Glossary of Terms for Eco-Friendly Jewelry Packaging

2024-10-29

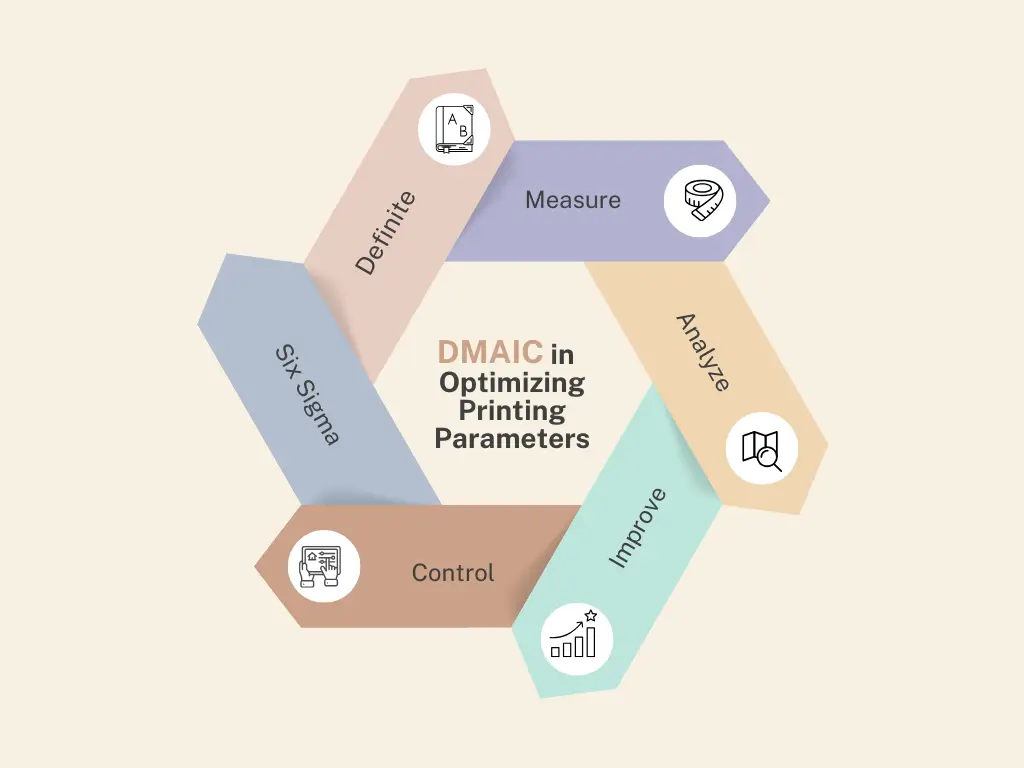

Many jewellery packaging businesses have quality concerns about custom card printing. You should solve custom card printing issues by using the DMAIC method to optimize printing parameters and choose the right printing technology and high-quality card materials you can select appropriate materials such as glass-like cardboard for high gloss, adjusting the coating type and formulation.

Custom card printing holds significant importance for jewellery packaging businesses. It serves as a unique bridge between businesses and customers, enhancing brand recognition. Through personalized cards, businesses can effectively showcase their brand culture, especially with customized holiday cards.

Personalized cards as a special connection between businesses and customers, they can reinforce customers’ sense of belonging and loyalty. Businesses can showcase their brand culture through customized products such as holiday cards. In a highly competitive market, businesses offering custom card printing services are better able to attract customers. Personalized card printing, as an effective marketing tool, can help businesses stand out from their competitors.

Modern printing technology not only improves production efficiency but also reduces costs. These technologies allow for the rapid production, of personalized cards while reducing the waste and errors in traditional printing. We Richpack have conducted this experiment: through surface modification, a special coating is added to the surface of the ordinary card-making substrate, and the main raw materials of the coating are synthesized using the principle of molecular design, and the best coating formula is selected to control the polarity and surface tension of the coating within a reasonable range so that it can not only inkjet printing, but also offset printing or screen printing, and realise the organic combination of digital printing technology and traditional printing technology. This project shows that the custom card-making process is simplified, and the card-making cost is greatly reduced.

In the realm of custom card printing for jewellery packaging, several challenges often emerge. As we’ve explored the importance of custom cards in enhancing brand recognition and improving efficiency, it’s crucial to address the common issues that can arise.

Printing and packaging researchers find that the print quality of different brands of paper cards, even if it is produced by different batches from the same manufacturer, can vary greatly. This is mainly because of the different interactions between the ink and the paper, leading to problems such as poor ink drying, powder loss, and reverse transfer of printing spots.

The biggest feature that distinguishes the sheet-fed lithographic offset printing process from other printing methods is that it uses oxidative polymerization dry viscous ink with the highest viscosity and the largest viscous tension among all printing inks. Since the lithography process involves two liquids, water, and ink, achieving a proper water-ink balance has become the most basic condition for ensuring printing quality.

The high cohesion of viscous inks also helps to control ink diffusion and dot expansion, which allows sheet-fed offset printing to print high-screen line (250 lpi or higher) images with higher resolution, or Fl screen technology with smaller dots, to reproduce the rich layers and vivid colors of the original image more realistically.

When you use high-gloss special cardboard, although the whiteness and gloss of self-made high-gloss cardboard can be close to imported aviation glass cardboard, there may be differences in printing quality. A journal study published by Paper Science and Technology shows that the printing gloss of the samples obtained under the printing conditions of fast-drying ink is higher than that of the samples printed with ordinary ink, which is because the drying speed of fast-drying ink is faster than that of ordinary ink, and the rapid drying of the ink film on the paper surface can reduce the amount of binder penetrating the pores of the paper, thereby improving the gloss of the printed matter.

In custom card printing, colour accuracy is the first important thing. However, different devices (such as monitors and printers) have different colour presentations, which may cause the colours in the design draft to be inconsistent with the actual printed colours. For example, when proofreading the design draft, it looks bright red on the monitor, but it becomes dull brown after the printing result comes out.

In addition, factors such as ink characteristics and paper ink absorption during the printing process will also affect the final presentation of the colour. Different brands and models of ink have different colour saturation and hue, and the texture and whiteness of the paper will also reflect and absorb the colour, thereby changing the appearance of the colour.

If the image resolution is too low, it will cause problems such as blurred images and jagged edges, which will seriously affect the overall effect of the card. We are now in 2024, and even AI can create high-definition impact products. If our custom cards are not high-definition, it will greatly affect customers’ perception of our brand. Of course, low pixelation is sometimes also an artistic style-pixel art. In addition, it is not the case that the higher the resolution, the better. Too high a resolution may increase the file size, slow down the processing speed, or even cause compatibility problems during printing. For some complex images, such as photos or illustrations, the appropriate resolution needs to be determined according to the actual printing size and requirements.

We aim to provide practical solutions to address the common issues in custom card printing. By understanding the importance of custom card printing for enhancing brand recognition and improving efficiency, we can now focus on finding the best ways to ensure high-quality results.

Choosing the right printing technology and high-quality card materials is the basis for improving print quality. The use of high-definition retransfer technology and holographic overlay technology can significantly improve the security and printing quality of custom cards. In addition, the use of PETG specialty sheets can improve the printing effect and durability of the card.

You can use the DMAIC method to optimize the printing parameters to improve the printability of your custom cards.

D means defending the problems in the custom card printing process, such as unstable print quality and high defect rate, then you set goals to improve print quality and reduce defect rates, and identify key parameters that affect print quality, such as ink concentration, print speed, temperature, and more.

”M ” means measuring data, you can use statistical tools (e.g., MSA, control charts) to collect data for the current printing process, and ANOVA (Analysis of Variance) and DOE (Design of Experiments) methods can be used to identify factors that have a significant impact on print quality.

“A'” means causal analysis, regression analysis, and Interaction diagram which can analyze the impact of the interaction between various factors on the printing quality.

”I” means improving process capability, you can reduce defect rates by adjusting process parameters and improving the Process Capability Index (Cpk).

Finally, “C “means controlling and monitoring the process, correcting anomalies in time. We need to closely monitor the operation of printing equipment, such as printing speed, pressure, and other parameters. Even small changes in these parameters may show significant differences on the card, such as line clarity, colour uniformity, etc.

If you need high gloss and good printability, glass-like cardboard can be selected to troubleshoot custom card issues. For cardboard that requires special visual effects, such as UV-coated cardboard or foil-stamped cardboard, you can select polyester film as the substrate, coated with an alcohol-soluble dyeing resin layer, and the polyester aluminized film is made by vacuum aluminium film.

Secondly, the type and formulation of the coating have a significant impact on the print quality and performance of the cardboard. You can use calcined kaolin can improve the hiding of the coating and the opacity of the paper. In addition, you better adjust the ratio of china clay to calcium carbonate in the coating, so the openness of the coating and the ink absorption can be optimized.

Besides, when you select materials and coatings, consider their environmental friendliness and cost-effectiveness. You can use calcined kaolin not only to improve coating properties but also to reduce production costs. You should choose materials that are recyclable or biodegradable can reduce environmental impact.

With our specialization in custom cards, we have built a reputation for professionalism and extensive expertise in addressing custom card printing issues. Our thorough knowledge of custom card printing allows us to offer clear guidance to assist clients.

We hope this information brings fresh inspiration for your troubleshooting of custom card printing. Richpack is a leader in jewellery packaging, with substantial experience in cosmetic packaging too. If you’re looking for custom packaging solutions or something like this, click here to contact us.

In this blog, we have delved into the world of custom card printing for jewelry packaging businesses. Common issues like printability and printing quality evaluation exist, You can select the right printing technology and materials, along with using methods like DMAIC to optimize parameters. You need to consider environmental friendliness and cost-effectiveness in material selection. As the industry progresses, staying abreast of the latest advancements will enable businesses to create superior custom cards. By addressing these issues and implementing quality concerns, businesses can ensure that their custom cards are of the highest quality.

In recent years, consumers become more concerned about sustainability when shopping for jewellery. Your products and the materials you choose to package your jewellery are equally important. Here’s a list of 5 key principles for designing eco-friendly packaging for jewellery. Hope these design principles will help you to create both sustainable and stunning packaging, meeting your… Continue reading How to Solve Custom Card Printing Issues Effectively

Size is one of the elements we need to refer to when we buy anything. For gifts, different gifts need to be adapted to the appropriate and accurate size of the gift box, so as not to appear out of place. Choosing the right size not only enhances the presentation but also ensures that the… Continue reading How to Solve Custom Card Printing Issues Effectively

Sustainable packaging has gradually become a hot spot in the jewelry packaging industry. Sustainability is not only about strategic thinking but also about the responsible dimension of supply chain cooperation, and global regional development. In today’s case, we will focus on the sustainable and environmentally friendly packaging practices of Vivienne Westwood, and understand how to optimize… Continue reading How to Solve Custom Card Printing Issues Effectively

Box Lunch Gifts for Surprising Gift Occasions – Customizable and Easy-to-Use Gift Cards by Richpack for Seamless Ordering and Delivery

Adorable Cute Packaging for Cosmetics to Elevate Your Brand – Customizable Designs for the Cosmetic Packaging Market by Richpack

Cosmetics Packaging Labelling Solutions | Custom Cosmetic Packaging Labels for Beauty and Skincare Brands Bulk Order Options From Richpack

Custom Cardboard Makeup Eyeshadow Packaging Box Paper Cosmetic Box

View More

Custom Cardboard Shampoo And Conditioner Packaging Box For Shampoo Lash_Shampoo Box

View More

Biodegradable Cardboard Packaging Boxes for Corporate Gifts | Eco-Friendly Packaging Solutions for Businesses Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)