Finding the right balance between beauty and use is tough. I see many retailers struggle with this daily. Custom drawer trays solve this by making your storage look high-end. They protect your pieces while giving your customers a great view.

Packaging Strategies Magazine says 72% of people buy jewelry based on the packaging. Grand View Research thinks the market will hit USD 8.9 billion by 2027. I tell my clients that better trays mean better sales. This is a smart move for your brand image.

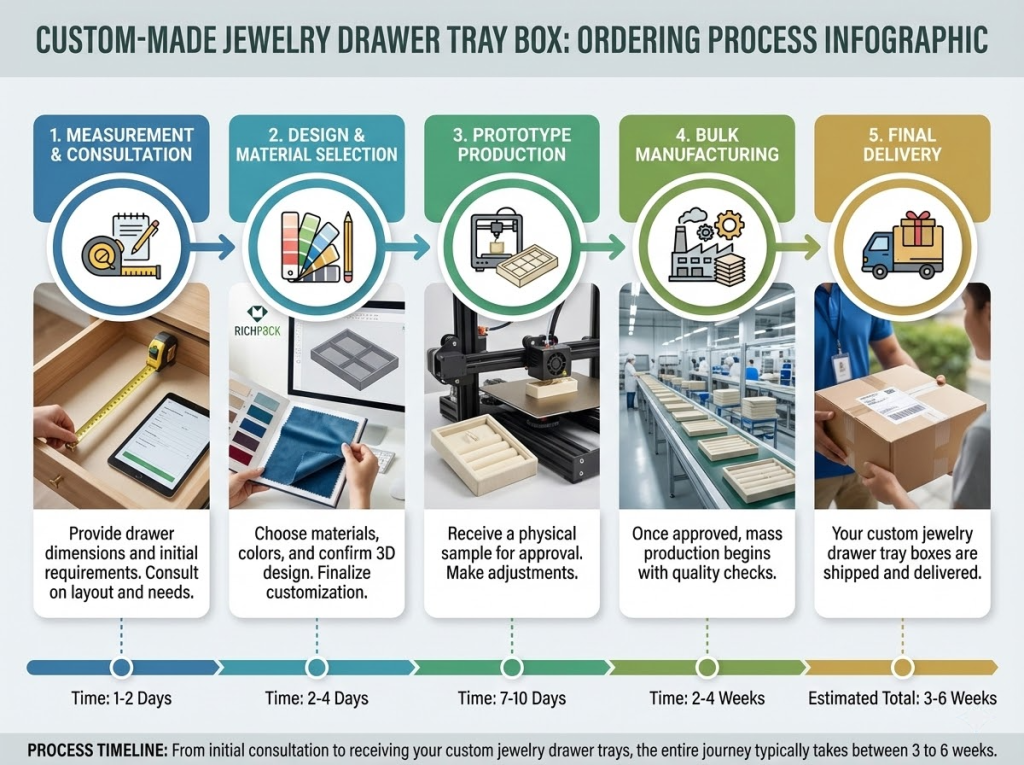

Now, I’ll show you how to order these for your shop. We will cover materials, minimum orders, and production times. This helps big chains and small shops alike. You will get the facts needed to match your brand and budget.

I’ve seen how custom drawer trays change a retail space. These specialized inserts fit perfectly inside your drawers or display cases. They help you use every inch of space. You also create a consistent brand look.

You can customize more than just the size. I recommend choosing specific layouts for rings, necklaces, or watches. Leading makers like Richpack and Häfele shared some great data with me. Brands using custom trays see a 34% increase in product value. Customer satisfaction scores also jump by 28%.

The market has a few main tray types for different needs. I’ll break down the most common ones I use with clients.

Ready-made trays often leave gaps and waste space. They look generic and do not match your brand. Custom solutions fix these problems for you.

The materials you choose change your costs and look. I see many owners struggle to balance quality with a tight budget. You need a setup that looks high-end but lasts for years. Knowing your options helps you save money while keeping a luxury feel.

Velvet is still the top choice for most shops. I’ve looked at many fabric guides over the years. Most makers use three main types of fabric today.

Makers use thin polyester fibers to make microfiber velvet. It feels as soft as natural velvet but stays clean much longer. I recommend this for most big orders. It usually adds USD 2 to USD 4 per square foot. Top brands use microfiber because it is easy to clean.

Cotton velvet is a good, eco-friendly pick. It feels very soft to the touch. But I’ve noticed it wears out fast from daily use. It costs about 15% to 20% less than microfiber. Save this for displays that people do not touch often.

Silk velvet is the most expensive path you can take. It feels amazing and has a deep shine. You will pay USD 8 to USD 12 per square foot for this. I only suggest this for the most elite brands. It is too fragile for most store drawers.

Suede options give you a tough, leather-like finish. Ultra suede looks like real skin but is much thinner. It works great if your brand has a clean, modern look. Many suppliers offer this in many colors at fair prices.

The base of the tray decides how long it lasts. It also changes how heavy the tray feels. Most of my clients pick one of these three options.

Composite board is the best way to save money. Most makers wrap this in velvet for a solid feel. It stays stiff without getting too heavy. I find it can hold up to 15 pounds easily. Most boards are 3mm to 5mm thick.

I suggest MDF when you need very specific shapes. It works well for trays with many small slots. One pro I know uses thin MDF with soft padding. It holds glue well but can warp in wet air. You must seal it right to keep it flat.

Solid wood is the top tier for quality. I love using cherry or walnut for a rich look. It makes the tray heavy and much more durable. Be ready to pay 40% to 60% more for this. I only suggest this for the most luxurious brands.

The colors you choose change how people see your jewelry. I’ve seen data showing black velvet makes items look more expensive. It can boost the value people see by 31%. Lighter tones like beige work better for wedding rings. They feel softer and more inviting to customers.

Most shops keep about 10 core colors in stock. You can usually find black, gray, or navy without any trouble. These colors do not raise your minimum order size. Many sellers offer 12 colors for any custom job.

You can match your exact brand color with Pantone codes. I should warn you that this leads to much larger orders. You might need to buy 1,000 units at once. Big suppliers will send you a proof to check the color first.

If you are just starting, stick to stock colors. I always tell new brands to keep things simple first. You can move to custom colors as you grow. This helps keep your brand looking the same everywhere.

MOQs are often the biggest hurdle for jewelry brands. I see many owners struggle with custom packaging at first. Knowing how MOQs work helps you spend your budget wisely. It lets you buy based on your current business stage.

MOQs are the minimum units a factory needs to start production. I know it seems like a lot. But factories have real costs for machines and labor. Richpack says MOQs are the break-even point for production costs.

For custom trays, MOQs change based on how complex you go. Basic setups usually need 100 to 200 pieces. Box Agency offers 100 units of drawer boxes to help startups. This is a great way to start small.

Moderate customization often requires 200 to 500 pieces. Kesheen sets their standard MOQ at 200 units. They usually require one style and color for this batch.

Full custom work starts at 500 to 1,000 pieces. I suggest 1,000 units for the best price per piece. High-end materials can push these numbers to 5,000. This happens when fabric mills set their own limits.

I always tell my clients to look at where their money goes. Most B2B research shows a clear cost split. Materials take 40% to 50% of the total budget. This includes wood, board, and fabric. Premium fabrics can raise your price by 40% over standard ones.

Labor and production take about 30% to 35%. Skilled workers wrap velvet and cut materials by hand. Etsy artisans focus on hand-made quality. This care justifies the higher price.

Design and setup fees are 15% to 20% of the bill. You pay for CAD drawings and 3D views on the first order. Factories often waive these fees for orders over 1,000 units. Richpack spreads these costs across bigger orders to help you.

Logistics and packing add 5% to 10%. This covers freight and protective boxes. Bulk orders save you money on shipping per unit. I always recommend shipping more at once to save.

Real-World Pricing Examples:

Don’t let high MOQs stop you from getting custom trays. I use a few tricks to help small brands. First, find flexible makers. Some artisans on Etsy love working with small batches. One maker in Poland even offers MOQs based on your specific needs.

Second, use materials the factory already has in stock. This avoids the high minimums from fabric mills. I suggest asking for their stock swatch book. It is a quick win for your budget.

Third, try to combine your orders. You can group different tray sizes into one run. This helps you hit volume discounts. It also lowers your setup fees.

Finally, focus on building a real relationship. Factories become more flexible once they trust you. Many suppliers offer better prices for repeat business. Long-term partners always get the best deals.

I have helped many brands through this process. You need a clear plan to get great results. This workflow ensures your trays match your vision. You will avoid costly errors and stay on schedule.

Good measurements lead to a perfect fit. I always ask for three key numbers.

My clients often share great tips. One client deducted 1/8 inch from their measurements. The trays fit perfectly because of that small gap. Most makers build with a tiny perimeter gap anyway. I suggest you confirm their standards first.

You must know your inventory before you start. I recommend a full jewelry audit.

Categorize Your Collection: Group your rings, necklaces, and watches together. Count every piece you want to store. A top organizer I work with does this. She sorts by type to pick the right trays.

Common options include:

Many makers offer pre-set templates. These templates fit different size ranges. Using them can save you a lot of time.

Pros will give you a quote and proof. I always look for these details.

Initial Contact: Send your drawer sizes and material choices. Tell them what you want to store. I often see makers ask for four main things. They need size, material, wall type, and quantity.

CAD and 3D Drawings: Good suppliers create technical drawings first. I find this step really important. You can change the layout or add a logo. One customer told me their rep was very fast. They sent a design for approval right away.

Pricing Breakdown: Your quote should list all costs. Look for material, labor, and shipping fees. I like it when suppliers show price breaks for large orders.

Timeline: Makers must give you a firm date. Samples usually take 7 to 10 days. Bulk production takes 2 to 4 weeks. Always plan for shipping time, too.

You should never skip the sample. I use samples to check quality in person.

Sample Investment: Most shops charge USD 50 to USD 200. They usually credit this back to your big order. This small cost stops huge mistakes later.

What to Inspect:

Expect a wait of 3 to 10 days. I suggest you add this to your project plan.

Production starts after you sign off. I track the timeline closely.

I usually see this timeline:

The full cycle usually takes 20 to 45 days. Wood trays might need 10 extra days. I have seen some shops offer rush service. They can finish in 8 to 10 days for a fee.

Checking your order saves you money and keeps your customers happy. I’ve learned that knowing what to look for helps you hold suppliers accountable.

I only work with makers who check every single piece. I always look for three things: appearance, bonding strength, and how it works.

Visual Inspection Points:

Structural Integrity:

Good suppliers stand by their work with clear rules.

Your choice of supplier affects every part of your brand. It hits your quality, costs, and peace of mind. I’ve seen many brands lose money by rushing this step. Take your time to vet partners now to grow faster later.

You generally have two choices for jewelry trays. Each one serves a very different goal. I’ll show you how to pick the right path for your needs.

Don’t just trust a pretty website. I look for specific signs before I sign any deal. Here is what I watch for in a good partner.

Green Flags (Signs of Reliability):

Red Flags (Warning Signs):

I’ve found that staying with one partner pays off. Your business gets better as the bond grows. Here is why I value loyalty in this trade.

Expect to wait 4 to 7 weeks for your order. I’ve found that this timeline is standard for most projects. Samples take 1 to 2 weeks. Bulk work needs 2 to 4 weeks.

Shipping adds another 1 to 2 weeks. You can pay extra to cut this time in half. Wood trays take about a week longer than other types. Plan for your big sales events.

I often help clients mix sizes in one batch. Most factories allow this to save you money. You will still face a small minimum order for each size. This usually stays between 100 and 200 pieces.

Combining sizes helps you get better volume pricing. It also lowers your setup fees. Talk about your full list of needs during the quote. Ask about modular sets that fit together easily.

Fit depends on how well you measure your drawers. I see most makers leave a tiny gap for safety. This gap is usually about 1/16 of an inch. If the tray is off by 2mm, they should replace it.

You must provide the right numbers first. Measure your drawer at several points. Watch out for handles or hardware inside. I always tell my clients to subtract 1/8 inch. This safety margin ensures a smooth fit.

Most modern fabrics are safe for your jewelry. I look for suppliers who use safe glues. These glues won’t tarnish your gold or silver. Soft stones like pearls need extra care.

You might want anti-tarnish fabric for those pieces. I check for material safety data sheets on high-value items. Microfiber is a great choice, too. It protects well and stays clean longer.

These trays work for both storage and sales. I see many store owners use them for private viewings. A nice tray makes your brand look better. Some trays even stack or have removable parts.

Pick colors that match your store’s style. Black velvet often makes jewelry look more expensive. Lighter colors feel more like a modern boutique. Tell your maker how you plan to use them.

Each fabric needs its own care routine. Microfiber is the easiest to keep clean. Just use a soft brush or a light vacuum. For spots, use a damp cloth and mild soap.

Let the tray air dry fully before use. Real cotton velvet is much harder to maintain. It can be crushed easily if you are not careful. Ask for stain-resistant fabrics for busy stores. This keeps your displays looking fresh every day.

Custom trays are a smart move for your brand. They protect your stock and impress your guests. Good trays help you charge a premium price. You need to make smart choices at every step.

Learn the costs and the real timelines. This helps you avoid big mistakes. It works for small shops and big chains. Focus on the fit and the quality.

The industry changes fast with new materials and designs. Keep an eye on new trends. Never settle for poor work or a bad fit. Your trays tell your brand story. Make sure they say the right thing.

Just submit your email to get exclusive offers (reply within 12 hours)