Emerging Trends in Perfume Packaging Boxes: What’s New for 2024

2024-10-24

From humble beginnings to high-tech innovation, jewelry paper bag manufacturing has evolved dramatically. Over the years, the world of jewelry paper bag manufacturing has undergone quite a few transformations, driven by technological advancements, changing consumer preferences, and a growing focus on sustainability. As we delve deeper into the evolution and future of jewellery paper bag manufacturing technology, it’s important to understand how we got here and the exciting possibilities for paper bag packaging developments in the future.

Consumer demand for environmentally friendly alternatives to single-use plastic bags is increasing rapidly. Next I will use the PEST model to analyze for you the reasons for its rise:

Politics: Governments are implementing regulations and bans on single-use plastics, further accelerating this trend. For example, the European Union implemented a ban on single-use plastic cutlery, straws and other items in 2021. The Canadian federal government has also announced plans to ban single-use plastic products, including plastic bags, straws and cutlery, in 2021. In addition, several U.S. states and cities have implemented their own regulations to reduce the use of single-use plastics, such as California’s ban on single-use plastic bags and New York City’s ban on foam food containers.These policies are fueled by a growing awareness of the detrimental effects of plastic waste, which pollutes ecosystems, harms marine life, and contributes to overflowing landfills.

So, at the same time, paper came into the limelight as a versatile material, and with it came a huge consumer demand for paper bag packaging. We would like to recommend our paper bags and more packagings for jewelry, we have the authority of FSC,GRS,BSCI, you can rest assured to buy!

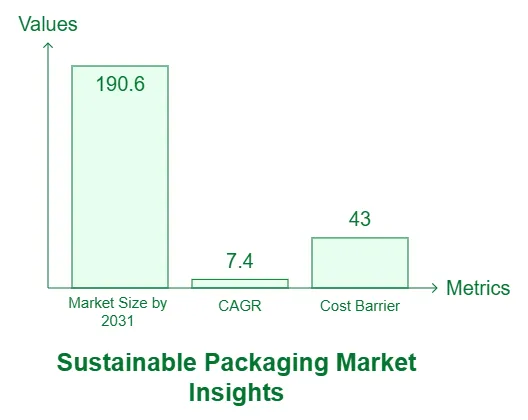

Economy: The sustainable packaging market is growing rapidly and is expected to grow to $190.6 billion by 2031, at a CAGR of 7.4%. This growth is primarily driven by increased consumer demand for environmentally friendly packaging and innovative measures taken by companies to meet market demand. However, despite the long-term business value of sustainable packaging, its initial cost is usually higher than that of traditional packaging, which has become a challenge for many companies. Nearly 43% of brands cite cost as a major barrier to their transition to sustainable packaging. However, as your demand for sustainable packaging increases, we can realize economies of scale in production. The higher the production volume, the lower the unit cost, which reduces the total cost of producing sustainable packaging such as paper bags for you.

Society: Consumers are increasingly concerned about environmental and social responsibility, which directly influences their purchasing decisions. More and more consumers are willing to pay a premium for products with sustainable packaging. For example, brands in the food and beverage industry are adopting innovations such as low-carbon glass bottles and label-free packaging to reduce their environmental impact. In line with this trend, the use of fine paper bags as packaging material in the jewellery industry not only enhances the reputation of the brand, but also strengthens consumer loyalty to the brand.

For this reason, Richpack has prepared customizable and personalized paper bags for you, which can promote environmental awareness and at the same time make consumers feel good about your brand through packaging!

Technology: Technological advances are one of the key drivers for sustainable packaging. The development of new materials, such as bio-based materials and biodegradable plastics, has made packaging more environmentally friendly. In addition, the application of smart packaging technologies can extend the shelf life of products and reduce waste. For example, Life Cycle Assessment (LCA) and Life Cycle Inventory (LCI) are used to guide packaging design to minimize environmental impact. Technological advances have also facilitated the improvement of recycling and reuse systems, enabling better recycling of packaging materials. We’ll be talking about the other processes below, so scroll down if you want to know more.

The rise of sustainable packaging has been driven by a combination of political, economic, social and technological factors. Government policies and regulations provide a clear direction for enterprises; economic growth and increasing consumer demand provide impetus for the market; social concern for environmental protection enhances the reputation of brands; and technological advances make it possible to realize sustainable packaging.

The creation of paper bags begins with selecting appropriate raw materials. Sustainable and recycled paper materials, such as kraft paper, recycled paper, and specialty papers, are commonly used.

In making their pulp, fillers and additives, including minerals and chemicals, are incorporated into the pulp to improve the paper’s strength, opacity, and printability.

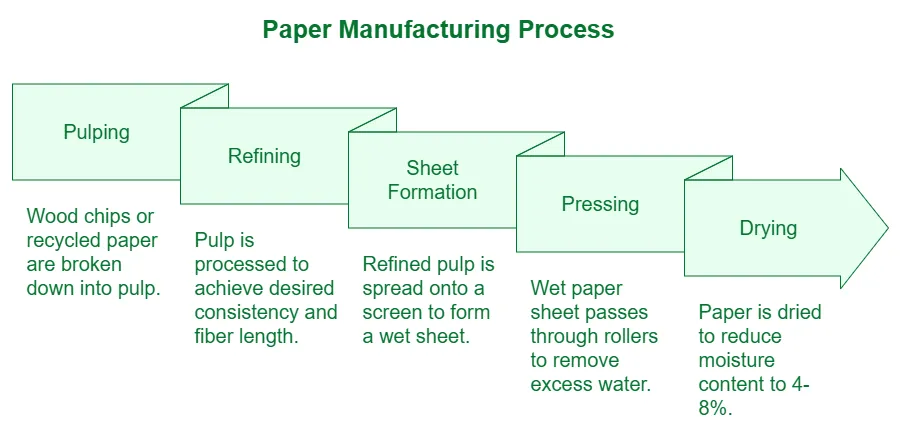

The transformation of raw materials into paper involves several crucial steps. The initial stage is pulping, where wood chips or recycled paper are broken down into a fibrous slurry called pulp using either mechanical or chemical processes. Mechanical pulping grinds the wood into fibers, while chemical pulping uses chemicals to dissolve lignin and separate cellulose fibers.

After pulping, the pulp undergoes refining to achieve the desired consistency and fiber length, influencing the final paper’s strength and texture. For example, in the study applied for by Kemira, the pulp is diluted to a specific consistency (e.g., 0.8% or 1.75%) and then further refined to achieve the desired SR value (Shear Resistance value), which ensures that the pulp has the proper consistency and fiber length. Subsequently, the refined pulp is spread onto a moving mesh screen, forming a wet sheet of paper in a process known as sheet formation.

The wet paper sheet then passes through a series of rollers and presses to remove excess water. Finally, the paper is dried using heated cylinders or large air dryers, reducing the moisture content to between 4-8%.

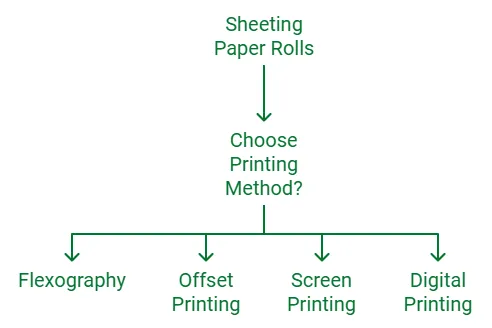

Large rolls of paper are sheeted, or cut into sheets of specific dimensions, based on the desired bag size. For branded or customized bags, the paper sheets are printed using various methods, including flexography, offset printing, screen printing, and digital printing.

In addition to this, the design of paper bags often combines traditional craftsmanship with modern technology in the production of jewellery packaging. For example, using the technique of quilling, thin strips of paper can be curled into intricate shapes to create unique jewellery packaging.

The printed paper sheets are then fed into a bag-making machine, which precisely folds and shapes the paper into a continuous tube. This tube is then cut to the desired bag length, and the bottom of the bag is formed using adhesives. Depending on the intended use, various bag styles are produced, including flat bags, satchel bags, and block bottom bags.

Handles, typically made of twisted paper, flat tape, or other materials, are attached to the bags for carrying convenience. Attachment methods include adhesives or mechanical fasteners.

Please rest assured that we will choose the process that suits your order quantity, or listen to your choice based on your costs and needs.If you want to make your own jewellery paper bag, please contact us!

A rigorous inspection process ensures that the finished bags meet quality standards for strength, size, and finish. Automated inspection methods, such as vision systems, and stress tests are employed to identify defects and ensure durability. For example, the durability of a paper bag can be measured by means of a pressure test (in accordance with the standard EN 13590:2003), which specifies a test method for paper bags when repeatedly carrying heavy loads.

In addition, the inspection of jewellery packaging paper bags can be divided into factory inspection and type inspection. The factory inspection program includes appearance quality, size deviation, performance indicators, food safety requirements and raw materials. Type inspection covers raw materials and processes, performance and other aspects.

Paper bag machines come in various types, each designed for specific bag sizes and applications.

The high-grade handheld paper bag forming machines and high-grade flat creasing and cutting machines are usually the paper bag machines commonly used for jewellery packaging paper bags. These machines are suitable for making high-grade gift paper bags, capable of handling high-grade rigid paper of 128-300 g/m² and molding in one go, using hot melt adhesive, various OPP, varnish, matte oil, glossy glue and other materials.

In addition, the high-grade handheld paper bag molding machines are equipped with automatic paper suction, gluing and gluing functions, which are suitable for assembly line operation. These machines are able to meet the high requirements of jewellery packaging for paper bag quality, aesthetics and functionality.

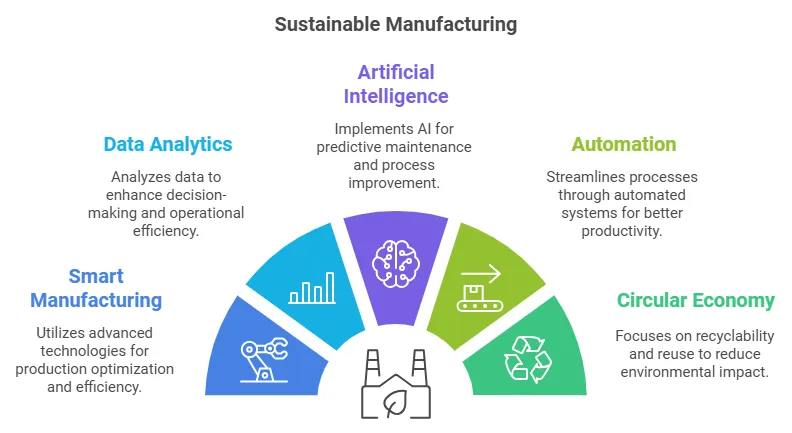

Automation plays a critical role in modern paper bag manufacturing, driving efficiency and consistency. There are a number of automated equipment specifically for jewellery packaging, such as automatic high-speed square bottom round (flat) rope handbag machine, which uses servo motor drives and computer systems to improve the production speed and accuracy, thus achieving mass production to meet market demand.

Automated processes ensure precision in cutting, folding, and gluing, resulting in strong, durable, and visually appealing bags. Furthermore, automation minimizes material waste, contributing to environmental sustainability and cost savings.This is also in line with the environmental concepts that we adhere to.

Regional differences in paper bag manufacturing practices exist, influenced by factors such as demand, production norms, and environmental regulations. Source notes a difference in operational flexibility between Turkish and European paper bag machines, with Turkish machines producing smaller batches of the same product to align with local demand trends. This highlights how regional preferences for bag sizes, types, and designs impact manufacturing practices. Therefore, we recommend you to choose the unit volume according to your target customer group.

Furthermore, the prevalence of specific paper bag machine manufacturers also varies across regions based on market demand and local expertise. Differing environmental regulations influence production processes and material choices. For example, some countries have banned the manufacture and distribution of plastic shopping bags with a thickness of less than 30 micrometers.

The future of paper bag machines lies in combining smart manufacturing with sustainability principles.

The potential of bioplastics, which decompose quickly and have a smaller environmental impact than traditional plastic bags, is another area of innovation. However, the current development of its field is still only the tip of the iceberg, The need to study the environmental protection and beautiful jewellery packaging paper bags, need more analysis and experimentation.

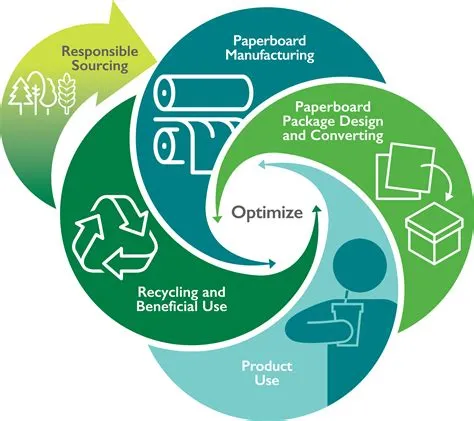

Paper bag technology plays a crucial role in transitioning to a more sustainable future. The shift from plastic to paper bags brings numerous benefits, including reduced environmental impact, increased recyclability, and support for a circular economy. Continuous innovation in paper bag manufacturing is essential for meeting evolving sustainability standards, enhancing efficiency, and fulfilling market demands. jewellery paper bags in particular are an environmentally friendly choice due to their biodegradable and recyclable nature.

Together with Richpack, both businesses and consumers can contribute to a greener, more sustainable future by making smart choices about packaging materials and supporting the circular economy.

Customers are increasingly looking for eco friendly cosmetic packaging that uses sustainable materials to protect the planet. For cosmetic companies specialising in skincare and beauty products, adopting more sustainable packaging is key to gaining customer trust and potentially boosting sales. However, it’s a challenge since eliminating traditional packaging materials, like plastic, isn’t feasible in the cosmetics industry. While we… Continue reading The Evolution and Future of Jewellery Paper Bag Manufacturing Technology

Did you know that 72% of consumers say creative jewelry packaging influences their purchase decisions? For Monet Jewelry, packaging isn’t just a protective layer—it’s a marketing powerhouse. In this article, we’ll explore six innovative Monet Jewelry packaging ideas that not only enhance brand image but also align with customers’ expectations. With expert insights from Richpack,… Continue reading The Evolution and Future of Jewellery Paper Bag Manufacturing Technology

It is important to understand the functions and differences of various jewelry packaging materials. Whether for packaging professional or a designer of an independent jewelry brand. When purchasing or customizing jewellery packaging, it is necessary to choose good packaging to add colour to the product and brand. In addition, different materials play a unique role… Continue reading The Evolution and Future of Jewellery Paper Bag Manufacturing Technology

Distinctive and Refined Personalized Paper Gift Bags with Custom Designs | Ideal for Jewelry Retailers Looking for Unique and Branded Gift Packaging

Durable and Biodegradable Compostable Paper Bags for Sustainable Packaging | Eco-Conscious Solutions for Jewelry Retailers and Boutique Stores

Elegant and Customizable Kraft Paper Bags with Custom Prints | Bespoke Packaging for Jewelry Retailers and Special Event Gift Packaging

Are Brown Paper Bags Recyclable – Learn About Green and Eco-Friendly Paper Recycling Bags and More Available Sustainable Options for Packaging

View More

Bespoke and Durable Custom-Printed Paper Bags for Retail Stores with Logos | Perfect Branding Solutions for Jewelers Needing Eye-Catching Retail Packaging

View More

Cost-Effective Custom Paper Bags with Logo Wholesale – Branded Paper Bags in Bulk with Richpack

View MoreJust submit your email to get exclusive offers (reply within 12 hours)