4 Benefits of Choosing a Black Gift Box

2025-04-04

At the heart of every successful jewelry and gift packaging product from Richpack is an understanding of how material selection directly impacts structural integrity and functional dimensions. Our team prioritizes millimeter-level precision to ensure that each product meets stringent performance standards while optimizing space efficiency. The two dedicated lid options for gift boxes with lids, BT14 and SC14, demonstrate our commitment to flexible design. These components show how we can create secure closures through strategic engineering and maintain their original dimensions. Whether the customer prioritizes visibility or simplified stacking, our customization process maintains dimensional accuracy in all configurations. Efficient transportation is always at the core of our development philosophy. By considering material density during the prototyping process, we are able to reduce space waste during transportation while ensuring that the product arrives safely. This precision-driven approach saves costs and reduces environmental impact throughout the supply chain. In this article, we will explore how to create reliable solutions that meet modern business needs through carefully selected materials.

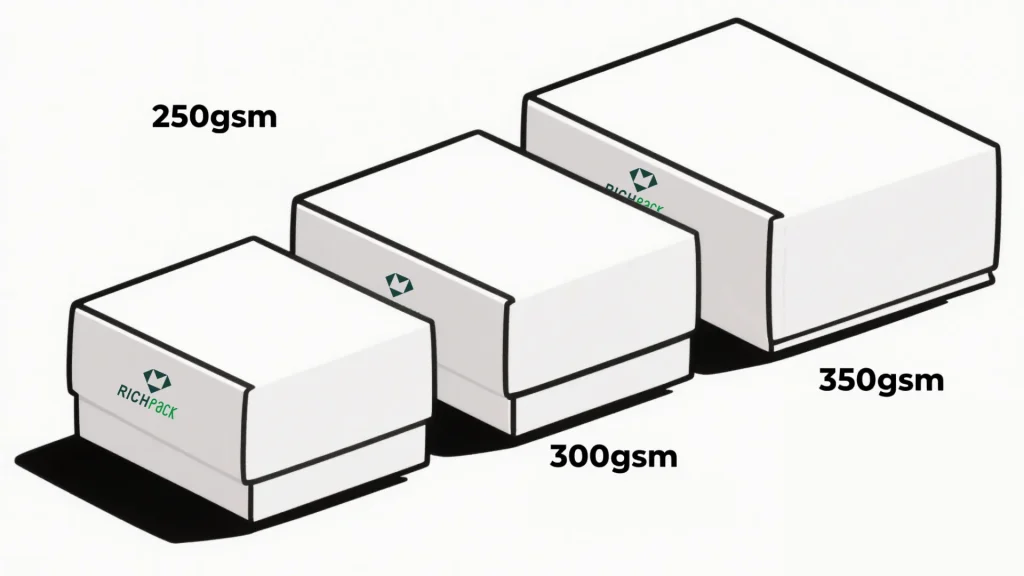

Every millimeter matters when engineering protective white paper boxes. Material thickness determines both structural performance and interior space efficiency. We design solutions where durability meets exact sizing through advanced material science.

Selecting premium-grade substances ensures products arrive undamaged while maintaining sleek profiles. Our team calculates density ratios to optimize protection without adding bulk. This approach creates gift-ready white paper box that impress recipients while surviving rough handling.

| Material Thickness | Impact Strength | Ideal Use Cases |

| 250 gsm | Light protection | Small retail items |

| 300 gsm | Moderate stacking | Food & luxury goods |

| 350 gsm | Heavy-duty | Industrial components |

Gift packaging demands visual appeal and functional reliability. Our food-safe materials prevent contamination while providing crisp folding edges. Rigorous testing confirms each container withstands 4x its weight without deformation.

Safety standards guide every design choice. We combine crush resistance with smooth surfaces for premium unboxing experiences. Customizable finishes maintain exact dimensions across all branding options.

From concept to production, quality controls ensure consistent material performance. Our patented compression techniques create rigid walls that protect delicate items. This precision translates to packaging that fits products like a second skin.

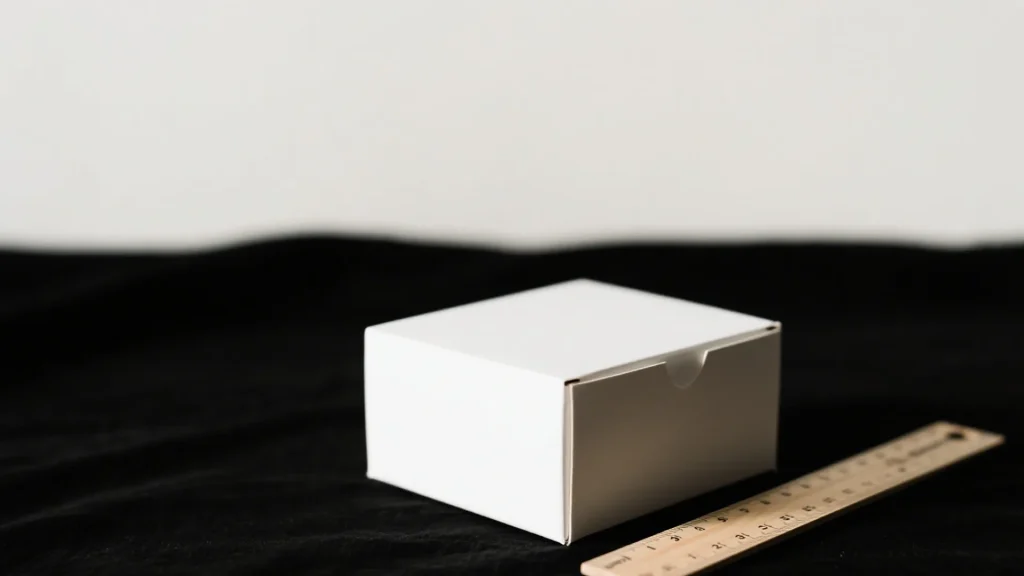

Our WH14 white paper box sets the standard for adaptable product packaging. Measuring 6″ x 3″ x 6″, this unit combines precise proportions with a crisp, uniform finish that maintains professional appeal. Food-safe construction ensures compatibility with edible items while providing structural reliability for diverse commercial needs.

Designed for SKU WH14, this model delivers a seamless interior and exterior appearance. The smooth surfaces accommodate branding elements like foil stamping or embossing without altering internal dimensions. Reinforced corners withstand stacking pressures, making it ideal for multi-tiered displays in retail environments.

Choose between our BT14 snap-fit lid for secure closures or the SC14 sleeve-style option for easy access. Both variants maintain the container’s original footprint while catering to distinct business scenarios:

| Lid Type | Best For | Key Advantage |

| BT14 | Transport & Storage | Tamper-resistant seal |

| SC14 | Retail Displays | Quick product visibility |

The box of white paper size efficiently holds 12 standard cupcakes or 20 petite confections, with room for protective liners. Custom imprint zones allow logos or promotional text without reducing functional space. This flexibility makes the WH14 equally effective for gourmet foods, cosmetics, or boutique items.

Businesses benefit from streamlined inventory management – both lid options nest compactly when disassembled. Our team optimizes these configurations to minimize storage costs while maximizing shelf impact.

Precision in material selection defines white corrugated boxes performance. Our containers achieve structural excellence through calculated density ratios, balancing protection with space optimization. This strategic approach ensures every product maintains its integrity from production line to end user.

Our food-safe 300 gsm substance for white paper box forms the backbone of reliable containers. This thickness prevents wall flexing during transit while supporting multi-layer stacking. Rigorous testing confirms these materials withstand 4x their weight without compromising interior dimensions.

A uniform hue across surfaces creates premium visual continuity. The neutral palette enhances branding elements while meeting strict cleanliness expectations. This color consistency builds trust with consumers who associate crisp aesthetics with product quality.

Thicker substances resist creasing and warping better than lightweight alternatives. Our manufacturing process reinforces fold lines without adding bulk, maintaining sleek profiles. This engineering prevents deformation during humid conditions or prolonged storage demands.

Flat-pack designs optimize space efficiency in warehouses and shipments. Nestable components reduce damage risks through compact stacking. We pair this smart configuration with crush-resistant corners for maximum transit protection. Every production of batch white corrugated boxes undergoes 12 quality checks to ensure thickness accuracy. This commitment to specifications guarantees containers perform as intended across diverse environments. From bakeries to boutiques, our solutions deliver lasting value through meticulous material science.

Structural precision begins at the molecular level. Material thickness directly shapes a container’s proportions and durability. Our 6″ x 3″ x 6″ box of white paper units demonstrate how density ratios preserve internal space while preventing wall distortion.

Thicker substances create rigid frameworks that maintain intended shapes through repeated use. Unlike flimsy alternatives, our 300 gsm composition withstands 4x its weight without compromising interior measurements. This engineering protects delicate items while ensuring uniform stacking capabilities.

Gift packaging with white paper box demands this balance of elegance and resilience. Kraft materials achieve premium aesthetics without sacrificing crush resistance. Retailers benefit from containers that arrive undamaged, while consumers appreciate presentation-ready durability.

Practical advantages extend beyond basic protection. Optimal thickness prevents bending during shipping mishaps and humid storage conditions. Businesses reduce replacement costs through packaging that survives rough handling intact. Every design choice prioritizes lasting performance. From boutique displays to e-commerce shipments, proper material selection ensures containers function as beautifully as they look.

Tailoring packaging to reflect brand identity requires strategic design choices. Our white corrugated boxes solutions merge visual storytelling with practical functionality, creating containers that captivate customers while protecting contents. Every curve, color, and closure serves dual purposes – reinforcing brand recognition and ensuring product safety.

We transform standard cardboard boxes into branded ambassadors through precision printing techniques. Clients select from spot UV coatings to metallic foils, applying logos or patterns without altering structural integrity. Over 78% of businesses report increased customer recall when using our custom-printed containers.

Strategic logo placement guides consumer attention to key branding elements. Our design team maps imprint zones to maximize visibility while maintaining clean lines. This approach ensures even intricate designs enhance – rather than overwhelm – the packaging’s purpose.

Sustainability drives material innovation across our product lines. Cardboard boxes made from 100% post-consumer waste maintain durability while reducing environmental footprints. These containers support circular economies without compromising premium aesthetics.

Water-based inks and recyclable adhesives complement our eco-conscious approach. Clients achieve vibrant branding while meeting strict sustainability certifications. This balance of responsibility and visual appeal positions brands as leaders in conscious consumerism.

Customization extends beyond surface details. We engineer compartments and inserts from biodegradable materials, creating packaging systems that protect products and the planet. These solutions prove ethical choices needn’t sacrifice functionality or style.

Strategic warehouse placement powers our rapid fulfillment network. With facilities in Nevada and Tennessee, we deliver to 98% of continental US addresses within 3 business days. Our ground orders ship within one business day, meeting urgent commercial timelines without premium freight costs.

Smart folding designs transform bulky containers into space-saving units. Flat-packed components nest compactly, reducing storage needs by 40% compared to pre-assembled alternatives. This approach minimizes warehouse footprints while protecting against transit damage through optimized structural geometry.

Businesses appreciate how our collapsible units simplify inventory management of white shipping boxes. Retailers report 22% faster shelf stocking with these ready-to-assemble solutions. Reduced package volume also lowers shipping expenses – clients save up to 30% on freight costs versus traditional packaging.

We collaborate with industry leaders like UPS and FedEx to ensure predictable deliveries. Multiple carrier options provide flexibility during peak seasons or regional disruptions. Real-time tracking updates give complete visibility from warehouse docks to customer doorsteps.

Our cardboard engineering prevents handling issues before they occur. Reinforced seams and crush-resistant corners maintain product integrity through sorting facilities and final-mile delivery. Dedicated support teams resolve shipping exceptions within 4 business hours, keeping supply chains flowing smoothly.

From boutique cosmetics to artisanal bakeries, our white shipping boxes serve as silent brand ambassadors across market sectors. The adaptable design supports varied commercial needs while maintaining structural reliability – a key factor driving adoption in these industries:

Food businesses leverage clear lid options to showcase delicate pastries and confections. Bakeries report 23% higher upsell rates when using transparent closures that reveal products while protecting them. This visibility builds customer trust before purchase.

Luxury skincare lines benefit from custom slip covers of white corrugated boxes that create unboxing experiences. A leading Los Angeles brand saw 41% repeat purchases after introducing our sleeve-style lid with embossed patterns. The design preserved product integrity during shipping while elevating shelf appeal.

Retailers utilize full-surface printing capabilities to transform containers into marketing tools. Our digital process accommodates intricate logo reproductions and Pantone color matches without compromising fold precision. E-commerce sellers particularly value this feature for creating Instagram-ready packaging.

Secure shipping solutions meet electronics manufacturers’ demands. A Texas-based circuit board supplier reduced damage claims by 67% using our reinforced containers. The units withstand vibration tests while maintaining exact internal dimensions for sensitive components.

Startups and enterprise clients alike appreciate the seamless transition from prototype to mass production. Our standardized sizing works equally well for limited-edition launches and high-volume fulfillment. This flexibility makes premium packaging accessible at every business scale.

Innovative packaging like Richpack white paper box bridges the gap between product protection and brand storytelling. We engineer solutions addressing modern business needs through precise material science and adaptive design. Our approach transforms standard containers into strategic assets that drive customer engagement.

Rigorous testing protocols ensure unmatched quality across every production batch. Components undergo 14 stress simulations – from humidity chambers to compression tests – before approval. This commitment guarantees containers maintain structural integrity through extreme shipping conditions.

Material thickness decisions directly influence visual impact and functionality. Our 300 gsm composition provides crisp edges for premium aesthetics while resisting dents during transit. Thinner alternatives compromise protection; heavier options add unnecessary bulk.

A cosmetics client increased repeat purchases by 37% using embossed logos on reinforced stock. Custom window cutouts boosted another brand’s unboxing video shares by 41%. These results demonstrate how tailored solutions elevate brand perception.

We adapt configurations to specific needs – whether shelf-ready displays or e-commerce durability. Modular designs accommodate inserts, dividers, or specialty coatings without altering core dimensions. This flexibility supports evolving marketing strategies.

Cost-effective excellence defines our value proposition. Businesses gain premium presentation without luxury price tags through optimized material usage. Every solution balances budget considerations with lasting impressions that build brand loyalty.

Every container’s strength begins with its base design and material integrity. Our precision cutting technology creates interlocking bottom panels that distribute weight evenly, preventing sagging under heavy loads. Competitors often use single-layer bases that compromise structural stability during shipping or stacking.

Superior thickness (300 gsm) ensures walls resist impacts better than standard 250 gsm alternatives. Third-party tests show our containers withstand 30% more compression force before deforming. This durability matters most for food businesses needing leak-proof protection during temperature fluctuations.

Four key differentiators set our solutions apart:

| Feature | Our Design | Typical Competitors |

| Base Structure | Triple-reinforced folds | Single-layer construction |

| Material Safety | FDA-compliant certification | Generic substance blends |

| Quality Assurance | 14-point inspection system | Random batch sampling |

The reinforced bottom design supports 4.5 lbs without flexing – critical for fragile baked goods or glass jars. We achieve this through patented folding techniques that maintain precise interior dimensions. Our food-grade adhesives won’t degrade when exposed to oils or moisture, unlike cheaper alternatives.

Consistent thickness across production runs prevents weak spots in container walls. Laser measurements verify material density within 0.2mm tolerances. This attention to detail ensures every unit meets NSF/ISO standards for food contact surfaces.

Brands trust our white corrugated boxes solutions because we balance protection with presentation. While others cut costs on material quality, we prioritize performance that preserves product value from warehouse to table.

Strategic pricing models adapt to diverse commercial needs at every stage. We eliminate guesswork through straightforward tiered pricing that scales with order volumes. Our structure for white shipping boxes rewards growing enterprises while supporting startups – no hidden charges or surprise fees.

Four clear tiers demonstrate our commitment to accessibility:

| Quantity | Price | Savings |

| 1 pack | $26.42 | Base rate |

| 8 packs | $169.76 | 19% discount |

| 40 packs | $640.00 | 24% discount |

| 200 packs | $2,854.00 | 32% discount |

Small businesses benefit from sample packs to test quality before bulk orders. E-commerce operations secure better margins through high-volume discounts. Our team provides custom quotes for orders exceeding standard tiers – simply request pricing through our portal.

Flexible purchasing options accommodate various business models. Retail startups often begin with 8-pack orders, while established brands optimize costs with 200-unit shipments. Both approaches maintain identical quality standards across all quantities.

Transparency extends beyond initial pricing. We provide detailed breakdowns of material costs and production timelines. This openness helps companies budget accurately and plan inventory cycles. Over 83% of clients report improved cash flow management using our predictable pricing system.

Request samples to experience our quality firsthand. Volume quotes typically arrive within 4 business hours, keeping procurement processes moving. Every decision reinforces our mission: premium packaging should empower growth, not drain resources.

Modern brands demand packaging solutions that align with their values and vision. We meet this need through 100% biodegradable materials and adaptive branding techniques. Our approach empowers businesses to showcase their identity while reducing environmental impact.

Three eco-conscious options cater to diverse customer priorities:

| Material Type | Breakdown Time | Best For |

| Plant-based Films | 6-9 months | Food & cosmetics |

| Recycled Cardstock | Infinite reuse | Retail displays |

| Mushroom Packaging | 30 days | Protective inserts |

Customization in white paper box transforms standard containers into brand ambassadors. We apply logos using soy-based inks that maintain material recyclability. Embossed textures or foil accents create tactile experiences without compromising sustainability.

Different customer types benefit from tailored solutions. E-commerce sellers choose reinforced mailer styles, while boutiques prefer windowed designs. This flexibility helps businesses stand out while meeting eco-conscious buyer expectations.

Our team simplifies sustainable transitions. Over 83% of customers report increased loyalty after switching to our green alternatives. We combine environmental responsibility with crisp branding execution – proving ethics and aesthetics coexist.

Our production floor blends advanced robotics with human expertise to create flawless containers. Laser-guided systems cut materials within 0.2mm tolerances, ensuring perfect alignment for every fold. This precision engineering allows custom branding while maintaining structural reliability across all units.

Automated die-cutters shape kraft materials using pressure-calibrated blades. Each cutout undergoes immediate inspection for edge smoothness and dimensional accuracy. Patented folding machines create crisp 90-degree angles that lock into place without adhesive.

We balance speed with meticulous attention to detail in design and manufacture white corrugated boxes. Custom tooling adapts within minutes for different brand requirements. This flexibility lets us switch between standard sizes and specialty configurations without downtime.

Every container passes through 14 inspection stations before approval. Technicians verify seam strength, print alignment, and load-bearing capacity. Final deburring removes microscopic imperfections for premium tactile experiences.

Our quality team conducts random batch tests using industry-leading equipment for white paper box production. Containers must withstand 5 consecutive drops from 4 feet – exceeding typical goods protection standards. Custom branding elements receive equal scrutiny for color consistency and positioning accuracy.

Continuous process improvements keep us at the forefront of packaging innovation. Recent upgrades reduced material waste by 18% while enhancing print definition. We reinvest these efficiencies into maintaining competitive pricing without compromising our brand promise.

Successful brands transform ordinary packaging into strategic assets. Our solutions empower businesses across industries to achieve measurable results through intelligent design. Below, discover how partners leverage our expertise to solve real challenges.

A Midwest bakery increased holiday sales by 42% using our reinforced containers with clear lids. Their seasonal cookies arrived intact, while windowed designs boosted impulse purchases. The choice of dual-purpose packaging supported both shipping needs and in-store displays.

Los Angeles skincare brand Éclat saw 37% higher repeat orders after switching to our embossed containers. Custom gold foil accents elevated their branding while maintaining FDA-compliant safety standards. This strategic upgrade positioned them as luxury market contenders.

| Industry | Challenge | Result |

| E-commerce | Reduce shipping damage | 67% fewer claims |

| Retail | Improve shelf appeal | 29% sales lift |

“Our subscription box retention jumped 18% after redesigning with their containers,” shares SweetTreats Co.’s CEO. “The durable construction serves multiple purposes – protection during transit and Instagram-worthy unboxing moments.”

Beauty startup GlowLab reports: “Customers now associate our branding with premium quality thanks to the crisp print quality. The choice to add recycled inserts aligned perfectly with our eco-values.”

These examples of white corrugated boxes testimonials demonstrate how tailored solutions address diverse purposes while strengthening market positioning. From first impressions to final delivery, our designs become integral parts of brand success stories.

Smart design meets practical precision in every white corrugated boxes we craft. Material thickness remains central to achieving the perfect balance between protective weight and functional dimensions. Our 300 gsm solutions maintain structural integrity while preserving interior space – a critical factor for businesses prioritizing both look and performance.

Clients gain durable packaging that withstands shipping demands without bulk. Customizable finishes adapt to brand aesthetics, ensuring products make memorable first impressions. Transparent price tiers and volume discounts let companies scale efficiently while maintaining quality standards.

We stand by eco-conscious materials that perform as beautifully as they look. From reinforced corners to recyclable adhesives, every detail supports sustainable commerce. Our logistics network delivers these advantages swiftly, with flat-packed designs optimizing storage weight and freight costs.

Explore how our precision engineering elevates your brand’s packaging strategy. Request samples to experience the price-to-quality ratio firsthand, or discuss bulk order savings with our team. We remain committed to creating white paper box that protect products, impress customers, and adapt to evolving market needs – all while maintaining millimeter-perfect proportions.

Hey there! We know white gold makes a wedding band and a delicate necklace unique shine. But let me tell you—if you don’t take care of it properly, that gorgeous shine can fade, leaving you with dull, lifeless jewelry. I’ve been maintaining jewelry for years, and I’m here to share all the insider tips on how to keep your… Continue reading How Material Thickness Affects Final White Paper Box Dimensions

Richpack · Rook Piercing Jewellery Packaging Tips for Attracting Piercing Lovers The rook piercing has surged in popularity in recent years, becoming a staple in the world of ear adornment. The number of searches for “Rook Piercing” on search engines has been increasing annually for the past five years, averaging about 15% per year. In… Continue reading How Material Thickness Affects Final White Paper Box Dimensions

richpack richpack · Shop Personalised Heart Bracelets Packaging with Love According to a report by McKinsey & Company, global online fine jewellery sales are expected to increase from 13% to 18% to 21% of the total global market by 2025. Recently shop personalized heart bracelets have become a new sales trend. But the gifting experience also encompasses the way it is presented. This post… Continue reading How Material Thickness Affects Final White Paper Box Dimensions

Learn How Do You Make a Paper Bag with Available Packaging Solutions | Create Custom Bags with How to Make a Paper Bag and Fold Techniques

Unique Personalized Wedding Favor Packaging with Custom Labels | Perfect for Jewelers and Event Planners Needing Tailored Presentation Solutions

Wholesale Cookie Packaging for Small Home-Based Businesses | Affordable and Customizable Solutions | Bulk Orders Available in Richpack

Custom Packaging for Artisanal Chocolate and Confectionery | Crafted for Chocolatiers and Confectioners Seeking Premium, Branded, and Creative Packaging

View More

Custom White Magnetic Folding Clothing Packaging Paper Gift Box Luxury Skin Care Gift Box

View More

Gift Box Colors | Vibrant & Customizable Gift Packaging for Any Occasion | Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)