2025 Top 7 Packaging Trends for Moonstone Jewelry

2024-12-05

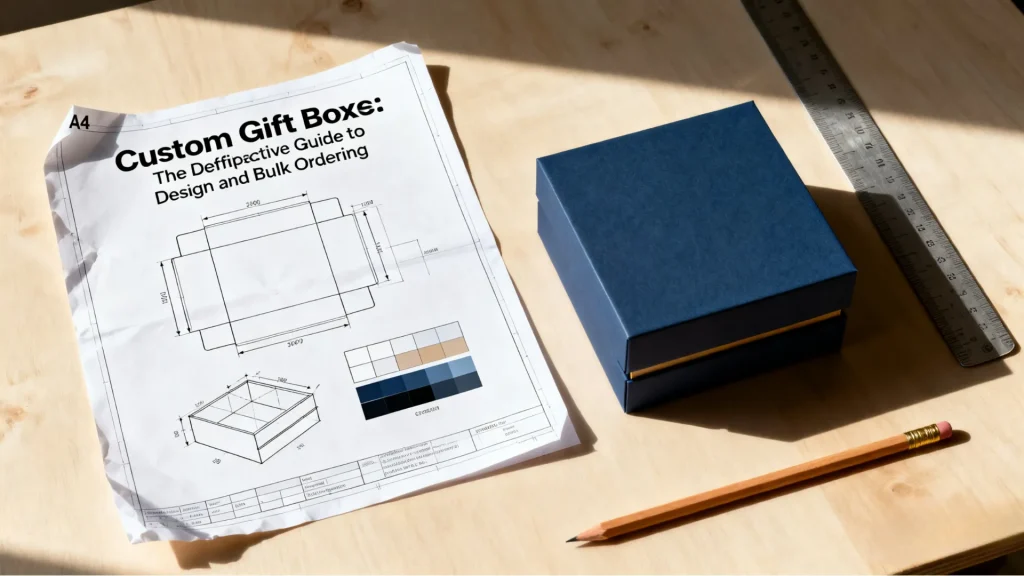

As a discerning brand owner or procurement manager, you know that custom packaging is the first physical interaction your customer has with your jewelry. Navigating the journey from a design brief to a bulk shipment requires a trusted, experienced partner.

At Richpack, with over 15+ years of B2B manufacturing expertise, we turn complex procurement into a transparent, stress-free 6-step process. This definitive guide is designed to empower you with the knowledge needed to achieve premium quality, optimal cost efficiency, and brand-perfect execution. We believe that choosing Custom Jewelry Packaging Services over off-the-shelf solutions is the key to Unveiling Branding Potential.

The Procurement Challenge: You need a reliable cost estimate and production feasibility before dedicating internal design resources.

The journey begins with clarity. We align on your brand’s commercial and creative goals immediately. The price range for a custom jewelry packaging services project is wide, generally from $0.21 to $69.44 per unit per unit, heavily dependent on material and volume. Understanding this pricing guide is the first step in Jewelry Packaging Solutions: Case Studies on Delivery Delays, MOQ, and Cost

Key Inputs Required:

Richpack’s Deliverables:

Feasibility Assessment: Analysis of your design against manufacturability.

Transparent Preliminary Quotation: An initial estimate outlining main cost drivers.

Deep Dive on Costs: Understand how material type (Paper vs. Wood vs. Leather) and volume impact your total investment. Read our guide: How to Control Jewelry Packaging Cost: A Complete Guide.

The Procurement Challenge: The design must be aesthetically unique, structurally sound, and chemically safe for the jewelry.

This is where your abstract brand motif (story, culture, or product geometry) is translated into a technical drawing, actively avoiding the low-cost “Industry Public Mold” trap. For those in e-commerce, this phase is crucial for Creating Custom Jewelry Packaging for E-Commerce Success.

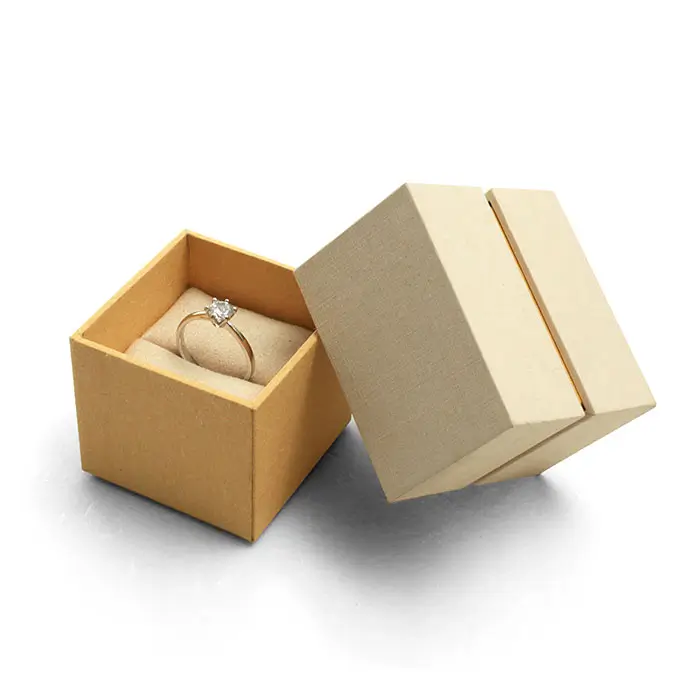

The inner lining is the core component of protection. e ensure the design is matched to the jewelry’s shape, size, and characteristics, which varies significantly depending on the jewelry’s material.

We specialize in structures that create a unique user experience. You can see how we apply innovative structural thinking to various products, even for specific items like How to Choose the Right Jewelry Box Shape: A Complete Guide to Pros and Cons.

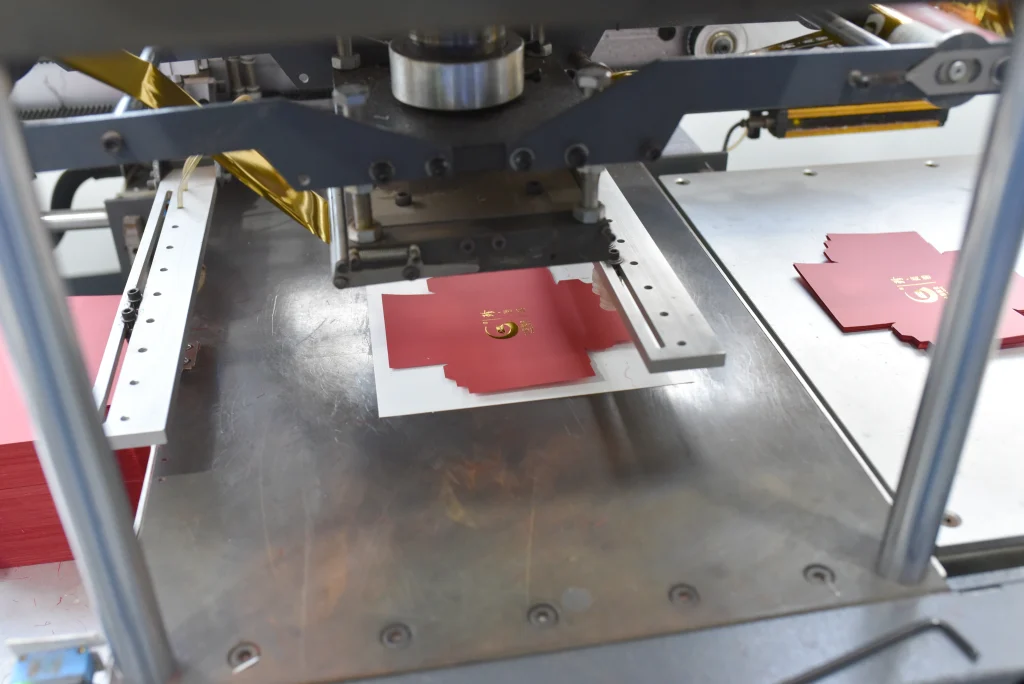

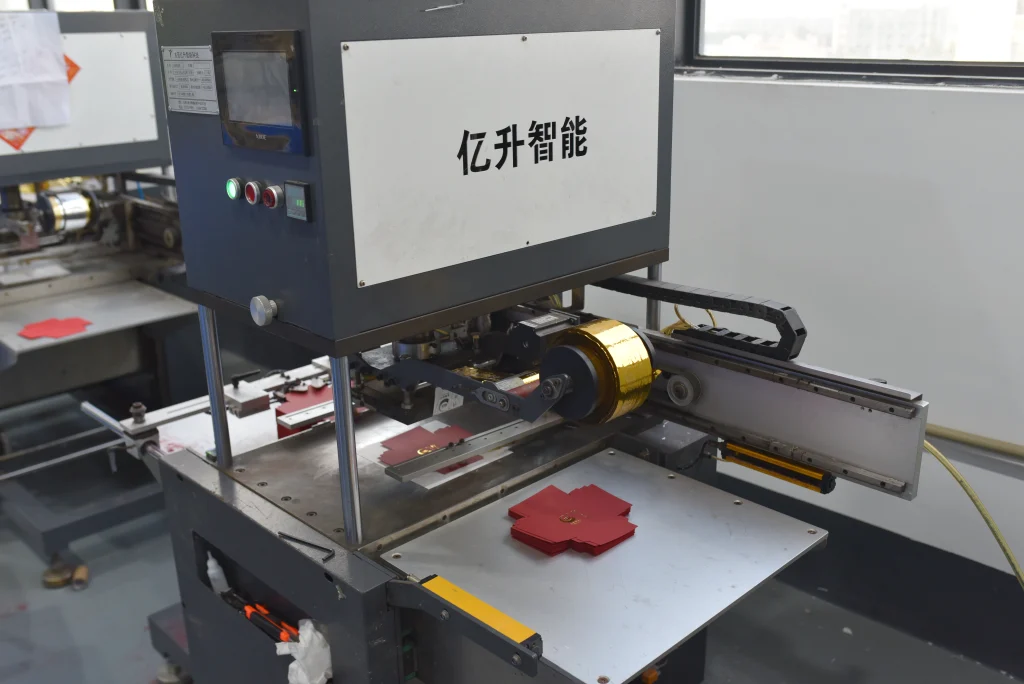

We offer a range of finishing techniques, ensuring the final look matches your brand’s specific tone. You can learn more about these processes in The Ultimate Guide to Jewelry Packaging: From Design to Sourcing & Production.

| Craftsmanship | Effect & Tone | Cost Impact |

| Hot Stamping/Foil | Classic Luxury. Uses heat and metal foil for high shine, essential for high-end boxes. | High (incurs mold fees). |

| Embossing/Debossing | Subtle Sophistication. Creates a 3D texture without ink or foil. | High (incurs dual mold fees). |

| Spot UV | Creates a gloss/matte contrast for graphic elements. | Modern & High Contrast. |

Aesthetics Deep Dive: See how different finishes and box structures align with contemporary trends in our Top 10 Eco-Friendly Jewelry Packaging Options for Sustainable Brands

The Procurement Challenge: You need physical assurance on the feel, fit, and colour fidelity. Commitment to a large order should only happen once you have a tangible, flawless sample in hand

The Procurement Challenge: *How is premium quality maintained across thousands of units, and how is B2B risk mitigated?*

Volume Production Timeline: Once the sample is approved, mass production typically requires 2–4 weeks (15–30 days). Wood/MDF materials generally require an additional 6–10 days due to processing.

Richpack boxes are engineered with a multi-layered protection system.

The Procurement Challenge: The full brand experience must be delivered flawlessly to the final customer.

Our partnership extends to delivering the complete Brand Packaging Solution.

Choosing Richpack means choosing a system built for B2B scale and precision. The premium cost of custom packaging is an investment that yields significant long-term returns:

Brand Value Creation:

Custom packaging can precisely convey the brand identity and elevate perceived value.

Customer Loyalty:

High-quality presentation and custom protection enhance customer satisfaction and promote repeat purchases.

Social Amplification:

Unique, visually engaging packaging encourages customers to share photos online, creating valuable secondary marketing.

Quick Takeaways: The 6-Step Summary

The decision to utilize professional Custom Jewelry Packaging Services marks a critical turning point for any brand seeking scale and luxury perception. Your packaging is the silent salesperson, the final handshake, and the lasting memory that reinforces product value. By following Richpack’s systematic 6-step roadmap, you gain not just a container, but a fully engineered brand asset—from the initial cost transparency of Step 1 to the final delivery security of Step 6. We eliminate procurement risk by making quality transparent and consistency guaranteed. Partner with Richpack to transform your unboxing experience from a transaction into a testimonial.

What is the most challenging part of your current packaging procurement process? Share your thoughts below!

Ready to partner with a trusted manufacturer? For a broader look at market ideas, check out our Top 25 Jewelry Packaging Manufacturers and Suppliers (2025) and discover The Definitive Guide to Wholesale Custom Jewelry Boxes: From Branding to Budgeting.

Ready to transform your brand’s unboxing experience?

Request a Custom Quote & Packaging Consultation

Did you know that 72% of consumers say that packaging design influences their purchase decisions? In the jewelry industry, where brand image and uniqueness are paramount, packaging can make all the difference. In this article, we will delve into the top 10 customizable jewelry packaging options. These options will enable your brand to convey its… Continue reading Richpack: The Definitive Guide to Custom Jewelry Packaging Services

In 2025, jewellery packaging has evolved from a simple afterthought to a powerful marketing asset. By mastering the art of stamping, brands are selling an entire experience.

Whether it's a corporate gift or a personal gift, the Richpack black gift box is the ideal choice to make your gift more high-end and unique.

Bulk Gift Boxes for High-Volume Buyers with Custom Branding | Cost-Effective Solutions for Wholesale Purchases

Chic Earring Gift Boxes: Exceptionally Secure and Ultra – Fashionable Jewelry box for Every Earring Ensemble

Christmas Gift Packing – Artful Packing that Spreads the Christmas Glow for Delightful Unwrapping

Affordable Gift Boxes with Custom Designs for Boutique Jewelers | Tailored Packaging Solutions | Budget-Friendly Options Available

View More

Bespoke Packaging Solutions for Luxury Jewelry | Ideal for High-End Jewelry Brands Seeking Exclusive and Sophisticated Packaging Designs

View More

Black box with lid for jewelry | Matte black rigid packaging box with lid | Custom sizes and bulk orders at Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)