2024 Ranking the 10 Best Sustainable Jewelry Packaging Brands

2024-11-26

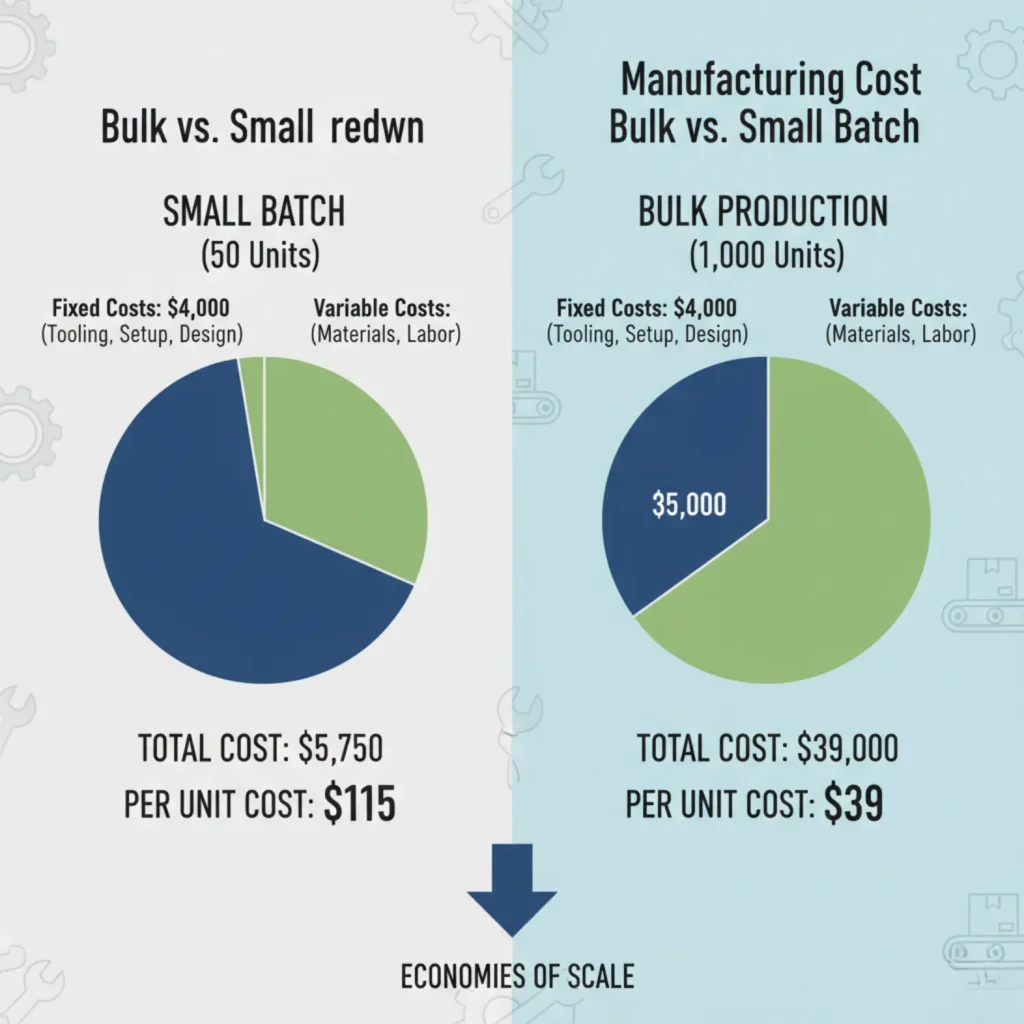

When you receive a quote for 50 custom jewelry boxes and discover the per-unit cost is nearly double what you expected, you’re not alone. Small batch jewelry packaging consistently surprises business owners with pricing that averages 15-30% higher per unit than larger orders due to economies of scale. The jewelry box packaging market, valued at $175.3 billion in 2024 and projected to grow at a 5.4% CAGR according to Market.us research, reflects increasing demand for premium packaging solutions. However, understanding why small quantities command premium pricing—and how to navigate these challenges strategically—can transform your approach to packaging procurement.

This comprehensive guide reveals the economic realities behind small batch pricing, provides detailed cost breakdowns based on industry data, and offers proven strategies to optimize your packaging investment without compromising quality. We’ll walk you through the core reasons for these costs and equip you with actionable strategies to not only reduce expenses but also elevate your brand’s presence. Whether you’re a startup or a growing e-commerce business, this guide is your definitive resource for mastering jewelry packaging.

The seemingly excessive cost of small batch jewelry packaging isn’t arbitrary pricing—it reflects fundamental economic principles that govern manufacturing industries worldwide. Understanding these underlying factors helps you make informed decisions about your packaging investments.

Manufacturing operates on the principle that fixed costs decrease per unit as volume increases. In jewelry packaging production, this creates a natural tension between small batch needs and economic efficiency.

Consider tooling costs: a custom die for embossing your logo costs approximately $1,500 whether you produce 50 boxes or 5,000 boxes. For a 5,000-unit order, this represents $0.30 per box. For 50 units, the same tooling adds $30 per box—a 100-fold difference in per-unit impact.

Machine setup presents similar challenges. A packaging production line requires 2-3 hours of setup time regardless of order size, during which operators adjust settings, calibrate equipment, and conduct test runs. This setup time, costing approximately $800-1,200 in labor and machine time, dramatically affects small orders while becoming negligible for large production runs.

Labour allocation follows the same pattern. Skilled operators who could efficiently produce thousands of units instead focus on small batches, reducing overall productivity and increasing per-unit labor costs by 300-500% compared to high-volume production.

Tooling represents one of the most significant cost factors in custom packaging, yet it remains largely invisible to buyers focused on material and labor costs. Each custom element requires specific tooling:

Die-cutting tools for custom shapes range from $500-800 for basic rectangular boxes to $1,200-1,800 for complex geometric designs. Embossing dies for logo application cost $1,500-2,500 depending on detail complexity. Hot stamping plates for foil application add another $800-1,500 per design.

For specialty constructions like magnetic closure boxes, assembly jigs costing $2,000-4,000 ensure consistent placement of magnetic strips and proper box alignment. These tools, essential for quality consistency, represent pure fixed costs that must be recovered regardless of quantity produced.

Setup costs extend beyond tooling. Machine operators spend considerable time adjusting tension settings for different paper weights, calibrating cutting depths for various materials, and fine-tuning adhesive application rates. Each material change requires cleaning cycles and test runs, consuming both time and materials.

Material procurement for small quantities faces multiple cost penalties that compound the overall pricing challenge. Suppliers typically establish minimum order quantities based on their own operational efficiency, creating a cascade of increased costs for small batch customers.

Premium materials like textured papers, specialty fabrics, and metallic finishes often carry MOQs of 500-1,000 sheets or meters. When you need materials for 50 boxes, suppliers must break bulk packages, adding handling charges of $50-150 per material type. This “less than minimum” pricing can inflate material costs by 200-300% above bulk rates.

Specialty coatings and finishes present additional challenges. UV coatings, aqueous coatings, and laminations require minimum substrate quantities to justify machine setup. Small quantity orders may require hand-application of finishes, dramatically increasing both cost and production time.

Colour matching for branded packaging adds another layer of complexity. Custom color mixing requires minimum batch sizes, and excess material from small orders cannot be efficiently reused, creating waste that must be absorbed into project costs.

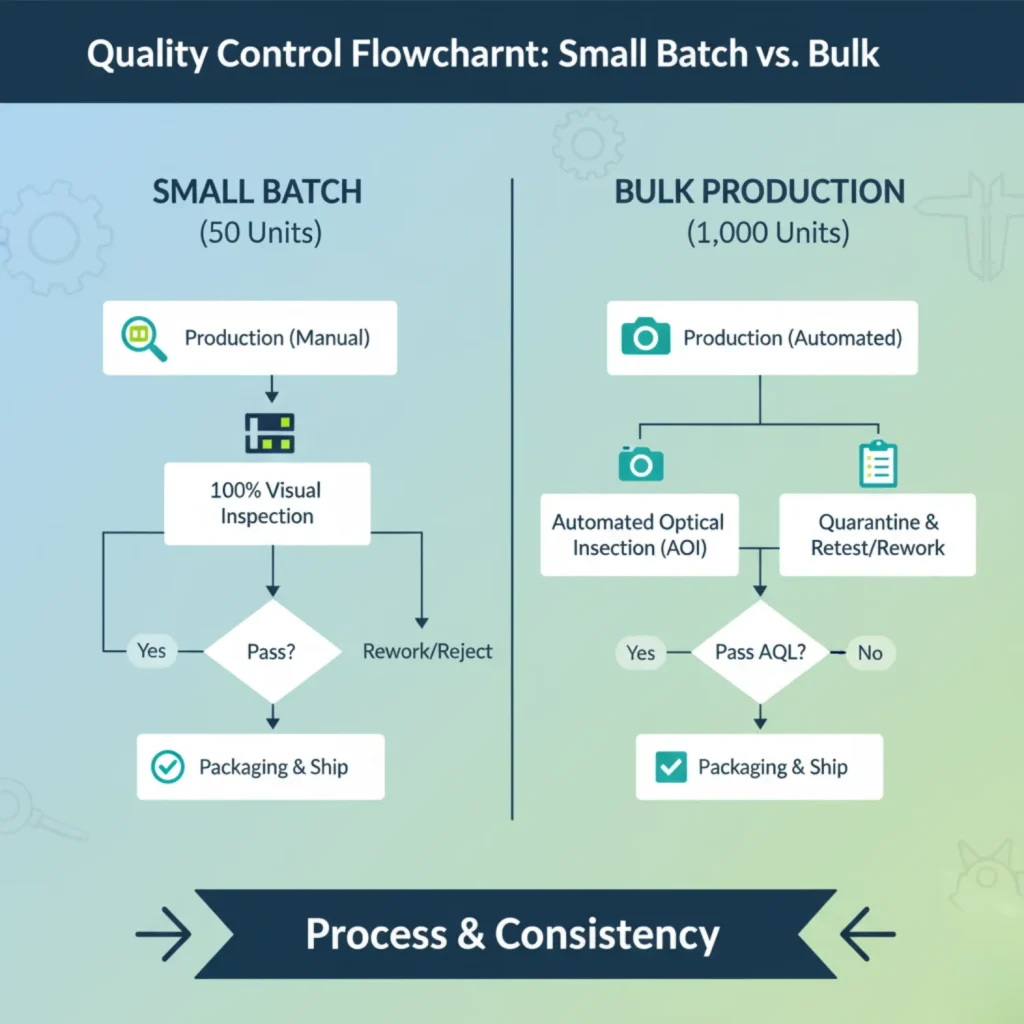

Small batch production inherently requires more manual intervention than automated high-volume manufacturing, significantly impacting labor costs and production efficiency.

While large orders benefit from automated cutting, folding, and gluing processes, small batches often require hand assembly to maintain cost efficiency. Automated equipment setup costs exceed the value of small production runs, necessitating manual processes that increase labor time by 400-600% per unit.

Quality control for small batches demands individual attention to each piece. Large volume production can rely on statistical sampling, but small orders require 100% inspection to ensure customer satisfaction. This inspection process adds 2-3 minutes per unit in labor time.

Skilled operators must frequently switch between different projects and setups when handling small orders, reducing overall efficiency. These transition periods, where no productive work occurs, must be allocated across the small batch orders being produced.

Understanding the detailed cost components of small batch packaging enables more accurate budgeting and better supplier negotiations. Industry analysis reveals that small batch premiums aren’t arbitrary but reflect genuine operational realities.

Production costs divide into two distinct categories, each behaving differently as quantity changes. Fixed costs remain constant regardless of order size, while variable costs scale proportionally with volume.

Design services for custom packaging extend far beyond aesthetic considerations, encompassing structural engineering, material compatibility testing, and production optimization—all crucial for functional, manufacturable packaging.

Structural design ensures your packaging protects contents while remaining cost-effective to produce. Engineers consider material properties, stress points, closure mechanisms, and assembly methods. This technical design phase typically requires 8-12 hours of professional time at $75-125 per hour.

Graphic design and brand integration involve logo placement optimization, color palette development, and typography selection that works within manufacturing constraints. Professional designers spend 6-10 hours refining visual elements, costing $450-1,250 per project.

Prototyping and testing represent additional development costs often overlooked in initial budgeting. Creating functional prototypes for approval requires materials, tooling, and production time equivalent to 5-10 finished pieces. Structural testing for durability and function adds another $200-400 to development costs.

Quality assurance for small batches requires different approaches than high-volume production, often resulting in higher per-unit inspection costs while maintaining necessary quality standards.

Small batch production cannot rely on statistical sampling methods used in large volume manufacturing. Instead, 100% inspection becomes necessary to ensure customer satisfaction and prevent quality issues that could damage brand reputation.

Inspection protocols include dimensional accuracy verification, color consistency checking, structural integrity testing, and finish quality assessment. Each unit requires 2-3 minutes of inspection time, representing significant labor investment for small quantities.

Testing protocols for custom designs may require destructive testing of sample units to verify structural integrity and durability. These test samples represent additional material and production costs that must be absorbed into the project pricing.

Transportation and fulfillment costs for small quantities face similar economies of scale challenges as production, often representing a larger percentage of total project cost than anticipated.

Small shipments cannot achieve the per-unit efficiency of full truck loads or container shipments. A 50-unit jewelry box order typically ships via express courier at $2-4 per unit in freight costs. The same per-unit freight cost for a 1,000-unit order might be $0.50-1.00 per unit using LTL freight services.

Packaging and handling for small orders requires individual attention that larger orders can batch process. Custom cushioning, individual wrapping, and careful packing to prevent damage during transit adds 3-5 minutes per unit in fulfillment labor.

Insurance and liability considerations for small, high-value shipments often result in higher relative costs than larger shipments. Premium packaging materials and expedited shipping options frequently chosen for small orders further increase fulfillment expenses.

While small batch premiums are inherent to the manufacturing process, strategic approaches can significantly reduce your packaging costs without compromising quality or brand impact. These proven methods address the root causes of high small batch pricing.

For a broader perspective on managing your budget, read our comprehensive guide on How to Control Jewelry Packaging Cost: A Complete Guide.

The most effective cost reduction strategy involves utilizing existing tooling and proven designs rather than creating completely custom solutions. Experienced packaging suppliers maintain libraries of existing tools and dies that can be adapted for your needs.

Standard box configurations with established tooling can reduce setup costs by 60-80%. Instead of creating a completely custom structure, consider adapting proven designs through branding, color selection, and material choices. Many suppliers offer 20-50 standard configurations that can be customized through printing and material selection.

Modular tooling systems allow suppliers to create variations using interchangeable components. A base die set might accommodate different lid styles, closure methods, or size variations without requiring completely new tooling. This approach can reduce tooling costs from $2,000-4,000 to $300-800 per variation.

Template-based design services streamline the development process while reducing design costs. Rather than starting from scratch, professional designers work from proven structural templates, focusing on visual customization rather than engineering new solutions. This approach typically reduces design time by 40-60%.

Strategic material selection balances quality perception with cost efficiency, often achieving a premium appearance at reduced cost through informed choices about substrates, finishes, and construction methods.

Substrate alternatives can provide a similar aesthetic impact at reduced cost. Premium textured papers might be replaced with embossed standard papers that achieve similar tactile effects. High-end fabric coverings could be substituted with paper alternatives that simulate texture and color.

Finish consolidation reduces the complexity and cost of production. Instead of combining multiple special finishes, focus on one signature element that creates maximum impact. A single foil accent often provides more brand impact than multiple subtle finishes while reducing production complexity.

Construction simplification maintains functionality while reducing manufacturing steps. Magnetic closures might be replaced with ribbon ties or tuck-in flaps that provide adequate security at lower cost. Complex multi-level constructions could be simplified to two-piece designs that achieve similar functionality.

Working with suppliers to identify material equivalents from their preferred vendor networks can significantly reduce material costs. Suppliers often maintain relationships with multiple material vendors and can identify alternatives that meet your specifications at better pricing.

Strategic order planning can substantially reduce costs through timing optimization and volume aggregation, even when working within small batch constraints.

Seasonal timing affects both material costs and production capacity. Ordering during suppliers’ slower periods—typically January-March and September-October—can result in 10-20% cost reductions as suppliers offer preferred pricing to maintain production flow.

Volume aggregation across multiple projects can achieve better pricing even for small individual orders. If you anticipate needing different packaging types throughout the year, combining orders can improve overall pricing while maintaining individual project flexibility.

Production scheduling coordination with suppliers allows for cost-effective planning. Suppliers can often offer better pricing for orders that fill production gaps or complement larger projects already in their schedule.

Buffer inventory strategies for core packaging needs can justify slightly larger minimum quantities. If certain packaging elements remain consistent across multiple projects, ordering moderate quantities for inventory can reduce per-unit costs while maintaining flexibility for variations.

Thoughtful design simplification can dramatically reduce production costs while maintaining professional appearance and brand integrity. The key lies in identifying which elements truly drive brand perception versus those that add cost without proportional benefit.

Structural simplification focuses on proven box configurations that minimize production complexity. Two-piece telescoping designs often provide better cost efficiency than hinged constructions while maintaining a premium appearance. Straight cuts are more cost-effective than curved or complex geometries.

Color reduction strategies can maintain visual impact while reducing production costs. Single-color designs with strategic use of paper texture or embossing can appear more sophisticated than multi-color printing. Spot colors often provide better cost efficiency than full-color printing for small quantities.

Finish prioritization directs budget toward elements that create maximum brand impact. A single premium finish applied strategically often creates more impressive results than multiple subtle finishes. Foil stamping on a textured substrate might provide better perceived value than multiple printing processes on smooth stock.

Standardization of components across different packaging needs can create internal economies of scale. Using consistent closure methods, corner constructions, or liner materials across different box sizes allows for better supplier pricing and inventory management.

Selecting the right packaging supplier for small batch needs requires different evaluation criteria than high-volume procurement. The ideal supplier balances flexibility, quality, and cost-effectiveness specifically for smaller volume needs.

For a deeper dive into making the right choice, be sure to check out our complete guide on How to Choose the Best Jewelry Packaging Solution for Your Brand.

Effective supplier evaluation for small batch jewelry packaging requires a comprehensive assessment framework that goes beyond basic pricing comparisons. The most successful partnerships emerge from suppliers who demonstrate genuine capability and commitment to smaller volume clients.

Production Capability Assessment should examine actual small batch experience rather than just general manufacturing capacity. Request examples of similar projects, including photographs of finished products and case studies demonstrating problem-solving approaches. Suppliers experienced with small batches understand the unique challenges and have developed efficient workflows to minimize costs.

Quality Management Systems for small batch suppliers require different approaches than high-volume manufacturers. Evaluate their inspection processes, sample approval procedures, and defect resolution protocols. The best small batch suppliers maintain detailed documentation for each project and can provide comprehensive quality reports even for small orders.

Design and Engineering Support capabilities often differentiate excellent small batch suppliers from adequate ones. Assess their ability to optimize designs for cost-effectiveness without compromising functionality. Experienced suppliers can suggest modifications that reduce costs while maintaining or improving performance.

Communication and Project Management become crucial for small batch success. Evaluate responsiveness, project tracking capabilities, and proactive communication about potential issues. Small batch orders require more frequent touchpoints and updates to ensure satisfaction.

Minimum Order Quantity policies reveal crucial information about a supplier’s business model and their compatibility with your small batch needs. Understanding these policies helps identify suppliers genuinely equipped to serve small volume clients effectively.

True MOQ vs Published MOQ often differ significantly. Many suppliers publish standard MOQs for marketing purposes but maintain flexibility for specific situations. Direct discussion about your actual needs often reveals willingness to accommodate smaller quantities at adjusted pricing rather than refusing the business entirely.

MOQ Structure Analysis examines how suppliers calculate and apply minimum requirements. Some suppliers maintain separate MOQs for different services: lower MOQs for standard configurations, higher requirements for completely custom designs. Understanding these distinctions helps optimize your project approach.

Volume Progression Planning with suppliers can establish pathways for cost reduction as your business grows. Discuss how pricing evolves with volume increases and whether suppliers offer volume commitment discounts for planned future orders.

Flexibility Indicators reveal supplier adaptability beyond stated policies. Suppliers willing to split orders across multiple delivery dates, accept partial payments, or modify specifications mid-project demonstrate the operational flexibility essential for small batch success.

Comprehensive service capabilities often provide more value than competitive pricing alone, particularly for small batch clients who require additional support and guidance throughout the packaging development process.

Design Services Integration should encompass both aesthetic and functional design support. Evaluate suppliers’ ability to translate your brand vision into manufacturable packaging solutions. The best suppliers offer design optimization suggestions that improve both appearance and cost-effectiveness.

Prototyping and Sampling capabilities allow you to evaluate designs before committing to full production. Assess turnaround times, sample accuracy, and the supplier’s willingness to iterate designs based on your feedback. Comprehensive sampling reduces the risk of production issues and ensures final results meet expectations.

Logistics and Fulfillment Support can add significant value for small batch orders. Some suppliers offer inventory management, direct-to-customer shipping, or integration with fulfillment platforms. These services can reduce your operational complexity while improving customer experience.

Technical Support and Consultation throughout the project lifecycle distinguishes superior suppliers. Evaluate their willingness to provide guidance on material selection, design optimization, and future planning. The best suppliers function as strategic partners rather than simple manufacturers.

Successful small batch packaging procurement benefits significantly from long-term supplier relationships that can evolve and improve over time. Strategic partnership development creates mutual value and improves cost-effectiveness.

Partnership Development Approach should focus on mutual benefit and growth potential. Discuss your business plans and growth projections with potential suppliers. Those interested in growing with your business often provide better service and pricing than those viewing you as a transactional client.

Communication and Feedback Systems enable continuous improvement in the partnership. Establish regular review processes to discuss performance, identify opportunities for improvement, and plan future projects. Open communication prevents small issues from becoming major problems.

Volume Growth Planning allows suppliers to invest in your success through tooling retention, preferential scheduling, and pricing improvements as volumes increase. Discuss how the partnership might evolve as your business grows and establish mutual commitments for future collaboration.

Innovation and Development Collaboration can provide competitive advantages through exclusive access to new materials, techniques, or designs. Strategic suppliers often share emerging trends and capabilities with valued partners before making them broadly available.

Here are a few examples of how brands like yours leveraged strategic packaging to reduce costs and elevate their brand perception.

A New York-based, direct-to-consumer fine jewelry brand faced a common dilemma: how to create a premium unboxing experience with a limited initial budget. Their biggest challenge was the high per-unit cost of custom-moulded packaging, which threatened to consume 30% of their total product cost.

Our Solution: By applying the “Leveraging Existing Tooling” strategy, we guided them to use a standard two-piece box with an off-the-shelf insert. The custom element was a unique foil-stamped logo and a signature ribbon color, which utilized a single, small hot stamping plate. This simplified approach avoided the high fixed costs of new tooling and complex assembly.

The Result: They successfully launched with a professional, branded package. The per-unit packaging cost was reduced by over 60% compared to their initial quote, cutting the cost from $12 to $4.50 per unit. This allowed them to allocate more budget to marketing and inventory, accelerating their brand’s growth.

A rapidly growing Etsy seller specializing in handmade silver jewelry needed to professionalize its packaging. Their existing supplier’s high MOQs and long lead times were causing inventory issues, forcing them to over-order or risk running out of stock during peak seasons.

Our Solution: We shifted their approach from large, infrequent orders to a “Volume Progression Planning” model. We worked with a supplier who offered flexible MOQs and negotiated a tiered pricing structure. This allowed the seller to place multiple smaller, more frequent orders throughout the year, better aligning with their sales flow and reducing the need for large buffer inventory.

The Result: They reduced their packaging-related capital tied up in inventory by 50% and improved their order fulfillment efficiency. The consistent supply and professional packaging led to a 20% increase in positive customer reviews mentioning the “beautiful box and presentation,” which in turn boosted their search ranking on the platform.

A high-end boutique was looking for a unique packaging solution that would reflect their brand’s commitment to artisanal craftsmanship. Their challenge was creating a highly complex, multi-layered box with magnetic closures that felt bespoke, without the prohibitive cost of custom engineering for a small quantity of 200 units.

Our Solution: We focused on “Design Simplification Without Compromising Quality.” Instead of an entirely new structure, we adapted a sophisticated two-piece box design. We replaced a costly custom-dyed linen with a premium embossed paper that had a similar tactile feel. The magnetic closure was integrated using existing jigs, and a single, custom debossed logo was the only new tooling required.

The Result: The boutique achieved its goal of a luxury-grade unboxing experience while reducing the overall project cost by 35%. The final packaging successfully communicated the brand’s unique identity, justifying the higher product price point and reinforcing its luxury positioning in the market.

Navigating small batch jewelry packaging successfully requires understanding the economic realities behind premium pricing while implementing strategic approaches to optimize costs. The inherent challenges of small volume production—from tooling amortization to material sourcing inefficiencies—create legitimate cost premiums that smart buyers can address through informed decision-making.

The most successful small batch packaging strategies combine realistic cost expectations with creative approaches to value optimization. Leveraging existing tooling, optimizing material selection, and building strategic supplier relationships can reduce costs by 30-50% while maintaining quality and brand impact.

Remember that packaging serves as a crucial brand touchpoint that influences customer perception and repeat purchase decisions. The investment in quality packaging often generates returns through improved customer experience, reduced return rates, and enhanced brand value that justify the premium costs associated with small batch production.

For jewelry brands serious about growth and professional presentation, partnering with experienced packaging specialists who understand small batch challenges while offering comprehensive design, production, and strategic guidance can transform packaging from a cost center into a competitive advantage.

Ready to optimize your jewelry packaging strategy? Contact our packaging specialists for a comprehensive consultation that addresses your specific needs and objectives. We’ll provide detailed cost analysis, design recommendations, and strategic planning to ensure your packaging investment delivers maximum return while building long-term brand value.

Have you ever wondered what makes the packaging of a luxury jewelry box so captivating? It all comes down to the printing process. Before diving into the technicalities, it’s essential to grasp the basics of printing. Discover how printing processes shape the allure of luxury jewelry packaging. This includes three main stages: prepress, press, and postpress. In… Continue reading The Ultimate Guide to Small Batch Jewelry Packaging

Explore humidity-resistant coatings, lid alignment tech, and feedback-driven improvements for packaging that survives shipping while elevating unboxing experiences. Ideal for brands prioritizing consistency, sustainability, and premium presentation.

We believe that with systemic change across the jewelry packaging supply chain, and through collaboration, we can reach net zero emissions.

Amber Jewelry Packaging | Natural Elegance Meets Sustainable Packaging

View More

Custom Jewelry Pouches with Logo for Promoting Your Brand | Logo-Emblazoned Pouch Design

View More

Custom Jewelry Show Displays for Trade Shows and Events – Eye-Catching Vendor Jewelry Displays and Unique Jewelry Displays from Richpack to Elevate Your Brand

View MoreJust submit your email to get exclusive offers (reply within 12 hours)