10 Best Alternatives to Plastic Packaging for High-End Jewelry

2024-11-19

If you’ve ever worried about your precious jewels getting jostled around during shipping, you’re in the right place. Today, we’re diving deep into the world of jewelry packaging seismic tests, and trust me, it’s going to be an exciting ride. That’s where Richpack comes in. We’re all about providing top-notch jewelry packaging solutions, and our seismic-tested packaging is like a superhero cape for your precious pieces. And guess what? We use some seriously cool technology, like high-speed cameras, to show just how effective our double-wave-peak shock-proof materials are on a level 4 vibration table.

Now that we’ve set the stage and understand why jewelry packaging seismic tests are so crucial, you’re probably itching to know what exactly goes into ensuring this top-notch protection. Well, there are several key factors that come into play, and we’re about to break them down for you.

Jewelry is made up of a variety of materials, from brittle gemstones like emeralds and sapphires to delicate chains and intricate settings. A simple jolt during transit can dislodge a gemstone, bend a prong, or even break a chain. For example, a high-end diamond engagement ring with a prong-set center stone is particularly vulnerable. If the packaging doesn’t provide adequate protection, the prongs could get knocked out of place during shipping, and the diamond might fall out. That’s a nightmare scenario for both the customer and the jewelry brand. So, when designing jewelry packaging for seismic protection, we at Richpack take into account the specific fragility of each type of jewelry. We use materials and cushioning techniques that are tailored to keep these precious items safe.

Shipping jewelry can expose it to all sorts of vibrations and shocks. Whether it’s being jostled around in a delivery truck, tossed around in a cargo plane, or rattled on a conveyor belt at the post office, the jewelry needs to withstand these forces. Different modes of transportation have different vibration and shock profiles. For instance, air freight might have more sudden jolts during takeoff and landing, while ground transportation could have more continuous vibrations from the road. A level 4 vibration table, which we use in our tests at Richpack, simulates a relatively high-level of vibration that jewelry might experience during transit. Our double-wave-peak shock-proof materials are designed to handle these vibrations and shocks, ensuring that your jewelry remains intact.

The packaging materials used for jewelry need to be compatible with the jewelry itself. Some metals can react with certain types of plastics or cushioning materials, causing tarnishing or discoloration. For example, silver jewelry can tarnish when it comes into contact with sulfur-containing materials. At Richpack, we carefully select our packaging materials to ensure that they are not only great at providing seismic protection but also safe for the jewelry. Our double-wave-peak shock-proof materials are made from high-quality, non-reactive substances that won’t harm your precious pieces.

So, we’ve covered all the important factors you need to keep in mind when it comes to jewelry packaging seismic protection. But how do you actually go about creating a packaging solution that can pass these tough tests? That’s where our step-by-step guide comes in. Let’s roll up our sleeves and get practical!

At Richpack, we start by choosing the perfect materials for the job. Our double-wave-peak shock-proof materials are a game-changer. These materials are designed with a unique structure that can absorb and dissipate shock waves effectively. First, we consider the density and flexibility of the material.

A material that is too rigid won’t be able to absorb shocks well, while a material that is too soft might not provide enough support. Our double-wave-peak materials strike the perfect balance. They are made from a combination of polymers that are engineered to be both flexible and strong. We also take into account the environmental impact of the materials. For those interested in sustainable options, read here to learn more about our eco-friendly jewelry packaging solutions.

Once we have the materials, we focus on the packaging structure. The design needs to be such that it cradles the jewelry in place and distributes any shock forces evenly. For a ring, we might use a custom-shaped insert that holds the ring securely and has extra cushioning around the stone and the band. For a necklace, the packaging might have a special compartment with soft, padded walls to prevent the chain from tangling and the pendant from getting damaged. We use 3D modeling software to create prototypes of the packaging design and test them virtually before moving on to physical samples. This allows us to make any necessary adjustments quickly and efficiently.

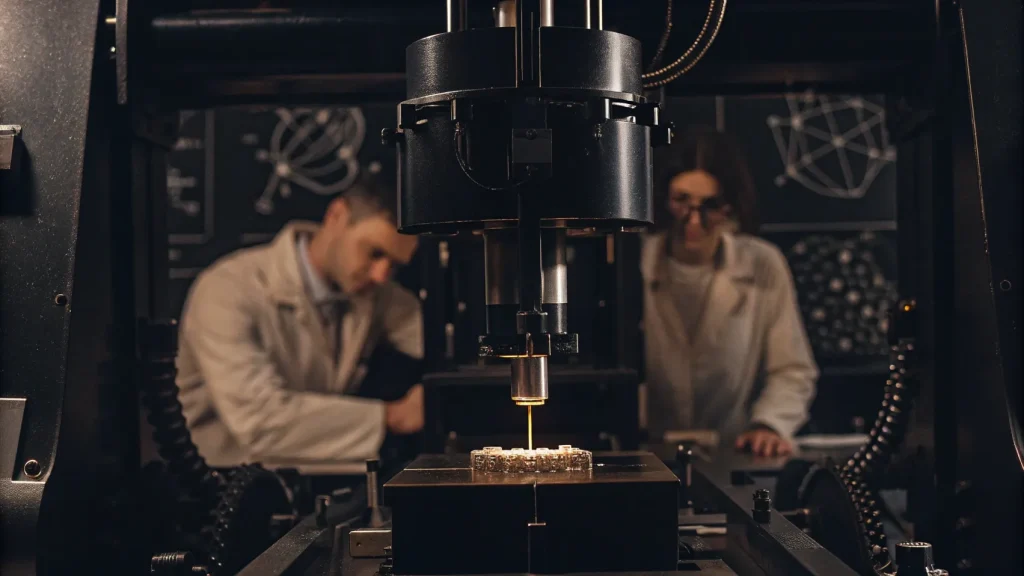

Now comes the exciting part-the seismic test! We place the jewelry-filled packaging on a level 4 vibration table. This table is calibrated to produce vibrations that mimic the harsh conditions of transit. We then use high-speed cameras to record the entire process. The high-speed cameras can capture every movement of the jewelry inside the packaging. As the vibration table starts to shake, we watch closely to see how the double-wave-peak shock-proof materials perform. If there are any signs of the jewelry moving around too much or coming into contact with the sides of the packaging, we know we need to make some adjustments. After the test, we review the footage from the high-speed cameras to analyze the performance of the packaging in detail.

Based on the data collected from the seismic test and the footage from the high-speed cameras, we analyze the results. If the jewelry was well-protected and there were no signs of damage or excessive movement, we know we’re on the right track. However, if there were any issues, we go back to the drawing board. We might need to adjust the thickness of the cushioning, change the shape of the insert, or even select a different type of material. At Richpack, we’re constantly striving to improve our packaging designs to provide the best possible protection for your jewelry.

With the step-by-step process of creating seismic-resistant jewelry packaging under your belt, you might be thinking, “That’s all great in theory, but how does it work in the real world?” And you’re absolutely right to wonder! To give you a better understanding, we’re going to share some real-life examples of successful packaging solutions and also throw in some handy tips that you can use right away.

Let’s take the example of a luxury jewelry brand that was shipping its high-end diamond bracelets. Before partnering with Richpack, they had experienced a significant number of damaged items during transit. We designed a custom-made packaging solution for them using our double-wave-peak shock-proof materials. The packaging had a specially designed insert that held the bracelet securely in place. After conducting the seismic tests and making some minor adjustments, the brand started using our packaging. The results were amazing! The number of damaged items during transit dropped from 10% to less than 1%. The brand was not only able to save on replacement costs but also improve customer satisfaction.

Ensuring that your jewelry packaging can withstand seismic forces is crucial for the success of your jewelry business. By considering factors like the fragility of the jewelry, vibration and shock levels in transit, and material compatibility, you can make informed decisions about your packaging. The step-by-step guide we’ve provided, from selecting the right materials to conducting seismic tests and analyzing the results, can help you create a packaging solution that offers NASA-level protection for your precious jewels.

Our pursuit of extreme packaging protection reflects our commitment to end-to-end quality control from design to manufacturing. In our core design philosophy, functionality and aesthetics are equally important.

And remember, at Richpack, we’re here to help. Whether you need advice on choosing the right packaging materials, want to learn more about our customization options, or are interested in seeing how our double-wave-peak shock-proof materials can work for you, don’t hesitate to reach out. Contact us and let’s start a conversation. Let’s work together to ensure that your jewelry arrives at your customers’ hands in perfect condition, every time!

Jewellery packaging is a key element in building your brand’s identity and customer experience.

Richpack · 6 Packaging Strategies For Napier Jewelry Napier Jewelry is a brand with a rich history that dates back to the early 20th century. Exceptional Napier jewellery packaging is essential to maintaining the prestige and appeal that collectors and enthusiasts expect. Whether it’s an exquisite velvet-lined Napier jewellery necklace box or a luxurious vintage… Continue reading NASA – Level Protection: A Complete Breakdown of the Jewelry Packaging Seismic Test Process

Have you been troubled by cosmetic packaging fit issues? At Richpack, we specialize in custom cosmetic box solutions for wholesalers and retailers. From precise design services to prototyping and expert collaboration, we offer full support to solve cosmetic packaging fit issues. 1. Common Causes of Cosmetic Packaging Fit Issues When cosmetic packaging doesn’t fit the products, it… Continue reading NASA – Level Protection: A Complete Breakdown of the Jewelry Packaging Seismic Test Process

Adorable Cute Packaging for Cosmetics to Elevate Your Brand – Customizable Designs for the Cosmetic Packaging Market by Richpack

View More

Custom Box Paper Cosmetic Packaging Buy Paper Box,Nail

View More

Custom Branded Cosmetic Packaging for Luxury Beauty Products | Ideal for Brands Needing Elegant and Tailored Packaging Solutions

View MoreJust submit your email to get exclusive offers (reply within 12 hours)