30+ Jewelry Packaging Ideas to Elevate Your Brand (2026)

2025-07-10

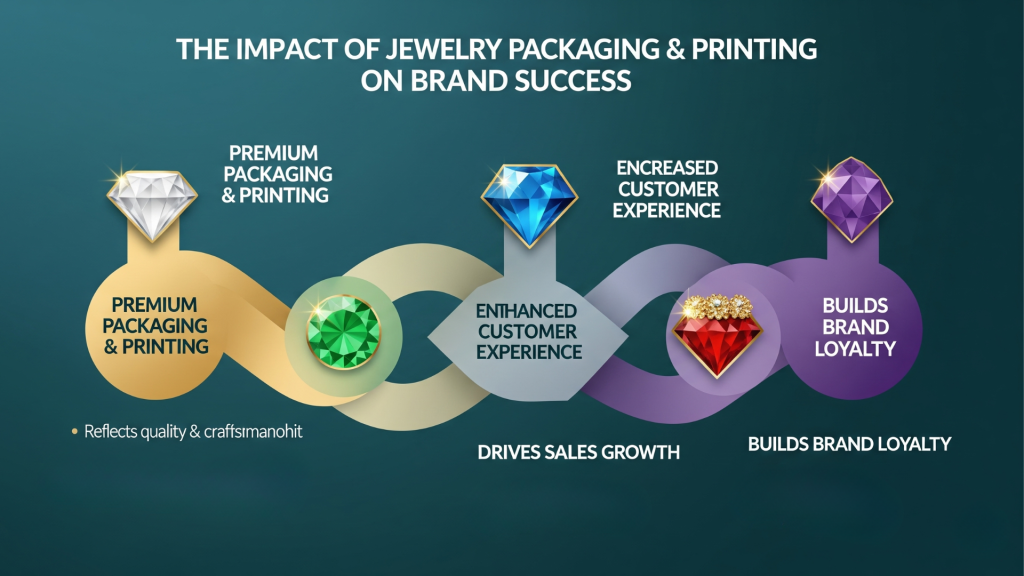

Your jewelry packaging is the first physical interaction a customer has with your brand. The right printing technique does more than just apply color to a box; it tells a story of quality, craftsmanship, and luxury. But with so many options, how do you choose? This guide cuts through the confusion, focusing specifically on what matters for jewelry brands. We’ll compare the top 6 custom jewelry packaging printing methods, helping you make a strategic choice that enhances your brand and captivates your customers.

Choosing how to print your packaging isn’t just a final step in production; it’s a foundational element of your brand strategy. The texture of an ink, the sharpness of a logo, and the vibrancy of a color directly communicate your brand’s worth to your customers before they even see the jewelry inside.

For a luxury item like jewelry, the unboxing experience is part of the product itself. A crisp, perfectly executed print job suggests attention to detail and high quality, reinforcing the customer’s purchase decision. Conversely, a faded or imprecise print can cheapen the perception of the exquisite piece it contains, creating a disconnect that harms brand loyalty.

Every jewelry brand faces the challenge of creating stunning packaging that aligns with their budget. Some printing methods produce photo-quality results but come with high setup costs, while others are more budget-friendly for large volumes but may not capture fine details. Understanding this trade-off is critical to maximizing your return on investment.

Maintaining brand consistency across different product lines and production runs is paramount. Your signature brand color should look the same on a ring box produced in May as it does on an earring box produced in November.

A strategic packaging partner is essential for this, providing the expertise in color management and quality control to ensure your brand presentation is flawless, every single time.

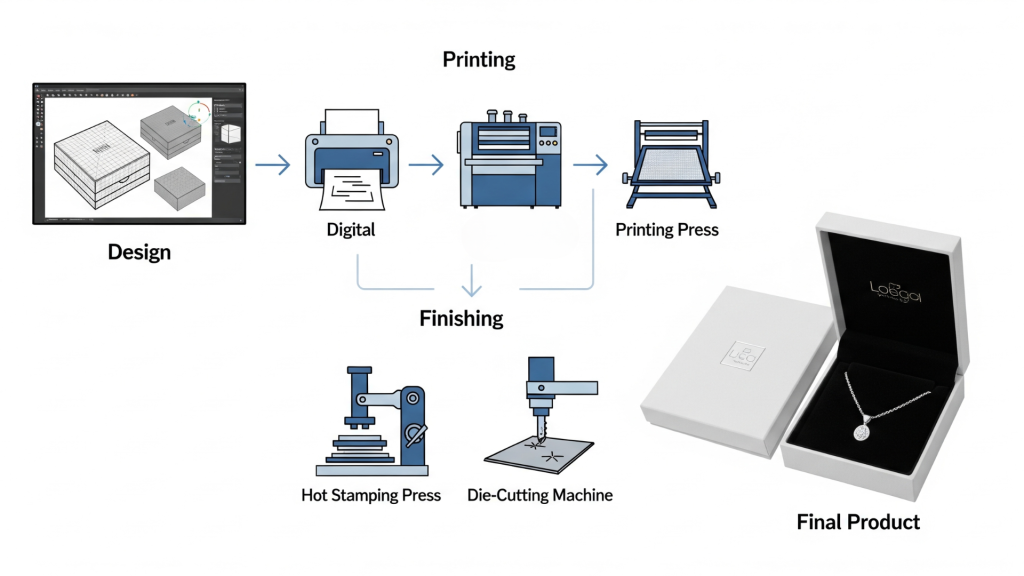

Let’s explore the core printing techniques. We’ve tailored our analysis to focus on what truly matters for creating exceptional jewelry packaging, helping you understand the best applications for each.

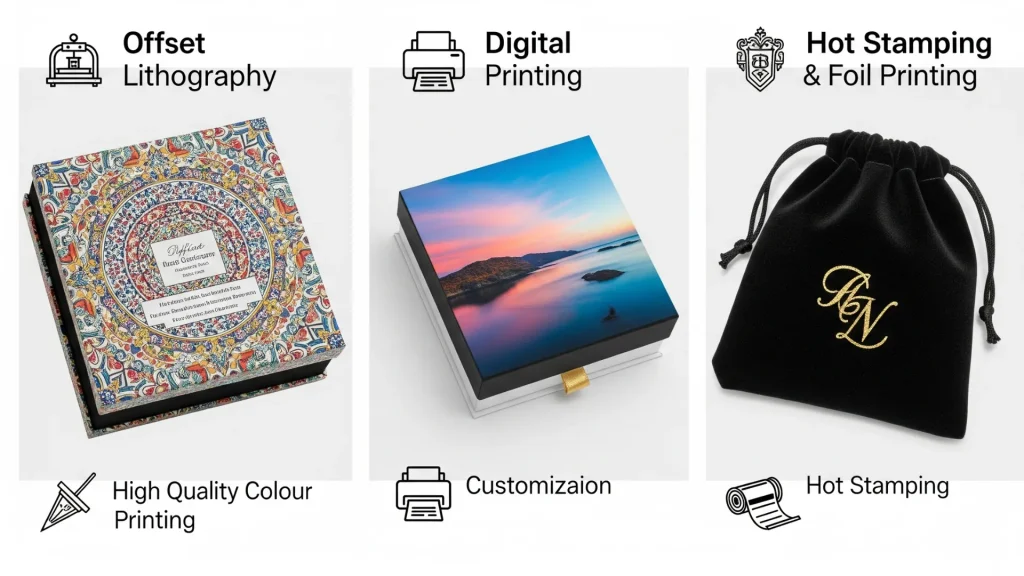

Offset printing, or lithography, is the benchmark for high-quality commercial printing. It works by transferring ink from an aluminum plate to a rubber “blanket,” and then onto the packaging material. This indirect process results in incredibly sharp, clean images and is especially effective for premium paperboard and cardstock used in luxury boxes. Want to learn more? Read our detailed guide on How Jewelry Brands Leverage Offset Printing for Luxury Packaging.

It offers unmatched color accuracy, making it perfect for reproducing specific brand Pantone (PMS) colors. It excels at capturing the fine lines and intricate details common in luxury branding. For larger production runs of a single design, it becomes highly cost-effective.

The main drawback is the high initial cost of creating the custom printing plates. This makes it less economical for very small, limited-edition runs or if your design changes frequently.

Digital printing applies a design directly from a digital file to the substrate, much like a desktop inkjet printer but on a much larger and more sophisticated scale. It eliminates the need for printing plates, which revolutionizes the production process for jewelry packaging.

With no plate costs, it is the most cost-effective solution for short runs, which is ideal for emerging designers or limited-edition collections. It offers incredible flexibility, allowing for personalized packaging or multiple design variations within a single order with ease. Turnaround times are also significantly faster.

The cost per unit is higher than offset for large quantities. While modern digital presses are excellent, matching a specific PMS color with 100% accuracy can sometimes be more challenging than with offset.

Flexography uses a flexible relief plate and is a fast, efficient process best suited for simpler designs and high volumes. Think of it as a highly advanced version of stamping, capable of printing on a wide variety of materials, including paper and corrugated cardboard.

It has a very low per-unit cost on large production runs and is one of the fastest printing methods available. It works well on a variety of materials, including the corrugated cardboard of shipping boxes.

The print quality is generally lower than offset or digital, and it struggles to reproduce fine details and photographic images. This makes it unsuitable for the primary, high-end packaging that holds the jewelry.

This technique involves pushing ink through a stenciled mesh screen onto your packaging. Because the ink is applied in a thick layer, screen printing produces exceptionally vibrant, opaque colors that are difficult to achieve with other methods.

It creates stunningly bold and rich colors, especially on dark-colored paper or fabric pouches. The thick ink layer gives the print a unique, slightly raised texture that adds a tactile dimension to your packaging. It is adaptable to many materials, including fabric, glass, and wood.

The process is slower than other methods and is not well-suited for printing photographic images or designs with fine gradients. Each color requires a separate screen, which can increase the cost for multi-color designs.

Gravure printing involves engraving the image onto a metal cylinder. It is known for producing prints of exceptional detail and quality, and it is the method of choice for many of the world’s largest luxury brands for their mass-produced packaging.

The print quality is outstanding, capable of reproducing photo-realistic images with remarkable consistency over millions of copies. The process is extremely fast and efficient at very high volumes.

The cost to create the engraved cylinders is extremely high, often running into the tens of thousands of dollars. This makes it financially unfeasible for anything but massive, continuous production runs with unchanging designs.

Hot stamping is not an ink-based process but a finishing technique that uses a heated die, pressure, and a thin foil to apply a design to a surface. It is the key to achieving a true, brilliant metallic finish. This technique is often used for creating beautiful, personalized touches on packaging, such as a custom coffee gift box with a lid.

As it is a separate process applied after printing, it adds to the overall cost and production time of your packaging.

The cost to create the engraved cylinders is extremely high, often running into the tens of thousands of dollars. This makes it financially unfeasible for anything but massive, continuous production runs with unchanging designs.

To simplify your decision, we’ve created a comparison table tailored to the needs of a jewelry brand.

| Characteristic | Offset | Digital | Flexography | Screen Printing | Gravure | Hot Stamping |

| Print Quality | Excellent (Photo-realistic) | Very Good (Near Photo-realistic) | Good (Simple Designs) | Excellent (Lines/Solids) | Excellent (Photo-realistic) | Excellent (Metallic Sheen) |

| Low Volume Cost | High | Low | Low | Medium | Very High | Medium |

| High Volume Cost | Low | High | Very Low | Low | Very Low | Medium |

| Luxury Feel | High | Medium | Low | High (Tactile) | Very High | Very High (Metallic) |

| Special Effect Compatibility | Excellent | Excellent | Good | Excellent | Good | Excellent |

| Best Jewelry Use | Main Product Boxes | Small Batches/Personalized | Shipping/Support Materials | Fabric Pouches/Special Lids | Ultra-High Volume/Luxury | Logos/Borders |

Selecting the right technology is only half the battle. The expertise of your packaging supplier is what brings your vision to life. A true partner does more than just print; they provide guidance and ensure quality.

Maintaining brand consistency across different product lines and production runs is paramount. Your signature brand color should look the same on a ring box produced in May as it does on an earring box produced in November. For example, at Richpack, we’ve implemented robust color management systems and use spectrophotometers to ensure your brand’s color remains flawless across every batch, a key factor in our partnership with global jewelry brands.

A supplier experienced with jewelry packaging understands the need for precision, the importance of premium materials, and the nuances of creating a luxury feel. We have a proven track record of successful collaborations with jewelry brands, tackling challenges from intricate die-cuts to perfect foil application.

This is a critical question. A professional partner should have a robust color management system, using tools like spectrophotometers to ensure your signature brand color remains consistent whether you order 500 boxes or 50,000. They should be able to provide proofs and color drawdowns for your approval.

Ask about their proficiency with digital printing and their minimum order quantities (MOQs). A flexible partner will be able to offer high-quality solutions for your limited-edition runs without forcing you into a large, expensive inventory commitment, helping you manage cash flow and respond nimbly to market trends.

Your printing choice is a direct reflection of your brand’s value and a critical component of your customer’s experience. As we’ve seen, there is no single “best” method; the right choice is a strategic one that depends entirely on your specific goals for quality, volume, and budget. From the impeccable detail of offset to the flexibility of digital and the luxurious touch of hot stamping, each technique offers a unique tool to build your brand story.

Ultimately, navigating these options successfully often comes down to collaboration. Working with an expert partner who deeply understands the nuances of Christmas gift boxes with lids and jewelry packaging is the key to transforming a simple box into a powerful brand statement.

Ready to elevate your brand’s packaging? Contact Richpack today to discuss your project and discover the perfect printing solution for your collection.

With a white background, they can reduce distractions and accentuate the charm of products. High-quality materials are used in the production, such as cardboard of different thicknesses and eco-friendly materials, and they go through multiple quality inspections.

Richpack Custom Jewelry Packaing · 6 Steps Packaging Design Process At Richpack Packaging Packaging is the silent salesman. It’s the first thing a customer sees, and it can make or break their decision to buy. It’s a powerful marketing tool that communicates your brand’s story and values. Studies show that 7 in 10 customers are swayed… Continue reading 6 Types of Packaging Printing Techniques to Elevate Your Jewelry Brand

Lithography can help design and print unique jewelry boxes. This adds a personal touch to your jewelry. Choosing the right materials and preparing them well is key to making eco-friendly and attractive jewelry boxes.

Cardboard Chocolate Box: Three-Tiered Tempting Treats for All Occasions

Cosmetic Packaging Sets with Matching Designs | Perfect for Beauty Brands Needing Cohesive and Branded Packaging for Skincare and Cosmetics

Eco-Conscious Custom Recyclable Jewelry Packaging for Premium Brands | Ideal for Luxury Jewelers Needing Branded, Sustainable Packaging Solutions

Adorable Baby Gift Boxes | Custom Newborn & Infant Gift Packaging | Premium Baby Shower Gift Sets

View More

Bespoke Compact Travel Jewelry Trays with Secure Closures | Custom, Durable Packaging for Retail Businesses and Wholesale Jewelry Suppliers in Bulk Orders

View More

Bulk Jewelry Packaging Solutions with Fast Delivery | Customizable Designs for Retailers and Wholesalers Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)