2026 Top 7 Packaging Trends for Moonstone Jewelry

2024-12-05

DTC brands spend 18-34% more on packaging than their traditional retail counterparts. The cost gap is a result of 3 key factors: over-engineered boxes, hidden shipping fees, and reckless redesign cycles. In this article, we will not only uncover the reasons behind this cost disparity but also provide actionable solutions, debunk common myths, and answer frequently asked questions.

The significantly higher packaging costs for DTC brands compared to traditional retailers are no trivial matter. As we’ve briefly touched on the short answer, it’s now time to dig deeper and comprehensively analyze the root causes behind this phenomenon. Understanding these reasons is crucial for DTC brands aiming to optimize their operations and bottom lines.

In the physical retail space, products are often presented in basic trays, with a cost of approximately $0.18 per unit. The focus here is mainly on in-store display and functionality. However, DTC brands are in a different ballgame. They have to satisfy two distinct requirements: surviving the often-harsh shipping process and creating an impression that is worthy of being shared on social media platforms like Instagram.

Surviving shipping hell is no easy feat. DTC brands need to use materials that are 2.3 times thicker than those used in physical-store packaging. This brings the cost of materials to around $0.33 per unit. Additionally, to create an unboxing experience that wows customers, they often include custom inserts, which add another $0.08 per unit. In total, the packaging cost per unit for DTC brands can reach up to $0.67, which is a whopping three times the cost of physical-store packaging.

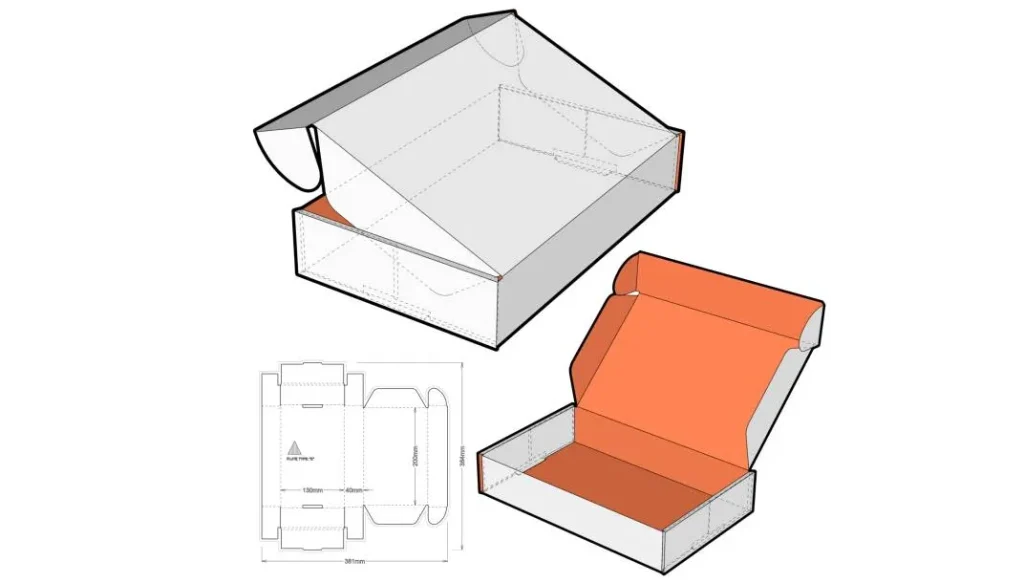

Richpack, a leading player in the jewelry packaging industry, offers a custom jewelry packaging solutions to this problem. Our jewelry boxes are designed to be flat-packed for shipping, which saves a remarkable 67% in storage space. This not only reduces storage costs but also makes the shipping process more efficient. The boxes also come with swappable inserts, eliminating the need for a complete redesign every time a new product is launched. This not only saves time but also a significant amount of money. And when it comes to protection, these boxes are military-grade, having been pressure-tested up to 53psi, ensuring that products reach customers in perfect condition.

Carriers like UPS have a pricing model that is not just based on the weight of the package but also on its volume. This means that even if a package is lightweight, if it has a large volume, it will be charged more. For example, consider a box with dimensions 6″x6″x3″ and an actual weight of 0.9 lb. UPS might calculate the shipping cost as if the package weighs 3 lb, resulting in a 36% fee hike.

Take the case of Luxury brand Maison Rêve. They were struggling with high shipping costs due to the bulky packaging of their products. After partnering with packaging expert team, they were able to implement a slim packaging solution. This packaging folds to half its original thickness, uses air cushions instead of foam, and stacks tightly in shipping boxes. As a result, Maison Rêve saved a whopping $7,200 per month in shipping costs. This not only improved their bottom line but also made their shipping process more sustainable by reducing the amount of packaging waste.

The 2023 DTC Packaging Report reveals a startling statistic: 84% of DTC brands redesign their packaging for every product launch. This constant redesign cycle is a major cost driver. Each time a brand decides to redesign its packaging, it incurs several costs. First, there are the costs associated with creating new molds, which can be upwards of $2,800. Then, there is the waiting time for production, which can range from 18-26 days. During this time, the brand is unable to bring its new product to market, potentially losing out on sales opportunities. Another major cost is the issue of dead stock. Most packaging suppliers have a minimum order quantity (MOQ), often around 5,000 units. When a brand redesigns its packaging, it may end up with a large amount of unsold, or dead, stock from the previous design.

Richpack offers a modular system that addresses these issues head-on. With this system, brands can swap logos in just 72 hours, without having to worry about MOQs. This allows for quick and cost-effective rebranding. The system also allows brands to mix different materials, such as vegan leather and recycled PET, giving them more flexibility in creating a unique brand image. And perhaps most importantly, the modular system enables brands to reuse 90% of the components for new products, significantly reducing the need for complete redesigns and the associated costs.

Now that we’ve grasped the reasons behind the soaring DTC packaging costs, it’s equally important to be aware of the common misconceptions that might be silently draining your resources. These myths can mislead DTC brands into making unwise decisions.

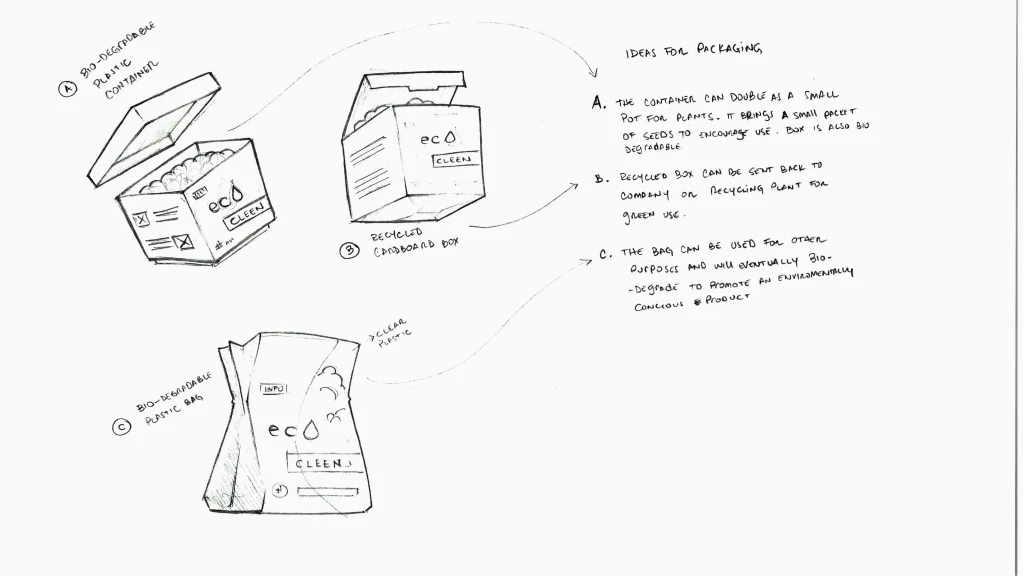

One of the most prevalent myths in the packaging industry is that going eco-friendly automatically means higher costs. However, the reality is quite different. Brands that have opted for sustainable packaging solutions, such as using plant-based foam, have actually seen cost savings. To discover more, click here. They can benefit from tax credits, which can save up to $0.07 per unit. Lighter materials used in eco-friendly packaging also result in lower shipping costs. And on top of that, these brands often see a 41% increase in Instagram tags related to sustainability, which can lead to increased brand awareness and potentially more sales.

Many DTC brands are under the impression that getting custom packaging is a long and arduous process that takes up to six months. In reality, this is far from the truth. At Richpack, 82% of custom orders ship in just 12 days. This is made possible through the use of 3D digital prototypes, which have a 48-hour turnaround time. Richpack also has a pre-approved material library, which speeds up the decision-making process. And for brands that don’t need large quantities, there are no MOQs, allowing them to order as few as 50 units if needed.

The idea that using cheap packaging is a cost-effective solution is a dangerous myth. Take the case of skincare brand GlowBar. They initially opted for cheap boxes to save money. However, this led to a staggering 23% return rate due to damaged products during shipping. After switching to Richpack’s durable design, their return rate dropped to just 1.7%. This not only saved them money on returns but also boosted repeat purchases by 17%. In fact, for every $1 spent on the new packaging, GlowBar earned an additional $3.10 in revenue.

With a clear understanding of the cost-driving factors and the myths to avoid, you might still have some burning questions. To address those, here are the answers.

A: Absolutely! Packaging can have a significant impact on a brand’s bottom line. And a 17% increase in the repeat purchase rate can increase the lifetime value (LTV) of a customer by $6.20. All these factors combined can lead to a substantial boost in profits.

A: At Richpack, we believe in transparent pricing. Our custom packaging starts at $0.39 per unit for orders of 1,000 units or more. This price includes free 3D design revisions, ensuring that you get the perfect packaging design. We also provide damage insurance of up to $5,000, giving you peace of mind. And to top it off, we offer climate-neutral shipping, which is not only good for the environment but also a selling point for eco-conscious customers.

Implementing the right packaging strategies can lead to significant cost savings in a relatively short period. Here’s a breakdown of some strategies and their associated cost savings and timeframes:

| Strategy | Cost Saving | Timeframe |

| Foldable Designs | 29% | 2 weeks |

| Right-Sized Boxes | 36% | Immediate |

| Modular System | 41% | 3 days |

73 brands have already put these strategies to the test. They have achieved 22-29% lower costs in just 90 days. Customer satisfaction scores have also seen a significant improvement, with an average of 9.2 out of 10, compared to the industry average of 7.8. And inventory turnover has become 41% faster, ensuring that products are moving off the shelves (or out of the warehouses) more quickly.

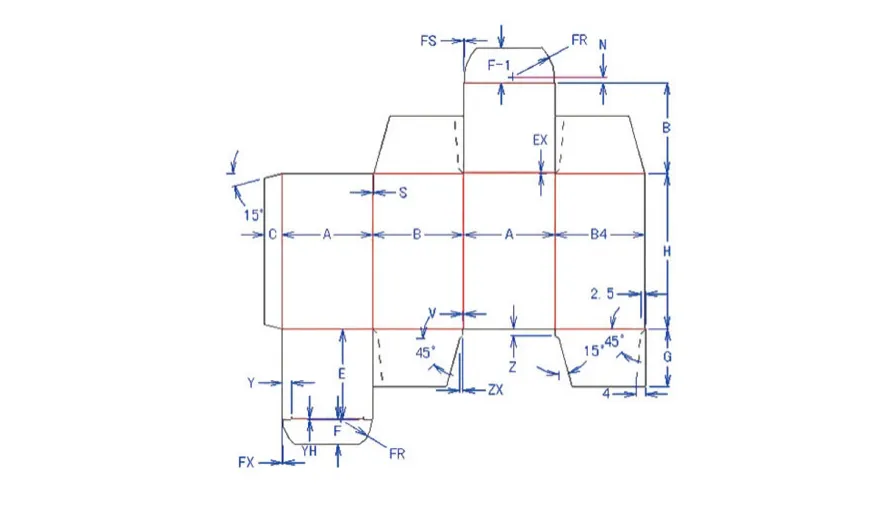

If you’re a jewellery or gift DTC brand looking to reduce your packaging costs without sacrificing quality or brand image, you can contact us for help. We offer a free cost analysis and accurate die cutting templates, which include a custom savings estimate tailored to your brand’s specific needs. You’ll also receive a 3D prototype of your ideal packaging, allowing you to visualize how it will look and function. And for qualified brands, we provide 50 free samples so you can experience the quality of our packaging firsthand.

Eco-friendly packaging for shop astrology jewelry on sale has a very good prospect in 2025 because recent market studies reveal that the astrology-themed jewelry sector experienced a 5.7% growth rate, with projections estimating the market size to exceed $22.8 billion by 2031. 2023 Buying Green Report shows 82% of respondents overall would be willing to pay more for sustainable… Continue reading 3 Key Reasons Why DTC Brand Packaging Costs Outpace Those of Physical Stores

As a professional jewellery packaging supplier with 16 years of experience, Richpack has been exploring ways to perfectly blend innovative design with sustainability. We believe that understanding and using eco-friendly packaging terms is essential not just for our team and customers, but for the entire jewellery industry. This glossary contains core terms and concepts related to sustainability in the jewellery packaging… Continue reading 3 Key Reasons Why DTC Brand Packaging Costs Outpace Those of Physical Stores

Gift-giving is always a perfect way for people to show appreciation and love for each other. However, the packaging often ends up as waste. As the statistics show, over a million plastic products are discarded every minute. This harsh reality has drawn a demand for eco-friendly alternatives, particularly in gift packaging. Millennials are widely recognized… Continue reading 3 Key Reasons Why DTC Brand Packaging Costs Outpace Those of Physical Stores

High-Quality Laminated Paper Bags for Special Events | Elegant and Customized Packaging Solutions for Jewelry Merchants and Exclusive Occasions

Large Order Discounts for Wholesale Jewelry Packaging | Cost-Effective Solutions for Bulk Buyers Customizable Designs Available Richpack

Richpack Cost-Effective Small Quantity Cosmetic Packaging for Independent Skincare Brands | Ideal for Small Businesses Needing Tailored Packaging in Low Volumes

Cost-Effective Custom Paper Bags with Logo Wholesale – Branded Paper Bags in Bulk with Richpack

View More

Creative Brown Paper Bag Puppets for Fun Crafting Activities – Learn How to Make a Paper Bag Puppet with Richpack’s Customizable Easter Paper Bags for Kids

View More

Customizable Wholesale Perfume Boxes with Bulk Discounts | Ideal for Distributors and Brands Looking for Cost-Effective Packaging Solutions

View MoreJust submit your email to get exclusive offers (reply within 12 hours)