Effective Printing Techniques for Logo Customization on Christmas Gift Boxes with Lids

2025-05-17

In the context of today’s hyper-automated manufacturing landscape, “craftsmanship” in packaging design is not a rejection of industrial efficiency, but rather an obsession with perfection and microscopic detail.

True craftsmanship manifests in the nuances that machines often miss: the razor-sharp definition of a box’s corner, the natural drape of fabric lining, and the precise air resistance (damping) felt during every opening and closing. For a custom Magnetic Gift Box manufacturer like Richpack, craftsmanship is the physical extension of a brand’s soul. It requires producers to transcend the role of mere executors and become guardians of aesthetics, ensuring that every package leaving the factory floor carries a deep respect for the consumer and a reverence for the brand’s value.

There is a fundamental chasm between large-scale mass production and hand-finished packaging—a gap that often dictates a product’s final market positioning.

While automated assembly lines can churn out standardized folding cartons with incredible speed and cost-efficiency, they often struggle with complex structures and specialty materials. Machines can leave behind industrial traces—glue seams that aren’t perfectly flush or edges that feel slightly raw.

In contrast, packaging infused with human artistry carries a distinct “warmth.” In Richpack Packaging’s high-end workshops, seasoned technicians hand-calibrate boxes that have been pre-formed by machines. This is particularly crucial for V-grooved rigid boxes; manual intervention ensures the 90-degree folds remain as sharp as a knife edge—a level of crisp precision that fully automated equipment rarely achieves. Hand-finishing does not merely solve the technical challenges of irregular shapes or textured papers; it elevates an industrial product into a collectible artifact.

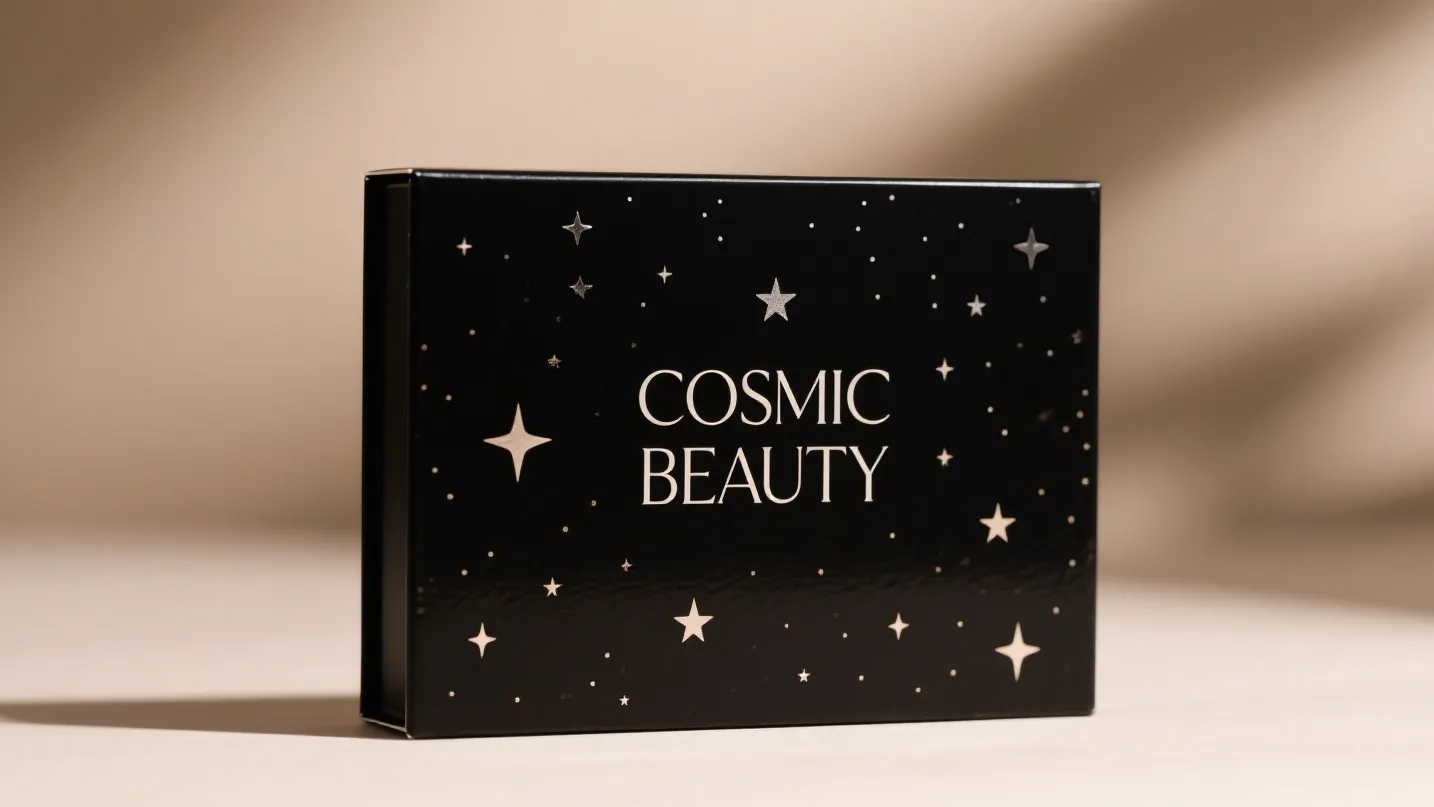

The beauty industry is, at its core, the business of selling dreams and confidence. As the primary touchpoint, packaging bears the weight of these aspirations.

In this visually driven sector, craftsmanship is the bedrock of brand trust. Consumers subconsciously equate the tactile quality of the packaging with the efficacy of the product inside. A flimsy bottle or a rough carton casts doubt on the purity of a face cream, whereas a flawlessly polished, substantial package signals “safe,” “effective,” and “precious.” Particularly in the luxury skincare and fragrance markets, craftsmanship is not merely an aesthetic choice but a commercial imperative. It supports high price premiums, ensuring consumers feel their investment is justified.

Craftsmanship is the driving force behind the “Quiet Luxury” aesthetic. In current beauty trends, true luxury isn’t about plastering oversized logos everywhere; it’s about the mastery of materials and execution. By selecting high-grammage specialty papers, flawless glass, and hand-polished metal accents, brands convey an unspoken superiority.

Richpack has found that through techniques like micro-textured embossing or spot UV coating measured in microns, we can create visual depth that is understated yet profound. This obsession with detail ensures that the moment a consumer touches the box, they recognize the brand’s elite status, distinguishing it instantly from the mass market.

A solid brand identity rests on unwavering consistency. Whether it’s minimizing colour variance across different SKUs or maintaining production stability over years of batches, high-level craftsmanship is required.

In printing, even a Delta E (colour difference) shift invisible to the untrained eye can disrupt the visual harmony of a retail shelf, weakening the brand’s professional image. Craftsmanship requires manufacturers to manage colour and materials with scientific rigour, ensuring that the tactile grain of the paper and the lustre of the foil stamping remain astonishingly uniform. This consistency across time and space is the most powerful language a brand has to promise reliability.

Every deliberate detail is a chapter in the brand’s narrative. Craftsmanship encourages designers to use structural layering, opening mechanisms, and hidden visual elements to guide the consumer’s emotional journey.

When a customer unties a ribbon, feels a leather-like texture on paper, or discovers a gold-foiled mantra hidden beneath the product tray, they are reading the brand’s story. Richpack specializes in complex structural designs—such as tiered drawer boxes or magnetic closures with specific tactile feedback—to prolong the pleasure of the unboxing experience. This turns a simple purchase into an exploration of the brand’s spirit.

In bespoke packaging, structural precision is the skeleton of craftsmanship. An excellent cosmetic box must find the perfect equilibrium between protection and aesthetics. This requires tight collaboration between designers and engineers to calculate every fold angle and locking mechanism.

For example, in rigid lift-off lid boxes, Richpack repeatedly tests the air suction (the “piston effect”) between the lid and base. We aim for that premium “slow-glide” resistance that feels luxurious rather than loose or stuck. Furthermore, internal inserts must fit the product within a 0.5mm tolerance, ensuring the item remains immovable during transit. This engineering precision speaks volumes about the brand’s manufacturing standards.

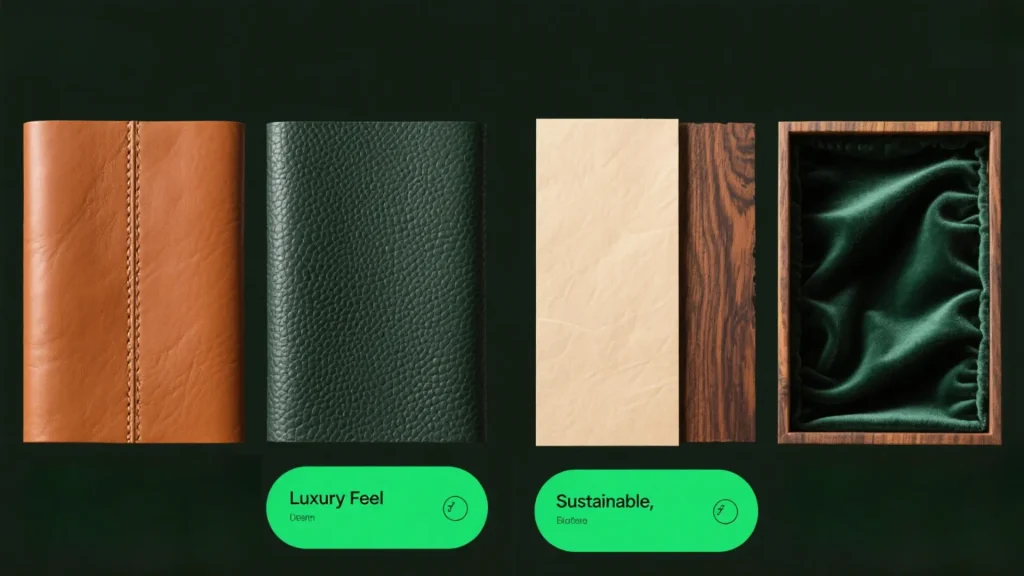

Material is the skin of craftsmanship. From papers that feel as soft as skin to linen-textured stocks and brushed aluminum, every choice must be deliberate. True craftsmanship implies a deep understanding of how materials behave—not solely their initial look, but their stability under different humidity levels and their physical aging. In Richpack’s material library, even simple black cardstock is graded by fiber length, stiffness, and “true black” purity. Only top-tier materials can support high-end design requirements.

Color is a core brand asset, and print quality determines its fidelity. Craftsmanship in printing means absolute loyalty to the color management system. Unlike standard CMYK printing, high-end beauty packaging often relies on Pantone (PMS) spot colors for richer, purer saturation without visible halftone dots.

This requires press operators with the eye of an artist and the discipline of a technician, capable of adjusting ink formulas in real-time based on paper absorption. Richpack utilizes advanced spectral color measurement tools alongside experienced press captains to ensure a brand’s signature “Hermès Orange” or “Tiffany Blue” is perfectly synchronized across different substrates.

Post-press finishing gives the packaging its soul. Whether it’s deep 3D embossing or intricate hot foil stamping, craftsmanship is defined by tolerance measured in hairsbreadths. Foil plates must register with printed patterns with a deviation of less than 0.1mm. Embossing must be deep enough to provide dimension but controlled enough not to crack the paper fibres. Richpack technicians understand that these seemingly tedious processes create the play of light and shadow that turns a box into a piece of art.

In the digital age, touch is a scarce commodity. Skilled packaging brings it back. Studies show that tactile feedback directly influences value perception—heavy, soft-touch packaging is perceived as having a higher intrinsic value. Craftsmanship involves fine-tuning paper grain direction, embossing depth, and coating friction to create a “sticky” tactile experience. Richpack combines materials and techniques to ensure the packaging sells itself the moment it is picked up.

Craftsmanship extends beyond beauty; it encompasses utility. Skilled design anticipates the user scenario. Packaging must protect fragile glass bottles from logistics chaos while remaining effortless to open. Well-designed ribbon pulls, magnetic closures with just the right snap, and ergonomic insert layouts are all hallmarks of good craftsmanship. Richpack conducts rigorous drop tests and opening tests to ensure the packaging is a fortress for the product but a welcoming gift for the user—no frustration allowed.

Unboxing is the “Moment of Truth.” Packaging infused with craftsmanship choreographs this moment into a captivating micro-movie. From the crisp sound of tearing a seal to the resistance of the lid and the final reveal, every second is designed. Statistics show that over 60% of consumers say the unboxing experience impacts repeat purchase intent. Richpack helps brands trigger a dopamine rush through sensory pleasure, building a deep emotional bond in those crucial first minutes.

Sustainability and craftsmanship are allies. Precision manufacturing is the most effective way to reduce waste. At Richpack, craftsmanship means calculating material yield to the millimetre. Optimized die-cut layouts minimize offcuts, and precise structural engineering allows us to use less material for the same structural integrity. Furthermore, a high yield rate (fewer defects) is a massive contribution to the environment, saving both energy and raw materials.

As environmental consciousness rises, craftsmanship evolves to master eco-friendly materials. Using FSC-certified paper, moulded pulp, or biodegradable materials to create luxury packaging is a new challenge. It requires superior skill to mask the impurities or colour variations of recycled materials using textures or layering, ensuring they look as premium as virgin stock. Richpack actively explores soy-based inks and glue-free structural designs, proving that green packaging can still have a luxurious soul.

Craftsmanship strives to create packaging with longevity, not trash. When a box is exquisite, sturdy, and beautiful, consumers hesitate to throw it away, repurposing it for storage or display. This “second life” extends the packaging’s lifecycle, reduces environmental burden, and keeps the brand logo in the consumer’s living space as a permanent billboard. Richpack encourages the use of durable greyboard and wear-resistant papers to create rigid boxes that endure, integrating sustainability into the full product lifecycle.

In today’s hyper-competitive beauty market, the battle on the shelf is won or lost in seconds. Packaging with artisanal quality commands attention through visual tension and unique texture. It acts as a “Visual Hammer.” Differentiated details—a unique structural shape or a rare foil colour—become brand codes, building a visual moat that makes the brand instantly recognizable in a sea of sameness.

Packaging quality is a direct projection of brand integrity. A brand that is meticulous about its packaging details is perceived as being equally meticulous about its ingredients and R&D. This transfer of trust is vital for new brands to gain a foothold and for established brands to maintain dominance. Richpack’s data suggests that brands investing in packaging craftsmanship see lower complaint rates and a significantly higher frequency of keywords like “premium” and “carefully made” in customer reviews.

Craftsmanship creates the “Halo Effect” that justifies premium pricing. When consumers are moved by the artistry and aesthetics of the packaging, their price sensitivity decreases—they are willing to pay for the “art.” More importantly, this above-and-beyond quality experience drives satisfaction, leading to high repurchase rates and brand loyalty. Every dollar invested in packaging craftsmanship yields returns in brand equity and customer stickiness.

Finding a partner who can execute true craftsmanship is crucial. It requires a supplier with both advanced hardware and deep technical heritage. Brands should assess a factory’s ability to handle complex processes, such as combining multiple finishing techniques or automating irregular box shapes. Richpack advises visiting the facility to evaluate the showroom and the technical team’s experience—only a team that truly understands the craft can foresee risks during the design phase and offer viable solutions.

For high-end packaging, QC cannot be an afterthought. A qualified partner must have a comprehensive quality management system, from raw material inspection to inline monitoring and 100% final inspection. Richpack enforces strict QC standards that go beyond dimensional checks to include sensory details: glue overflow, cracking on fold lines, and insert flatness. This paranoid attention to detail is the only way to ensure zero-defect delivery.

True craftsmanship is born from collaboration. The ideal packaging partner is not merely a factory, but a design consultant. They should offer extensive customization options and possess the engineering capability to turn an artist’s sketch into a production-ready blueprint. Richpack prides itself on a collaborative design process, where our technical team optimizes structure, cost, and feasibility in real-time, co-creating packaging that balances aesthetics with manufacturability.

The future of craftsmanship embraces digital manufacturing. Laser cutting, 3D printing, and robotic arms will elevate precision to new heights while retaining the “soul” of tradition. Richpack envisions a “Machine Skeleton + Human Soul” model—using automation for high-precision structural forming, followed by skilled technicians for delicate finishing and assembly.

As demand for personalization explodes, craftsmanship will pivot toward flexibility. We will see a rise in small-batch, high-couture packaging for limited editions or influencer kits. This requires manufacturers to have rapid response times and flexible scheduling. Richpack is ready to support the “Less but Better” market demand, helping brands capture niche segments.

Innovation fuels the continuation of craftsmanship. Future packaging will break boundaries with new materials, smart interaction (NFC/AR), and sensory inks. However, Richpack believes that innovation must be grounded in solid craftsmanship. Innovation is only valuable when it meets the baseline of impeccable quality.

In the beauty industry, your packaging is your most expensive billboard and your silent salesperson.

Richpack has dedicated more than 15 years to the art of high-end packaging manufacturing. We are not merely box makers; we are engineers of brand value. From precise structural design to rigorous hand-assembly, we infuse the artisan spirit into every step to ensure your brand shines.

Don’t let mediocre packaging dim the brilliance of your product. Contact the Richpack team today. Let us define a bespoke packaging solution with extreme craftsmanship and professional service to create the next unboxing classic that the market will talk about.

A: Not necessarily; it depends on your specific needs. Fully automated production is ideal for large-scale, standardized orders due to high efficiency and consistency. However, for high-end gift boxes requiring razor-sharp edges (like 90-degree V-grooves), complex irregular structures, or intricate insert assembly, handcrafted packaging handles the delicate details machines cannot, delivering a unique “warmth” and luxury feel.

A: Absolutely not. With today’s technology, Richpack can utilize high-level techniques such as deep embossing, hot stamping, or silk screening to impart rich textures and premium lustre to recycled paper or FSC-certified materials. “Sustainable Fashion” is now a luxury statement in itself—eco-consciousness and opulence can coexist perfectly.

A: Compared to standard items, high-craft packaging involves more manual steps (such as hand-wrapping and precision assembly), typically requiring 35-45 days. For a complex first order, Richpack recommends allowing extra time for prototyping and adjustments. “Slow is smooth, and smooth is fast”—this ensures mass production is flawless.

A: We recommend prioritizing “Paper Texture” and “Logo Hot Stamping.” Choosing a specialty paper with inherent texture (tactile paper) instantly elevates the handheld experience without expensive full-coverage printing. Combined with high-precision foil stamping or blind embossing of your logo, you create a visual focal point with a high ROI.

A: Traditional factories often require high MOQs, but Richpack understands the need for limited editions or new product testing. We offer flexible production solutions. While the per-unit cost for small batches will be slightly higher, we guarantee the same artisan-level quality and detail control as our mass production runs.

The perfume packaging market, valued at USD 3.31 billion in 2023, is projected to reach USD 5.95 billion by 2032, with a CAGR of 6.84%, reflecting a steady increase in demand for perfume packaging solutions worldwide. Brands must adopt innovative and sustainable strategies to thrive. This article highlights essential elements of impactful perfume packaging and… Continue reading The Role of Craftsmanship in Custom Cosmetic Packaging Boxes

Have you ever wondered why paper cosmetic packaging like some makeup boxes grab your attention on the shelf even before you know what’s inside? Or why do you get a feeling of luxury and delight when you unwrap a new lipstick? It all comes down to the magic of packaging. In the fiercely competitive beauty… Continue reading The Role of Craftsmanship in Custom Cosmetic Packaging Boxes

With options in materials and engraving techniques, they're suitable for various industries, making them a great choice for businesses aiming to stand out.

Charming Custom Logo Gift Bags for Special Gifts – Branded Gift Bags to Make Your Presents Stand Out

View More

Custom Logo Embossed Black Cardboard Beauty Products Box With Window Pink Art Paper Packaging

View More

Eco-Friendly Gift Boxes in Large Quantities for Wholesalers | Sustainable Packaging Solutions Custom Designs Available

View MoreJust submit your email to get exclusive offers (reply within 12 hours)