A Guide to Picking the Right Sizes for Custom Gift Boxes

2024-10-10

Have you been troubled by cosmetic packaging fit issues? At Richpack, we specialize in custom cosmetic box solutions for wholesalers and retailers. From precise design services to prototyping and expert collaboration, we offer full support to solve cosmetic packaging fit issues.

When cosmetic packaging doesn’t fit the products, it can lead to many problems. Let’s examine the common causes of these fit issues so you can avoid them in the future.

You might think measuring is straightforward, but it’s easy to get wrong. If you don’t measure your products accurately, the packaging won’t fit. This can cause your products to move inside the box, leading to damage. Always double-check your measurements. Use precise tools and techniques to ensure accuracy. Remember, a small measurement error can lead to big problems.

A study finds that in the process of designing a custom cosmetic box, if the design fails to accurately reflect the actual size of the product or if the size control is not strict during the production process, it can lead to a mismatch between the packaging and the product. For example, if a package is incorrectly dimensioned or measured, the package will not properly contain the product.

Besides, the new national standards have strict requirements for the number of layers and voids of cosmetic packaging. If companies fail to comply with these regulations when designing packaging, it can lead to too loose or too tight packaging, affecting the protection and adaptability of products.

Design flaws often contribute to cosmetic packaging fit issues. Sometimes, the design looks great on paper but doesn’t work. Maybe the packaging is too tight or too loose. These flaws can stem from not considering the product’s shape or size during the design phase. You need to collaborate closely with designers who understand the nuances of cosmetic packaging. They should focus on functionality as much as aesthetics.

Furthermore, suppose the custom cosmetic box design does not accurately grasp consumers’ psychological activities and needs. In that case, it may lead to the boxes not meeting consumer expectations, affecting the product’s market performance.

Finding the right solutions becomes crucial when you face cosmetic packaging fit issues. Let’s explore some effective strategies to ensure your packaging fits perfectly.

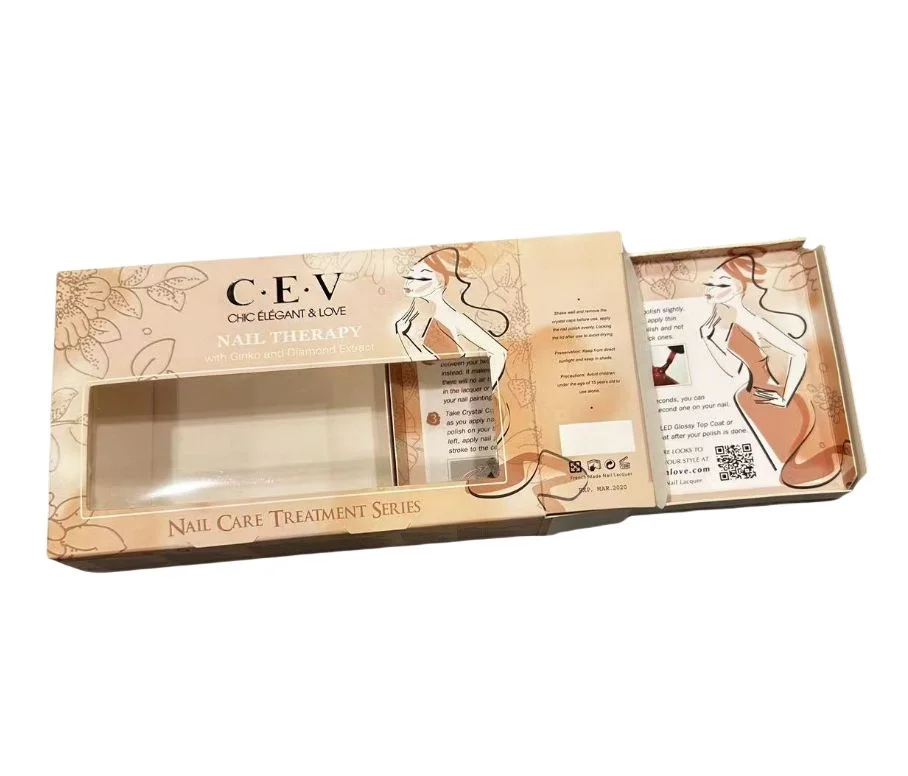

Custom cosmetic boxes can be a game-changer for your brand. It allows you to create packaging that fits your products like a glove.

Tailored design services allow you to work with experts to understand your brand’s unique needs. They focus on creating designs that look good and function well. By considering your products’ specific dimensions and shapes, these services help you avoid common cosmetic packaging fit issues. You get packaging that enhances your product’s appeal, ensuring safety during transit.

Shape grammar has advantages in enhancing the uniqueness and innovation of custom cosmetic packaging materials for beauty.

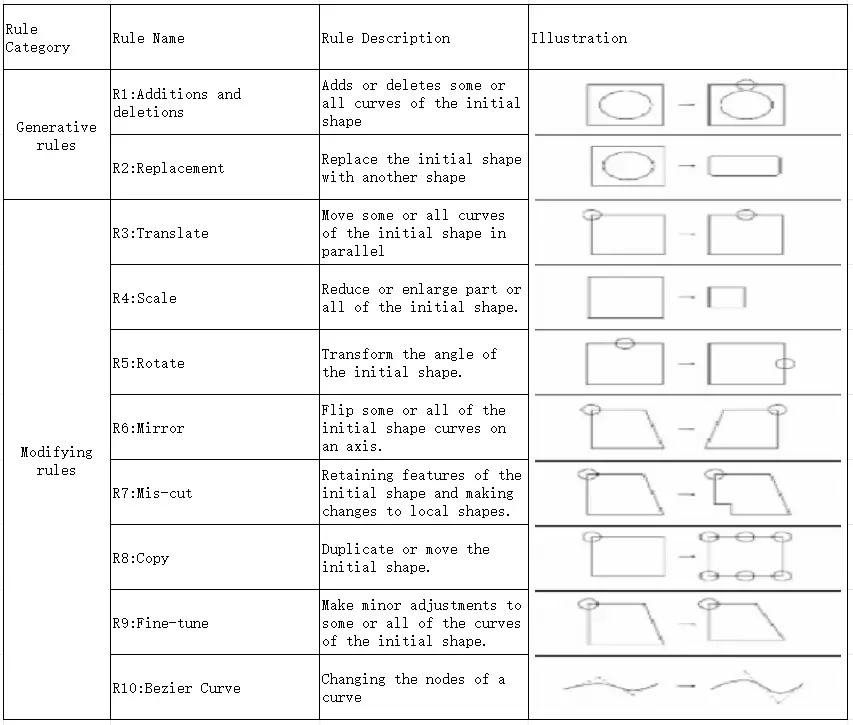

Shape Grammar (SG) is an arithmetic structure proposed by George Stiny in 1972 that affects the evolution of shapes through rule changes. Shape Grammar can derive new shapes and structures from initial shapes through a set of established rules and methods according to the designer’s specific needs. Shape Grammar has been applied by scholars in industrial design, art, and other fields for its advantages of saving labour, shortening cycle time, and maintaining the identity and continuity of brands and shapes.

Table Shape grammar derivation rules (author’s own drawing)

Prototyping and testing are essential steps in the custom cosmetic boxes process. Creating prototypes lets you see how your packaging will look and function before full-scale production. Testing these prototypes helps identify any potential fit issues early on. This proactive approach saves you time and money in the long run. You can make packaging adjustments to ensure your custom cosmetic boxes meet all your requirements.

Article RAPID TOOLING Additive manufacturing of blow moulds for rapid prototyping of cosmetic bottles, which examines the prototyping of custom cosmetic packaging, a preliminary model of the packaging is first created through rapid prototyping techniques. This step can be achieved through 3D printing technology, specifically 3D printed prototype moulds utilizing blow moulding, which can significantly shorten the development cycle of new prototypes while maintaining prototype costs. For example, point cloud data of a product model can be obtained using handheld laser scanning technology, then processed by software to generate a 3D model, and finally, a physical model can be made by a rapid prototyping machine. This approach combines reverse engineering and rapid prototyping techniques, shortens the manufacturing cycle, improves production efficiency, and meets production requirements.

Working with professional companies like Richpack can provide valuable solutions to cosmetic packaging fit issues. You can consult with experts in the packaging industry, which offers numerous benefits. These professionals bring a wealth of knowledge and experience to the table. They can guide you in selecting the right materials and designs that minimize custom cosmetic packaging fit issues. As Brandon Frank, owner of Pacific Packaging Components, Inc., says: ” You must design Packaging and beauty brands with the end in mind, selecting packaging materials and formats with a greater likelihood of being recycled.

FAQ 1: What causes cosmetic packaging not to fit products?

Incorrect measurements and design flaws are common causes. Incorrect measurements can lead to products moving and potential damage. Design flaws may result from not considering product shape and size or not meeting consumer needs.

FAQ 2: What are solutions to fit issues?

One solution is custom cosmetic packaging with tailored design services and prototyping/testing. Collaborating with professional packaging companies is also helpful.

FAQ 3: Why are prototyping and testing important?

It allows seeing packaging function before total production, identifying fit issues early, saving time/money, and enabling adjustments. 3D printing can be used for prototyping moulds.

This blog discusses proper cosmetic box fit to enhance your brand’s image. By implementing the solutions discussed, you can ensure your custom cosmetic boxes fit perfectly and align with eco-friendly practices. Many consumers, especially women over 35, value eco-friendly custom cosmetics.

We trust this information will inspire your next product packaging solution. At Richpack, we specialize in jewellery box packaging and have vast experience in custom cosmetic packaging. Our in-depth knowledge of cosmetic packaging solutions enables us to accurately determine whether you comply with specifications.

Ready to solve your cosmetic packaging fit issues with custom solutions? At Richpack, our expertise in custom cosmetic boxes ensures a perfect fit for every product. Contact us today to explore your options!

Customers are increasingly looking for eco friendly cosmetic packaging that uses sustainable materials to protect the planet. For cosmetic companies specialising in skincare and beauty products, adopting more sustainable packaging is key to gaining customer trust and potentially boosting sales. However, it’s a challenge since eliminating traditional packaging materials, like plastic, isn’t feasible in the cosmetics industry. While we… Continue reading Common Cosmetic Packaging Fit Issues & Solutions with Custom Cosmetic Boxes

A report by Klarma reveals that consumers across all generations are increasingly focused on sustainability when purchasing beauty products. This means that choosing the right packaging for your cosmetic products isn’t just about aesthetics and functionality—it’s also a key step toward sustainability. Businesses need to rethink their packaging strategies and embrace eco-friendly solutions. In this article,… Continue reading Common Cosmetic Packaging Fit Issues & Solutions with Custom Cosmetic Boxes

In retail, before customers even try a product, the first thing they notice is the packaging. The right packaging grabs attention and helps your brand stand out on the shelf, while the wrong packaging can make buyers turn to other options. So, how can a brand stand out in such a crowded marketplace? The answer lies… Continue reading Common Cosmetic Packaging Fit Issues & Solutions with Custom Cosmetic Boxes

Cost-Effective Affordable Cosmetic Packaging for Large Orders | Custom Packaging Solutions for Distributors Seeking Bulk Product Packaging

Custom Gold Foil Folding Luxury Card Lipstick Packaging Box Custom

Luxury Cosmetic Packaging Boxes with Gold Foil Embossing | Tailored for Brands Needing High-End, Branded Packaging for Exclusive Products

Custom Eco-Friendly Cosmetic Packaging for Environmentally Conscious Brands | Ideal for Beauty Brands Focused on Green and Branded Solutions

View More

Custom Logo Recyclable Skincare Brush Set Box Packaging Luxury Cosmetic Makeup Gift Packaging Paper

View More

Custom Printed Logo Paper Box Luxury Cosmetic Manicure Lipstick Box Custom Nail Polish Pac

View MoreJust submit your email to get exclusive offers (reply within 12 hours)