Gorjana Jewellery’s Packaging Design:From California Inspiration to Global Recognition

2024-11-21

Cosmetics is almost every girl has, it can be said that cosmetics is also a very good sales of products, young girls in the purchase of cosmetics not only to buy good quality, in the selection of the appearance of the box is beautiful or not is also a factor affecting whether they buy, therefore, businesses will not only select good quality cosmetics, cosmetics packaging box printing will also be very important. Today, we will give you a brief introduction to the process and precautions of cosmetics packaging box customization, hoping to help you.

First of all, designers need to fully communicate with customers, understand the characteristics of the product, the target market and the orientation of consumer groups, only clear this information, in order to design products that meet the market demand.

After fully understanding the needs of customers, it is necessary to organize a team to brainstorm and form a unique packaging design scheme, which mainly needs to consider the shape and structure of the packaging box, material color, size and other factors.

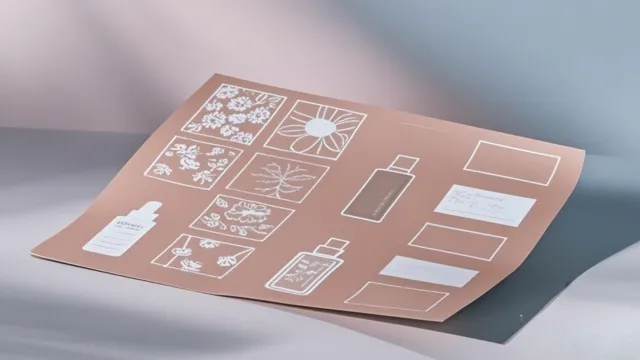

Based on the preliminary requirements analysis and creative ideas, make detailed design documents (including all the details mentioned above), and the most important thing is to conform to the design concept of the brand. After designing the document and confirming the document, it is necessary to make the plate first (four-color printing is four screen plates, a spot color is a spot color plate, the number of spot colors is more than the number of plates). Using the creative method of atlas tree, analyze the specific design of packaging design, including process, visual elements, materials, super symbols and so on. Then send the documents to the manufacturer for proofing.

First of all to determine the box type and material, at the beginning we need to determine what box type of packaging box, conditional can also be developed by structural engineers a new structure. The material is divided into two large pieces, the material used for structure and the material used for decoration, the structure is generally gray board, density board, electronic fiber board, etc., these materials are moderately soft and hard gray board is more commonly used, density board is generally used for high-end products, density board is relatively hard and not easy to deformation, electronic fiber board will not be affected by moisture and the environment.

Decorative materials General paper, generally need to print color patterns are used to make face paper, you can also use special paper to do decoration, paper special paper can choose different paper corresponding to different surface printing and surface treatment. The decorative material can also be made of leather, which can highlight the high-end and luxury of the product.

The customer will review the proofing results, confirm that they are correct and proceed to the next step, and modify them if necessary.

Printing is the first and crucial step in the production stage, usually using offset (color printing) technology. In the offset printing process, ink is applied to the plate on which the image is engraved and then transferred to the substrate through a roller called a rubber blanket. This technique offers several advantages, including better ink image transfer, and is one of the most common forms of commercial printing.

After the end of the printing step, it is necessary to carry out the surface treatment process, including the film coating process and the polishing oil process, which can increase the high-end and exquisite degree of the packaging product.

The final step in production is to die cut and fold. Die cutting is the necessary process before folding paste box, through the design of the box structure to determine the knife plate, die cutting with the knife plate to confirm the position and corner line, remove the useless corners, and then you can fold paste box. (This step requires careful alignment of the line position, if it is not aligned, it is a substandard product).

After the end of the production phase, the quality of the boxes produced is checked to ensure that each box meets the quality standards.

The qualified packaging boxes are packed and ready to be shipped. This process involves careful selection and packaging of each item, ensuring they meet our high standards for quality and safety.

Finally, the effectiveness of the packaging design is evaluated through market research and user feedback, and necessary improvements can be made based on the feedback.

The customization of cosmetic packaging boxes is a systematic project covering multiple links, focusing on details and quality. In this article, we have gone through a complete customization of cosmetic packaging boxes step by step from in-depth communication with customers to understanding their needs, to creative thinking and careful design, to rigorous material selection, fine sample production, and subsequent mass production understanding. However, the cosmetic box is not only for the completion of packaging so simple, if you are willing to learn more, please click here to contact us, our paper packaging solutions will also help your cosmetics brand sustainable strategy breakthrough.

Customers are increasingly looking for eco friendly cosmetic packaging that uses sustainable materials to protect the planet. For cosmetic companies specialising in skincare and beauty products, adopting more sustainable packaging is key to gaining customer trust and potentially boosting sales. However, it’s a challenge since eliminating traditional packaging materials, like plastic, isn’t feasible in the cosmetics industry. While we… Continue reading The Journey of Creating Cosmetic Packaging Boxes From Concept to Finished Product

Have you been troubled by cosmetic packaging fit issues? At Richpack, we specialize in custom cosmetic box solutions for wholesalers and retailers. From precise design services to prototyping and expert collaboration, we offer full support to solve cosmetic packaging fit issues. 1. Common Causes of Cosmetic Packaging Fit Issues When cosmetic packaging doesn’t fit the products, it… Continue reading The Journey of Creating Cosmetic Packaging Boxes From Concept to Finished Product

In retail, before customers even try a product, the first thing they notice is the packaging. The right packaging grabs attention and helps your brand stand out on the shelf, while the wrong packaging can make buyers turn to other options. So, how can a brand stand out in such a crowded marketplace? The answer lies… Continue reading The Journey of Creating Cosmetic Packaging Boxes From Concept to Finished Product

Cosmetic Packaging Sets with Matching Designs | Perfect for Beauty Brands Needing Cohesive and Branded Packaging for Skincare and Cosmetics

Bespoke Cosmetic Boxes for Small Beauty Brands with Low MOQ | Perfect for Niche Beauty Businesses Needing Customized Packaging Solutions

Custom Luxury Boston Essential Oil Bottle Packaging Carton Perfume Kraft Paper Box With Gold Fo

Cosmetic Packaging Sets with Matching Designs | Perfect for Beauty Brands Needing Cohesive and Branded Packaging for Skincare and Cosmetics

View More

Cosmetics Packaging Labelling Solutions | Custom Cosmetic Packaging Labels for Beauty and Skincare Brands Bulk Order Options From Richpack

View More

Cosmetic Eyeshadow Palette Packaging Hardcover Picture Frame Gift Paper Shadow Box Shadow Box

View MoreJust submit your email to get exclusive offers (reply within 12 hours)