2026 Jewelry Brand Custom Packaging Stations: Which Warehousing Firms Are Worth Choosing?

2025-09-03

Have you ever pondered why certain luxury gift boxes seem like a remarkable experience on their own, while others are simply plain and ordinary? The solution resides not just in their design but more significantly in the strategic use of materials.

A high-end gift box is no ordinary container. It’s a brand’s tactile statement, a significant aspect of the product’s identity, and the first chapter of an amazing unpacking experience. For brand managers aiming to raise their brand image, or procurement directors attempting to balance quality and cost, knowing the materials and workmanship underlying luxury packaging isn’t just important—it’s crucial.

In this tutorial, Richpack will properly steer you. We’ll unveil the basic materials, high-end surface finishing processes, and strategic considerations that convert a normal box into a compelling brand asset.

Keep in mind that when we get down to discussing how to create a genuinely unique packing experience, everything begins with one essential question: What materials will we actually use?

Think of it this way: the materials you choose create the basis for all future designs. This is not only about looks; more significantly, it sets the tone for the whole moment when buyers open the product.

In the high-end packaging market, there’s a fascinating trend: paper and paperboard are absolutely hot subjects right now, and for good reason.

Their adaptability is astonishing. Using the same fundamental paper material, you can create radically diverse brand experiences. The goal is to discover which font best expresses your brand narrative.

Coated paper, such as C1S (single side coated) and C2S (double sided coated) art paper, is an excellent choice for luxury gift boxes when the design requires clear, brilliant, and vivid colours that “pop” off the surface. If the design you produce has to exhibit clear, brilliant, and vivid colors—colors psychology that “pop” off the surface—coated paper is your perfect option.

What makes it remarkable is its smooth, glossy white surface, which performs incredibly well with offset printing. Your business logos, photos, and all the meticulously created features will all show with incredibly high clarity and rich brightness.

Black paper instantly elevates the entire look of a gift box to one of elegance and class, signalling to recipients that the contents are remarkable Black paper has an almost mystical quality. It quickly lifts the whole look to elegance and class. When people see its rich, glossy black surface, they know for sure that whatever is within must be something remarkable.

Black paper works very well for high-end items or for once-in-a-lifetime situations when you want to create a powerful impression even before opening the box.

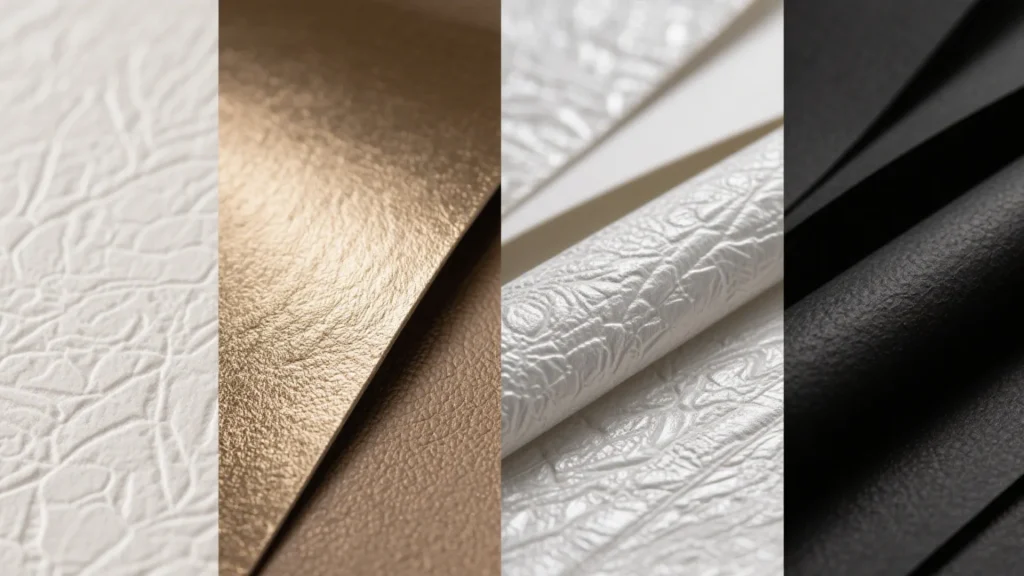

That’s exactly where its great charm lies. Specialty papers extend the experience from people’s visual perception to more dimensions. The type of material we’re talking about makes people unable to resist wanting to touch it with their hands, adding a full set of sensory experiences to your packaging.

Embossed paper has a special surface texture that makes people unconsciously want to stroke it with their fingers. Leather-like paper has a unique appeal. It retains the delicate, classic look of real leather without the various troubles that come with handling genuine leather.

As for metallic paper, its core function is to create striking and memorable visual effects. It can instantly catch people’s eyes even from the other end of the room.

Textured Paper: With its unique surface texture, textured paper elevates the overall appearance of the gift box and makes the perceived value seem even higher. When combined with foil stamping and embossing, it excels at adding value to products, offering durability, tear resistance, and customisability.

Leatherette Paper: This material mimics the appearance of genuine leather, providing a sophisticated look without the complexities of real leather. Its smooth, elegant, leather-like texture, durability, and ease of customisation make it ideal for high-end items. Leatherette paper is flexible, allowing it to be easily moulded and shaped for desired gift box forms.

▪ Metallic Paper: Featuring a shiny, reflective surface, metallic paper creates an eye-catching and visually striking appearance, imparting a sense of luxury and elegance. These metallic effects can be achieved through metallic inks or laminating films, offering sharp details, saturated colours, and a unique pearlescent surface.

Kraft paper delivers a completely different style. It has a natural, simple quality that aligns with sustainability values and a sincere attitude. This paper is strong, durable, and cost-effective, and also has a rich, vintage texture.

In contrast, ivory board features a pure, bright white luster. It is commonly used in high-end cosmetics and perfume packaging. Both materials can perfectly match specific brand images.

We often spend a lot of time focusing on surface aesthetics, but the components that truly matter are the structural parts beneath.

These materials determine whether your packaging feels premium in someone’s hands, protects the contents inside, and delivers on the promises conveyed by its external design.

Rigid board, often called chipboard, is actually the core material for high-quality packaging. This thick board can be made into sturdy, non-deformable boxes. When consumers hold them, they can clearly feel the weight. It’s this solid, durable feel that immediately conveys the product’s high quality and attention to detail.

When you need high-strength protection—for example, for heavier products or items that need to be shipped and moved multiple times—corrugated fiberboard is your ideal choice.

Its multi-layer structure delivers excellent strength and compression resistance, a feature no other material can match. When product protection becomes an absolute must, corrugated fiberboard is the top choice.

Sometimes, a project calls for materials that are completely outside the usual range. Wood offers natural beauty and excellent durability, and you’ll often find it in high-end wine and jewelry packaging.

In contrast, tinplate and plastic provide unique visual effects and levels of protection, respectively, depending on your specific usage goals.

Velvet & Fabric Materials

When aiming to infuse packaging with an unparalleled sense of luxury, softness, and tactile indulgence—qualities that turn a simple box into a memorable sensory experience—velvet and fabric materials stand in a league of their own. Unlike rigid paper or board, these textiles wrap the packaging in a gentle, sumptuous touch, instantly elevating the perceived value of the contents and signaling to recipients that they’re about to uncover something extraordinary.

Velvet

Velvet, with its dense, plush pile and subtle sheen, is the epitome of opulence. Its unique texture invites immediate tactile engagement—people can’t help but run their fingers over its smooth, velvety surface, creating a moment of connection that paper-based packaging rarely achieves. This material excels in high-end gifting scenarios, such as luxury menswear subscription boxes (think premium socks, silk ties, or leather accessories), limited-edition grooming kits, or high-value hobby items (like handcrafted watch tools).

Velvet’s color versatility adds to its appeal: deep, rich hues like burgundy, emerald, or jet black amplify its luxurious aura, while softer neutrals (ivory, taupe) lend a refined, understated elegance. It also pairs beautifully with premium finishing touches—foil stamping (for logos or monograms) or embossing—where the contrast between the velvet’s softness and the crisp, metallic or raised details creates a striking visual and tactile balance. Beyond aesthetics, velvet offers a protective layer too: its plush texture cushions delicate items inside, preventing scratches or damage while feeling indulgent in the hand.

Fabric Clusters

Fabric clusters—encompassing materials like cotton, linen, silk, and microfiber—bring versatility, texture, and a warm, approachable luxury to packaging. Unlike velvet’s opulence, these fabrics often lean into “elevated comfort” or “artisanal charm,” making them ideal for brands that want to feel premium yet relatable.

Cotton/Linen: These natural fibers have a breathable, textured surface that aligns with sustainability and rustic-luxe aesthetics. Cotton or linen-wrapped boxes work beautifully for artisanal food subscription boxes (gourmet snacks, small-batch preserves), handcrafted grooming products (beeswax balms, organic soaps), or hobby kits (knitting supplies, wooden crafting tools). Their neutral tones (off-white, natural beige, soft gray) act as a blank canvas for customisation—think screen-printed logos in muted colors or hand-tied ribbon accents that enhance their artisanal vibe. They’re also durable and reusable; many consumers repurpose cotton-wrapped boxes as storage for small items, extending the brand’s lifecycle.

Silk/Microfiber: For a lighter, more delicate luxury, silk or microfiber fabrics shine. Silk’s subtle luster and smooth drape add a touch of sophistication without feeling overly formal, making it perfect for high-end accessory boxes (silk scarves, premium cufflinks) or skincare sets with fragile components (glass vials of serums, handcrafted face rollers). Microfiber, a synthetic alternative, offers similar softness with added durability and stain resistance—ideal for packaging that needs to withstand minor handling (e.g., monthly grooming boxes with liquid products). Both materials can be tailored to fit box shapes seamlessly, creating a sleek, streamlined look that feels polished and intentional.

A key advantage of fabric materials is their ability to evoke emotion: velvet speaks to indulgence and celebration, while cotton/linen feels like a thoughtful, personal touch, and silk/microfiber conveys refined elegance. Like velvet, fabric clusters also pair well with complementary materials—think a linen-wrapped box with a kraft paper insert for product separation, or a velvet-lined interior for a rigid board watch box—blending textures to create a multi-layered, memorable unboxing experience. For brands focused on sustainability, organic cotton or linen (certified by GOTS or OEKO-TEX) adds an eco-conscious edge, aligning tactile luxury with ethical values.

We’ve selected the right material base, which is great. But the real magic happens during the finishing and customization process.

It’s no exaggeration to say this is the stage where a basic packaging idea transforms into a piece that truly reflects a brand’s identity. It’s like the huge difference between a well-built building and one that’s meticulously crafted, with every detail polished over and over.

Post-processing is the key step that takes our packaging from functional to experiential. You’ve surely had this experience: you pick up a box and immediately sense that what’s in your hand is out of the ordinary.

That’s the feeling we want to create. Specifically, we add layers to the printed surface so people can actually touch and feel this rich texture.

Lamination may seem like just a practical step, but it’s actually one of the most flexible tools for brand expression. When we talk about lamination, we mean covering the packaging surface with a thin protective film. It not only safeguards your design but also enhances its visual appeal.

Matte lamination creates a refined, premium surface texture that exudes luxury when held. It’s often used on high-end rigid box packaging because it significantly elevates the overall tactile experience.

Glossy lamination follows a different process logic. It makes colors brighter and more vivid while effectively resisting scratches and moisture. Each choice sends a completely different brand message to consumers.

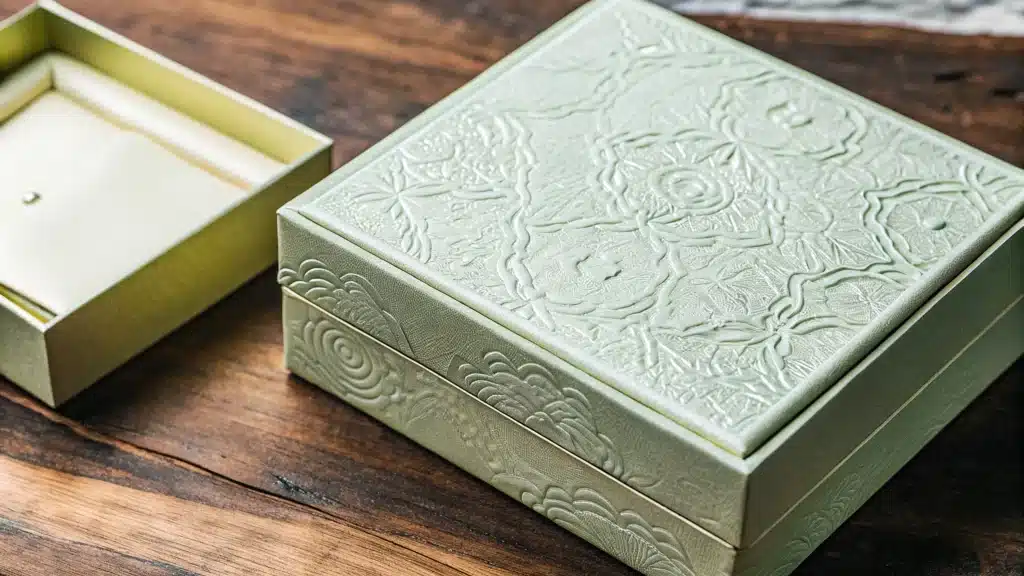

This step brings packaging to life and creates interactivity. Embossing (raising designs) and debossing (recessing designs) add real depth to the design. The raised parts reflect light in different ways, while the recessed parts invite people to touch them.

This technique works exceptionally well for highlighting brand logos or core design elements, making these key details unforgettable. When someone runs their finger over an embossed logo, they form a tactile connection with the brand—one that goes far beyond simple visual recognition.

In packaging discussions, one element is often overlooked: “internal structure.” Box inserts are crucial for creating the perfect unboxing experience. They serve two roles: protecting the product during shipping and setting the ideal scene for the product’s reveal when the packaging is opened.

The core of choosing inserts lies in fully understanding the product’s unique needs—including its size, weight, fragility, and the overall experience you want to create for consumers.

The core concept here is that packaging internal design isn’t just about protecting the product. More importantly, it should orchestrate this “discovery journey” for consumers when they first open the packaging. Every detail should help build anticipation and ultimately deliver on the brand’s promise.

We’ve already looked at all these excellent materials and surface treatment options. Now comes the critical part: how do you pick the one that truly fits your situation best?

This is more about creating a strategic fit between your product needs, brand story, and real-world circumstances.

When evaluating packaging options, you need to look at things from several key angles. Think of these angles as different lenses to examine your project. Answering these core questions clearly will help you find the solution that aligns with your business goals.

Let’s start with the most basic need: packaging must protect the product inside. This is non-negotiable—you can’t compromise it for the sake of good looks.

If your product is large or fragile, materials like corrugated cardboard and rigid paperboard aren’t optional; they’re a must. The structural stability of your packaging is the first step to keeping your promise of quality and reliability to customers.

This is where strategy comes into play. Your material choice must accurately reflect your brand’s core identity and values. You need to be clear: does your brand lean toward a minimalist, refined style, or does it focus more on a simple, authentic, and nature-friendly vibe?

Luxury brands usually prefer glossy materials and delicate textures to convey a high-end feel and superior quality. Brands that prioritize eco-friendly values, however, may opt for unbleached kraft paper. This material specifically highlights their commitment to sustainability.

Remember: the material itself has become part of your brand story. It’s not just packaging—it’s a way for your brand to express itself.

We can’t ignore practical cost issues. Budget matters a lot, and you need to balance it properly with the value your product delivers. Regular cardboard offers great value for money and works in many scenarios. High-end rigid boxes, while requiring more investment, deliver a correspondingly better user experience.

Sustainability adds a new dimension to cost considerations. Choosing recyclable or biodegradable materials isn’t just about environmental responsibility (though that’s extremely important). It also helps attract more eco-conscious consumers—people who make purchasing decisions based on these values. This choice not only helps your brand stand out in key areas but also may open up new market opportunities.

Pro tip: The right packaging decision comes from analyzing these factors comprehensively. You need to find a balance where all factors align with your specific business goals and brand positioning.

Table: Overview of Luxury Gift Box Materials and Their Benefits

| Material Category | Specific Material | Key Characteristics | Luxury Benefits |

| Paper/Paperboard | Coated Paper (C1S/C2S) | Smooth, glossy white surface, excellent for vibrant offset printing (70-250 g/m2). | Ensures clear, brilliant, vivid colours and high clarity for branding; improves smoothness, whiteness, and gloss, contributing to a premium look. |

| Black Paper | Rich, glossy black surface. | Immediately conveys elegance, class, and sophistication, making a bold statement for high-end or special occasions; matte black offers a powerful aura. | |

| Textured Paper | Unique surface texture. | Elevates overall aesthetic and perceived value; invites tactile engagement; enhances with foil stamping/embossing. | |

| Leatherette Paper | Mimics genuine leather, soft texture, wear-resistant. | Provides a sophisticated, elegant, and classic look without genuine leather’s issues; highly customisable and durable for high-end items. | |

| Metallic Paper | Shiny, reflective surface, metallic finish/visual effects. | Creates an eye-catching, visually striking appearance; imparts luxury and elegance; offers sharp details and saturated colours. | |

| Kraft Paper | Natural, simple quality, strong, durable, cost-effective. | Aligns with sustainability values and authentic brands; rich, vintage texture; versatile and robust for protecting luxury items. | |

| Ivory Board | Pure, bright white lustre, made from 100% virgin tree pulp (0.27-0.55mm, 210-400g GSM). | Offers a pristine, brighter look than art paper; popular for high-end cosmetics, perfumes, and small devices due to ease of printing/engraving. | |

| Structural Materials | Rigid Board (Chipboard) | Thick, dense board; forms a sturdy, non-deformable core. | Conveys immediate high quality and attention to detail through its solid, weighty feel; ensures structural integrity and premium presentation; ideal for high-value items. |

| Corrugated Fiberboard | Multi-layer structure (3, 4, or double wall); high strength, compression resistance. | Provides excellent protection for heavy or fragile items during transit, ensuring product safety; enhances perceived value through durability; can be customised. | |

| Premium Alternatives | Wooden Box Material | Natural beauty, exceptional durability, often covered with leather. | “Screams” sophistication and luxury; perfect for high-end wines, jewellery, and watches; reusable and customisable (engraving/painting) for a memorable unboxing experience. |

| Tinplate | Metal material. | Offers unique visual effects and levels of protection, suitable for specific luxury applications where a metal aesthetic is desired. | |

| Plastic (PP, PS, HDPE) | High tensile strength, durability (PP); high-impact strength, rigidity (PS); food-safe (PP). | Provides distinct properties for specific usage, such as food-grade luxury packaging or as robust internal moulds for delicate items like jewellery. |

Note: The micron value measures the thickness of paper and card (one micron equals one thousandth of a millimetre), while GSM (grams per square metre) refers to the weight of paper or card per square metre. Higher micron values generally indicate thicker, sturdier materials.

Ultimately, selecting the proper material for luxury gift boxes is a strategic choice. It significantly affects brand image and consumer experience. This demands significant study, where aesthetics, protection, and brand identity must ideally match. As this article reveals, there are numerous possibilities to pick from, but the one that best conveys your unique narrative is always the appropriate decision.

Are you now ready to convert your concept into reality and produce amazing personalized luxury gift boxes? Our staff is ready to support you every step of the way.

Contact us immediately to obtain a free quotation and make your packaging concept a wonderful reality!

An analysis of global jewellery consumer trends shows that 14k jewellery is gaining more traction in the face of rising gold prices, and retailers are driving sales of these high-margin products through aggressive marketing strategies: the jewellery industry is witnessing a surge in the popularity of 14k gold-plated jewellery. This trend is driven by the desire for high-quality pieces… Continue reading What Material is Used for Luxury Gift Boxes?

Moonstone jewelry has fascinated jewelry customers for centuries with its mysterious allure. But competition is fierce for brands to keep these customers interested. In fact, A Study shows increasing customer retention rates by 5% increases profits by 25% to 95%. So brands must pay attention to their packaging design. One way to achieve this is to… Continue reading What Material is Used for Luxury Gift Boxes?

Emily carefully selected a high-end wristwatch, considering it the perfect choice as gifts for a 50 year old man (her father). However, when she presented this heartfelt gift, it was packed in a simple cardboard box — her father froze. Awkward? Absolutely! Most consumers say that packaging affects their first impression of a brand. The packaging design… Continue reading What Material is Used for Luxury Gift Boxes?

Cardboard Chocolate Box: Three-Tiered Tempting Treats for All Occasions

Custom Christmas Gift Boxes for Food | Ideal Food Gift Boxes for Retail, Corporate Gifting, and Holiday Events Christmas Trending

Eco-Friendly Luxury Gift Boxes for Environmentally Conscious Brands | Sustainable Packaging Solutions | Custom Designs Available

Adorable Small Jewelry Travel Box – Safeguard Your Treasures While Traveling

View More

Beautiful Butterfly Box Gifts | Deluxe Butterfly Gift Boxes for Special Occasions and Unique Presentations Bulk Order Options from Richpack

View More

Branded and Sustainable Custom Eco-Friendly Jewelry Packaging with Brand Logo | Tailored for Jewelry Brands Needing Personalized and Green Packaging

View MoreJust submit your email to get exclusive offers (reply within 12 hours)