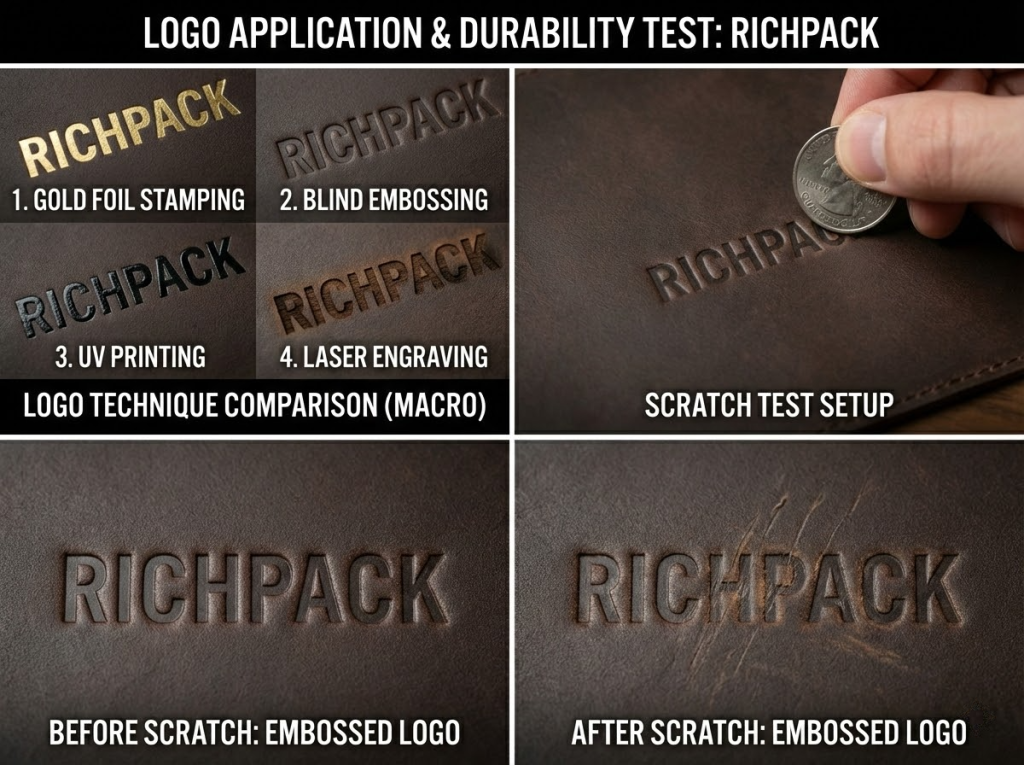

A common embarrassment: Logos look bright and crisp on samples, but after mass production, warehouse opening reveals scuffed logos on every box—making the entire batch look like used goods.

When choosing a watch box, consider custom logo craftsmanship, rephrase your questions into three practical ones: “Is it clear on camera? Is it durable to the touch? Is it consistent across batches?”

Buyer’s Guide to Craftsmanship Options:

If you want to sound like a pro when talking about shipping damage prevention, suggest conducting drop/vibration tests following ISTA guidelines—and make these tests a prerequisite for mass production.

You take samples to meet with distributors. Everyone says the boxes look premium. Two months later, mass-produced units arrive at the warehouse. You open them to find color mismatches, inconsistent magnetic feel, random insert tightness, and scuffed, whitened corners.

This isn’t bad luck. It’s because you treated design as the end goal—not as a controllable delivery process.

The following process can be used directly for a custom watch box packaging project management. Follow it, and custom watch boxes wholesale won’t be a gamble on batch quality.

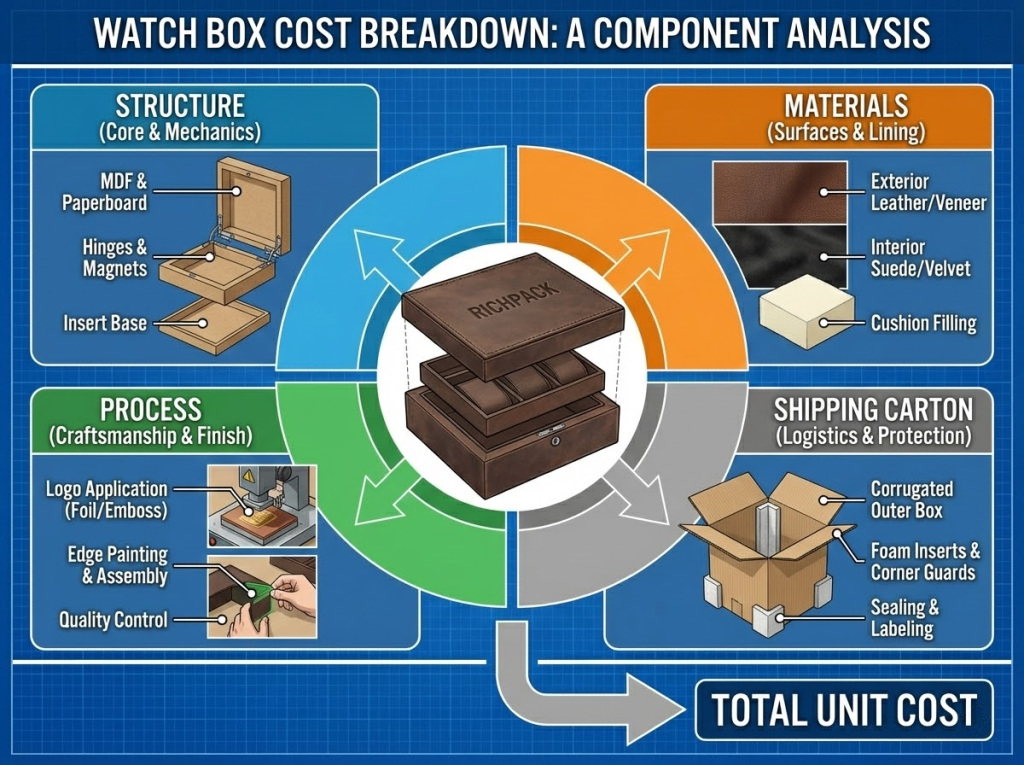

MOQ (Minimum Order Quantity) isn’t the suppliers trying to trick you. It’s usually set to cover three costs: mold/tooling expenses, material minimum order requirements, and production line changeover costs.

When you ask why prices are so high, don’t just focus on the total cost. I suggest asking suppliers to break down prices into three parts—this will instantly clarify your communication:

You can also ask suppliers for two types of quotes:

This way, you don’t need to be a math expert to see exactly where your money is going.

I never like hearing clients say, “It can be done in 3–4 weeks.” Because lead times need to be broken down into milestones—otherwise, you’ll never know where production is stuck.

For most projects, I break lead times into four phases (timelines vary by structure, craftsmanship, and quantity, but the logic stays the same):

If you’re an e-commerce operations director, I suggest working backward from your product launch date to decide whether to use overly complex structures. When facing tight deadlines, removing one high-risk process is often more effective than pressuring the factory to speed up.

A passing sample only proves the product can be made. A passing pre-production sample proves it can be made correctly at scale.

I once saw a custom watch gift box project where samples had sharp, clean foil stamping and flawless corners. However, during mass production, a paper batch change caused the foil-stamped edges to fray, making the entire batch appear like used goods. The project ended up needing full rework, wasting both time and money.

I suggest creating a checklist for pre-production sample approval—don’t rely on subjective feelings:

The worst part of purchasing is when you say, “It looks okay,” suppliers say, “It’s fine,” and finally, customers say, “This batch is unacceptable.”

I suggest writing at least these five criteria into your contract or RFQ. Even if you don’t specify exact numbers, define clear judgment methods:

This is where Richpack truly delivers strategic partner value. Choosing us isn’t just adding another supplier—it’s gaining a management system that identifies risks upfront and implements clear inspection standards. This way, when you expand across multiple SKUs and batches, your brand consistency won’t depend on luck.

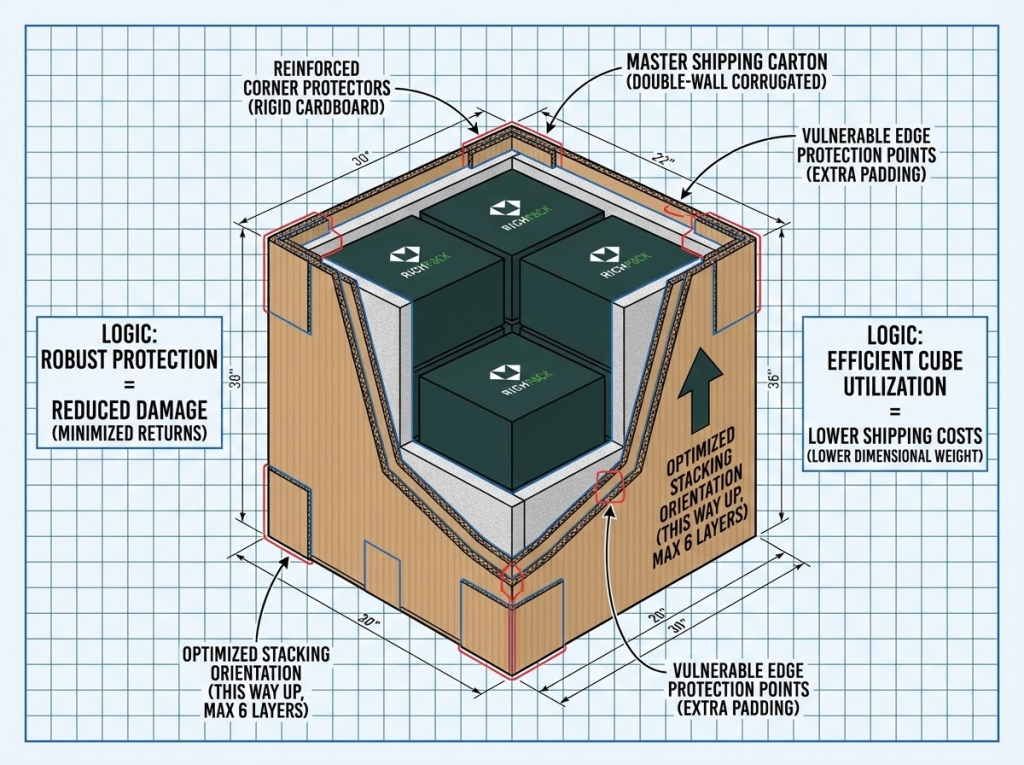

If you’re doing cross-border business, packaging shouldn’t just be thicker for safety. Too often, thicker packaging increases dimensional weight and crushes your profit margins with high shipping costs.

I usually tell teams to do two things first: Standardize outer carton sizes, and add localized protection to high-wear areas instead of thickening the entire box.

You can use these three battle-tested tips right away:

If you’ve read this far, you’ve probably realized that custom watch box packaging isn’t about making pretty boxes. It’s about stabilizing both brand experience and mass delivery at the same time.

I’ve seen too many projects win on sample aesthetics, only to lose on custom watch boxes wholesale due to color mismatches, tolerance issues, shipping damage, and delivery delays. You don’t need more complexity—you need more replicability.

You can remember the entire selection logic of this guide in one sentence:

Here’s a practical action checklist you can implement today:

Next time you open a carton in the warehouse, I hope you see boxes that are “ready to go on shelves” right away—not a pile of products that need rework, fixes, and reshooting. Write clear standards, and your team will have an easier time. Distributors will also be more willing to place reorders.

If you want to apply these methods to your own projects, I suggest two low-cost, high-return actions:

Just submit your email to get exclusive offers (reply within 12 hours)