30+ Jewelry Packaging Ideas to Elevate Your Brand (2026)

2025-07-10

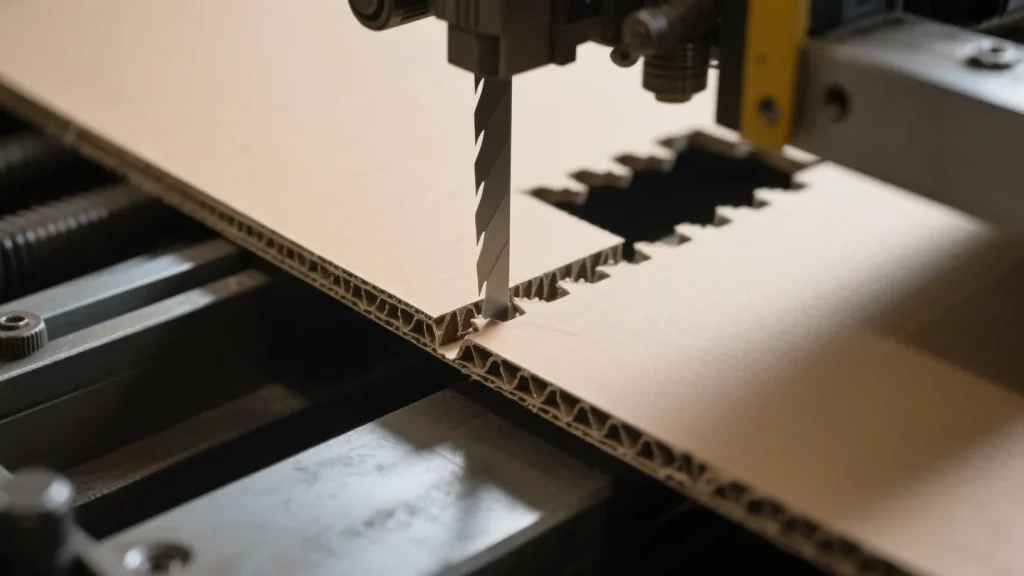

Die-cutting is a specialized manufacturing process that transforms packaging materials into unique shapes and designs using custom molds. It’s an indispensable technique in the jewelry industry, allowing brands to move beyond standard boxes and create truly custom packaging. By precisely cutting, scoring, and shaping materials, die-cutting ensures every fold and tab fits perfectly, resulting in a flawless final product.

This precision is key to crafting an unforgettable unboxing experience and reinforcing a brand’s luxury identity. A creatively designed box signals to customers that the product within is just as exceptional as its presentation. This technique allows for a wide range of custom solutions, including luxury packaging boxes with die-cut windows. In this article, we’ll dive deeper into the die-cutting process and its critical role in enhancing brand prestige.

Fundamentally, die-cutting is a manufacturing process that employs a specialized tool, known as a die, to precisely cut, score, crease, or perforate materials into specific shapes or patterns. While common across numerous sectors, its application in jewelry packaging elevates it to an art form, demanding micron-level precision and an understanding of how various luxury materials behave under pressure.

For jewelry boxes, die-cutting enables:

Moving beyond standard squares or rectangles, it allows for custom, brand-specific shapes, interlocking mechanisms, and unique closures that make a custom die cut box for jewelry truly distinctive.

It ensures that every component—from the outer shell to inner partitions and delicate inserts—fits together seamlessly, creating a premium feel and protecting the delicate contents.

In high-volume production, die-cutting guarantees uniformity across thousands of die cut boxes for jewelry, reinforcing brand consistency and quality perception globally.

Unlike conventional cutting methods that rely on single blades, die-cutting integrates multiple functions into one precise operation, making it indispensable for the complex requirements of luxury jewelry packaging.

The cornerstone of successful die-cutting is the die itself. This custom-engineered tool, often referred to as a “steel rule die” for packaging applications, acts as a precision mold tailored to the exact specifications of each jewelry box component.

Crafting the Die for Jewelry Packaging: The journey begins with a dieline—a meticulous 2D digital blueprint created using Computer-Aided Design (CAD) software. This dieline maps out every single cut, crease, score, and perforation line for the desired jewelry box die cut. For the intricate details often found in jewelry gift packaging, the dieline must account for:

Hairline Tolerances: Ensuring that even the smallest flaps or intricate cutouts align perfectly.

Material Thickness: Adjusting for the specific caliper of the paper, board, or specialty material to prevent crushing or tearing.

Integrated Features: Planning for windows, decorative cutouts, or precise slots for ribbons and closures.

Once the dieline is finalized, it’s transferred to a sturdy die board, typically made of high-quality wood. Using advanced laser cutters, the dieline pattern is precisely burned into the die board’s surface. This laser precision is crucial for the intricate designs of die cut boxes for jewelry, as it ensures that the channels for the steel rules are perfectly formed. Sharp steel rules (blades) are then meticulously bent by skilled die makers and inserted into these channels. Additionally, creasing rules (blunt steel strips) and various foam or rubber ejection elements are strategically placed on the die board to aid in material separation and ensure proper creasing during the pressing cycle.

Longevity and Investment: The creation of a custom die represents a significant upfront investment. However, this is a one-time cost per specific design. Once engineered, a high-quality die can withstand hundreds of thousands, or even millions, of impressions, making it exceptionally cost-effective for large production runs of custom die cut boxes. This means if you have multiple jewelry collections using the same structural design but different aesthetic branding, a single die can produce endless iterations of your die cut box for jewelry, offering immense long-term savings and brand consistency.

The die-cutting process is a symphony of precision engineering and controlled force, transforming flat material into the three-dimensional elegance of a jewelry box.

Material Preparation & Feeding: The chosen material—be it premium coated paper, specialty textured cardstock, rigid paperboard for outer wraps, or fine velvet-laminated foam for inserts—is prepared and precisely fed into the die-cutting machine. The material must be free of imperfections and correctly oriented for optimal results.

Die Mounting & Alignment: The custom-made die is securely mounted onto the die-cutting press. For jewelry packaging, accurate alignment is non-negotiable. Modern machines use sophisticated registration systems to ensure the die precisely aligns with pre-printed artwork, guaranteeing that logos, patterns, and design elements are perfectly centered within the jewelry box die cut.

The Pressing Cycle: This is where the magic happens. The die-cutting machine exerts immense, uniform pressure, firmly pressing the steel rule die into the material against a flat counter-plate (or another die in rotary systems). The sharp cutting rules shear through the material, while the creasing rules create clean, consistent folds.

Flatbed Die-Cutting: Most common for custom die cut boxes in jewelry, offering exceptional precision and versatility for intricate designs. The die presses down in a flat motion onto a stationary sheet of material.

Rotary Die-Cutting: While highly efficient for high-volume, simpler shapes (less common for highly intricate jewelry boxes), it involves a cylindrical die that rotates and cuts material fed between it and an anvil cylinder. This method offers speed but might be less precise for extremely complex, small-scale jewelry box die cut designs.

Digital/Laser Die-Cutting: For ultra-small batches, prototypes, or exceptionally intricate designs, laser die-cutting offers unparalleled precision without a physical die. It’s slower per piece but eliminates tooling costs and allows for on-the-fly design changes, making it ideal for unique, high-value jewelry gift packaging projects.

Stripping the Waste: After the cutting impression, the cut material remains attached to the waste material by small “nicks” in the die (bridges in the cutting rule). This waste material is then “stripped away,” leaving only the cleanly cut jewelry box components. For intricate die cut boxes for jewelry, this stripping process can be quite detailed, often involving automated stripping sections on the press or manual removal for highly complex or delicate designs.

Quality Assurance: Post-die-cutting, pieces undergo rigorous quality checks. This involves inspecting the cleanliness of cuts, the sharpness of creases, the absence of burrs or tears, and dimensional accuracy. For luxury jewelry packaging, even a millimeter of deviation can compromise the perceived quality and functionality.

The versatility of die-cutting stems from its multiple functionalities, each critical for different aspects of jewelry box construction:

This is the most basic function, cutting completely through the material to create the outer perimeter of a jewelry box die cut or individual components like lids, bases, or dividers. For premium packaging, the cleanliness and precision of these cuts are paramount, as ragged edges can detract significantly from the luxury appeal.

Scoring creates a partial cut or a precise indentation on the material’s surface without cutting all the way through. This weakens the material along a specific line, making it easier and cleaner to fold. For die cut cardboard boxes for jewelry gift packaging with intricate folding patterns, accurate scoring prevents cracking of the board or ink along the fold lines, ensuring a crisp, professional finish.

Creasing creates a distinct, durable fold line. This is crucial for the structural integrity and ease of assembly of any die cut box for jewelry. Proper creasing ensures that a gable box die cut for jewelry or any complex folding carton will assemble neatly and hold its shape robustly, enhancing both the aesthetic and protective qualities of the packaging. This function is particularly vital for custom die cut boxes that require multiple precise folds to form their final 3D shape.

Perforations create a series of small, intermittent cuts. While less common for the main structure of a jewelry box, it’s often used for tear-off sections on inserts, promotional cards, or integrated tags, allowing for easy, clean separation.

The precision of die-cutting is what truly elevates a piece of jewelry packaging from a simple container to a work of art. While the design provides the vision, the die-cutting process executes that vision with flawless accuracy, whether by creating intricate windows to showcase the product or by ensuring every fold and tab fits together seamlessly. This mechanical artistry is what transforms a flat sheet of material, shaping your plain white box into a luxurious, three-dimensional form that captivates the customer before they even see the jewelry inside.

The material choice profoundly influences the aesthetic and tactile experience of jewelry packaging, and die-cutting must adapt to its unique properties.

These are the most common materials for jewelry box die cut components, offering a vast array of colors, textures, and finishes (matte, gloss, metallic, tactile). Die-cutting achieves very clean, sharp edges on these materials, which is crucial for luxury appeal. Thickness (caliper) and fiber direction must be considered to prevent bowing or uneven cuts.

For the most luxurious, non-collapsible jewelry boxes, a rigid paperboard core is used. While the rigid board itself isn’t directly die-cut for its main structure, the decorative outer wraps and inner liners (made from paper or specialty materials) are precisely die-cut before being applied and wrapped around the rigid core.

Often used for internal lining or external wrapping of custom die cut boxes, these materials require specific die-cutting techniques to prevent fraying. Foam inserts for jewelry presentation are also precisely die-cut before being laminated with these luxurious fabrics.

Die-cutting is absolutely essential for creating the custom cavities within foam or EVA inserts that snugly hold each piece of jewelry. This ensures both protection and a stunning presentation, allowing a diamond ring or a delicate necklace to be perfectly showcased.

With increasing demand for eco-friendly solutions, die-cutting is now applied to recycled content board, biodegradable papers, and other sustainable alternatives. While these materials might have different fiber structures, modern die-cutting techniques are adapted to ensure clean cuts and robust structures for die cut cardboard boxes for jewelry gift packaging.

For jewelry brands, die-cutting is not merely a manufacturing step. It often becomes a strategic asset in the packaging of jewelry.

Customized jewelry die-cutting goes beyond the ordinary rectangular packaging. The unique shape, precise cutting and complex design immediately distinguish a brand, endow the packaging with more recognizability, and offer customers an unforgettable experience, establishing a closer connection and reflecting the brand’s unique story and values.

The ceremony of opening the jewelry box for luxury brands is a crucial moment. Die-cutting can directly contribute to this by ensuring that every fold is neat and tidy, every insertion perfectly supports the jewelry, and every closure is clicked satisfactorily. The precision of the die-cutting process for jewelry boxes enhances the tactile quality and visual appeal, transforming the simple unboxing into an immersive luxury experience that resonates with the high value of the products inside.

In addition to aesthetics, die-cutting ensures that internal components – such as precisely cut foam inserts or cardboard separators – securely hold delicate jewelry. This can minimize movement during transportation, prevent scratches, tangles or damage, and thereby protect the integrity of the product and the reputation of the brand. A carefully designed die-cut jewelry box is for protecting the first.

Although the initial investment in custom molds is significant, it will soon be amortized in mass production. The die-cutting machine operates at high speed, producing thousands of identical jewelry component die-cutting boxes per hour with minimal manual intervention. This efficiency significantly reduces the labor cost per unit, making customized, high-quality packaging economically feasible, even for growing brands.

Seamlessly integrated with luxurious finishing techniques

On the basis of die-cutting, high-quality decoration is established. It allows:

Embossing and de-embossing

Precise die-cutting ensures that raised (embossed) or recessed (de-embossed) marks and patterns are perfectly aligned on the packaging surface, adding a complex tactile dimension to custom die-cut boxes.

Foil stamping

The accuracy of the die ensures that the metal or colored foil is precisely applied to a specific area, creating a glittering accent that represents luxury.

On-site UV and lamination

Die-cutting is usually carried out after these surface treatments to ensure clear edges of the finished product.

Windows and inserts

Precise die-cut Windows allow for product visibility, while custom inserts (typically made using jewelry box die-cutting templates) ensure a perfect presentation.

The die-cutting process demonstrates the combination of meticulous engineering design and artistic vision in creating jewelry packaging. It is the key connection between conceptual design and tangible high-quality jewelry boxes, which can enhance brand reputation and please every customer. By understanding its nuances and strategic benefits, jewelry brands can make wise decisions and invest in packaging that truly reflects their inner brilliance.

In the future, die-cutting technology will continue to evolve along with industry trends, which means that brands can now choose eco-friendly die-cut cartons as packaging for jewelry gifts. Advanced digital die-cutting technology also offers greater flexibility for small, highly personalized operations, enabling brands to freely cater to niche markets or seasonal collections with unparalleled design freedom.

If you’re ready to explore these possibilities for your brand, you can inquire about custom solutions with Richpack.

Discover how white large box packaging structures elevate jewelry presentation, blending premium materials, precision design, and sustainability.

Drawer boxes are premium jewelry packaging featuring a telescoping design with an outer sleeve and inner sliding tray. Also called slide-out packaging, they create an elegant unboxing experience that builds anticipation while providing superior product protection and organization for jewelry brands. Picture this: your customer receives their jewelry purchase, slides open an elegant drawer box,… Continue reading Die-Cutting Process for Exquisite Jewelry Packaging

When Emily’s grandmother’s teacup arrived broken, she discovered our luxury keepsake boxes – where heirlooms get the protection they deserve. That’s why we craft each unique keepsake box with museum-grade materials and precision fits, because 73% of treasures last generations in proper storage. Clients like Mark use our best keepsake boxes to transform military dog tags into legacy gifts, proving these aren’t… Continue reading Die-Cutting Process for Exquisite Jewelry Packaging

Custom Luxury Cosmetic Packaging Boxes with Logo | Tailored Packaging for High-End Beauty Brands Needing Personalized Branding Solutions

Vertical Labret Jewelry Packaging | Custom Designs by Richpack for Modern Elegance

White and Gold Jewelry Boxes for Rings & Earrings | Custom Sizes, Branding Options | Richpack Wholesale

Adorable Cute Packaging for Cosmetics to Elevate Your Brand – Customizable Designs for the Cosmetic Packaging Market by Richpack

View More

Cardboard Chocolate Box: Three-Tiered Tempting Treats for All Occasions

View More

Creative Brown Paper Bag Decorations for Parties and Events | Stylish Star Paper Bags and Packaging Ideas to Decorate a Paper Bag

View MoreJust submit your email to get exclusive offers (reply within 12 hours)