Expert Roundup: Tips on Luxury Packaging

2024-12-02

In the premium men’s accessory market—dominated by Western markets like the US and UK—consumer psychology follows the principle of “Haptic Transfer.” Research shows that when a customer touches a high-weight, textured package, their brain subconsciously attributes those qualities (solidity, value, durability) to the product inside.

For B2B procurement managers and brand directors, the challenge isn’t just choosing a color; it’s engineering a tactile experience.

At Richpack packaging, we move beyond basic printing. We utilize industrial post-press technologies to create “Silent Sellers.” This guide explores the technical specifications and strategic applications of the top 5 finishes for men’s jewelry packaging.

The Finishing Techniques of the jewelry box have many advantages and can enhance the perceived value of the product and the overall brand experience.

Advanced packaging printing techniques such as gilding and partial UV can instantly enhance the quality and luxury of the product. In this case, consumers will associate exquisite packaging with high-quality products, thereby recognizing higher prices and enhancing brand reputation.

The continuous use of specific Finishing Techniques and colors can quickly establish brand recognition. Unique craftsmanship can become a signature element of a brand, enabling it to stand out in the highly competitive market.

Embossing/gravure printing and other techniques reflect the jewelry brand’s attention to every detail. This attitude of striving for excellence also implies that the brand is equally meticulous about the craftsmanship of the jewelry inside the box.

Techniques coating and surface treatment add a protective layer to the packaging box material, which has practical functions. In addition, the glossy and matte lamination helps prevent scratches, fingerprints, water stains, and daily wear and tear during transportation and handling.

Touch is one of the important senses for building memory. The soft surface treatment brings a unique velvety texture, with a high-end touch that engages multiple senses and leaves a lasting and pleasant impression of your jewelry brand.

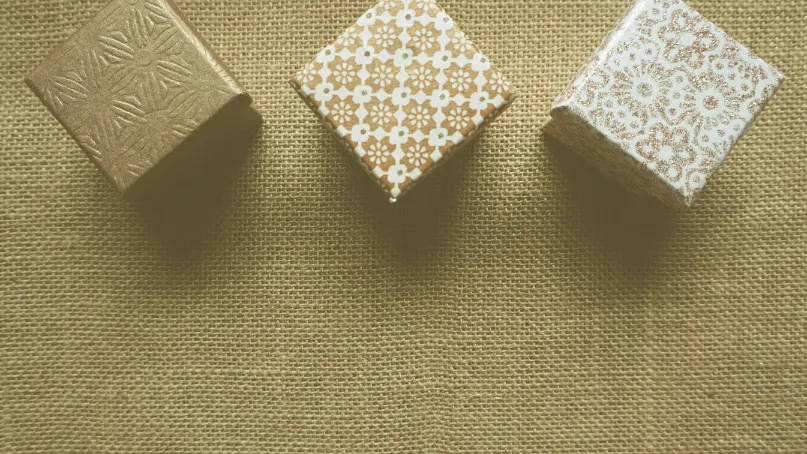

The US market currently favors Matte Gold and Copper, while the European market prefers Matte Black or White pigment foils for a minimalist Scandinavian look.

Hot stamping is a high-end printing process that uses heat and pressure to press a thin layer of metal foil or pigment foil onto the surface of an object. This is a dry process and does not require the use of liquid ink like conventional printing. The bright, reflective and durable surface effect of gilding is captivating. It is often used to enhance the luxury and exclusivity of jewelry packaging and is a good choice for printing logos on jewelry boxes.

Step A: Die Creation (The Mold)

The process begins with CNC machining or acid-etching your logo onto a metal block.

Magnesium Dies: Cheap and fast, used for short runs (under 1,000 units).

Brass/Copper Dies: Expensive and durable, used for high-volume runs and fine-line detailing. For premium men’s packaging, we prioritize brass because it holds heat better, ensuring crisp edges on complex logos.

Step B: The “Make-Ready” (Setup)

The die is mounted to the heating plate of the press. The machine is heated to a specific temperature range (typically 110°C to 150°C, depending on the foil type). The operator must manually adjust the “make-ready”—a backing sheet underneath the paper—to ensure the pressure is distributed evenly across the entire logo.

Step C: The Strike (Transfer)

The foil runs between the heated die and the packaging material.

The press descends. The heated die presses the foil against the paper with tons of pressure.

Activation: The heat melts the “Release Layer” (separating the color from the carrier film) and activates the “Adhesive Layer” (bonding the color to the paper).

Step D: The Stripping (Cooling)

As the die lifts, the unused foil (the waste matrix) is peeled away. Because the adhesive was only activated where the heated die touched, the gold/black foil remains permanently fused to your box, while the rest strips away cleanly.

While Gold Foil is standard, the modern masculine aesthetic in North America and Northern Europe leans towards Subtlety.

Standard metallic foil reflects light. Pigment Foil (Matte) absorbs it.

Debossing (pressing down) is superior to Embossing (raising up) for men’s packaging because it mimics the traditional craftsmanship of leather goods and bookbinding.

Anyone can deboss paper. But for a truly premium look, we recommend using Thermo-Reactive PU Leather.

Standard Spot UV is flat. For men’s jewelry, we recommend High-Build UV (often achieved via Scodix digital enhancement).

The Tactical Advantage

This technique simulates the look and feel of machined metal (like stainless steel, brushed aluminum, or titanium) on a paper-based package. It is typically achieved by laminating a micro-thin layer of Metalized Polyester Film (PET) onto the cardstock, followed by a specialized UV texturing pass that engraves fine, directional lines into the surface.

Men’s jewelry often features industrial materials—tungsten, carbon fiber, and surgical steel. A standard paper box creates a disconnect between the packaging and the product.

Brand Alignment: It creates a “Tech-Luxury” aesthetic perfectly suited for modern men’s accessories, smart rings, or heavy industrial chains.

Visual Weight: It visually communicates strength and engineering precision before the customer even opens the box.

Differentiation: On a shelf dominated by matte black paper boxes, the metallic sheen captures light and draws the eye without being “sparkly” or feminine.

Unlike hot foil, which is highly reflective and mirror-like, a Brushed Metal finish offers a muted, satin sheen. It interacts with light through its “grain direction” (which can be vertical or horizontal), creating deep shadows and highlights that mimic anodized metal. In tactile,it feels cooler to the touch than standard paper and features a subtle, grooved texture that provides resistance against fingertips, reinforcing the illusion of raw metal.

What is it? Flocking is a process where millions of tiny synthetic fibers (usually nylon, rayon, or polyester) are applied to an adhesive-coated surface. For the men’s market, we specifically recommend Microsuede—a shorter, denser fiber pile that mimics the premium leather found in luxury automotive interiors, rather than the long-pile velvet often associated with vintage women’s jewelry boxes.

Unlike satin or glossy paper, which reflects light, Microsuede absorbs almost all light. This creates a deep, matte background that forces 100% of the visual focus onto the polished metal and gemstones of the jewelry. Men’s jewelry (like Cuban links or signet rings) is often heavier than women’s. Smooth materials allow these items to slide and rattle. The high friction of microsuede holds heavy pieces firmly in place, ensuring a silent, secure transit and a premium presentation upon opening.

Microsuede flocking offers a rich, consistent depth of colour (especially in Midnight Blue, Charcoal Grey, or Jet Black). It looks uniform and architectural, avoiding the “crushed” or messy look of traditional velvet. It also provides a soft, warm grip. When applied to the exterior of a rigid box, it transforms hard cardboard into something that feels like a permanent keepsake case.

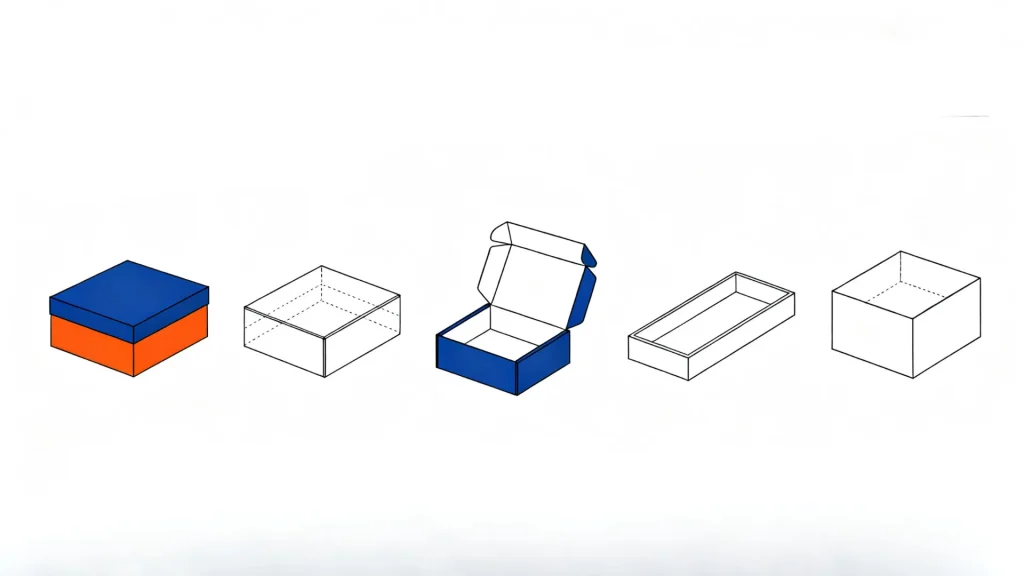

While a superior surface finish is crucial for visual appeal, the tactile authority of men’s jewelry packaging largely depends on its structural engineering. Perfect hot stamping cannot mask the inherent fragility of the box itself. To truly echo the mechanical precision of men’s accessories, we must go beyond the ‘skin’ and optimize the packaging’s framework.

If you look at an iPhone box or a Rolex box, you will notice the edges are razor-sharp 90-degree angles. This is not accidental; it is V-Grooving.

Folding Carton vs. V-Grooved Rigid Box

The “clunk” sound when placing a watch into the box determines the perceived quality.

Sponge vs. High-Density EVA

For procurement teams, balancing the budget is key. Here is how these finishes impact your unit cost:

| Technique | Setup Cost (Fixed) | Unit Cost Impact | Visual Impact (ROI) |

| Matte Foil Stamping | Medium (Die cost) | Low | High |

| Blind Deboss (Thermo) | Medium | Low | Subtle |

| High-Build Spot UV | Low (Digital) | Medium | Medium |

| V-Grooving | N/A (Process) | High (Slow production) | Critical for Luxury |

| Soft-Touch Lamination | None | Medium | Medium |

Choosing suitable finishing techniques for jewelry packaging requires a balance of brand identity, product needs, budget, and customer experience.

The role of finished men’s jewelry packaging should be a physical extension of your brand story and values. Therefore, please first choose an appropriate decorative style based on the tone of your brand. If your jewelry brand is positioned as a luxury or high-end brand, you can choose finishes that convey a sense of luxury and dignity, such as gilding (gold, silver, rose gold), embossing and soft-touch coatings. These techniques can create a rich tactile experience. If your brand style is a minimalist with a cool feel, choose a simple matte finish and pair it with a simple and eye-catching logo or strategic local UV lighting effects to convey refinement and innovation. If your brand is a handmade jewelry brand targeting environmental enthusiasts, you can choose natural, uncoated or textured surface treatments, such as kraft paper or organic fabrics (cotton, linen), to align with the values of sustainable development.

Different jewelry types require specific protection and presentation.

Delicate items (earrings, thin chains): Often need internal card backers or foam inserts with soft linings (velvet, satin) to prevent tangling and damage, which then dictates the shape and size of the outer box.

High-value items (engagement rings, heirloom pieces): Benefit from rigid boxes with plush internal linings to enhance perceived value and provide maximum protection.

Heavy/Sturdy items: Can use more durable packaging materials like wood or thick cardboard which can handle more rugged finishes like engraving or painting. If you are undecided on the base material, read our in-depth comparison: Leather vs. Wood vs. Velvet: Men’s Jewelry Box Guide.

We need to consider the needs of your jewelry customers; the unboxing process should be a memorable, multi-sensory experience. Combining a simple exterior finish with an unexpected interior finish, and employing multi-sensory surface treatments such as a soft-touch coating or a satisfying magnetic closure, can enhance the sensory appeal of men’s jewelry packaging. Adding a dark-toned branded ribbon, custom stickers, or handwritten notes to an elegant insert can make male jewelry buyers feel valued.

We need to develop a budget and find a balance that suits your business. Before placing a large order, be sure to order packaging samples with the desired surface finish to see and feel its appearance and performance firsthand. If your budget is limited, you can use a simple box structure with premium finishes only on key elements such as your logo, or use affordable finishes such as high-quality matte or glossy coatings instead of more expensive full-coverage special finishes. To understand how order volume impacts your unit costs and setup fees, refer to our Wholesale Jewelry Boxes MOQ & Pricing Guide. Furthermore, e-commerce packaging needs to be robust enough to withstand shipping, so prioritizing protective coatings and durable materials is crucial to preventing damage.

Many modern consumers prefer brands with eco-friendly packaging; 87% of consumers prioritize brands that use environmentally friendly materials, and 64% are willing to pay a 10%-20% premium for sustainable packaging. We need to consider using recycled paper or FSC-certified paper, and adopting minimalist designs to reduce waste and attract environmentally conscious buyers. Furthermore, we will pay attention to sustainable production practices when choosing jewelry packaging suppliers.

Manufacturing luxurious packaging is a science that requires an understanding of the material’s tolerance, thermochemical properties and structural engineering. For men’s jewelry, its product characteristics depend on weight, performance and durability, so the packaging must also convey the same message. Whether it’s the sharp V-shaped grooves, the understated embossing, or the industrial luster of brushed metal, these processes can all evoke consumers’ psychological associations with luxury and durability, thereby helping you achieve a higher retail price.

At Richpack, we can help you build a packaging ecosystem that can dominate the shelves.

Ready to engineer your packaging?

Review our case studies of custom printed jewelry boxes to see these technical specifications in action. Contact our jewelry packaging team immediately to request sample kits that include these 5 or more top-notch surface treatments and experience the differences for yourself.These processes can all evoke consumers’ psychological associations with luxury and durability, thereby helping you achieve a higher retail price.

A: Yes, but the sequence is critical. We usually apply the matte lamination first, followed by the Hot Foil stamping, and finally the High-Build Spot UV. However, we advise against overlapping foil and UV directly, as the UV varnish can sometimes peel off the smooth foil surface. We recommend a “registered gap” design where the two finishes sit side-by-side for maximum contrast.

A: Standard black paper shows fingerprints and scuffs easily. At Richpack, we use a specialized Anti-Scratch Soft-Touch Lamination. This maintains the velvet-like feel but adds a hardened chemical layer that resists fingernail marks and oil from handling, ensuring the box looks pristine even after shipping.

A: Standard PU is plastic-based, but we offer Water-Based PU options (DMF-free) that achieve the same color-change debossing effect without the harmful solvents used in traditional leather manufacturing. This meets the stricter environmental compliance standards of the EU and California markets.

Kraft paper costs $0.15-0.25/unit, greyboard $0.20-0.35/unit, and white card $0.30-0.50/unit for jewelry packaging. For high-volume wholesalers processing 10,000+ units monthly, kraft paper delivers 40-50% cost savings while maintaining professional quality and sustainable appeal. If you’re a jewelry wholesaler or retailer feeling the pinch from rising packaging costs in 2024, you’re not alone. The packaging industry… Continue reading Top 5 Finishing Techniques for Men’s Jewelry Packaging

Your jewelry box is the first physical interaction a customer has with your brand and a critical component of your product’s perceived value. For jewelry businesses, sourcing wholesale jewelry boxes is a strategic decision that balances style, protection, and cost-effectiveness. Purchasing wholesale can reduce your packaging costs by up to 50% or more compared to… Continue reading Top 5 Finishing Techniques for Men’s Jewelry Packaging

If you are customizing your brand’s jewellery box packaging, you must know the types of finishes for jewelry box. Like other components of jewellery packaging, the types of finishes for jewellery boxes have many points that make it challenging to make packaging decisions. To help you choose the best jewellery box, today, we will start with finishes… Continue reading Top 5 Finishing Techniques for Men’s Jewelry Packaging

Eco-Friendly and Sustainable Zero-Waste Jewelry Packaging Sets with Recyclable Components | Sustainable Solutions for Jewelry Brands | Richpack

Eco-Friendly Themed Packaging Sets with Sustainable Materials | Green Solutions for Jewelry Brands Seeking Sustainable Bulk Packaging Options

High-Quality and Innovative Reusable Jewelry Packaging Sets with Eco-Friendly Designs | Sustainable and Customizable Packaging Solutions

Custom Jewelry Display Boxes with Brand Logo for Retail Stores | Elegant Presentation for Retail Displays Richpack Corporate Gifting Solutions

View More

Custom Luxury Boston Essential Oil Bottle Packaging Carton Perfume Kraft Paper Box With Gold Fo

View More

Customizable Wholesale Perfume Boxes with Bulk Discounts | Ideal for Distributors and Brands Looking for Cost-Effective Packaging Solutions

View MoreJust submit your email to get exclusive offers (reply within 12 hours)