5 Benefits of Choosing Custom Jewelry Pouches for Your Products

2025-05-14

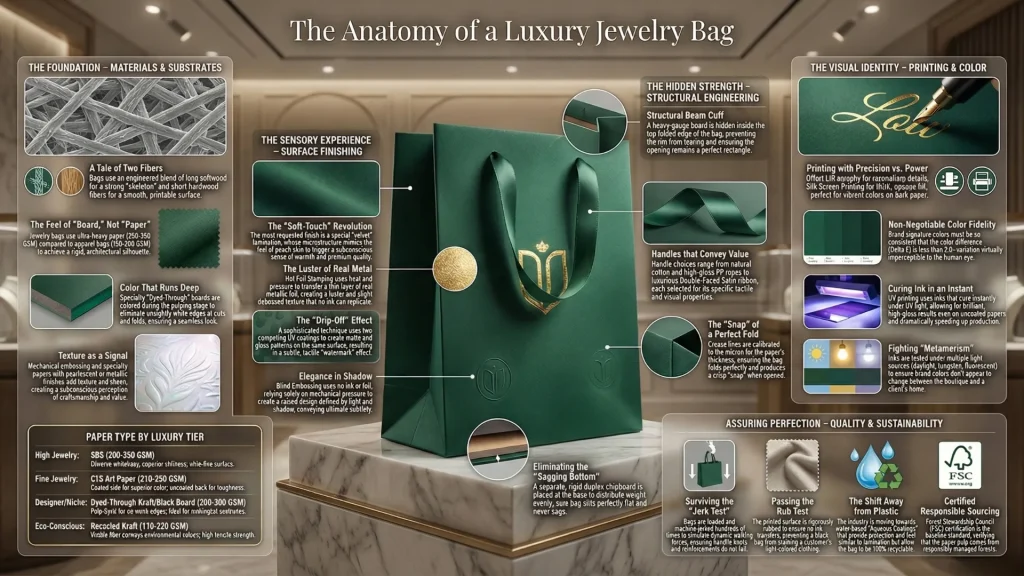

A paper bag is a critical extension of brand equity—a physical interface connecting the retail space to the consumer’s private sphere. The manufacturing of modern luxury jewelry bags represents a deep convergence of materials science, structural engineering, colour physics, and precision manufacturing. To satisfy the contradictory demands of being “robust as a shield yet tactile as silk,” the supply chain must navigate a delicate balance between tensile strength and tactile softness, visual opulence and environmental sustainability, as well as the flexibility of hand assembly versus the precision of automation.

In this article, we will discuss the technology and craftsmanship behind jewelry-specific packaging, covering everything from the selection of cellulose substrates to nanometer-scale surface coatings, structural optimization, and rigorous quality control systems.

The foundation of any premier packaging lies in the physical integrity of its substrate. For jewelry packaging, because the contents are typically small in volume but high in density (such as precious metals and gemstones) and possess high unit value, the paper must exhibit specific mechanical properties. These include superior stiffness, tear resistance, and folding endurance, while simultaneously serving as a flawless vehicle for high-fidelity printing.

The hand feel and mechanical strength of a bag are primarily determined by the fiber composition of the pulp and its manufacturing process. High-end jewelry bag manufacturing typically involves the engineered blending of two primary fiber types:

The most distinguishing feature of a luxury jewelry bag is its rigidity, often described as having a “board feel” rather than a “paper feel.” This physical attribute is strictly controlled by the paper’s basis weight, measured in Grams per Square Meter (GSM).

Unlike the 150-200 GSM paper typically used in the apparel industry, jewelry industry standards favor heavier materials, ranging from 250 GSM to 350 GSM. This high density is not only to support heavy jewelry boxes but, more importantly, to prevent the bag walls from bowing or warping when unloaded, thereby preserving the architectural silhouette of the packaging.

| Application Tier | Recommended Paper Type | GSM Range | Physical & Aesthetic Characteristics |

| High Jewelry | SBS (Solid Bleached Sulfate) | 300 – 350 GSM | Extreme whiteness, superior stiffness, a heavy “thud” upon closing, and an ultra-fine surface. |

| Fine Jewelry Retail | C1S (Coated One Side) Art Paper | 210 – 250 GSM | Coated side offers superior color reproduction; uncoated back retains fiber toughness. Ideal for small-to-medium sizes. |

| Designer/Niche | Dyed-Through Kraft/Black Board | 200 – 300 GSM | Pulp-dyed for no white edges at cuts. Showcases minimalist aesthetics with tight fiber structure and high tear resistance. |

| Eco-Conscious | Recycled Kraft | 170 – 230 GSM | Visible fiber texture conveys environmental values. High tensile strength, though slightly less stiff than coated stocks of equal weight. |

Beyond standard coated and uncoated stocks, the jewelry industry frequently employs “Specialty Papers” to convey exclusivity through texture.

A jewelry brand’s Visual Identity (VI) relies on the precise deposition of ink onto the substrate. The choice of printing technology for paper bags depends on volume, surface topology, and extreme demands for color fidelity.

Offset lithography remains the gold standard for high-volume luxury packaging, credited to its superior resolution and color control.

For extreme color saturation or printing on dark, rough textured substrates, silk screen printing is the preferred process.

Ultraviolet (UV) printing technology is becoming dominant in luxury packaging. UV inks contain photoinitiators that polymerize instantly upon exposure to specific UV wavelengths, rather than drying via solvent evaporation or absorption.

If printing provides visual information, finishing technology provides emotional context. By regulating the light reflectance and friction coefficient of the bag’s surface, a multi-sensory luxury experience is engineered.

Lamination involves thermally bonding a microscopic plastic film (usually PP or PET) to the paper surface. This layer serves two purposes: it significantly increases tear strength (crucial for fold corners) and establishes the aesthetic baseline.

Foil stamping is the signature process of jewelry packaging, imparting real metallic luster that no metallic ink can match.

A sophisticated technique growing in popularity is “Reverse UV” or “Drip-Off,” which creates matte/gloss contrast on a single plane without lamination.

A luxury jewelry bag is essentially a rigid container constructed from flexible materials. To maintain perfect geometry under load, precise structural engineering is required.

To prevent deformation during carrying, reinforcements are implanted in critical zones.

The handle is the first touchpoint of interaction. Its material, diameter, and connection method directly convey brand value.

Precise die-cutting ensures the bag forms a perfect square.

Crease Matrix: The depth and width of the crease channel must be calibrated to the micron based on paper thickness. Too shallow causes “cracking” (exposing white fibers); too deep cuts the fibers. For thick, dark-printed papers, localized humidification or heating is often applied before creasing to increase fiber pliability.

Gusset Geometry: Side fold lines must align precisely with the bottom flap creases to ensure the bag produces a crisp “snap” when opened and stands without wobbling.

Adhesive chemistry dictates the lifespan and environmental adaptability of the bag.

To ensure the bag safely protects high-value jewelry, rigorous physical and chemical testing is mandatory.

Modern luxury consumers demand that exquisite experiences do not come at the planet’s expense.

Traditional laminated bags are difficult to recycle.

The production of a jewelry paper bag is a game of extreme details. Beneath the minimalist exterior lies a complex decision matrix: Long-fiber strength vs. short-fiber smoothness? Chemical stability of UV ink vs. physical luster of Hot Foil? The absolute consistency of machine folding vs. the warm touch of hand assembly?

For jewelry brands, the paper bag is the final handshake of the transaction. The technologies detailed here—from 350 GSM solid bleached board to nanometric soft-touch lamination, from spectrally matched spot inks to jerk-tested cotton handles—collaborate to ensure this “handshake” conveys weight, permanence, and care.

Table 1: Printing Process Applicability Matrix

| Feature | Offset Lithography | Silk Screen Printing | UV Printing |

| Best Use Case | High-detail images, photography, gradients | Large solid color blocks, tactile effects, metallics | Fast turnaround, non-absorbent substrates |

| Ink Thickness | Thin (1-2 microns) | Very Thick (10-100 microns) | Medium (Dependent on settings) |

| Substrate Compatibility | Smooth papers (Coated) | Almost all (Textured, Dark, Cloth) | Almost all (Plastic, Metalized paper) |

| Dark Paper Color | Poor (Inks are translucent) | Excellent (High opacity) | Excellent (Ink sits on surface) |

Table 2: Handle Material Performance

| Handle Type | Material | Strength | Aesthetic | Cost | Eco-Friendliness |

| Twisted Rope | Cotton | Medium | Natural, Matte, Organic | Medium | High (Biodegradable) |

| Twisted Rope | PP (Polypropylene) | High | Glossy, Synthetic, Uniform | Low | Low (Traditional plastic) |

| Ribbon | Polyester Satin | Medium | Luxurious, Silky, High Gloss | High | Low (Unless Recycled PET) |

| Ribbon | Grosgrain | High | Textured, Structural | High | Varies by material |

At Richpack Packaging, we engineer brand experiences. From selecting the precise fibre blend for structural integrity to executing complex “drip-off” UV finishes that delight the fingertips, our expertise ensures your jewelry packaging is as exquisite as the pieces inside.

Whether you need a fully sustainable aqueous coating solution or a hand-assembled, multi-level embossed masterpiece, Richpack is your partner in precision luxury.

A: Unlike standard retail bags, luxury jewelry bags often use heavy boards (300+ GSM) and complex laminations that are sensitive to environmental changes.

Humidity Control: Paper is hygroscopic. Store bags in a climate-controlled environment with relative humidity between 40-60%. Excessive moisture can cause the “bottom board” to warp, while extreme dryness can cause the lamination to peel or the paper to crack at the folds.

Stacking: Do not stack cartons more than 5 high. The weight can crush the “gusset geometry” or leave permanent pressure marks on the soft-touch lamination of the bags at the bottom.

A: While a digital proof checks spelling and layout, it cannot simulate the physical interaction of light with Hot Foil or the tactile height of Embossing. Creating a physical sample requires making the actual metal dies (molds) and setting up the machinery just for one unit.

Recommendation: For orders involving complex multi-level embossing or specific foil colors, we strongly recommend a wet proof to benchmark the “hand feel,” even though it incurs a tooling setup fee.

A: Unpleasant odors can ruin the unboxing experience, especially for jewelry. This usually stems from solvent-based glues or insufficient UV curing time.

Our Protocol: At Richpack, we prioritize low-VOC (Volatile Organic Compound) adhesives and ensure a specific “airing out” period in a ventilated staging area post-production before packing them into shipping cartons. If your brand is highly sensitive to scent, please request our “Odor-Neutral” adhesive options during the consultation.

A: While automation ensures consistency, it requires significant setup time.

The Threshold: Generally, for orders under 3,000 – 5,000 units, semi-automatic or manual assembly is more cost-effective due to the high setup costs of automatic tube-forming machines.

The Exception: If your bag requires complex, non-standard sizes or unique ribbon attachments, manual assembly remains the only option regardless of volume, as machines are limited to standard “landscape” or “portrait” aspect ratios.

Learn how to choose eco-friendly materials for gift boxes with lids, exploring recycled paperboard, FSC-certified paper, bioplastics, and more.

Richpack · How to Tell Monet Jewellery Brand Story Through Packaging Art According to a study by Smithers Pira, the global packaging market is expected to reach $1.42 trillion by 2028, highlighting the growing emphasis on packaging. Monet jewelry packaging also tells this brilliance. But its unboxing experience, often overlooked, presents a potent opportunity to… Continue reading The Technology and Craft Behind Our Paper Bags for Jewelry

Richpack · Richpack Jewellery Boxes Inheriting and Advancing Napier Jewellery Packaging's Aesthetic and Eco-Intelligence Napier resonates with jewellery connoisseurs, evoking images of high-quality craftsmanship and innovative designs. Richpack, a leading provider of jewellery packaging solutions, is dedicated to creating boxes that embody sustainability and environmental responsibility while showcasing jewellery’s inherent elegance. In thig blog, we will discover how… Continue reading The Technology and Craft Behind Our Paper Bags for Jewelry

Luxury Packaging Sets for High-End Jewelry | Premium Custom Solutions with Richpack Matching Designs for Exclusive Jewelry Brands Seeking Elegant Bulk Packaging

Richpack Versatile and Recherché Small Containers with Lids – Durable and Secure Jewelry Display Solutions for Organized Storage and Beauty Amplification

Versatile and Resilient Gift Bags Paper for Every Occasion – Richpack Stylish Small Colorful Gift Bags Perfect for Any Gift Presentation

Bespoke and Durable Custom-Printed Paper Bags for Retail Stores with Logos | Perfect Branding Solutions for Jewelers Needing Eye-Catching Retail Packaging

View More

Custom Gift Cards with Branded Logos and Messaging | Richpack’s Tailored Solutions for Jewelry Stores Requiring Branded Packaging Options

View More

Eco-Conscious Recycled Paper Jewelry Bags with Branding | Ideal for Jewelry Wholesalers Looking for Sustainable and Custom Packaging Options

View MoreJust submit your email to get exclusive offers (reply within 12 hours)