5 Logo Techniques That Make a Jewelry Box Look Instantly Expensive

2025-06-19

Luxury jewelry brands are elevating their packaging with offset printing—delivering unmatched color precision, elegant finishes, and a premium unboxing experience that reflects the true value of their products and strengthens brand identity.

Luxury jewelry brands are now using offset printing for top-notch packaging. This technology helps them create packaging that shows off their brand’s elegance and sophistication. By doing this, brands can make packaging that looks amazing and also protects their products. It makes the customer’s experience even better.

Offset printing is like a fine art, made perfect for luxury. It’s a method that has been improved over time. It creates high-quality prints that are key for luxury packaging.

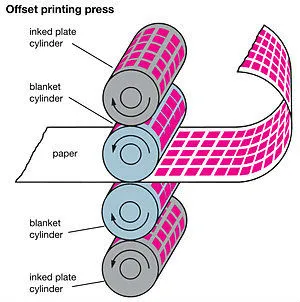

The Core Principle (Simplified)Offset printing works on a simple idea: oil and water don’t mix. This idea is like trying to mix two liquids that don’t blend. In printing, it helps transfer ink to a surface.

The process uses a plate. The image areas attract ink, while the non-image areas pull water. This keeps them clean and free of ink.

So, how is this unparalleled quality achieved? It unfolds in a meticulous three-stage process that combines digital precision with mechanical artistry.

Before any ink meets paper, the foundation for perfection is laid in the digital realm. This crucial pre-press stage involves preparing your design files for the printing press.

Design & Dielines: Your packaging design is laid out on a flat template called a dieline, which shows all the cuts, folds, and creases. Ensuring your artwork aligns perfectly with this dieline is paramount.

Color Conversion: This is one of the most common and critical steps. Your screen displays colors in RGB (Red, Green, Blue), but printing uses CMYK (Cyan, Magenta, Yellow, Black). Your designer must convert all files to the CMYK color space to ensure that what you print matches what you approved on screen.

Proofing: A digital or physical proof is created for you to approve. This is your final chance to check for typos, color issues, or layout errors before the costly plates are made.

With an approved proof, we move to the press. This is where your design comes to life.

Plate Making: A laser etches your CMYK-separated designs onto thin aluminum plates—one plate for each of the four colors. If you’re using a custom brand color, a separate plate will be made for that Pantone (spot) ink.

The Press in Action: The plates are loaded into the printing press. As the press runs, the plate is dampened with water and ink. The ink adheres only to the etched image, is transferred to the rubber blanket, and then perfectly pressed onto the paper.

Sheet-Fed vs. Web-Fed: For luxury packaging, sheet-fed offset is the standard. Individual sheets of high-quality paper or cardstock are fed into the press, allowing for incredible versatility with specialty materials. While slower than web-fed (which uses continuous rolls of paper for things like newspapers), modern sheet-fed presses are still remarkably fast, capable of printing up to 18,000 sheets per hour.

The printed sheets are flat and unfinished. The post-press stage is where they are transformed into the final, three-dimensional piece of art. This includes:

Finishing (The Midas Touch): This is where the magic happens. Techniques like foil stamping, embossing, debossing, and Spot UV are applied to the printed sheets to add texture, shine, and tactile elegance.

Cutting & Assembly: The finished sheets are precisely cut using the original dieline, then folded, glued, and assembled into their final box form.

Quality Control & Inspection: Throughout this process, technicians perform rigorous quality checks. They use tools like densitometers to ensure color consistency and magnifying lenses to inspect for any imperfections—smudges, streaks, or misalignments. Only the packages that meet the highest standards are approved.

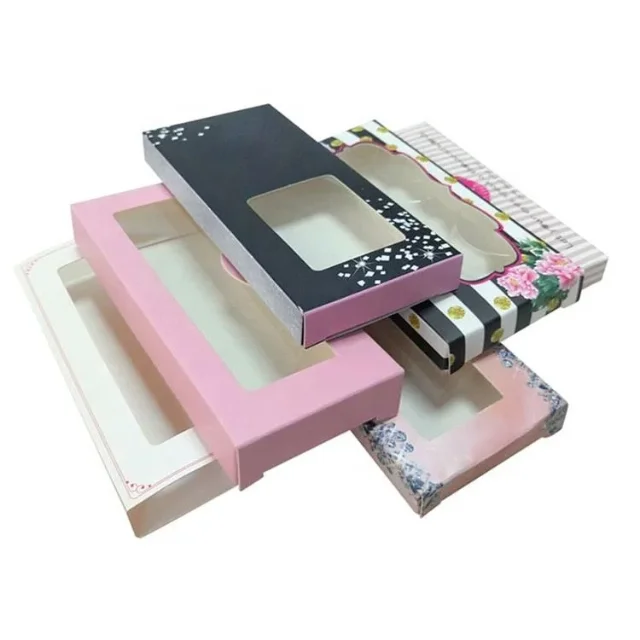

Luxury brands see packaging as more than a container. It’s an experience that starts with the unboxing. This is thanks to the high quality of offset printing. It offers unmatched detail and precision in color and material.

Color fidelity is key for luxury brands. It affects how consumers see the brand. Offset printing makes sure the packaging colors match the brand’s identity. This creates a consistent and recognizable image.

The CMYK process is vital in offset printing. It allows for rich, full-color images. Mixing cyan, magenta, yellow, and black inks produces a wide range of colors. This makes packaging vibrant and detailed.

Consistency is crucial for luxury brands. Spot colors, especially Pantone colors, help maintain this. Using Pantone colors ensures packaging materials match the brand’s colors. This strengthens the brand’s visual identity across all marketing.

Pantone colors also ensure precise color matching. This means packaging looks the same across different materials and finishes. Such consistency is vital for building brand recognition and loyalty. For more Pantone packaging trends, read 2025 Pantone Trends in Packaging: Avoid These Fatal Mistakes is enough.

Brands can add a luxury feel to packaging with metallic and specialty inks. These inks give a subtle sheen and sophistication. They make packaging stand out on store shelves and in online images.

Gold, silver, and other metallic inks create a sense of luxury and premium quality. Specialty inks add unique effects like glow-in-the-dark or textured finishes. These inks make the unboxing experience memorable and engaging for the consumer.

Offset printing lets jewelry brands add luxury to their packaging. Luxury packaging creates a special bond with the customer. The packaging’s finish is key to this.

Varnishing is a top method for luxury finishes in offset printing. It adds a glossy or matte look, improving both looks and feel. A top-notch varnish makes the packaging feel more high-end and classy.

Foil stamping is another way to add luxury. It uses metallic foil and heat to make the packaging pop. It’s great for logos and designs, giving the packaging a premium and eye-catching finish.

Spot varnishing and debossing add texture and interest. Spot varnishing makes some parts glossy and others matte. Debossing presses designs into the material, adding depth and class.

These finishes make the packaging look better and improve the brand experience. By using varnishing, foil stamping, spot varnishing, and debossing, jewelry brands can make packaging that’s both beautiful and reflects their luxury. If you’re curious about Debossing vs. Hot Stamping, read this one!

Choosing the right printing method is key for jewelry brands. Knowing the difference between offset and digital printing is essential.

Offset printing is traditional and offers high-quality results at a good price for big orders. Digital printing, however, is great for small, custom orders because it’s flexible and fast.

| Printing Method | Cost | Quality | Quantity |

| Offset Printing | Economical for large orders | High-quality, vibrant colors | Best for quantities over 1,000 |

| Digital Printing | Cost-effective for small orders | Good quality, with some color variation | Ideal for quantities under 1,000 |

When picking between offset and digital printing, think about what you need. Offset is best for big orders with the same design. But for small, varied orders, digital is quicker and more flexible.

In short, knowing the pros and cons of offset and digital printing helps jewelry brands choose the right packaging. This choice can make their brand look more luxurious.

Luxury jewelry brands see packaging as more than a box—it’s a curated experience that reflects their identity, values, and craftsmanship. Many turn to the offset printing process to produce packaging that resonates with their high-end clientele. The richness of detail, color accuracy, and ability to add premium finishes make offset printing the gold standard for luxury.

At Richpack, we specialize in creating custom jewelry boxes that combine advanced offset printing with luxurious materials and finishes. Our packaging solutions are designed to enhance the unboxing moment and elevate your brand’s perceived value.

Investing in luxury packaging through offset printing pays off in the long run. It reinforces brand image, encourages customer loyalty, and transforms each package into a shareable moment. With the ability to use specialty inks, textures, and coatings, offset printing becomes a powerful tool in defining your brand’s signature style—something we at Richpack help bring to life, one box at a time.

Before you go…

Choosing a premium product is just the beginning. Even the most luxurious item can lose its appeal if the packaging doesn’t match the quality!

Read my next article — “Expert Roundup: Tips on Luxury Packaging” — to make sure your packaging reflects the elegance of what’s inside.

For any jewelry brand, creating luxurious packaging that elevates the product is essential, yet its associated high costs constantly erode profit margins. The essence of this challenge isn’t merely about cutting expenses, but about making smarter strategic decisions that balance brand prestige with profitability. This guide reveals the complete, expert-level playbook for achieving that balance,… Continue reading How Jewelry Brands Leverage Offset Printing for Luxury Packaging

Selecting the right jewellery packaging suppliers is crucial for any jewellbusiness seeking to make a lasting impression. Whether you are searching for wholesale jewellery boxes to streamline operations or desire the allure of luxury jewellery packaging to enhance your brand image, this top 10 trustworthy suppliers in the USA list will guide you towards making informed decisions for your jewellery packaging solutions. This exploration encompasses a variety… Continue reading How Jewelry Brands Leverage Offset Printing for Luxury Packaging

Ever seen a necklace tangled in a mess or earrings lost in a drawer? A jewelry pouch with zipper might be the solution you’ve missed. These pouches protect, organize, and enhance your jewelry. They’re great for retailers shipping gifts or for keeping heirlooms safe. They prevent scratches, dust, and damage. Their sleek designs also make unboxing… Continue reading How Jewelry Brands Leverage Offset Printing for Luxury Packaging

Richpack Bespoke Custom Printed Cosmetic Boxes for High-Volume Orders | Tailored Packaging Solutions for Distributors and Brands Needing Large Orders

Custom-Printed Paper Bags for Jewelry Stores | Personalized Packaging Solutions for Retailers Needing Branded and Elegant Jewelry Presentation

Earring Holder Cards for Protecting Earrings – Dependable Holder Cards to Keep Your Earrings Safe

Charming Custom Logo Gift Bags for Special Gifts – Branded Gift Bags to Make Your Presents Stand Out

View More

Elegant Affordable Cosmetic Boxes with Custom Designs for Boutique Skincare Brands | Perfect for Small Businesses Needing Budget-Friendly Packaging

View More

Custom Jewelry Packaging Sets with Boxes, Pouches, and Bags | Richpack Tailored Packaging Solutions for Jewelry Brands Looking for Bulk Customization

View MoreJust submit your email to get exclusive offers (reply within 12 hours)