5 Must-Have Features in a Small Jewelry Box for Necklaces

2025-04-23

The global jewelry industry exists at a unique intersection of high-value artistry, historical legacy, and modern consumer psychology. In this environment, the container that houses a gemstone or a precious metal timepiece is far more than a protective vessel; it serves as a critical medium of brand communication. Industry experts often refer to the jewelry box as a brand’s “first handshake” with the customer, a physical manifestation of the quality and craftsmanship contained within. As the luxury packaging market continues its upward trajectory—projected to grow from 17.72 billion USD in 2025 to over 29.41 billion USD by 2035—the strategic selection of packaging structures has become a focal point for brand managers and logistical planners alike. This report provides an exhaustive technical and economic comparison of the two dominant structural paradigms in the sector: rigid (non-collapsible) boxes and foldable (collapsible) cartons. By evaluating these structures through the lenses of material science, protective performance, logistical portability, and consumer perception, this analysis aims to guide professional stakeholders in optimizing their packaging strategies.

The fundamental dichotomy between rigid and foldable jewelry packaging is rooted in the thickness and density of the substrates used, as well as the geometric principles of their assembly. Rigid boxes, frequently referred to in the trade as “set-up boxes,” are non-collapsible structures engineered from high-density chipboard or compressed paperboard. Conversely, foldable jewelry packaging, often characterized as folding cartons or collapsible boxes, relies on thinner paperboard or lightweight corrugated materials that are die-cut and scored to allow for flattening.

The material science of rigid boxes is defined by a heavy-gauge chipboard core, typically ranging from 1.5 mm to 3.0 mm in thickness. This chipboard is a composite of recycled fibers that have been compressed under high pressure to achieve a density measured between 800 and 1500 gsm (grams per square meter). This structural core does not fold; instead, it is held together by adhesives and then “wrapped” in a decorative outer layer of art paper, textured fabric, leatherette, or genuine leather. This layering process creates a sandwich-like structure that provides immense compressive strength.

Foldable packaging, like wholesale foldable small jewelry gift boxes, utilizes a much lighter material palette. Standard folding cartons for jewelry are typically manufactured from paperboard with a thickness of 0.3 mm to 0.6 mm (250 to 400 gsm). For items requiring slightly more reinforcement, manufacturers like Richpack utilize high-weight white cardboard or thin corrugated boards, such as E-flute or F-flute, which offer a balance of light weight and structural resilience. The thinness of these materials is a functional necessity, as it allows the material to be creased and folded multiple times without the fibers fracturing—a phenomenon known as “folding endurance” in paper science.

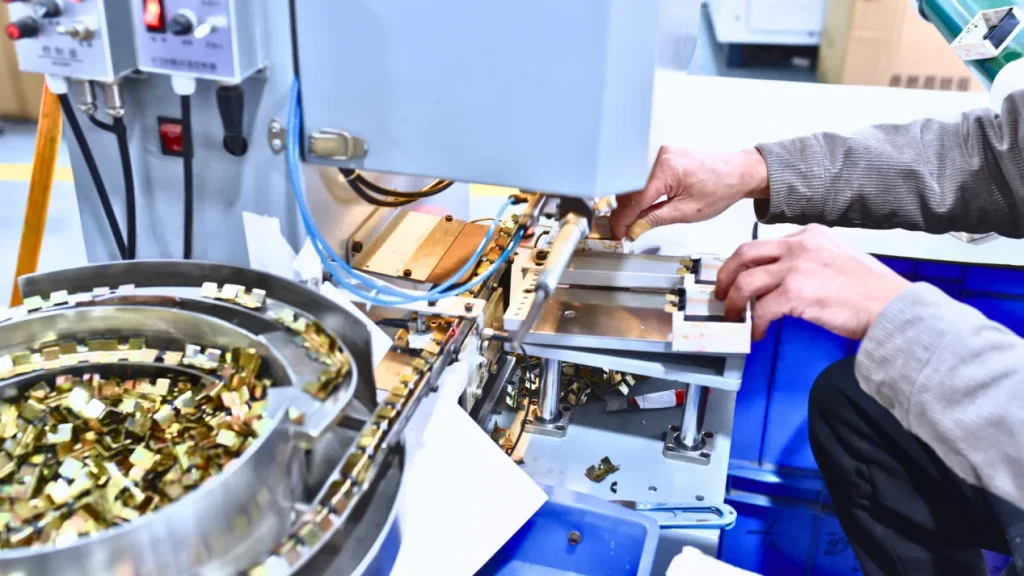

The assembly of a rigid box is a multi-step industrial process that often involves specialized machinery and, in many high-end cases, a significant degree of manual labour. The chipboard is cut into “blanks,” the corners are taped (with tape), and then the decorative wrap is applied using glue. Because these boxes are shipped in their final 3D form, the manufacturing process must account for the structural permanence of the corners, which cannot be undone without destroying the box.

Foldable cartons are the product of high-speed automated die-cutting and folding-gluing lines. A single sheet of paperboard is cut into a complex flat geometry, and specific areas are glued so that the box can be “popped” into shape by the end-user or a retail clerk. The efficiency of this process is unmatched, allowing for the production of millions of units with minimal manual intervention. However, this ease of assembly is also its primary structural limitation; the scores and folds that allow the box to collapse also represent inherent weak points where the material is thinner and more susceptible to tearing or creasing under stress.

| Feature | Rigid Boxes | Foldable Cartons |

| Substrate Thickness | 1.5 mm – 3.0 mm | 0.3 mm – 0.6 mm |

| Material Density | 800 – 1500 gsm | 250 – 400 gsm |

| Assembly Mode | Set-up (Non-collapsible) | Die-cut (Collapsible) |

| Structural Core | High-density chipboard | Thin paperboard / E-flute |

| Finishing Options | Wrapped (Fabric, Leather, Foil) | Printed / Laminated |

In the jewelry sector, protection is categorized into two distinct hazards: external mechanical stress (crushing and impact) and internal environmental damage (scratches and tarnishing). The mechanical performance of a box is largely a function of its “top-to-bottom compression strength,” which measures how much weight a box can support before the side walls buckle.

Rigid boxes are the industry benchmark for crush resistance. Their thick, non-collapsible walls act as a structural shell that protects delicate jewelry items—such as watches with complex movements or fragile gemstone settings—from the stacking pressure encountered in freight containers and warehouses. Laboratory observations indicate that rigid boxes maintain their shape under significant lateral and vertical loads, making them the preferred choice for expensive or fragile items.

Folding cartons, while resilient to light impacts, offer significantly less protection against heavy compression. Because the walls are thinner and the structure relies on folds rather than solid board, they can be crushed if a heavier package is stacked on top of them during transit. However, this vulnerability can be mitigated through the use of internal reinforcements. For instance, a folding box equipped with a high-density EVA (Ethylene-vinyl acetate) foam insert can achieve a degree of internal stability that rivals some rigid options for mid-range jewelry.

Protection also concerns the “unseen” movement within the box. If a ring or necklace is allowed to “roam” or rattle during shipping, it risks surface abrasion or chain tangling. Rigid boxes allow for the use of heavy, precisely molded inserts made of velvet-lined plastic, wood, or dense foam. These inserts are engineered with specific “recesses” and “angled cuts” to present the jewelry at the optimal angle while holding it securely in place.

Recent lab tests show that premium jewelry cases using reinforced structures and modular designs can reduce item damage by up to 83% compared to generic pouches. Specifically, velvet-lined compartments have been found to prevent chain tangling 92% more effectively than polyester alternatives. For independent designers and heritage brands, this protection is not just a logistical requirement but a way of preserving customer relationships; “every scratch avoided is a customer relationship preserved”.

Beyond mechanical impact, jewelry is sensitive to oxygen, moisture, and light. Rigid boxes, when wrapped in laminated papers or leatherette, provide a superior moisture barrier compared to uncoated folding cartons. Furthermore, high-end manufacturers like Richpack integrate anti-tarnish strips into the interior compartments of their boxes. These strips utilize chemistry to neutralize sulfur and other corrosive gases, maintaining the brilliance of silver and gold pieces for 18 months or more. This is particularly critical for the “long-tail” of retail, where a piece may sit in its box on a store shelf for several months before being purchased.

While rigid boxes excel in protection, they present significant challenges in terms of logistical portability and cost. The trade-off between “protection” and “portability” is perhaps the most critical decision point for businesses managing a high-volume supply chain.

The defining logistical trait of foldable packaging is its “flat-packed” nature. Because these boxes can be shipped and stored as 2D sheets, they offer a dramatic reduction in volume compared to assembled rigid boxes. Industry data suggests that foldable designs can reduce shipping volume by up to 75%. This has a direct ripple effect across the entire supply chain:

The weight difference between the two structures further influences the bottom line, especially in air freight. A rigid box, with its dense chipboard core, can be significantly heavier than a foldable paperboard box. In logistics, this contributes to the “volumetric weight” charges—where carriers charge based on the larger of the actual weight or the space occupied. Flexible and foldable pouches can weigh 85% to 95% less than equivalent rigid containers, which directly reduces freight costs and carbon emissions proportionally.

| Metric | Rigid Box | Foldable Box |

| Shipping Volume | 100% (Assembled) | Approx. 25% (Flat-packed) |

| Warehouse Space Required | 3x – 5x Higher | Optimized |

| Assembly Time | None (Pre-assembled) | Required (At point of sale/shipment) |

| Freight Cost Sensitivity | High (Weight & Volume) | Low (Lightweight & Compact) |

| Carbon Footprint (Logistics) | Higher (Due to volume) | 50% – 70% Lower |

While logistics favours foldable packaging, consumer psychology overwhelmingly favours the rigid box. In the luxury sector, the packaging is an extension of the product’s value proposition. The physical interaction with the box—often called the “unboxing ritual”—is a key driver of perceived value and brand loyalty.

One of the most powerful psychological tools in packaging is the “weight test.” Consumers subconsciously associate heavier, more substantial packaging with higher quality and durability. A rigid box, with its thick walls and solid feel, conveys a sense of “heritage” and “luxury” that a lightweight folding carton often cannot match. Research indicates that custom packaging can make a product seem 30% more valuable in the eyes of the consumer. Specifically, 63% of luxury buyers report that they are willing to pay up to 30% more for a product if it is presented in premium packaging.

The unboxing experience is a multi-sensory event. Rigid boxes allow for sophisticated mechanical closures, such as magnetic lids that provide a satisfying “snap” or ribbon ties that require a deliberate action to open. These features engineer a moment of anticipation and reverence for the jewelry inside. Furthermore, 85% of consumers remember brands that engage their sense of touch.

Manufacturers like Richpack leverage this by offering tactile finishes such as:

In the digital age, packaging has become a marketing tool beyond the initial purchase. A visually and tactilely satisfying unboxing ritual compels consumers to share their experience on social media. Data suggests that nearly 40% of online shoppers would share an image of a purchase on social media if it arrived in premium, gift-like packaging. For jewelry brands, this turns every customer into a “voluntary brand ambassador,” providing free organic exposure to thousands of potential buyers. A rigid box, which often serves as a long-term storage or display case, keeps the brand visible in the customer’s life long after the transaction is complete. For detailed insights on selecting these premium structures, refer to our Purchasing Guide for Wholesale Magnetic Gift Boxes.

Sustainability has shifted from a niche concern to a cornerstone of packaging strategy. By 2025, approximately 61% of luxury buyers will prioritize brands that use eco-conscious materials. However, the definition of “sustainable” differs between rigid and foldable structures.

Foldable cartons are often seen as more inherently recyclable because they are made from a single material (mono-material paperboard) that most municipal facilities can process easily. They also require less energy to manufacture and generate 50% to 70% fewer carbon emissions during transportation due to their space efficiency.

Rigid boxes packaging, while requiring more raw material and adhesive, offer superior reusability. Their durability means they are rarely discarded immediately; instead, they are repurposed as jewelry organizers or keepsake boxes. This commitment to longevity is a form of waste minimization. Furthermore, modern rigid boxes are increasingly made from 100% recycled chipboard and wrapped in FSC-certified (Forest Stewardship Council) papers, aligning them with high-end environmental standards.

Richpack packaging has been at the forefront of the “sustainable luxury” movement, developing tailor-made solutions for global leaders like ZARA. By optimizing material selection and focusing on recyclability, Richpack’s sustainable packaging for ZARA resulted in a 20% increase in customer satisfaction. For Marks & Spencer, Richpack provided solutions that reduced plastic usage by 60 million units and cut packaging costs by 25%. These results demonstrate that sustainability and profitability are not mutually exclusive when guided by expert structural design.

The choice between rigid and foldable packaging is ultimately a financial one, requiring an analysis of unit costs versus brand equity.

Folding cartons are significantly more affordable on a per-unit basis. For bulk orders of 1,000 units or more, basic foldable paperboard boxes typically cost between 0.30 USD and 1.00 USD each. In contrast, rigid set-up boxes range from 1.50 USD to 5.00 USD per unit, depending on the level of customization, materials, and manual labour involved.

For jewelry brands, the packaging cost must be viewed in relation to the retail price of the product. For items priced above 200 USD, the investment in a high-end rigid box typically represents less than 2% of the retail value. This small investment can justify a 15% to 20% retail price premium, as customers associate the higher quality packaging with a more exclusive product. For example, a 200 USD necklace in a standard paperboard box might retail at 200 USD, but the same piece in a walnut wooden box or a high-end rigid case could retail at 230 USD to 250 USD.

| Priority | Recommended Structure | Reason |

| Brand Prestige | Rigid Box | Superior tactile feel and perceived value. |

| High Shipping Volume | Foldable Box | 75% volume reduction for logistics savings. |

| Product Fragility | Rigid Box | High compression strength (up to 3 mm board). |

| Limited Budget | Foldable Box | 30% – 60% lower total delivered cost. |

| Environmental Reusability | Rigid Box | Sturdy enough for long-term home storage. |

To ensure that both rigid and foldable structures meet the demands of the modern global supply chain, they must undergo rigorous standardized testing. The International Safe Transit Association (ISTA) provides the primary framework for these evaluations.

High-performance manufacturers like Richpack implement a 100% QC inspection process to ensure structural integrity. This includes:

The jewelry packaging industry in 2025 and beyond is moving toward a fusion of physical and digital experiences.

Technology is revolutionizing the “unboxing” by creating immersive experiences. Augmented Reality (AR)-enabled boxes allow customers to scan a QR code to unlock artisan videos about the jewelry’s craftsmanship or even access virtual “try-on” filters. This tech integration is particularly popular with younger consumers and helps brands tell a deeper story without cluttering the physical design of the box.

Traditionally, high-quality custom packaging was only available to large retailers due to high Minimum Order Quantities (MOQs). However, companies like Richpack now specialize in “small quantity” custom packaging for independent designers and boutique stores. With MOQs as low as 500 pieces for full customization, small brands can now access the same luxury materials—such as genuine leather, anti-tarnish velvet, and magnetic closures—that were once reserved for the industry elite.

The selection between foldable and rigid jewelry packaging is a multi-dimensional strategic decision. Rigid boxes offer the ultimate in protection and prestige, leveraging high-density materials and superior craftsmanship to elevate a brand’s perceived value and engineer a memorable unboxing experience. They are the structural choice for high-end, fragile, and heirloom-quality jewelry. Foldable cartons, however, represent the pinnacle of logistical efficiency and cost-effectiveness. Their ability to flat-pack and reduce shipping volume by up to 75% makes them indispensable for high-volume retailers and e-commerce operations focused on sustainability and supply chain optimization.

As the industry moves toward 2025, the “middle ground” of customized packaging—where the strengths of both structures are combined—is becoming increasingly common. By partnering with experienced manufacturers like Richpack, brands can utilize advanced materials and precision engineering to ensure that whether a box is rigid or foldable, it serves as a loyal guardian of the brand story and a protector of the treasures within.

Elevate Your Jewelry Brand with Richpack’s Bespoke Packaging Solutions

Are you ready to transform your packaging from a simple container into a powerful brand asset? At Richpack, we combine over 20 years of expertise in luxury packaging with cutting-edge sustainable practices to empower over 300 global brands. Whether you require the uncompromising structural integrity of a custom rigid box or the logistical efficiency of our high-end foldable designs, our design team works closely with you to bring your vision to life.

His fingertips brush a new scratch on his Rolex—courtesy of that luxury velvet case. Across the room, his Omega fogs with humidity, while the Patek’s clasp snags in a too-tight slot. For watch lovers, storage isn’t just organization—it’s war. Sleek cases betray with flimsy liners; “protective” vaults bury treasures in bulk. Leather cracks, foam suffocates,… Continue reading Foldable vs. Rigid Jewelry Packaging: Which Offers Better Portability and Protection?

As more jewelry buyers seek transparency and sustainability, eco-friendly packaging is no longer optional—it’s a brand statement. In this guide, we’ll explore what sustainable jewelry packaging really means, which materials and design ideas work best, how to implement them, and which brands are already leading the way. Key Takeaways Introduction: Why Eco-Friendly Packaging Is the… Continue reading Foldable vs. Rigid Jewelry Packaging: Which Offers Better Portability and Protection?

Discover essential packaging secrets for safe jewelry shipping as a wholesaler!

Eco-Friendly Origami Boxes with Lids Made of Sustainable Materials | Combining Elegance and Function

Large White Gift Boxes with Lids | Custom Rigid Gift Boxes – Richpack

Luxury Packaging Solutions for High-End Fashion Retailers | Tailored for Fashion Brands Seeking Exclusive, Branded, and Elegant Packaging Designs

Big Black Gift Box with Foldable Lid – Oversized Rigid Packaging for Products & Gifts | Richpack

View More

Cosmetic Makeup Brush Set Packaging Gift Paper Box With Brush Box

View More

Durable Jewelry Box for Travel with Customizable Compartments – Secure Travel Jewelry Case for Easy Organization with Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)