Case Study: Implementing Sustainable Packaging Solutions in a Global Jewelry Supply Chain

2024-10-23

Having worked in jewelry packaging for years, I often hear clients say, “If the packaging supply breaks, the business stops too.” It’s no exaggeration—chain brands have seen thousands of store shelves sit empty because gift boxes didn’t arrive; startup founders have abandoned new product launches because minimum order quantities (MOQs) were too high; wholesalers have stared at competitors’ boxes, torn between torn between the dilemma of cutting costs and keeping quality.The three stories below are all true, pulled from our team’s client records. We’ve changed the names, but the anxiety, frustration, and eventual relief? Those are 100% real.

At Richpack, we’ve spent 15 years helping hundreds of jewelry businesses overcome these challenges. Our expertise in everything from small-batch production to global supply chain management has given us a front-row seat to our clients’ biggest headaches and how to solve them. Here are three stories from our files.

A large European chain faced a 22-day delivery delay, losing millions in sales.

We implemented a proactive, transparent supply chain with emergency stock.

The client regained “peace of mind” and avoided future losses.

Thomas, the procurement director at European jewelry wholesaler “EuroGem,” met me for coffee last spring. He clutched a crumpled leather jewelry box in his hand, his thumb brushing back and forth over the logo on the lid: “Look at this quality—this box almost sank our business for half a quarter last year.”

EuroGem operates 320 stores across 17 countries, and every quarter, they need 120,000 of these leather boxes without fail. They’re for their “Oath Diamond Ring”—a top seller that makes up 40% of quarterly sales, thanks to Europe’s busy spring wedding season. In Q2 2024, Thomas switched to a new supplier to save 5% on costs. The contract promised delivery by May 15, but on May 10, the supplier dropped a bombshell: “We’re out of leather. It’ll be 22 more days.”

“I sat in my office staring at the logistics tracker,” Thomas recalled. “Every time I refreshed it, the delay got longer.” He flew to the supplier’s warehouse the same day, only to find piles of unprocessed raw leather sitting idle. The supplier could only say, “Just wait a little longer.”

The real damage was in the stores: A location in Munich, Germany, had a third of its display cases empty. The store manager sent him a video of a customer picking up a diamond ring and asking, “Where’s the box?”—the staff had no good answer.

Five franchisees in Spain terminated their contracts outright, emailing, “If headquarters can’t even guarantee packaging, we can’t face our customers.” One even took down the “EuroGem Authorized Store” sign from its entrance.

That quarter, they lost over 8 million euros. “I spent every day either apologizing to store teams or writing reports to headquarters,” Thomas said. “I had zero time to focus on selling jewelry.” He reached out to Richpack early this year, and before signing the contract, he asked repeatedly: “Can you guarantee the same price every quarter? Can you let me see production progress in advance?”

We built him a “quarterly pre-production schedule”—locking in leather suppliers at the start of the year, keeping 10% of emergency stock in our Poland warehouse, and setting up a dedicated portal where he could track every step: from leather cutting to logo stamping to assembly. This let them fulfill sudden spikes in demand.

On May 14 this year, he sent a photo: rows of neatly stacked gift boxes in his warehouse, with a message: “Finally, I can sleep at night. The store manager told me yesterday—when the shelves are full, we feel secure.”

A new founder needed custom packaging but couldn’t meet the 5,000-unit MOQ, and smaller factories delivered low quality.

We provided low MOQ options and a collaborative design partnership.

The founder launched successfully, and repeat customer rates increased by 27%.

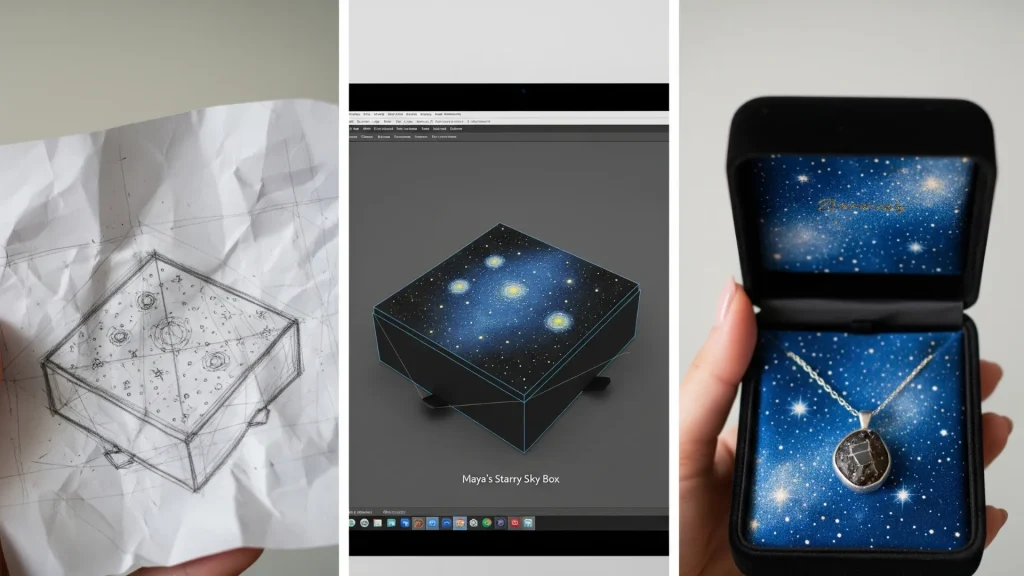

Maya found us right before Christmas last year. On our video call, her studio looked chaotic: jewelry samples (her “meteorite collection”) spread across her desk, a half-empty cup of cold coffee nearby, and a crumpled hand-drawn sketch in her hand—covered in star patterns.

“I want to make this ‘starry box’ for my meteorite necklaces,” she said. “But I’ve asked three factories, and all of them say the MOQ is at least 5,000. I’m just starting out—how could I possibly use that many?” Her brand, “Stella Ray,” was brand new. She was gearing up to launch her first meteorite jewelry line for the holiday season, but packaging had become a dead end.

She’d tried a small factory once, which promised “3,000 sets is doable.” But when the boxes arrived, the gold-foiled stars looked like blurry spots, and the corners were cracked. The factory just said, “We were in a rush—nothing we can do,” and refused to issue a refund.

“I stared at those bad boxes, and I almost cried,” Maya said. She even considered, “Fine, I’ll just use clear plastic bags.” But she couldn’t bear to pair cheap packaging with her carefully designed jewelry.

Our designer talked with her for three nights straight: first, turning her hand-drawn sketch into 3 revised renderings and asking, “Do you prefer the texture of velvet, or the structure of paper?” Then, we calculated her jewelry production volume—she was only making 1,000 pieces for the first run, so we set the MOQ for boxes at 1,000 too. Finally, we recommended “velvet + UV printing”—it gave the starry sheen she wanted, and cost less than gold foil.

Eighteen days after finalizing the design, Maya received the boxes. She sent us an unboxing video: opening the shipping carton, the velvet boxes glimmered faintly under the light, and the meteorite pattern inside matched her jewelry perfectly. She held up a recyclable dust bag and laughed: “You even added these! My customers are saying, ‘I want to keep the packaging too.’”

When she reordered earlier this year, she told us her repeat customer rate that Christmas was 27% higher than expected. One customer even bought a second necklace as a gift—just because they loved the box. “I never realized good packaging could help me keep customers,” she said.

Lisa runs a jewelry wholesale business in Hong Kong. She walked into our Shenzhen office right before Mid-Autumn Festival last year, carrying a black leather box from a competitor. She set it on the table: “Look at this—it’s from my rival. I want something similar, but 15% cheaper, and it needs to fit this year’s vintage trend. Can you help me?”

Her clients are mostly small-to-medium jewelry shops, so their packaging needs are practical: not too cheap (to avoid looking low-end), but not too expensive (to keep costs down). She’d tried two factories before—one said, “To cut 15%, we’ll have to use low-quality leather,” and the other said, “To look nice, you’ll have to pay more.” She’d been stuck for nearly a month.

We took apart her competitor’s box: it used top-grain Turkish leather on the outside, with embossed patterns inside—no wonder the cost was high.

By that afternoon, we gave her three samples: Option A: Almost identical to the competitor’s box, using Turkish leather. “$12.8 per unit—just a bit over your budget.” Option B: Cost-saving version, switching to high-quality Chinese PU leather and replacing embossing with gold stamping. “$10.9 per unit—saves nearly 15%, and feel the leather—it’s just as smooth as top-grain.” Option C: Vintage-inspired version, with a wooden base covered in leather, using Pingyao lacquer craftsmanship. “$11.5 per unit—more vintage flair, great for your high-end clients.”

Lisa turned the samples over in her hands, holding them up to the light to check the leather’s sheen. “I’ll try 2,000 of the PU leather ones first. If my clients like them, I’ll reorder 15,000 more.”

After the trial order arrived, she came back to tell us: One of her jewelry shop clients held the box for a long time and asked, “This looks just like XX’s box—why isn’t it more expensive?” The 2,000 boxes sold out quickly, and we fulfilled her 15,000-unit reorder via “synchronized production across two factories”—all delivered before Christmas. The boxes passed quality checks perfectly for things like “leather adhesion” and “logo clarity.”

The surprise? Her high-end clients saw Option C, and one ordered 5,000 units on the spot. “I never thought giving me more options would help me land new clients,” Lisa said, holding the wooden sample box—its lacquer glowed softly in the sunlight.

At the End of the Day, Clients Don’t Just Want “Boxes”—They Want “Peace of Mind”. The three stories all boil down to one thing: What these clients really wanted was simple. Thomas needed a “never-fails” supply chain, so he could focus on selling jewelry. Maya needed a partner to “turn her ideas into reality,” so she didn’t have to figure out craftsmanship alone. Lisa needed a “cost-smart plan,” so she didn’t have to choose between quality and budget.

After 15 years in jewelry packaging, we’ve learned: Clients don’t just look for a “supplier”—they look for a partner who solves problems. For more details about jewelry packaging, please read the complete guide here. A partner who lets them stop micromanaging production, stop stressing over MOQs, stop getting stuck on costs. As Thomas put it, “peace of mind”; as Lisa said, “a partner who helps me make money”; as Maya put it, “someone who gets what I want.” These things matter more than “on-time delivery” alone. Because for jewelry businesses, stable packaging isn’t just a nice-to-have—it’s the foundation of a stable business.

Ready to solve your jewelry packaging challenges? Get a free consultation to find a solution that works for your business, just like Thomas, Maya, and Lisa.

MOQs vary greatly depending on the supplier and materials used. While some factories require 5,000+ units, many partners specialize in helping small businesses and offer custom solutions with much lower MOQs, sometimes as few as 1,000 units.

Look for a supplier with transparent processes, clear communication, and a strong track record of on-time delivery. Requesting a production schedule and checking client testimonials can also provide peace of mind.

Yes. Investing in quality packaging can reduce costs from damage, returns, and customer complaints. More importantly, it can boost your brand’s reputation and lead to higher repeat business, which is far more valuable than initial cost savings.

Popular materials include velvet, cardboard, and wood, often paired with custom printing techniques like gold stamping or UV printing to create a unique look. The best material depends on your brand’s style and budget.

Packaging is a core part of your brand’s identity. It’s the first physical impression your customer has of your product. High-quality, thoughtfully designed packaging communicates care, value, and professionalism, reinforcing your brand’s message long after the purchase.

Your jewelry is stunning. But is your packaging telling the same story? Imagine a customer receiving your product. That moment is crucial. Great packaging doesn’t just protect your jewelry; it wows the customer. It turns a simple purchase into an experience. It can even turn buyers into loyal fans who share your brand on social… Continue reading Jewelry Packaging Solutions: Case Studies on Delivery Delays, MOQ, and Cost

Sarah K, a NYC jewelry designer, almost quit her business last year. Her handcrafted gemstone pieces were stunning, but clients kept walking out of her boutique empty-handed. Her jewelry storage and displays were drowning her designs in chaos. Then came the game-changer: swapping her cluttered trays for our vertical cork jewelry organizers with LED spotlights—a display solution that turned browsers… Continue reading Jewelry Packaging Solutions: Case Studies on Delivery Delays, MOQ, and Cost

Did you know that 72% of consumers say creative jewelry packaging influences their purchase decisions? For Monet Jewelry, packaging isn’t just a protective layer—it’s a marketing powerhouse. In this article, we’ll explore six innovative Monet Jewelry packaging ideas that not only enhance brand image but also align with customers’ expectations. With expert insights from Richpack,… Continue reading Jewelry Packaging Solutions: Case Studies on Delivery Delays, MOQ, and Cost

Bespoke Jewelry Boxes with Personalized Branding for Jewelry Labels | Tailored Packaging Solutions for Retailers

Black box with lid for jewelry | Matte black rigid packaging box with lid | Custom sizes and bulk orders at Richpack

Chic Small Box for Chain Necklaces – The Epitome of Jewelry Storage and Gifting Elegance

Are Brown Paper Bags Recyclable – Learn About Green and Eco-Friendly Paper Recycling Bags and More Available Sustainable Options for Packaging

View More

Art Deco Jewelry Boxes | Boasting Geometric Patterns | Crafted for Luxury Storage

View More

Biodegradable Jewelry Packaging with Personalized Designs for Retailers | Ideal for Jewelers Needing Green and Branded Packaging Solutions

View MoreJust submit your email to get exclusive offers (reply within 12 hours)